Patents

Literature

38results about How to "Fast carbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

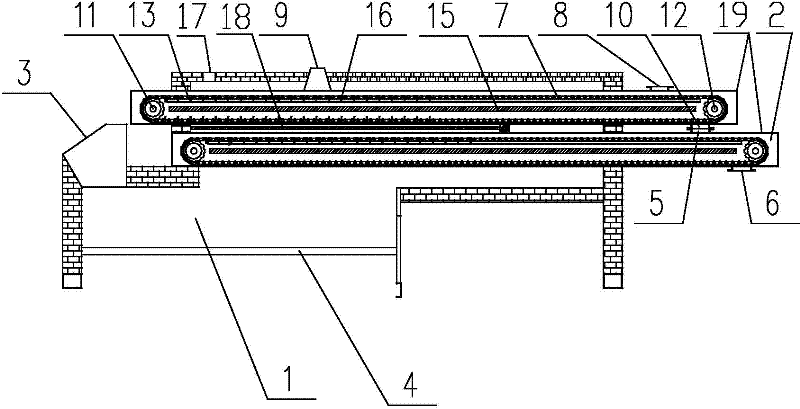

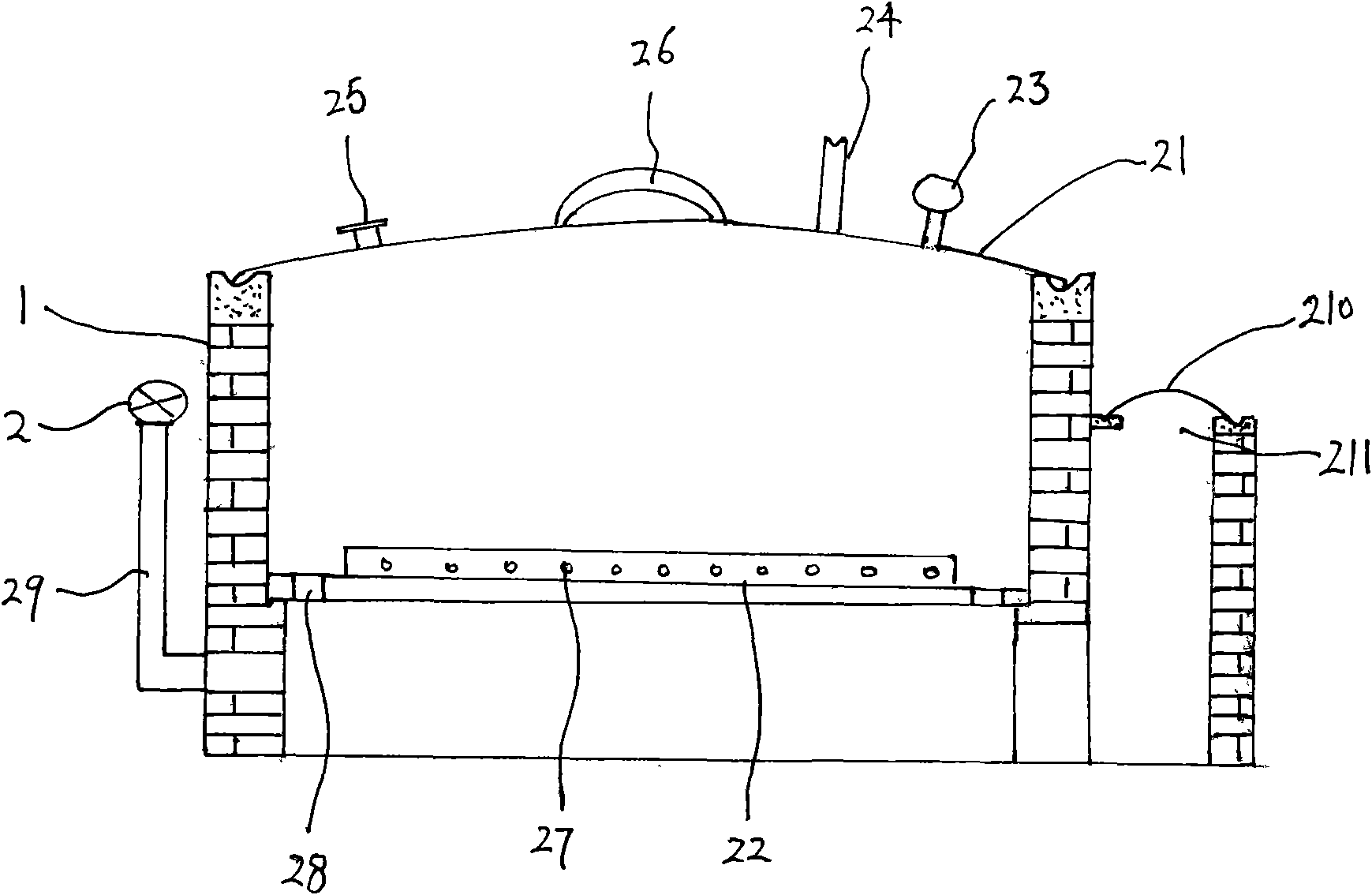

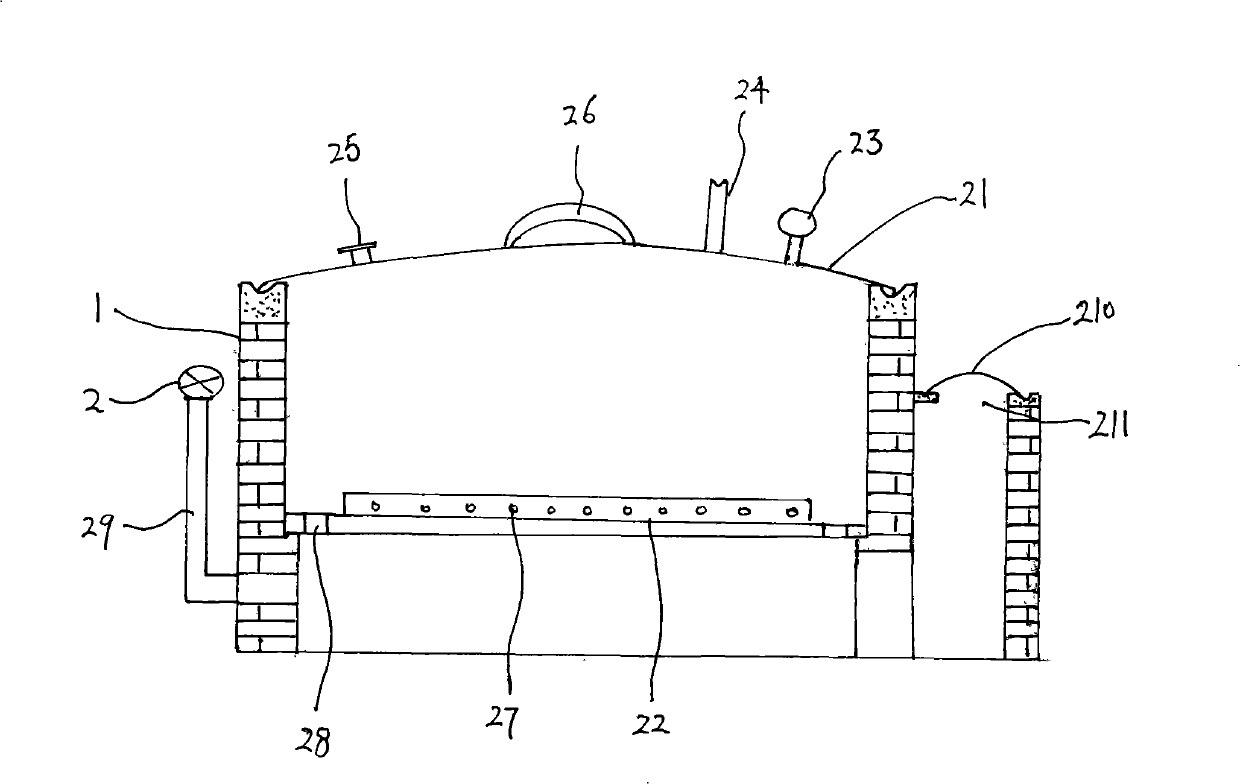

Biomass carbonization furnace

The invention relates to a biomass carbonization furnace which comprises a combustion chamber and a carbonization chamber arranged above the combustion chamber, wherein a fuel inlet is arranged at one end of the combustion chamber; a grate and a combustible gas combustion device are arranged in the combustion chamber; the upper part of the carbonization chamber is provided with a feed port of thecarbonization chamber; the bottom part of the carbonization chamber is provided with a discharge port of the carbonization chamber; a raw material circular conveying device of the carbonization chamber is arranged in the carbonization chamber; a drying chamber is also arranged above the carbonization chamber; the upper part of the drying chamber is provided with a feed port and a water vapor outlet of the drying chamber; the bottom part of the drying chamber is provided with a discharge port of the drying chamber; a raw material circular conveying device of the drying chamber is arranged in the drying chamber; and the discharge port of the drying chamber is connected with the feed port of the carbonization chamber. The biomass carbonization furnace provided by the invention is suitable for the pyrolysis and carbonization of biomass raw materials, and can increase the carbonization speed of the biomass raw materials and improve the carbonization quality of the biomass raw materials.

Owner:江苏华威龙玖环保科技有限公司

Preparation method of modified carbon fiber thermal insulation composite material

ActiveCN108017362AImprove thermal insulation performanceImprove adsorption capacityPhysical treatmentCarbon fibresFiberCarbon fibers

The invention discloses a preparation method of a modified carbon fiber thermal insulation composite material. The modified carbon fiber thermal insulation composite material is prepared from raw materials of silicon powder, coconut shell, phenol, polyvinyl alcohol, etc. The preparation method is characterized in that the coconut shell is used to prepare porous carbon fiber and undergoes a plurality of modification processes to obtain porous carbon fiber with high mechanical strength and high adsorption; and then the porous carbon fiber is impregnated with alkaline silica sol, so that the well-developed mesoporous structure of the silica sol makes the carbon fiber have high temperature resistance and extremely low thermal conductivity, and further strengthens the thermal insulation capacity of the carbon fiber. The obtained composite material is not only light in weight, but also has high thermal insulation ability and low thermal conductivity, so that use cost of the thermal insulation material is greatly reduced, and the modified carbon fiber thermal insulation composite material is suitable for the needs of thermal insulation materials in various fields.

