Steel tube traction machine

A tractor and steel pipe technology, applied in the tractor field, can solve the problems of uneven distribution of clamping force, inconvenient change of pipe fitting specifications, poor alignment and adjustment accuracy of clamping force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

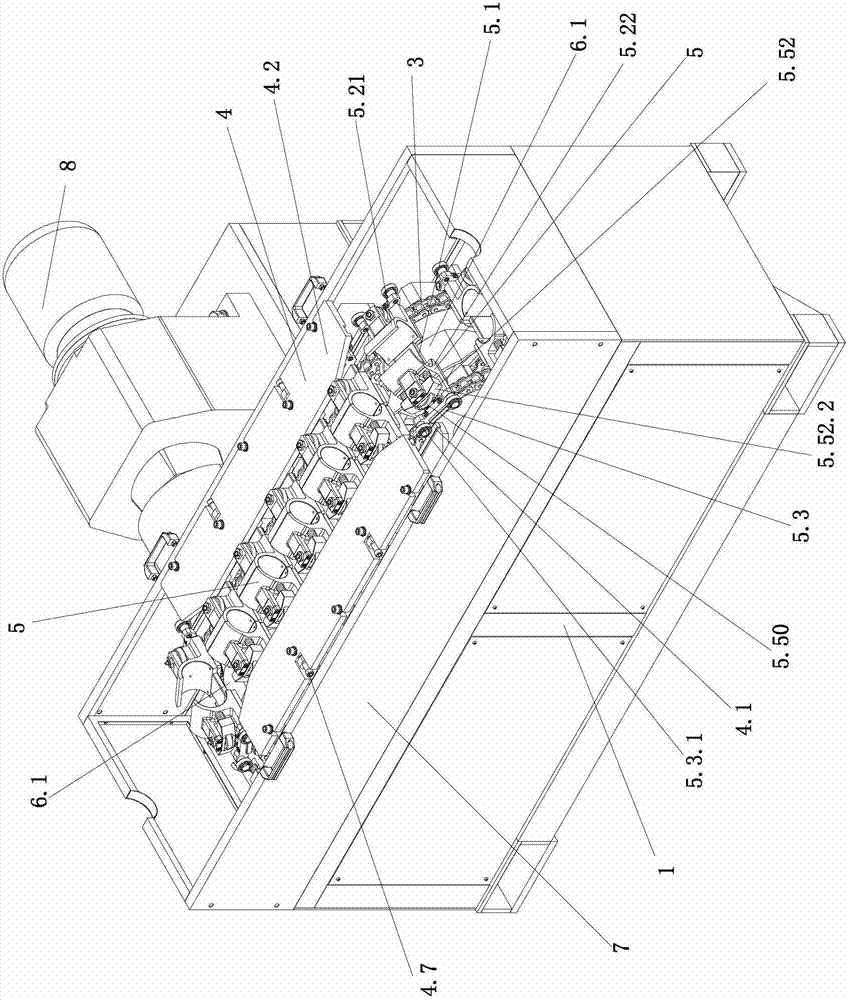

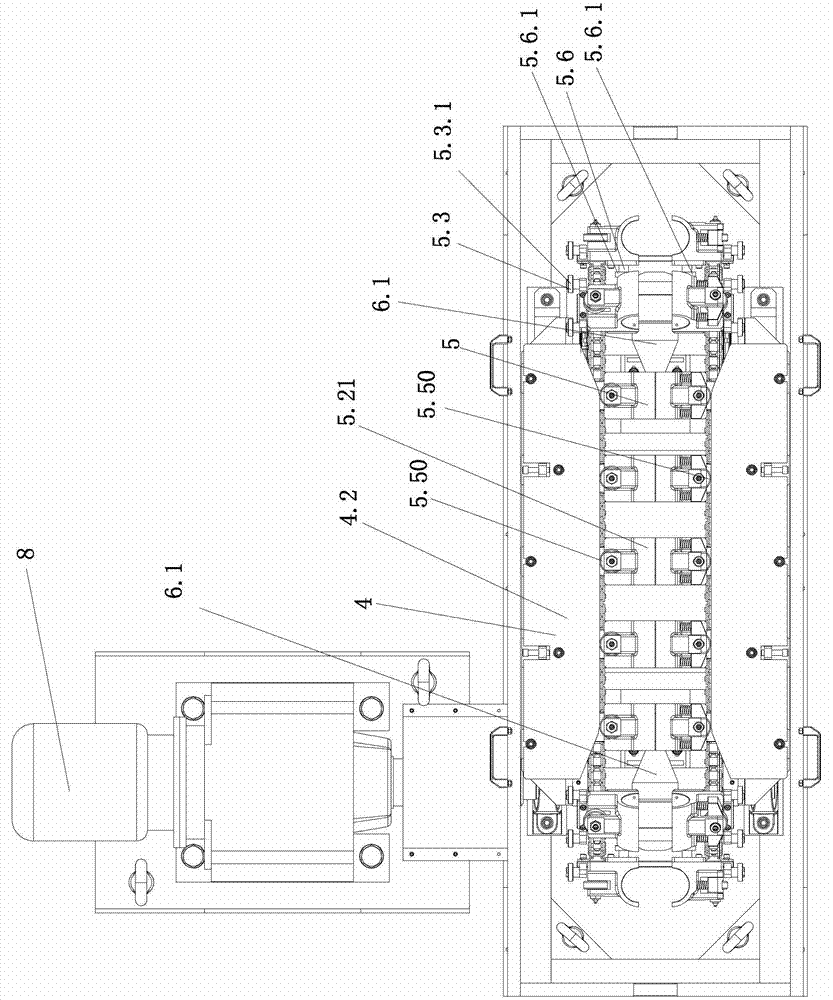

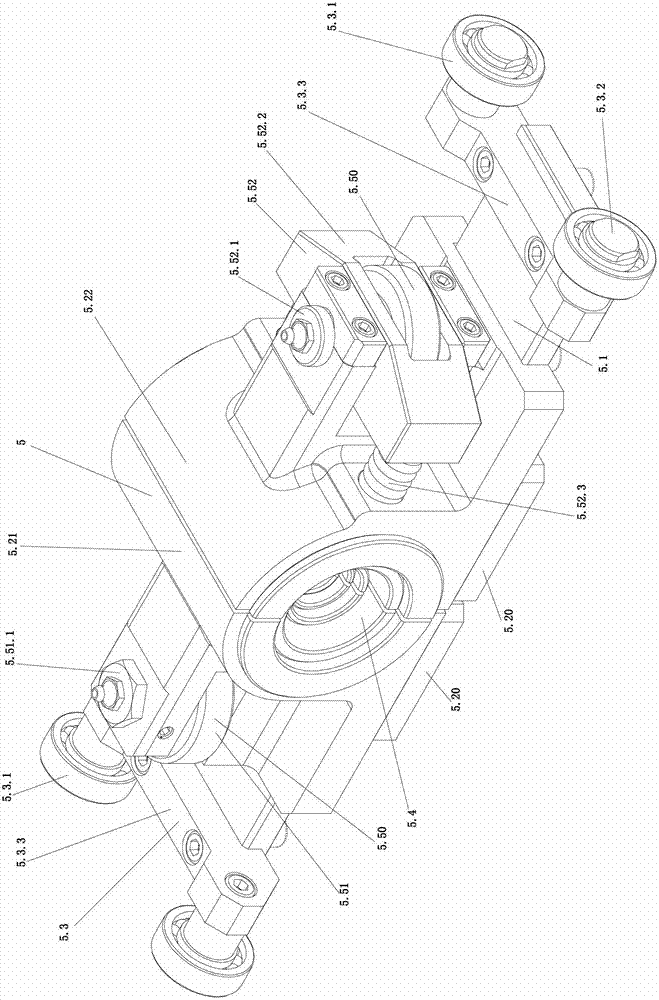

[0021] Such as figure 1 , figure 2 As shown, the present invention includes a frame 1, the main and driven shafts respectively rolling and supported on the left and right ends of the frame 1, the power source system including the motor, the reducer and the electrical control system, facing each other front and back, and rotating in the same direction The chain 3 and the corresponding sprocket wheel, the guide bracket 4, the clamps fixed on the left and right ends of the frame 1 respectively to open the bracket 6 and some chuck parts 5 for clamping pipe fittings, and the protective cover 7; the protective cover 7 It includes the side wall of the protective cover which is detachably connected to the upper end of the lower end of the frame 1 and the protective cover cover which is not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com