A modular mechanism and design method of an AGV transplanting system

A technology of system modules and design methods, applied in the fields of motor vehicles, transportation and packaging, can solve problems such as cost increase, and achieve the effect of reducing difficulty, reducing the number of AGV units, and reducing enterprise operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

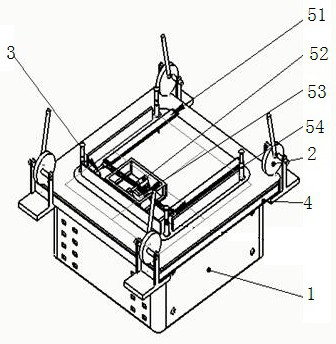

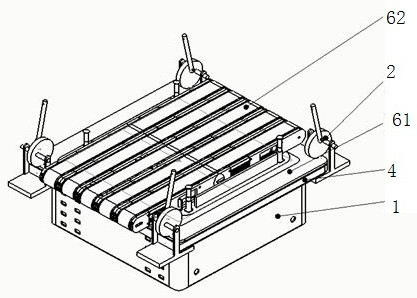

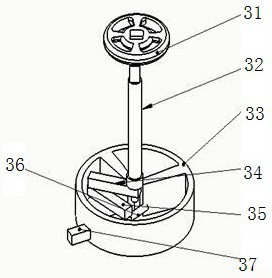

[0030] Embodiment: a kind of AGV transplanting system modular mechanism, such as Figure 1-2 As shown, it includes an AGV motion platform 1, a clamping mechanism 2, a locking mechanism 3, an auxiliary connecting plate 4 and a transplanting module, and the described transplanting module includes a transplanting module 5 based on a slide rail and a transplanting module 6 based on a conveyor belt. The above-mentioned AGV motion platform is connected to the transplanting module through the auxiliary connecting plate, and the clamping mechanism is used for clamping and fixing between the auxiliary connecting plate and the transplanting module. The auxiliary connecting plate is provided with a positioning hole, and the locking mechanism is used for For the positioning of the transplanting module, the locking mechanism is fixedly connected with the auxiliary connecting plate through the positioning hole. The design of this scheme realizes that an AGV motion platform is compatible wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com