Owner:嘉兴德毅新材料有限公司

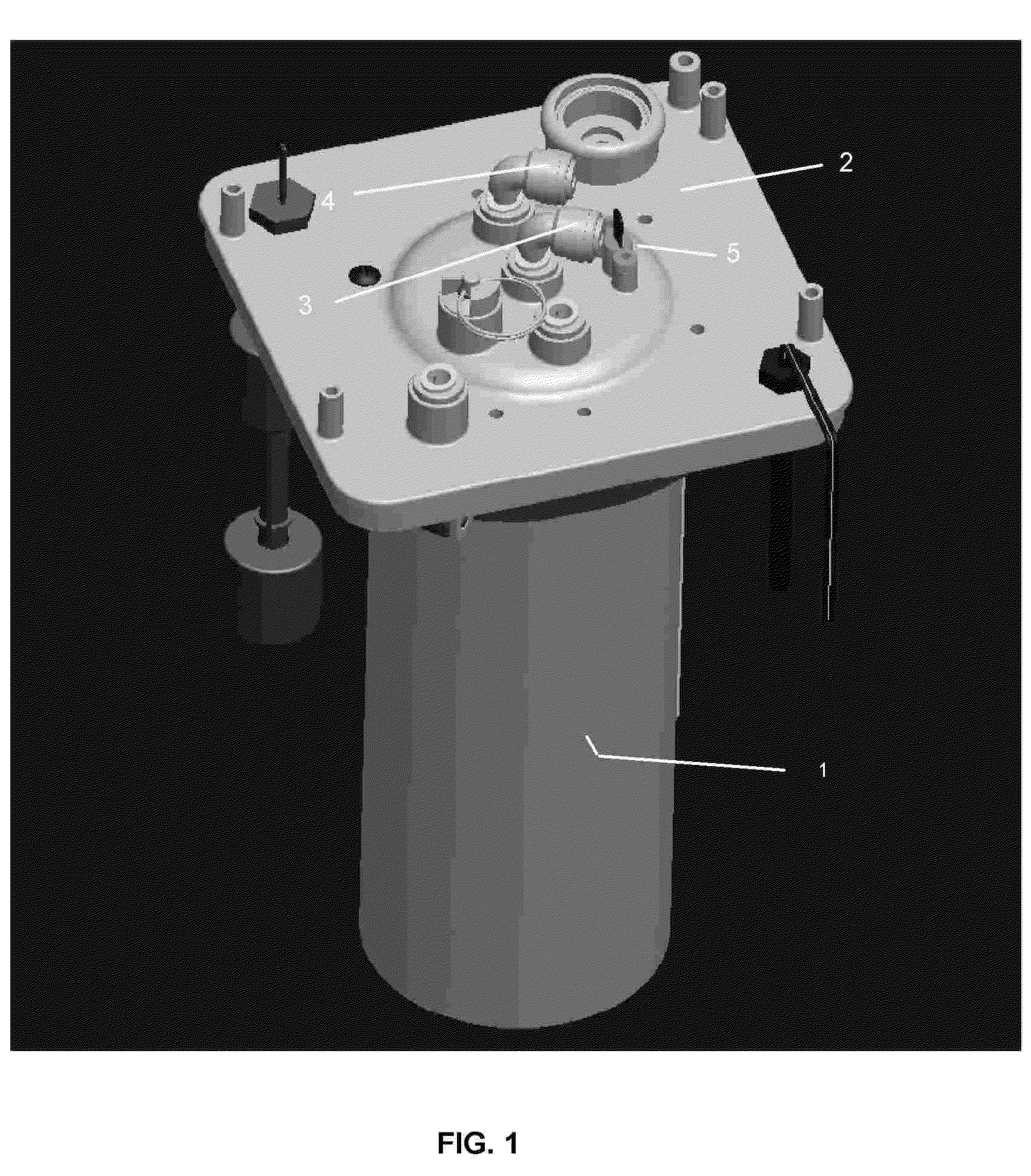

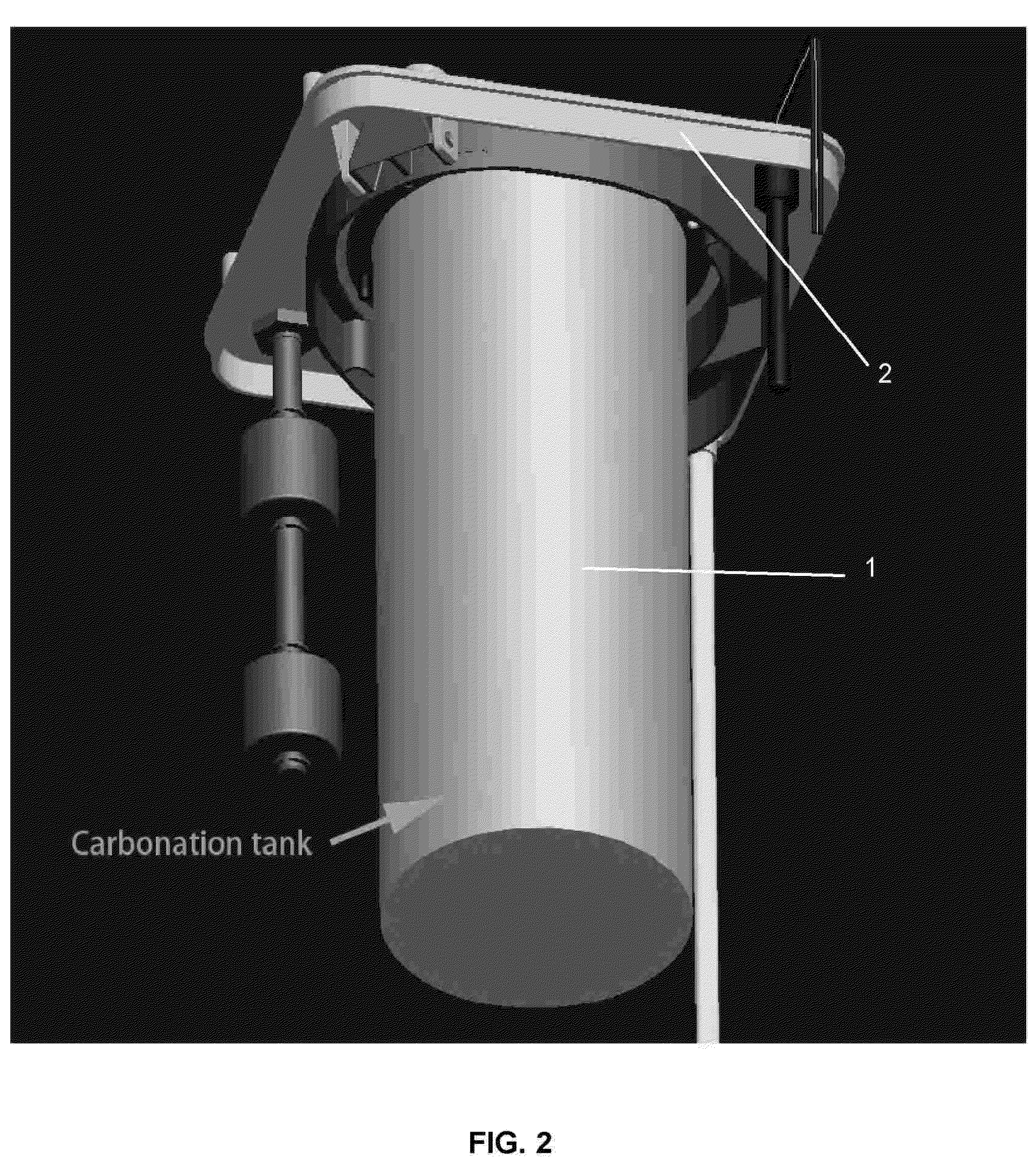

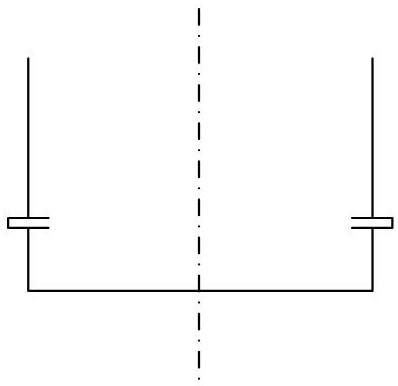

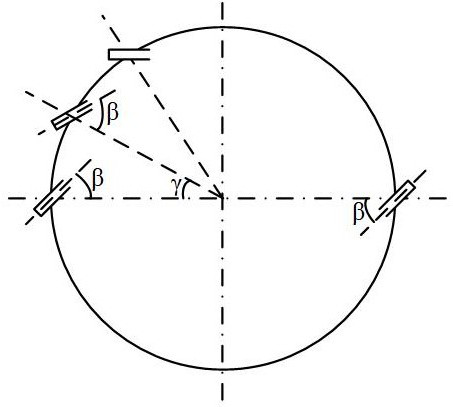

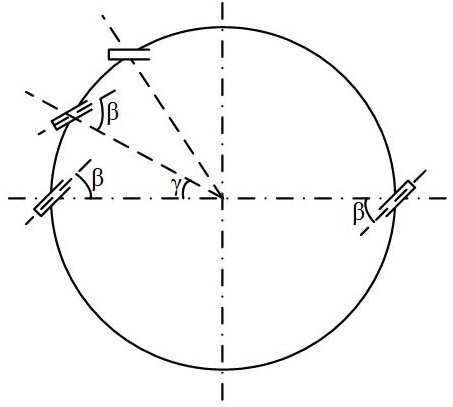

Method and Apparatus for Rapid Carbonation of a Fluid

InactiveUS20160220970A1Fast carbonizationIncrease surface areaMixing methodsMixer accessoriesSmall dropletCarbonization

A system and method for rapid carbonization of a fluid such as water. CO2 gas to be pumped into a vessel at an increased pressure greater than one atmosphere. Liquid is then injected into the vessel using the technique of atomization. Atomization is a process where the liquid is caused to take the form of a very large number of tiny droplets. This is done by giving the liquid angular momentum as it is sprayed out of one or more nozzles. The very large number of very small droplets have a tremendously increased surface area increased surface area of the gas-liquid boundary causes very rapid dissolving of the gas in the liquid. The required angular momentum is imparted to the liquid by a curved feed system and by specially shaped nozzles.

