Method for producing biomass charcoal and charring furnace with double furnace chambers therefor

A technology of biomass charcoal and carbonization furnace, which is applied in the direction of biofuel, coke oven, special form of carbonization, etc., can solve the problem of not being able to further increase the calorific value of combustible gas produced, and achieve the convenience of large-scale industrial production, delay the depletion time, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

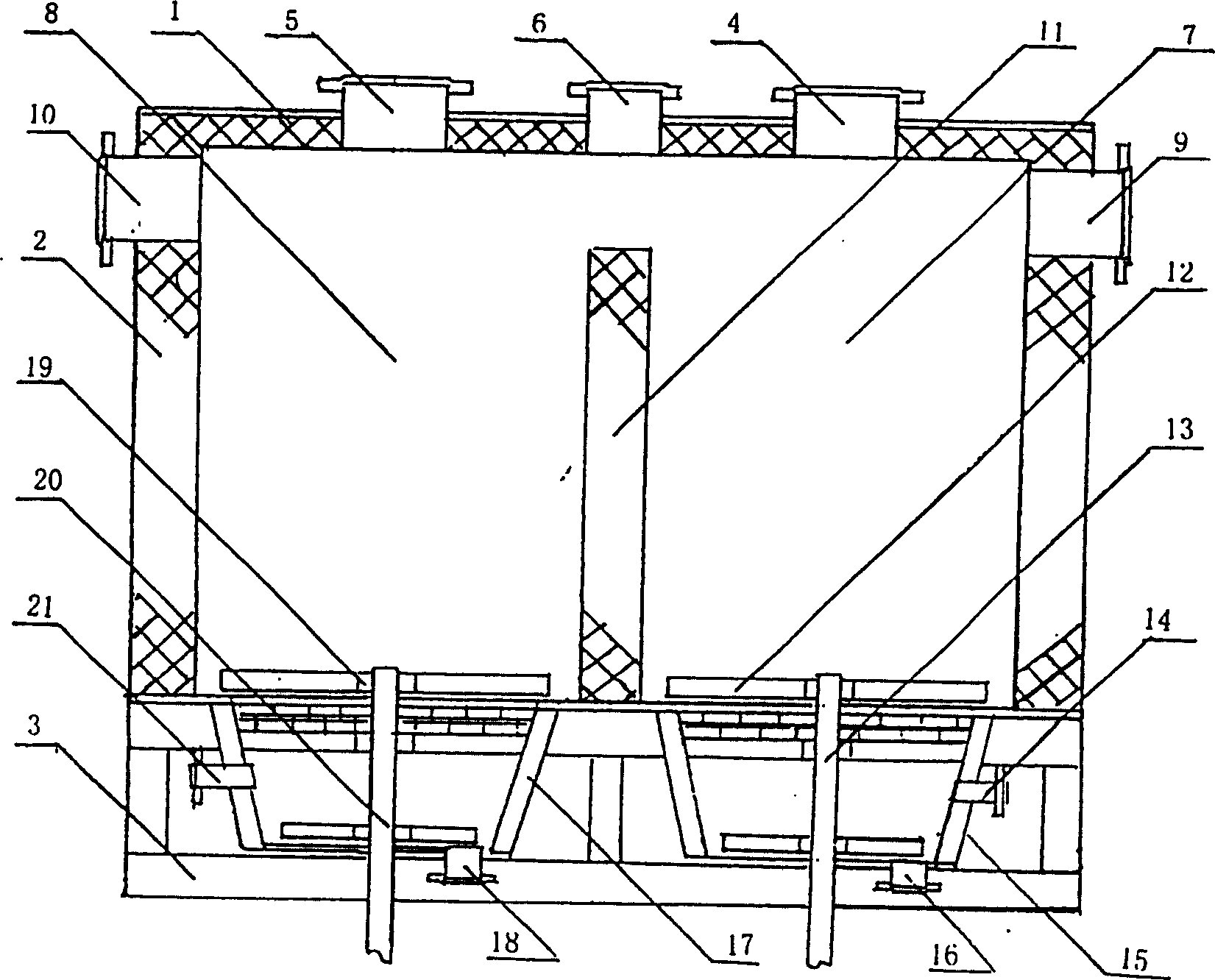

Embodiment 1

[0020] Corn stalks and sorghum stalks are used as main raw materials. After being chopped according to the above process, the dust and waste materials that do not meet the requirements for carbonization materials are screened and removed. After drying and dehydration, the moisture content is controlled at 15%. 4 meters, 2 meters in width, and 3 meters in the above-mentioned furnace carbonization chamber 8, add the undersieve straw fines and other agricultural and forestry wastes that are not suitable for carbonization materials into the gasification chamber 7 in the furnace to ignite , start the blower to blow air (gasification agent) into the air inlet pipe 14 at the bottom of the gasification furnace chamber, so that the gasification material added to the gasification furnace chamber 7 undergoes gasification reaction to generate a high-temperature combustible gas at 500-700 ° C. Under the action of the suction fan outside the furnace, the high-temperature combustible gas is s...

Embodiment 2

[0023] With branches and cotton stalks as the main raw materials, after being chopped according to the above process, the dust and waste materials that do not meet the requirements for carbonization materials are screened and removed, and then after drying and dehydration, the moisture content is controlled at 15%, and then long In the carbonization furnace cavity 8 in the above-mentioned furnace with a width of 6 meters, a width of 3 meters, and a height of 4 meters, the above-mentioned undersieve cotton stalk fines and other agricultural and forestry wastes that do not meet the carbonization materials are added to the gasification furnace cavity 7 in the furnace Ignition, start the blower to blow air (gasification agent) into the air inlet pipe 14 at the bottom of the gasification furnace chamber, so that the gasification material added to the gasification furnace chamber 7 undergoes gasification reaction to generate high-temperature combustible gas at 500-700 °C , under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com