Microstructure-type excimer laser delaminated processing method and device of ceramic material sealing ring

A technology of excimer laser and ceramic materials, which is applied in the field of ultra-precision machining of hard and brittle materials, and achieves the effect of eliminating the influence of thermal stress, improving flexibility and rapid processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

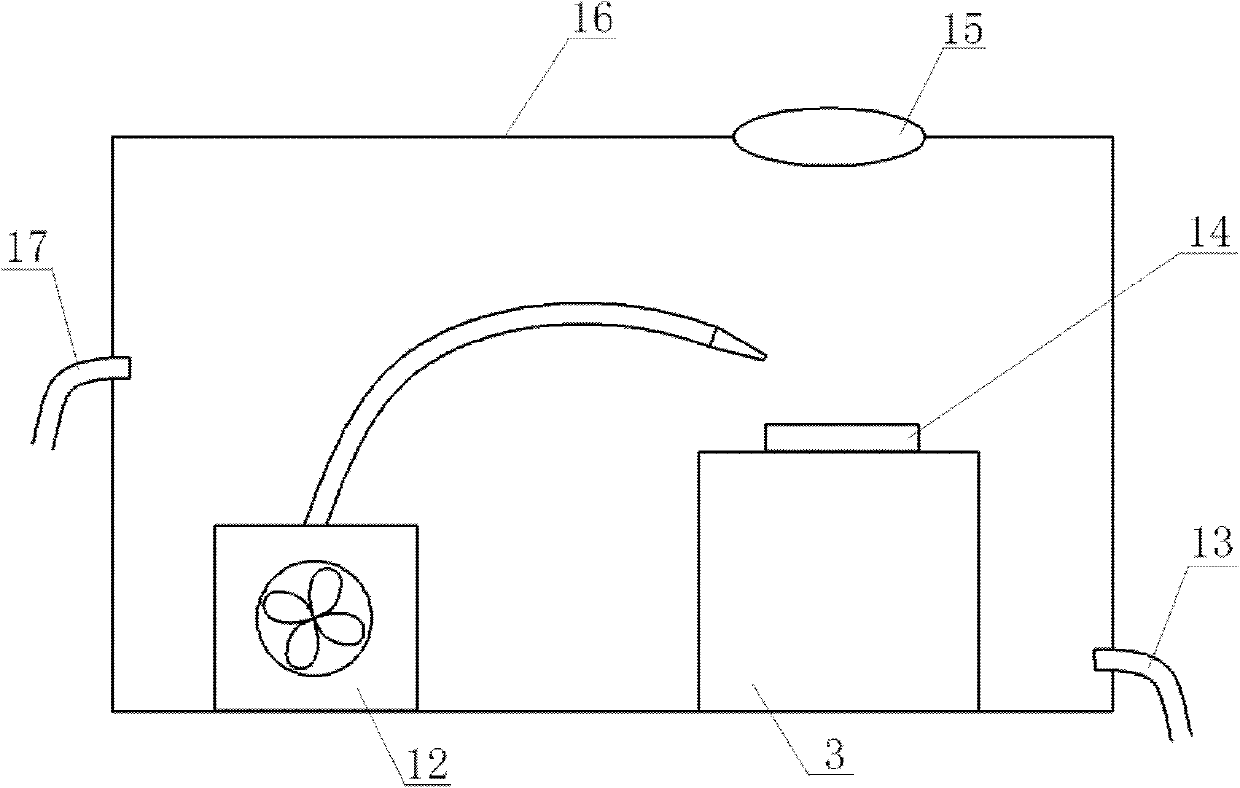

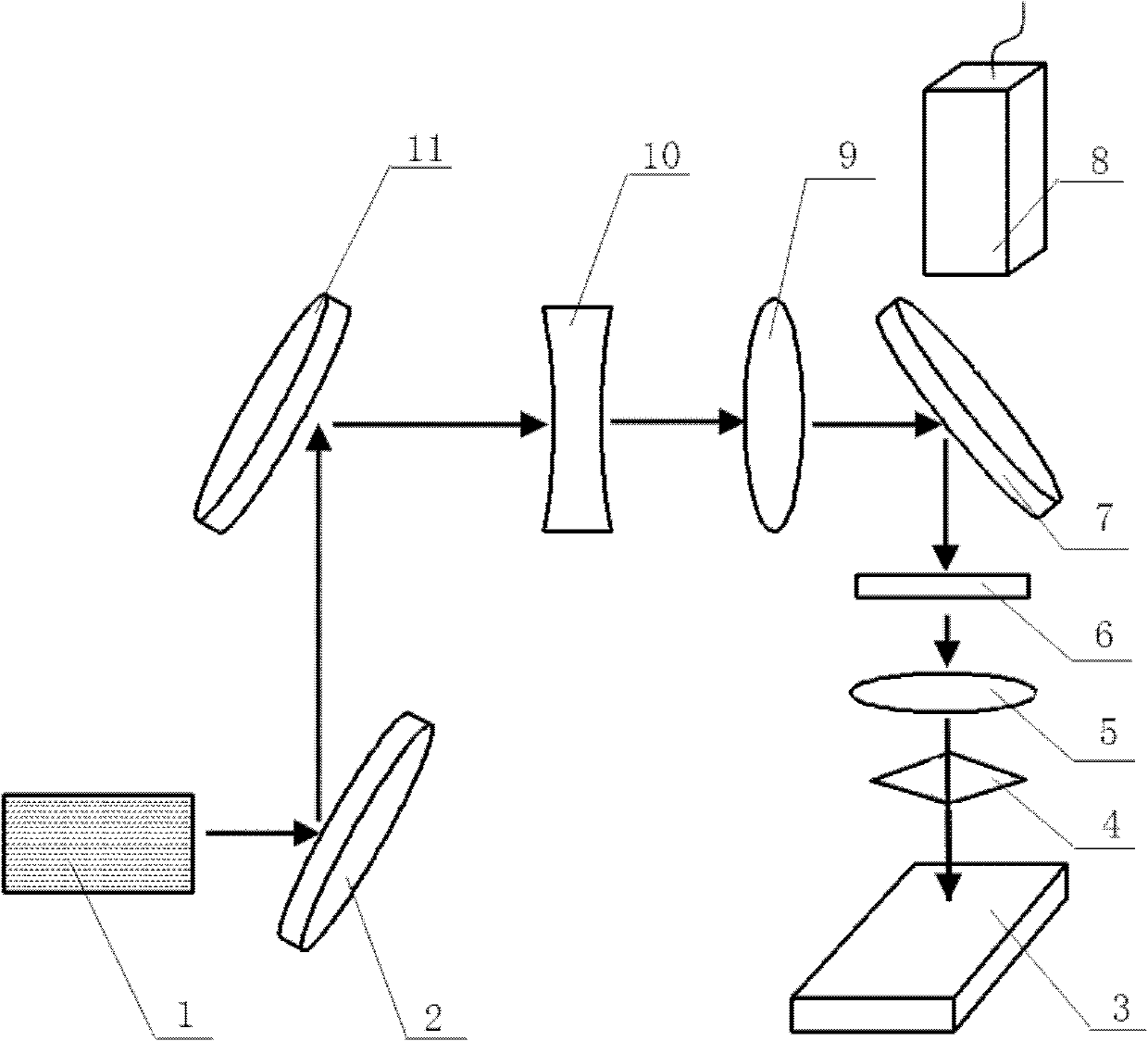

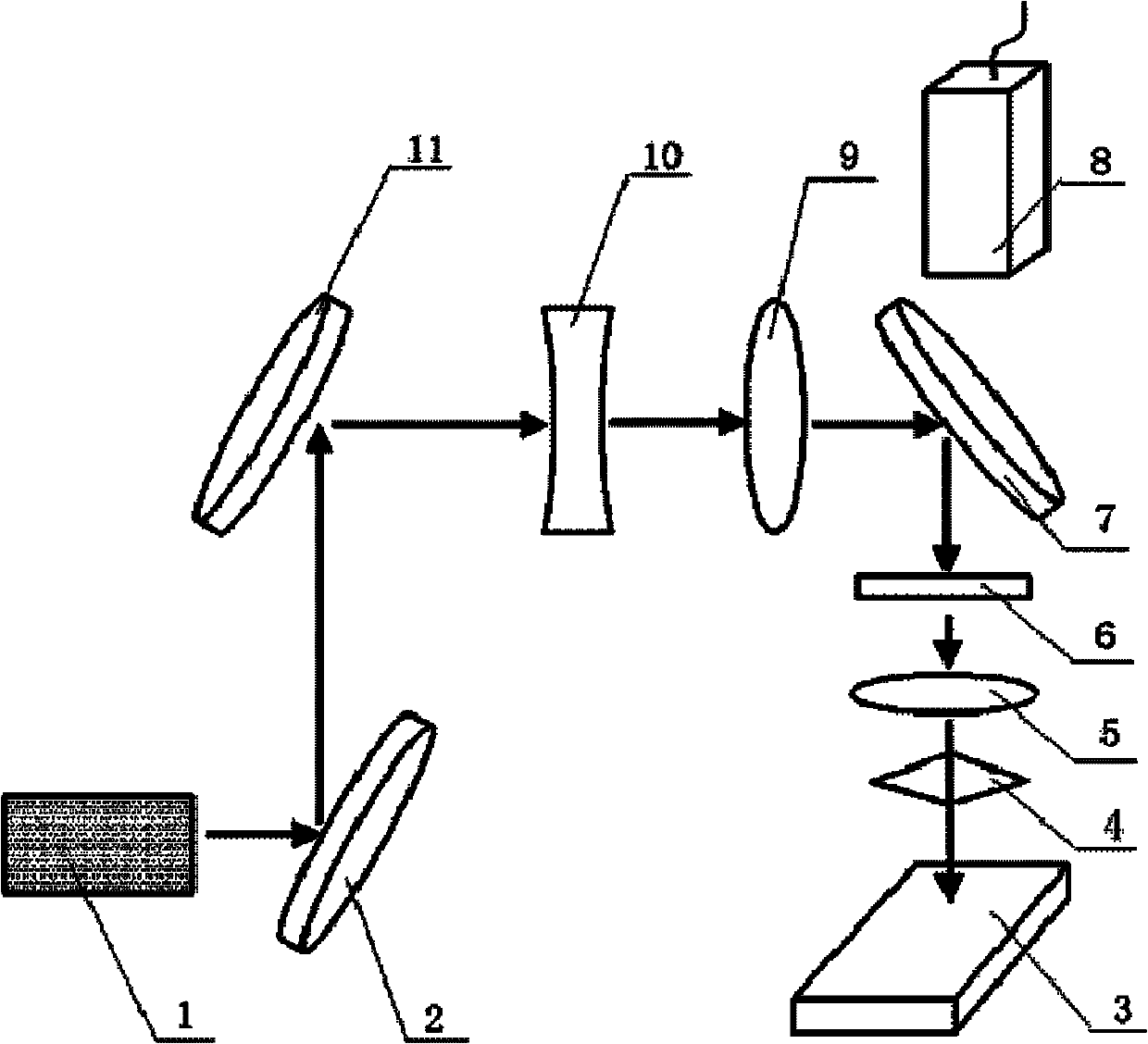

[0015] as attached figure 1 As shown, the excimer laser processing system of the present invention includes three mirrors, a workbench 3, a shutter 4, a focusing lens 5, a diaphragm 6, a monitor 8, and a beam adjustment device composed of a convex lens 9 and a concave lens 10. Wherein the combination of the first reflector 2 and the third reflector 11 is used to change the spatial position of the light beam, and expands enough space for the installation of other components of the system; the concave lens 10 is used to diverge the light beam, so that the light beam with a certain divergence angle in the light beam can be more Large divergence angle propagation, to achieve the purpose of eliminating beam interference with excessive divergence angle; convex lens 9 recollimates the divergent beam, and at the same time can obtain the required spot size by controlling the lens position; monitor 8 magnification factor is 50 times, used for focusing , positioning and monitoring the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com