Owner:LA VIT TECH

Preparation method of PVC special-purpose functional filler superfine active calcium carbonate with low oil absorption

InactiveCN102732065AIncrease productivityIncrease temperaturePigment physical treatmentPigment treatment with non-polymer organic compoundsCarbonizationBiological activation

The invention discloses a preparation method of a PVC special-purpose functional filler superfine active calcium carbonate with low oil absorption. The method comprises the following main steps of: allowing a kiln gas to enter a high-density calcium hydrate slurry for rapid carbonization; grinding by the adoption of a vertical type bead mill; mixing the grounded slurry with a saponified eleaostearic acid emulsion; synchronously completing dispersion of calcium carbonate and surface coating under the action of high shear force by an emulsification pump; and finally filtering and drying to obtain the product of the invention. The product is characterized in that its particle size distribution is 0.8-1.5 microns; activation grade is greater than 98%; oil absorption is less than 18 g / 100 g CaCO3; and there is no agglomerate phenomena. In addition, the product can be used as a high-grade PVC special-purpose functional filler.

Owner:CHIZHOU CELT NANO TECH

Coal-water slurry fuel and preparation method thereof

InactiveCN102746912ASave resourcesImprove utilizationLiquid carbonaceous fuelsFly ashEnergy consumption

The invention discloses a coal-water slurry fuel and a preparation method thereof. The coal-water slurry fuel includes components of charcoal, water and additives, wherein the additives comprise a dispersant and a stabilizing agent. The preparation method for the coal-water slurry fuel comprises a first step of performing hydro-thermal charing to the raw material biomass to get a mixture of the charcoal and water, and a second step of adding the additives to the mixture of the charcoal and water to obtain a crude product of the coal-water slurry fuel. According to the invention, the biomass, especially the agriculture residue, is used as a raw material to preparing the novel coal-water fuel which has the properties of environmental protection, high caloric value, and large caloric power. The preparation method for the fuel is low in energy consumption, economical and cheap, and easy for operation. The coal-water slurry product has low sulfur content, and has the advantages of few black smoke, big fire, full burning, no flying ash, clean burning, etc. in use.

