Visual micro spot welding and tin soldering automatic production line

An automatic production line and micro-point technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high human factors in product quality, unstable product quality, and high labor intensity of workers, so as to reduce product quality. The effect of unstable quality, saving manpower, and simple and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

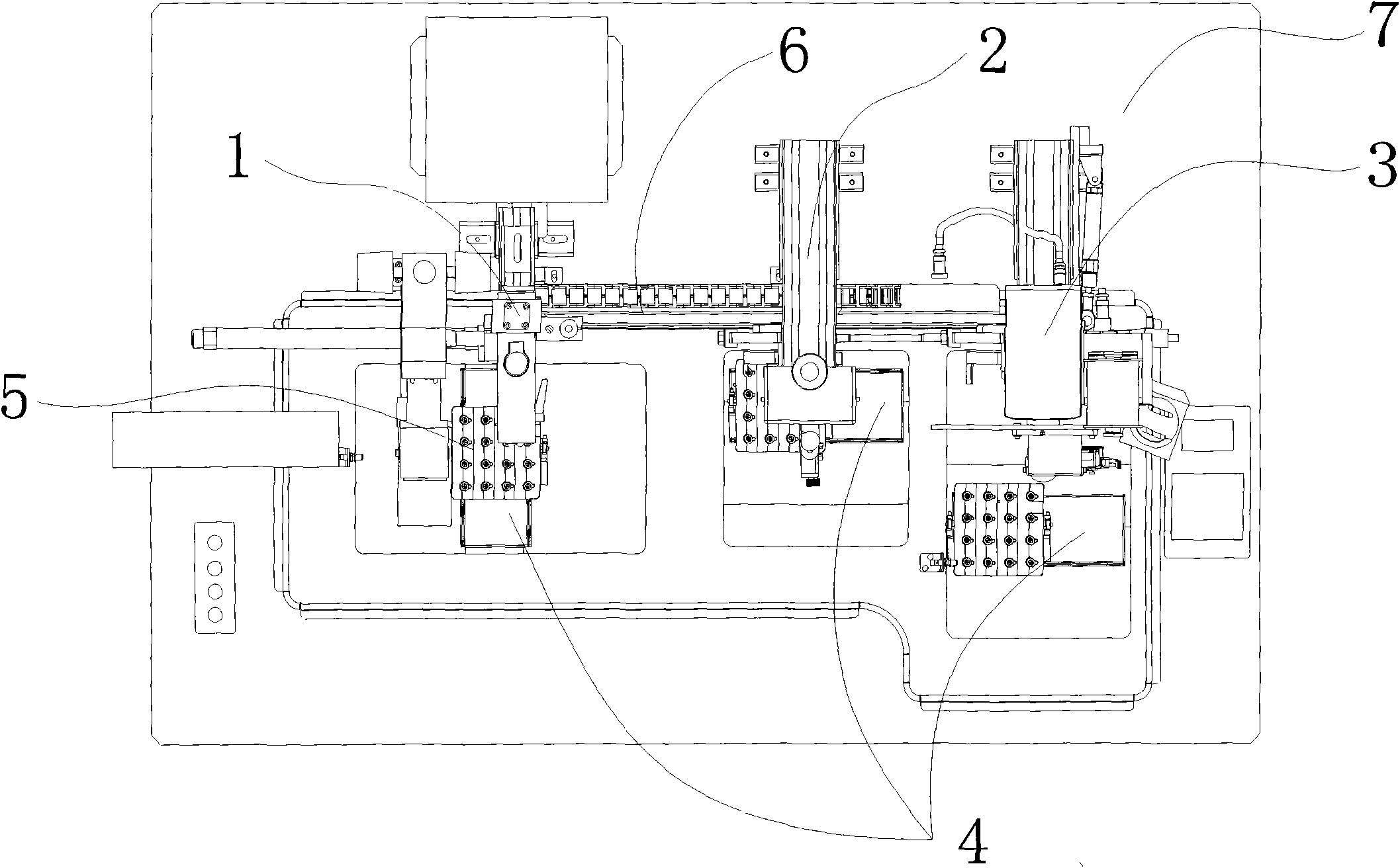

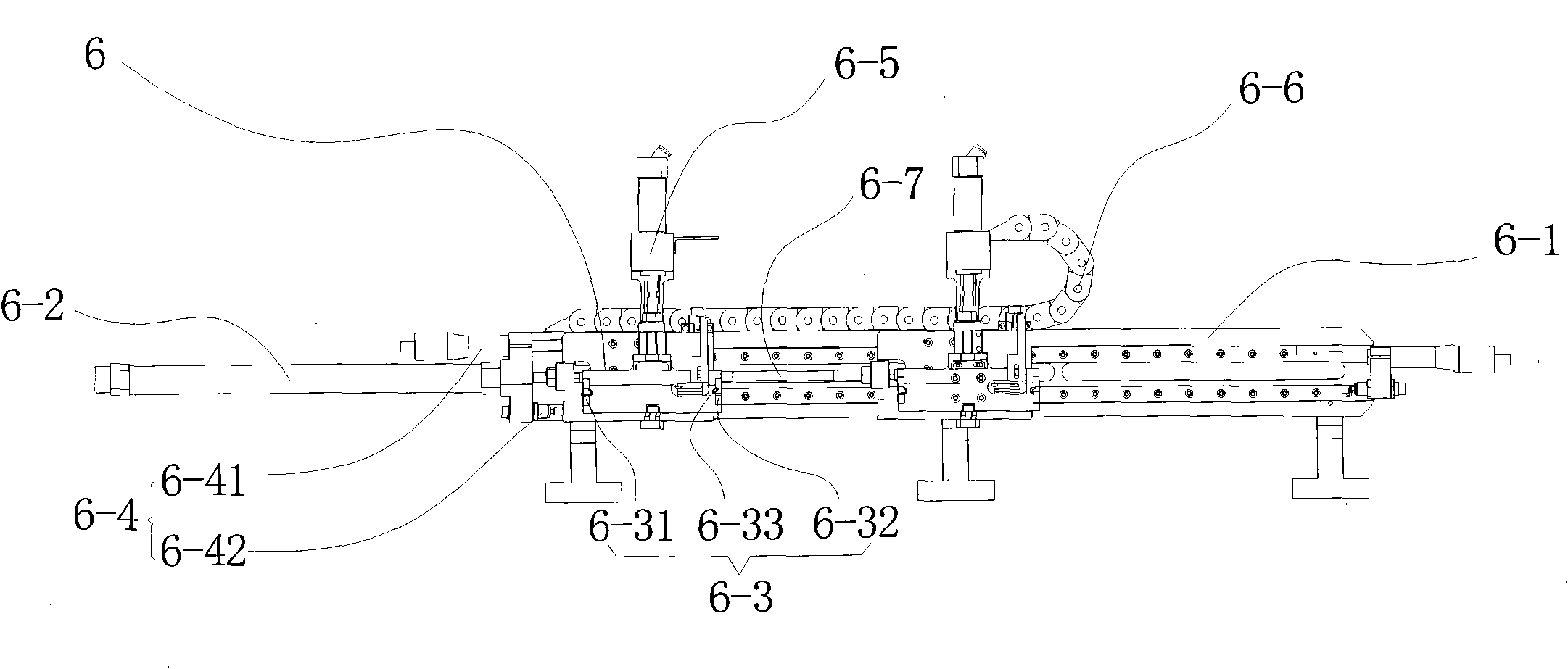

