Injection molding machine for flat needle material strap

A technology of injection molding machine and material belt, applied in coating and other directions, can solve the problems of reducing production efficiency, increasing enterprise cost, unable to realize automatic distribution of material belt, etc., and achieving the effect of stable and reliable feeding, stable and reliable traction, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

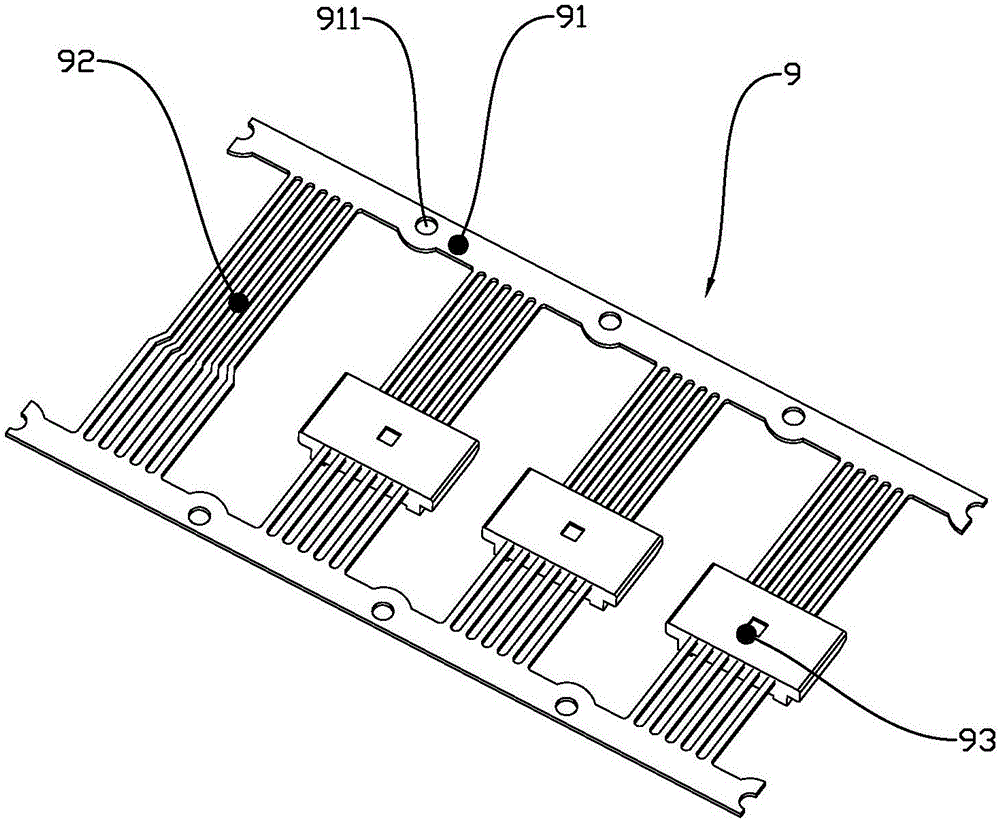

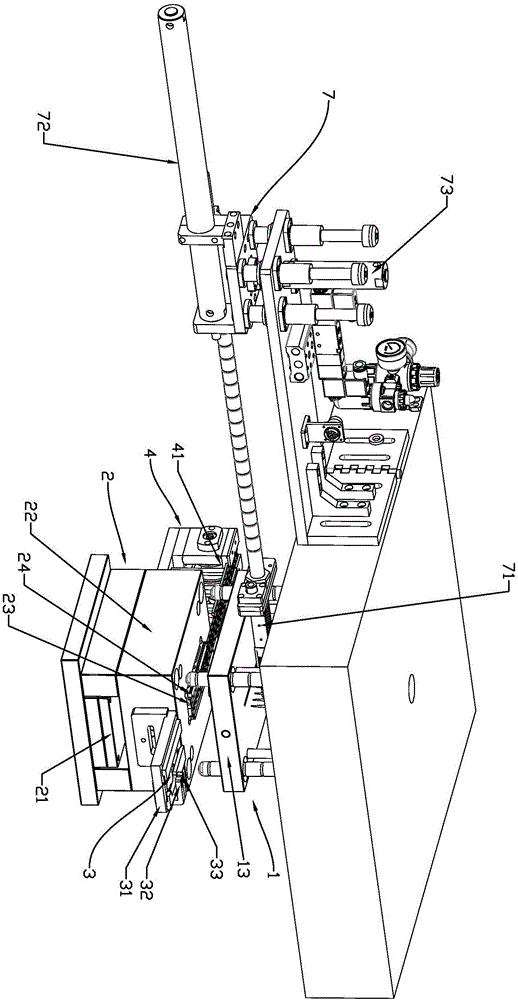

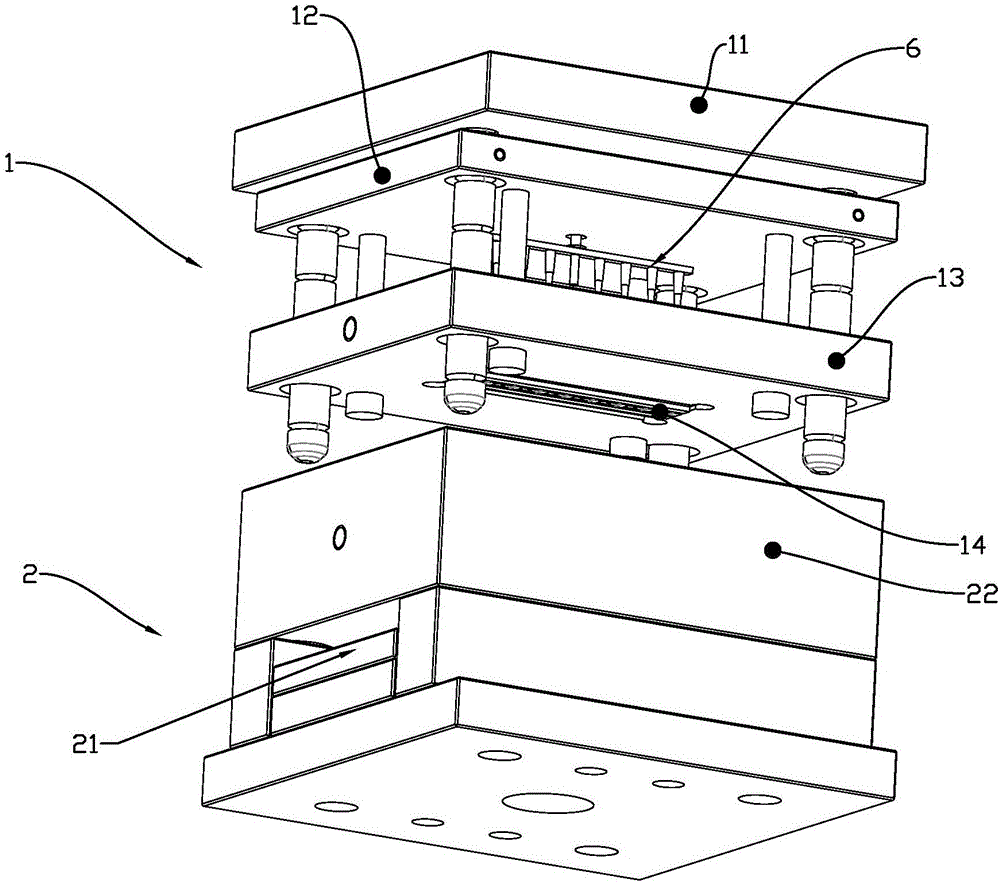

[0040] Such as Figure 2~13 As shown, a flat needle strip injection molding machine disclosed in the present invention includes a frame, an injection mechanism installed on the frame, and an injection mold positioned on the injection molding process. The injection mold includes an upper mold 1 and a lower mold 2, and the upper mold 1 and the lower mold 2 The mold 1 includes a matching upper mold base plate 11, a stripper plate 12, an upper mold core plate 13 and an upper mold core 14, and each plate body on the upper mold is connected through a guide shaft assembly, which is a conventional technology. It can be realized if there is technology, so it will not be repeated. The upper mold core 14 is installed on the upper mold core plate 13, the lower mold 2 includes an ejection mechanism 21, the lower mold core plate 22 and the lower mold core 23, and the lower mold core 23 is installed on the lower mold core plate 13. On the mold core plate 22, the upper mold core 14 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com