Owner:北京雷恩新材料科技有限公司

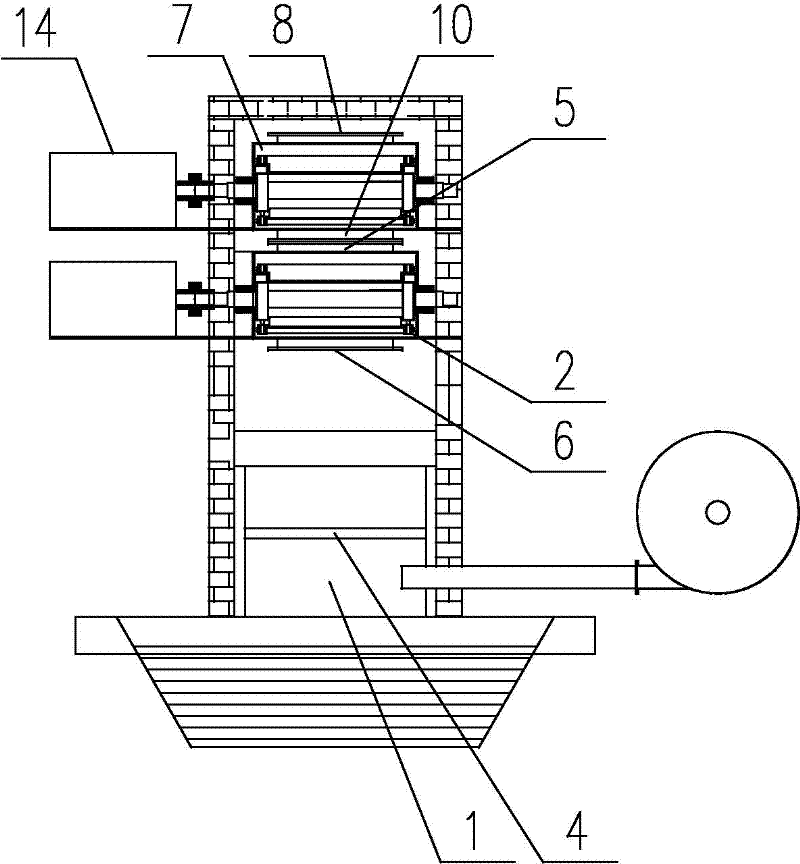

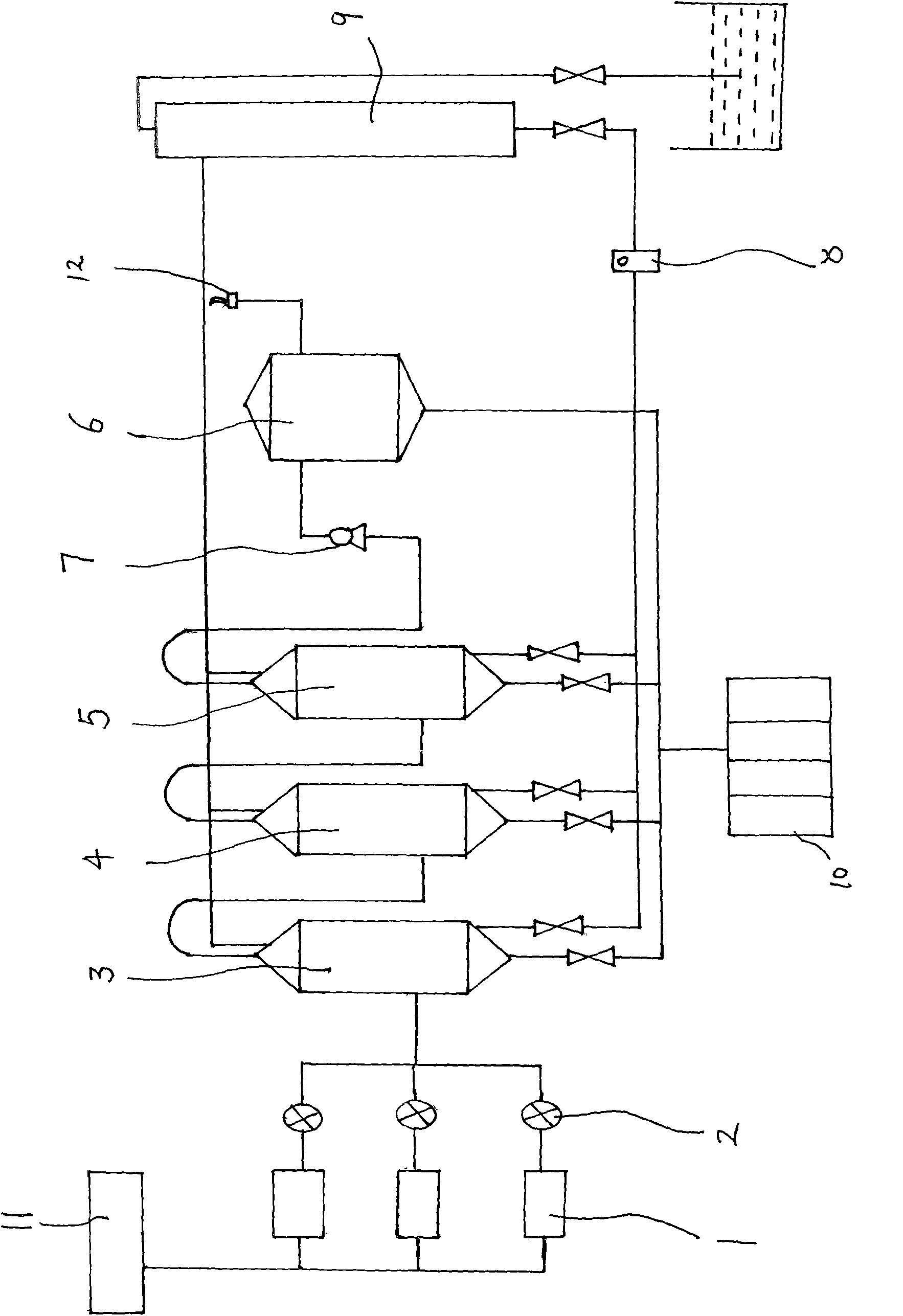

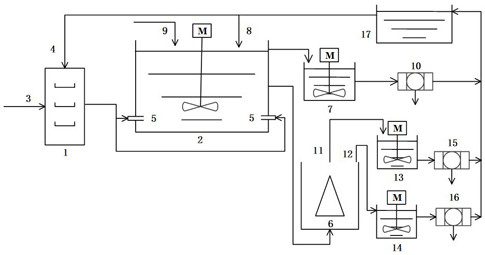

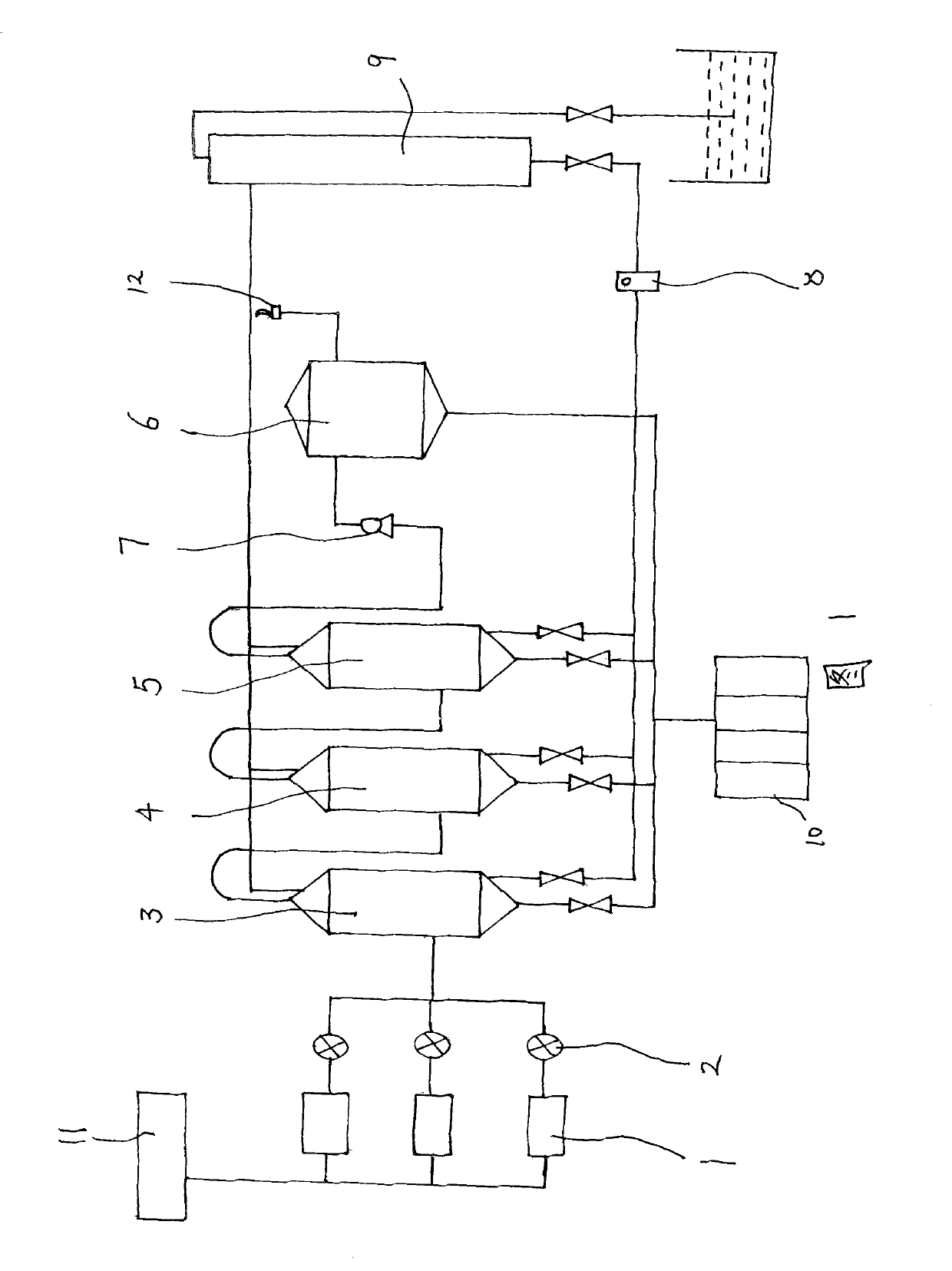

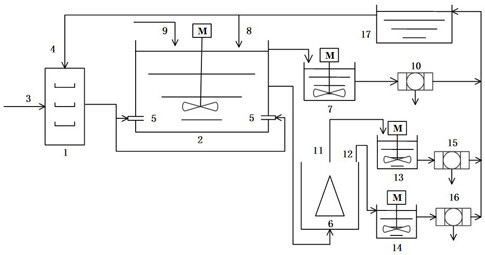

Biomass carbonizing and vaporizing equipment and technology thereof

ActiveCN101570691AThe amount of extraction is easy to controlEasy extractionChemical industryBiofuelsCarbonizationRaw material

The invention belongs to the technical field of biomass comprehensive utilization and discloses biomass carbonizing and vaporizing equipment and a technology thereof. The invention has the following main technical characteristics: the biomass carbonizing and vaporizing equipment comprises a furnace body with a control valve; the furnace body is orderly connected with a condensing tower, a screening tower, a centrifugal tower and a purifying tower, wherein, a frequency conversion fan is arranged between the centrifugal tower and the purifying tower; the condensing tower, the screening tower andthe centrifugal tower are connected with a separation cell and a water cooling tower with a temperature control circulating pump; and the furnace body is also connected with a gas separation unit which is used for rapidly extinguishing fire. The biomass carbonizing and vaporizing equipment and the technology thereof have high mechanization degree; the biomass carbonization and smoke-gas separating, extracting and purifying process are carried out in a fully-closed environment; all raw materials are converted into products; the whole process has no pollution or waste; and the invention realizes energy saving and environmental protection and changes wastes into valuables. The invention has the advantages of safe performance, high carbonizing speed, high extraction quantity and good quality.

