A dual-channel output mechanism for a soap printer

An output mechanism and printer technology, applied in the direction of mechanical conveyors, conveyors, conveyor objects, etc., can solve the problems that the equipment cannot fully meet the production requirements, increase the occupied area of the workshop, increase the length of the production line, etc. The effect of dividing the lane, shortening the production line, and reducing the number of machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

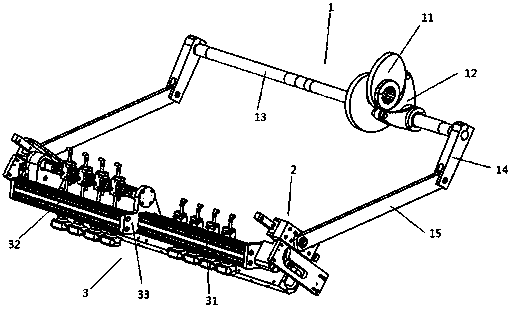

[0027] Such as figure 1 The dual-channel output mechanism of a new type of soap printer shown includes a power mechanism 1, a connecting mechanism 2, and a grasping mechanism 3. The power mechanism 1 is connected with the grasping mechanism 3 through the connecting mechanism 2; the power mechanism 1 includes a conjugate cam 11 , shift fork 12, driven shaft 13, two swing bars 14 and two connecting rods 15, the conjugate cam 11 is fixedly connected with shift fork 12, the shift fork 12 is fixedly sleeved with driven shaft 13, and the driven shaft 13 The left and right ends are respectively movably connected with one end of the fork 14 , the other end of the fork 14 is movably connected with one end of the connecting rod 15 , and the other end of the connecting rod 15 is movably connected with the connecting mechanism 2 .

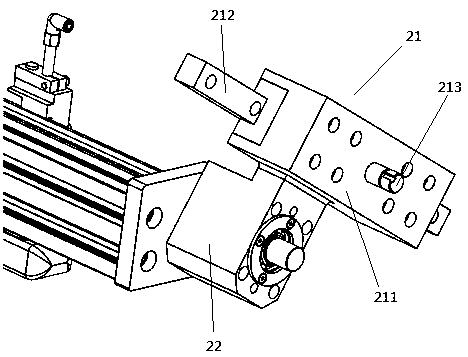

[0028] Such as figure 2 As shown, the connection mechanism 2 includes a slider assembly 21 and a small connecting rod 22 that provide linear reciprocating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com