Diffuseur of liquid pump

A technology of a dispenser and a liquid pump, which is applied in the directions of liquid distribution, liquid injection devices, household containers, etc., can solve the problems of poor discharge function of the liquid pump dispenser, deterioration of the discharge function of the liquid pump dispenser, and increase of the amount of liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made in detail to an embodiment of the invention, an example of which is illustrated in the accompanying drawings.

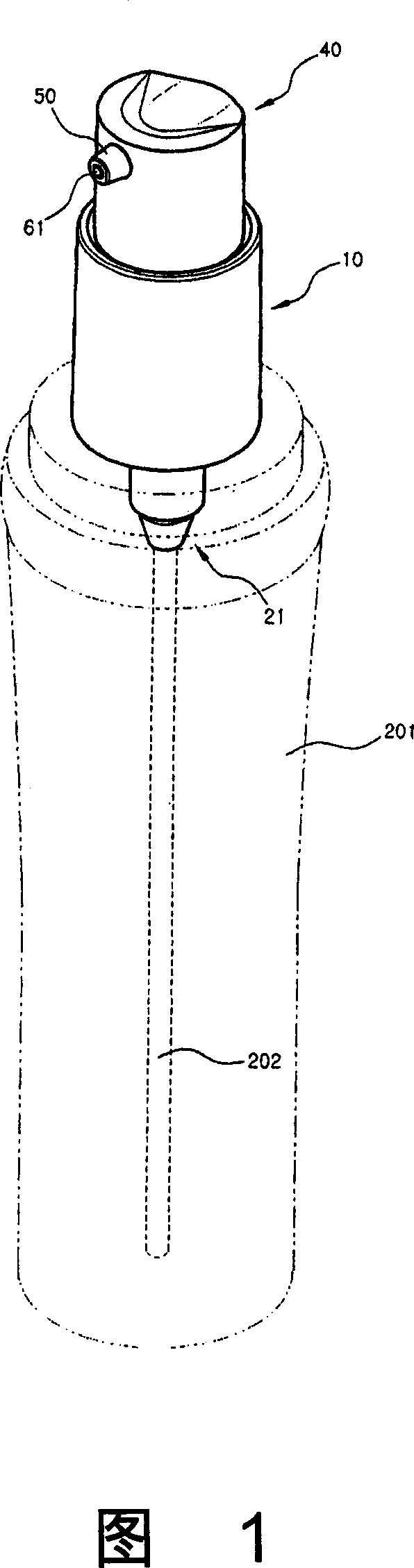

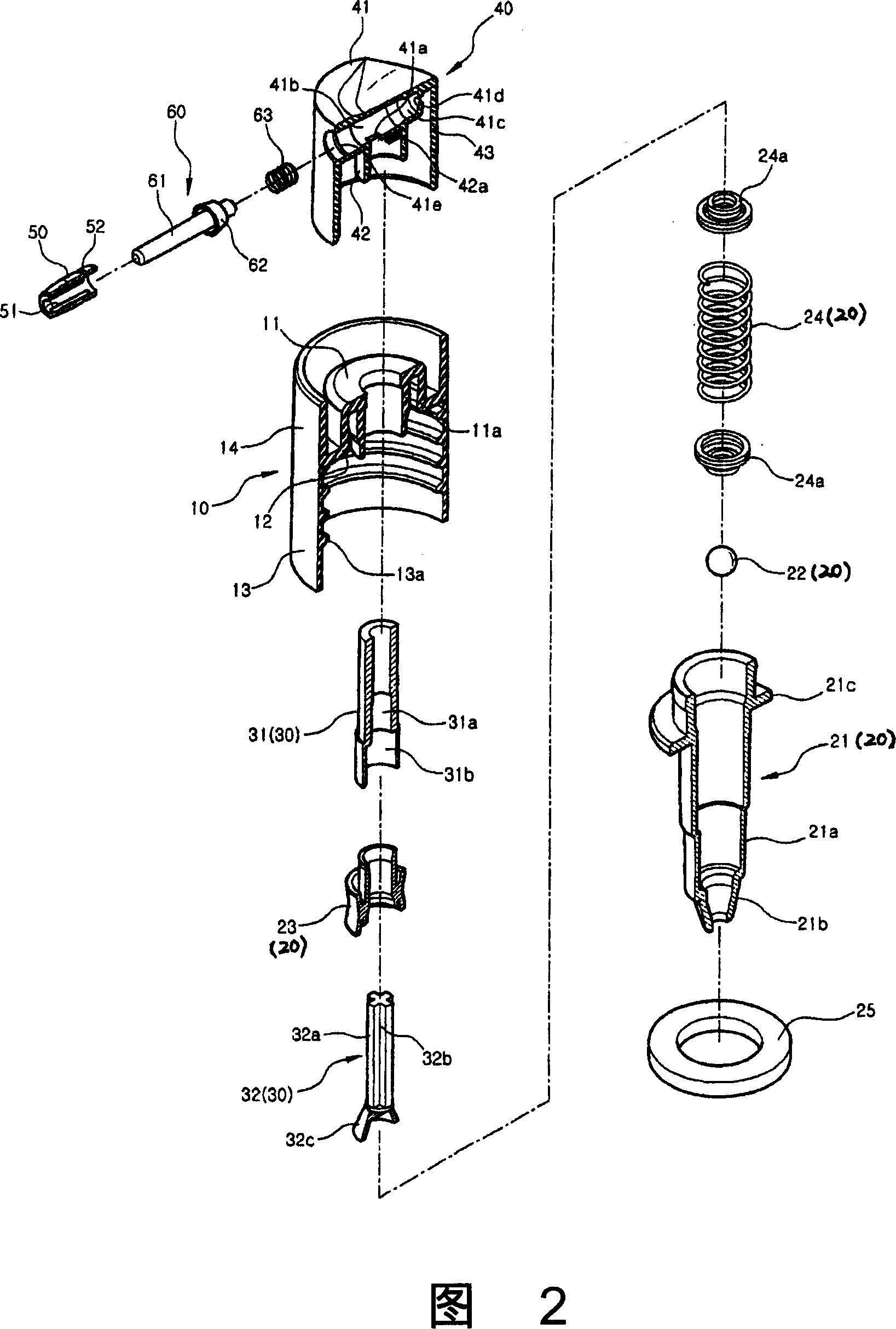

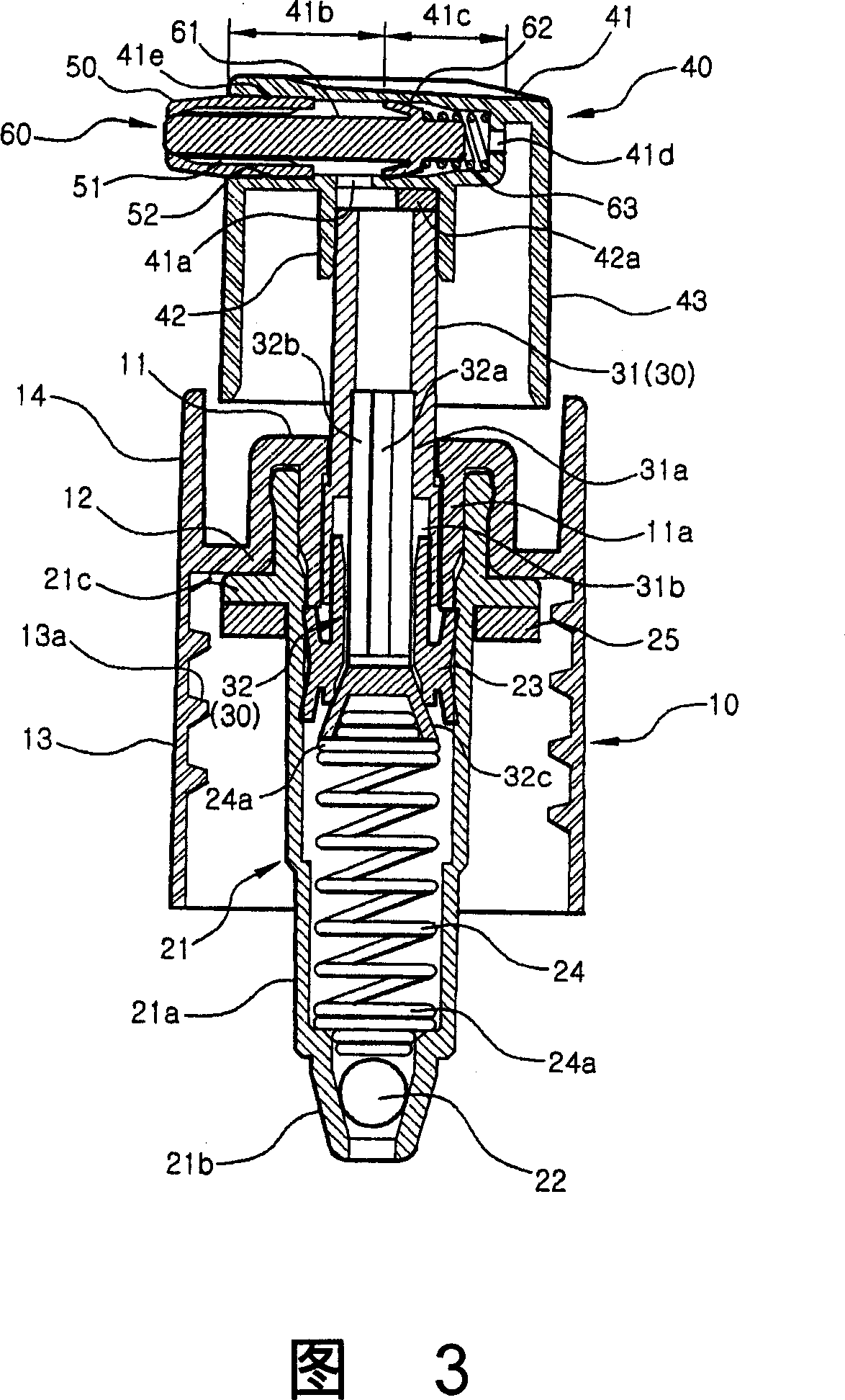

[0037] 1 is a perspective view showing the assembly of a liquid pump dispenser according to an embodiment of the present invention, FIG. 2 is an exploded perspective view showing a liquid pump dispenser according to an embodiment of the present invention, and FIG. An assembled sectional view of the liquid pump dispenser according to an embodiment of the present invention, FIG. 4 is a bottom view of the button shown in FIG. 3 , and FIG. 5 is a sectional view of the nozzle shown in FIG. 3 .

[0038] Referring to the accompanying drawings, the liquid pump dispenser according to the embodiment of the present invention comprises: a cap 10 coupled with the upper end of a liquid container 201; a pump operation part 20; a button 40 coupled to the upper end of the piston 30; a nozzle 50 installed through the front of the button 40;

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com