Owner:河北序然环保工程有限公司

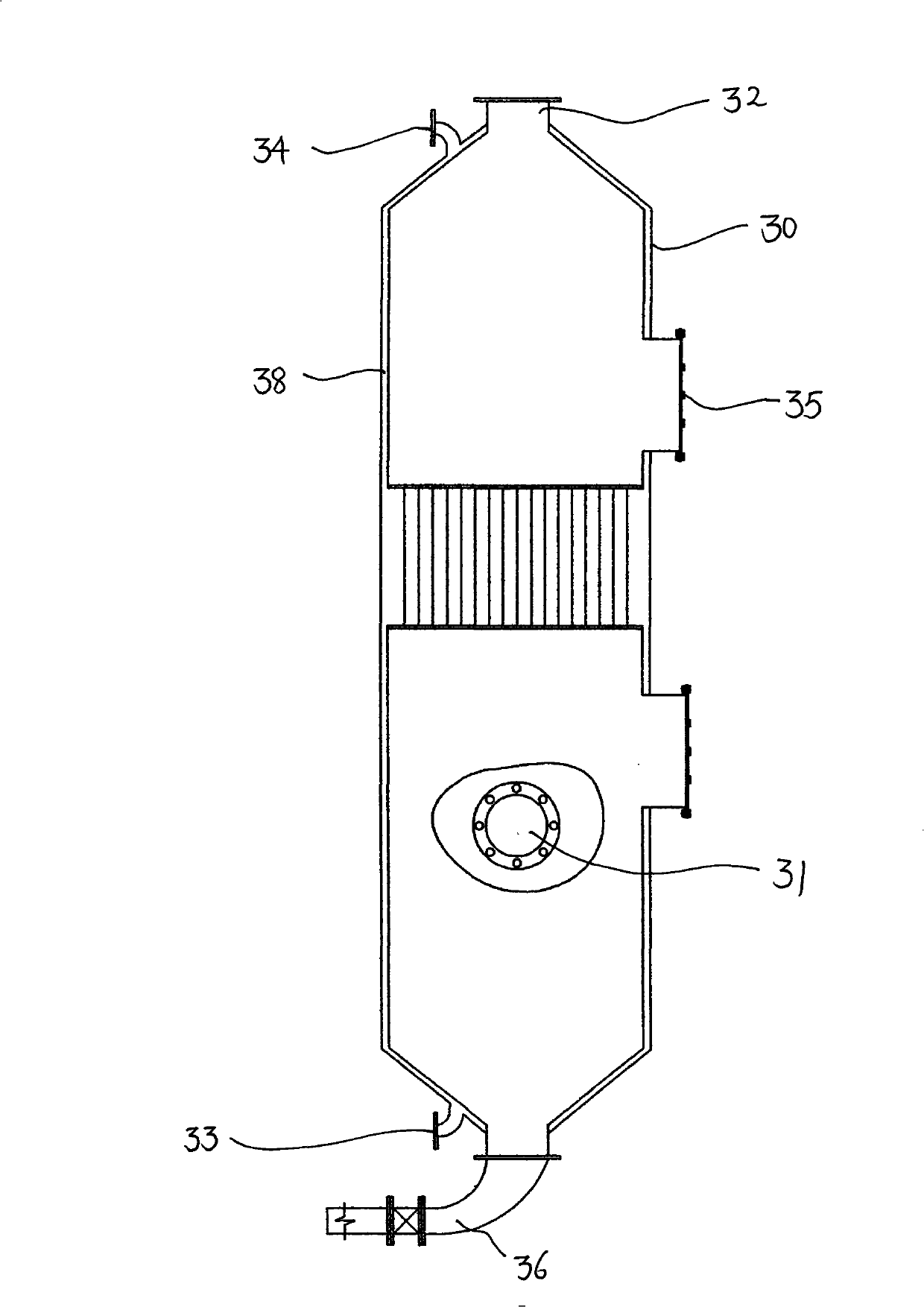

System device and method for preparing calcium carbonate by using micro-nano bubbles

ActiveCN112897561AContinuous operationEasy to operateCalcium/strontium/barium carbonatesMaterial nanotechnologyMicro nanoPhysical chemistry

The invention provides a system device and method for preparing calcium carbonate by using micro-nano bubbles, and the system device comprises a micro-nano bubble generation device and a reaction device which are connected with each other, and also comprises a first separation device and a centrifugal device which are separately connected with the reaction device, and a second separation device and a third separation device which are separately connected with the centrifugal device. The method for preparing calcium carbonate by using the micro-nano bubbles in the system device comprises the following steps: generating the micro-nano bubbles by using the micro-nano bubble generation device, enabling the micro-nano bubbles to enter the reaction device to be mixed with carbide slag for carbonization reaction, and then introducing the reaction system into the centrifugal device for separation, thereby obtaining calcium carbonate particles. According to the method, the grain size of calcium carbonate is controlled by carbonizing the carbide slag through the micro-nano bubbles, a crystal form control agent is not used, continuous operation can be achieved, intermittent operation can also be achieved, and the method and device have the advantages of being large in treatment capacity, high in carbonization speed, low in cost and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