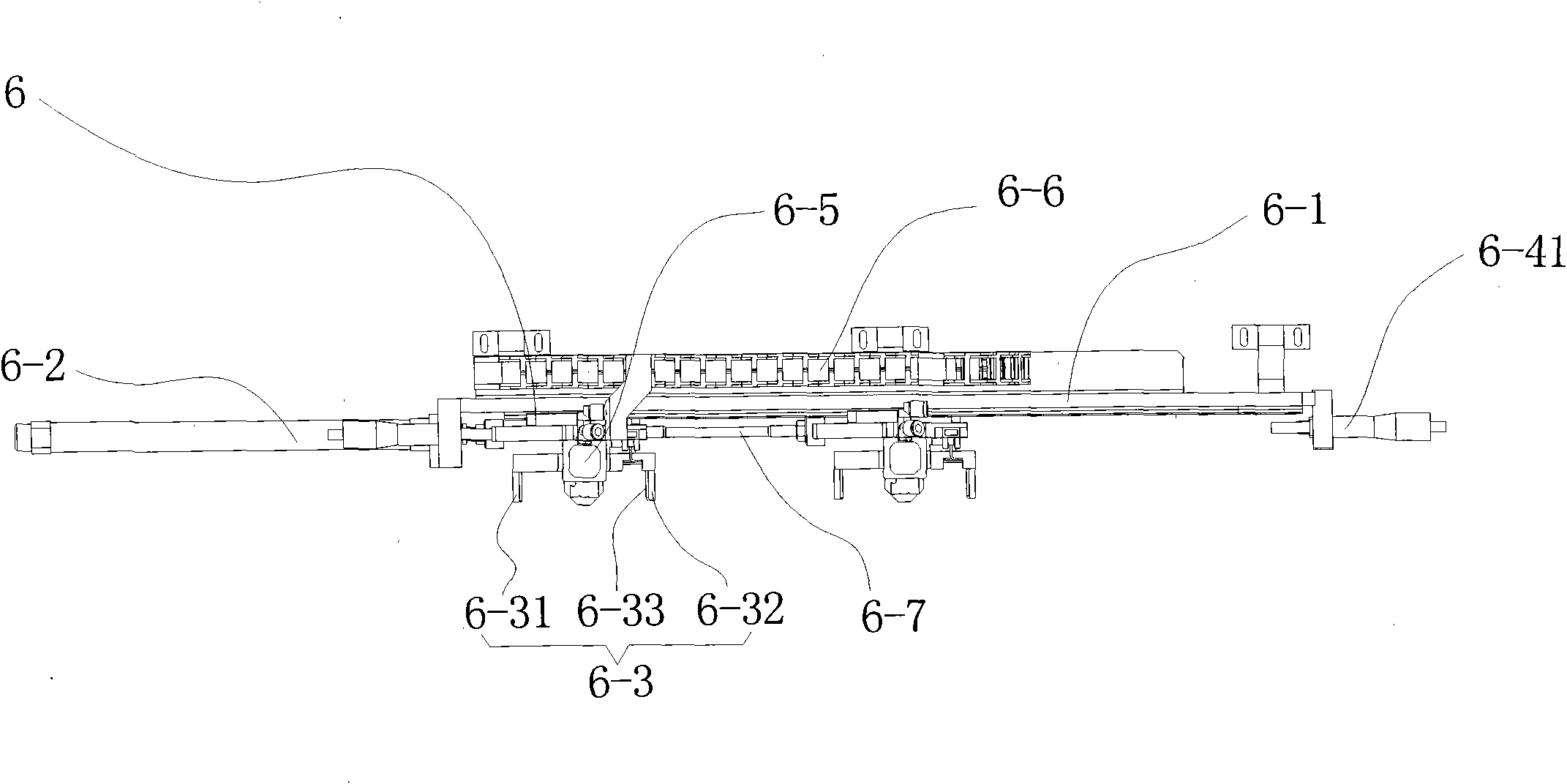

[0019] Such as Figure 1-Figure 5 A visual micro-spot welding and soldering automatic production line shown, including an automatic visual micro-spot welding mechanism 1, an automatic detection mechanism 2 and an automatic soldering tin mechanism 3, the automatic visual micro-spot welding mechanism 1, an automatic detection mechanism 2 and an automatic soldering tin mechanism The mechanism 3 is arranged on the bottom plate mechanism 7 in sequence from left to right and is arranged in a line. The bottom plate mechanism 7 is also equipped with three corresponding to the automatic visual micro-spot welding mechanism 1, the automatic detection mechanism 2, and the automatic soldering mechanism 3. The two-dimensional motion platform 4, the first two-dimensional motion platform is located directly below the automatic vision micro-spot welding mechanism 1, the second two-dimensional motion platform is located directly below the automatic detection mechanism 2, and the third two-dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com