Pneumatic vehicle tyre

A technology for pneumatic tires and vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., to achieve the effect of improving receiving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

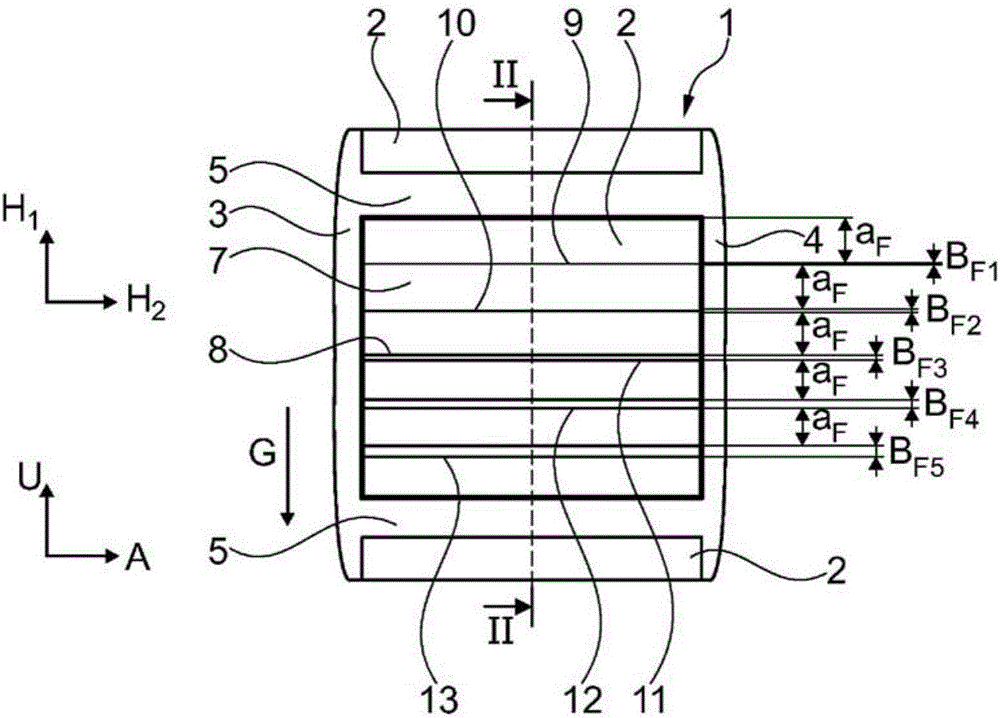

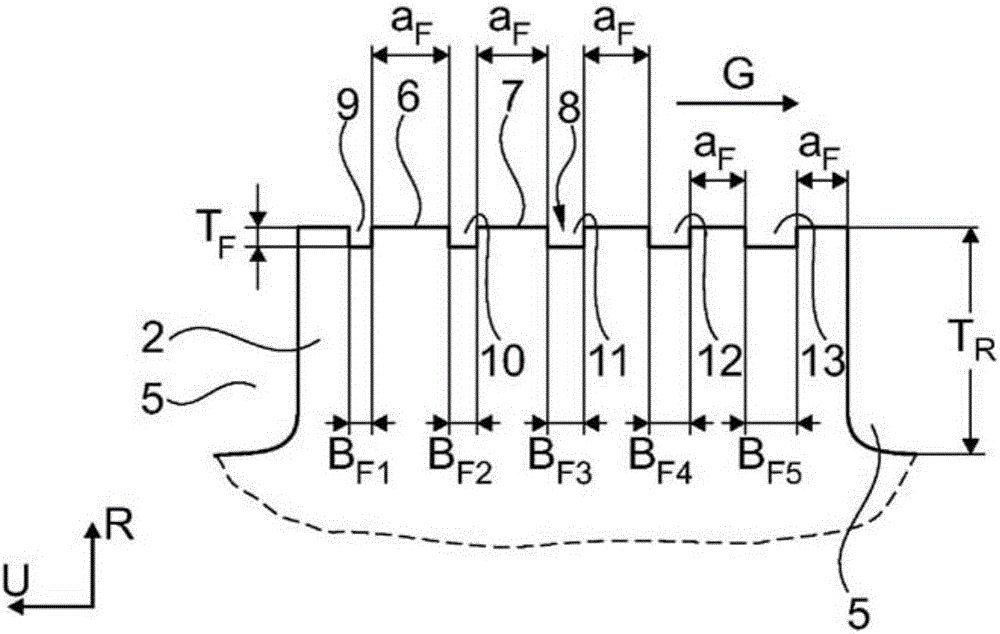

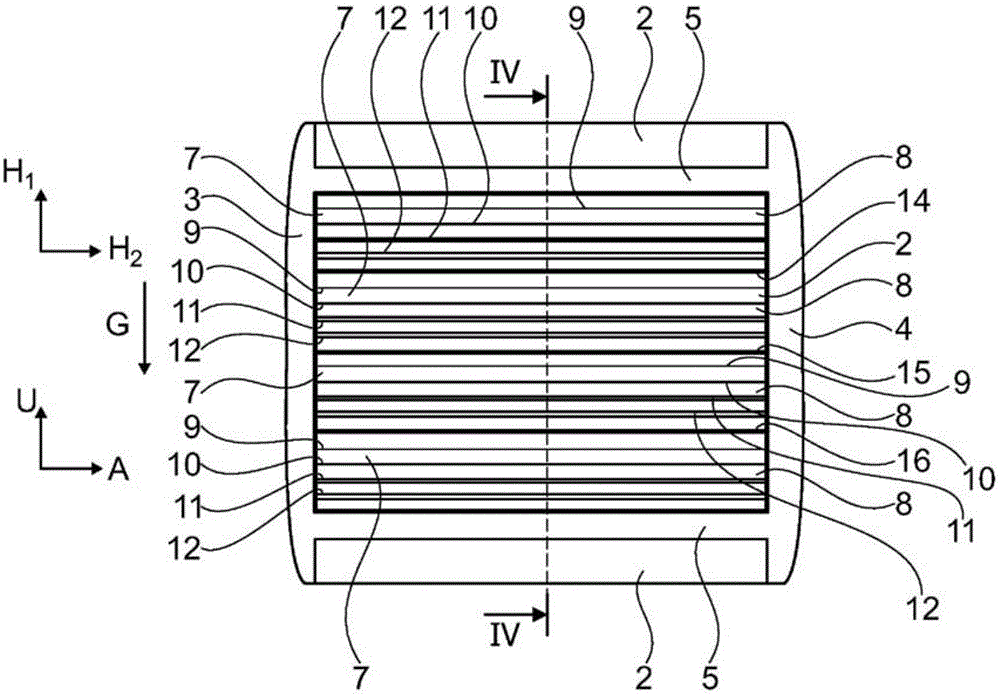

[0036] figure 1 and 2 A partial view showing a tread pattern of a vehicle pneumatic tire for a PKW (passenger car) with a known type of block row 1 formed at the circumference of the vehicle pneumatic tire Oriented in direction U and extending over the entire circumference of the vehicle pneumatic tire. The block row 1 is formed in a known manner from a plurality of radially raised block units 2 arranged one behind the other in the circumferential direction U of the pneumatic vehicle tire and correspondingly passed through a plurality of transverse The grooves 5 are spaced apart from each other. The row of blocks 1 is bounded in the axial direction A of the vehicle pneumatic tire towards one axial side by a circumferential groove 3 and towards the other axial side by a circumferential groove 4 in a known manner. These circumferential grooves 3 and 4 extend in a known manner over the entire circumference of the vehicle pneumatic tire and are oriented in the circumferential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com