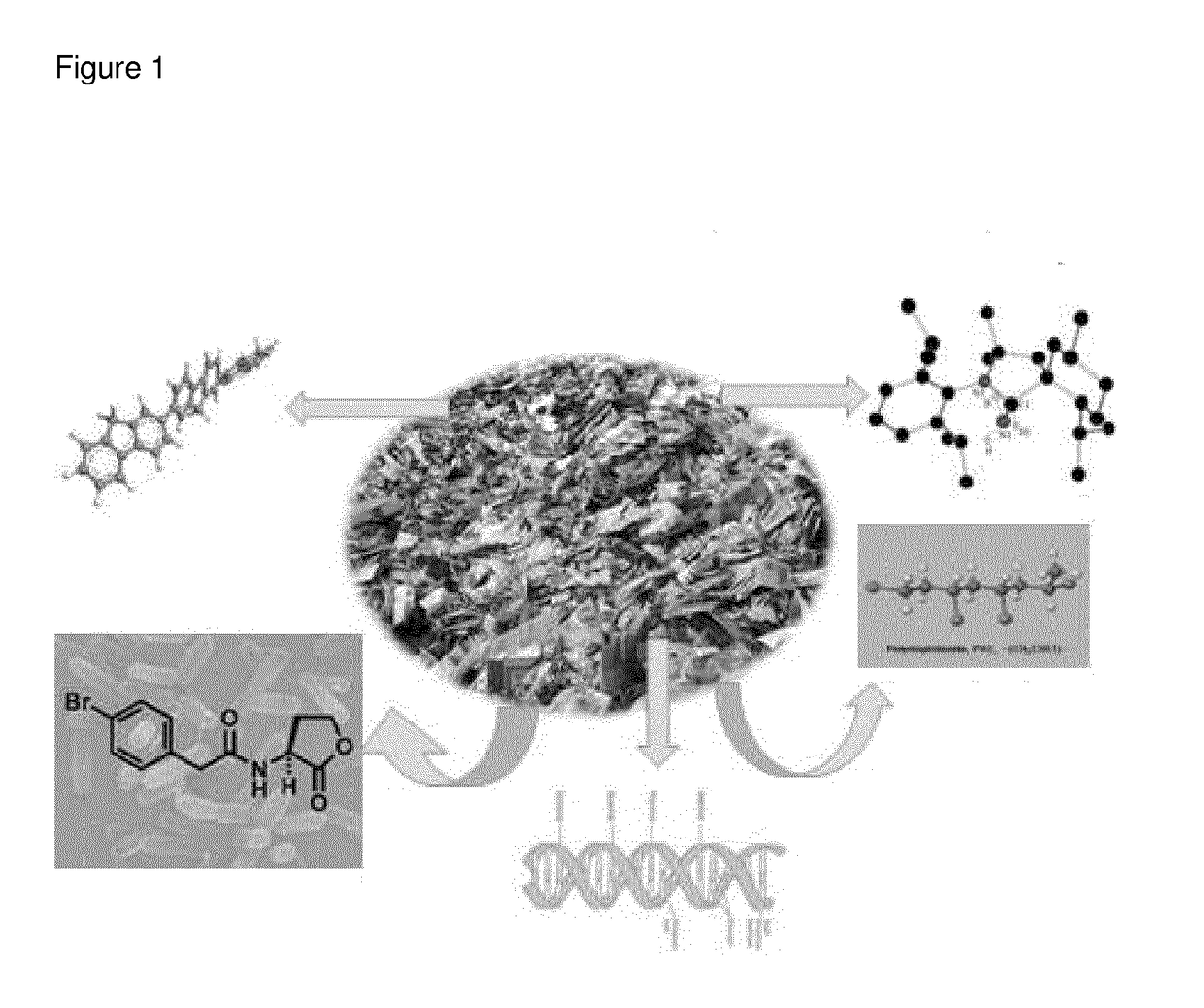

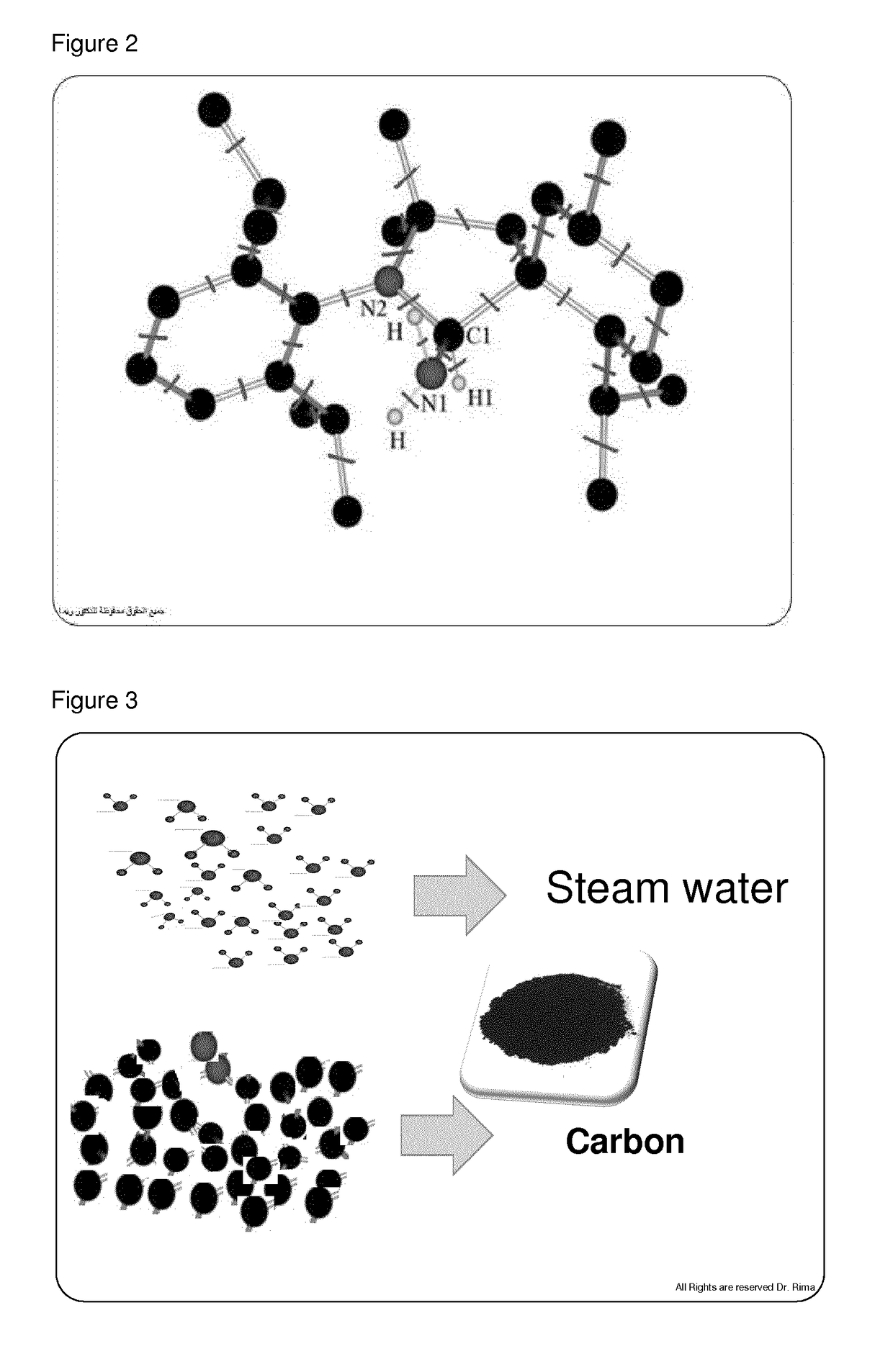

Method and apparatus for rapid dry carbonization of organic waste, apparatus and catalytic system associated to the method

InactiveUS20170313945A1Cheap methodEffective and fast transferMaterial nanotechnologyTransportation and packagingWater vaporCarbonization

A method for transforming waste into carbon in a reactor, said method comprising: a) drying the waste by submitting said waste to a pressure of at least 3 bar, and a temperature of at least 250° C.; b) releasing the water vapor out of the reactor, and; c) carbonizing at least partially the waste by maintaining said waste during a period of time of at least 5 minutes to a pressure of at least 3 bar, and a temperature of at least 250° C., thereby obtaining carbon; and d) optionally separating non-organic material from the obtained carbon.

Owner:RIMA IND S A L HLDG CO

Preparation method of modified carbon fiber for organic waste water adsorption and degradation

ActiveCN107983303AStop tangleAvoid reunionOther chemical processesAlkali metal oxides/hydroxidesFiberCarbon fibers

The invention discloses a preparation method of modified carbon fiber for organic waste water adsorption and degradation. The modified carbon fiber is prepared from raw materials of water glass, surfactants, ferrous sulfate, sodium borohydride, coconut husk, phenol and polyvinyl alcohol and the like. The coconut husk is used for preparing porous carbon fiber; through the many times modification process treatment, the porous carbon fiber with high mechanical intensity and high adsorption performance is obtained; finally, through soaking reaction, zero-valent iron is loaded onto the carbon fiber; the adsorption performance of the carbon fiber is used for enriching organic contaminants in the water body; the organic degradation is performed through the zero-valent iron; the goal of thoroughlyeliminating organic contaminants is achieved. The preparation method is simple; the reaction conditions are mild; the obtained product can be repeatedly utilized; secondary pollution cannot be generated on the environment; the method can be widely applied to the field of organic sewage treatment.

Owner:MAANSHAN XINZHOU GRAPES PROFESSIONAL COOP

Preparation method of special low-viscosity activated calcium carbonate for silicone adhesive

InactiveCN103818941ALess investment in equipmentFast carbonizationCalcium/strontium/barium carbonatesEmulsionCalcium hydroxide

The invention discloses a preparation method of special low-viscosity activated calcium carbonate for silicone adhesive. The preparation method comprises the following main steps: cane sugar being 0.3-0.8% of calcium hydroxide by weight is added in calcium hydroxide slurry; then kiln gas is introduced for quickly carbonizing; the initial temperature of the carbonization is controlled about 30 DEG C, and the final temperature is controlled about 55 DEG C; after the carbonization is finished, zinc chloride being 0.5-10% of calcium carbonate by weight is added in the slurry; the calcium carbonate slurry is grinded by adopting a vertical bead mill. Mixed emulsion of lauric acid and stearic acid is added in the grinded slurry; under the effect of a homogenizing pump, the dispersion of calcium carbonate and the surface coating are synchronously finished. Finally, the product is obtained by filtering and drying. The particle size of the product is within 0.3-0.8 microns; no agglomeration phenomenon is generated; the activation degree is higher than 99%; the oil absorption value is about 17 g / 100 g CaCO3. The viscosity of simulated pasty size is about 75,000 mPa.S; the simulated pasty size can be used as special low-viscosity functional filler for the silicone adhesive.

Owner:WUHU ZHUOYUE NANO NEW MATERIALS

Flame-proof armored rope core conveyer belt

ActiveCN100457580CImprove tensile propertiesImprove flame retardant performanceConveyorsPhosphateNeoprene

The invention relates to a flame-proof steel belt conveyor, which is based on the adhesive property between the flame-proof layer and the steel wire to improve the flame-proof, anti-abrasion, and conducting static electricity property of glue material by adjusting the proportion of raw material, adding flame-proof lubricant and using new conducting carbon black, to improve the whole property of invention and meet the standard of MT668-1997. Said invention mainly comprises steel wires and flame-proof covering glue layer. Wherein, the formulation of flame-proof covering glue layer comprises: neoprene in 80-100 deals; zinc oxide in 4-20 deals; accelerant (as melaniline) in 2-8 deals; conducting carbon black in 4-15 deals; solid flame-proof agent (as antimony oxide) in 20-59 deals; liquid flame-proof agent (as triaryl phosphate) in 5-20 deals; white carbon black in 5-20 deals; and solid frame-proof lubricant MB-202 in 3-8 deals.

Owner:QINGDAO RUBBER SIX CONVEYER BELT

Preparation method of modified-porous-carbon-fiber-loaded calcium chloride hygroscopic material

ActiveCN107938313AFast carbonizationHigh carbon yieldCarbon fibresElectro-spinningSodium carboxymethylcellulosePolyvinyl alcohol

The invention discloses a preparation method of a modified-porous-carbon-fiber-loaded calcium chloride hygroscopic material. The hygroscopic material is made from calcium chloride, sodium carboxymethylcellulose, diatomite powder, coconut shell, phenol, and polyvinyl alcohol. Porous carbon fiber made from coconut shell undergoes multiple modification treatment. The obtained porous carbon fiber is high in mechanical strength and good in adsorbability. The porous carbon fiber itself can adsorb a large amount of water vapour from air, and the porous structure is beneficial for loading calcium chloride. The composite material is good in moisture absorption, and a small amount of added nanometer diatomite provides components with better adhesion and support after moisture absorption, which is beneficial for reuse of the hygroscopic material after high-temperature drying. The hygroscopic material is non-pollution to the environment, is low in application cost, and is super high in economic value and environmental value.

Owner:MAANSHAN XINZHOU GRAPES PROFESSIONAL COOP

High-temperature heat transfer oil processed biochar and preparation method thereof

ActiveCN109082289AImprove adhesionImprove adsorption capacityBiofuelsIndirect heating destructive distillationFiberCompression molding

The invention relates to the technical field of biochars, particularly to a high-temperature heat transfer oil processed biochar and a preparation method thereof. The high-temperature heat transfer oil processed biochar is prepared from plant fiber and starch. The preparation method of the high-temperature heat transfer oil processed biochar comprises shredding and soaking the plant fiber into aqueous alkali, and then drying the soaked plant fiber; uniformly mixing the dried plant fiber with the starch, performing compression molding to obtain a fiber block; fixing the fiber block onto the bottom inside a high-temperature heat transfer oil carbonizing device, and filling in high-temperature heat transfer oil to carbonize the fiber block; performing oil removal treatment on the carbonized fiber block. The prepared high-temperature heat transfer oil processed biochar is high in absorbing performance and can be widely applied to the fields such as sewage purification and human and animalexcreta disposal, thereby being high in promotional value.

Owner:HUNAN UNIV OF TECH

Preparation method of adsorbing material for oil-containing wastewater

ActiveCN107792912AHigh strengthImprove adsorption efficiencyOther chemical processesAlkali metal oxides/hydroxidesCarbon fibersPorous carbon

The invention discloses a preparation method of an adsorbing material for oil-containing wastewater. The adsorbing material is prepared from polytrimethylene terephthalate, bisphenol A epoxy resin, vinylbenzyl trimethylammonium chloride, coconut shell, phenol, polyvinyl alcohol and the like. The preparation method comprises the following steps: preparing a porous carbon fiber from the coconut shell; carrying out modification treatment for multiple times to obtain a porous carbon fiber with high mechanical strength and high adsorptivity; combining the porous carbon fiber with the vinylbenzyl trimethylammonium chloride with excellent affinity to obtain an oil adsorbing elution material with good physical chemistry stability and excellent mechanical strength. With stability, the adsorbing material is suitable for being applied under various complex environmental conditions, has good environmental and economic benefits and is easy for large-scale production.

Owner:MAANSHAN XINZHOU GRAPES PROFESSIONAL COOP

A kind of preparation method of oily wastewater adsorption material

ActiveCN107792912BHigh strengthImprove adsorption efficiencyOther chemical processesAlkali metal oxides/hydroxidesCarbon fibersPolyvinyl alcohol

The invention discloses a preparation method of an adsorbing material for oil-containing wastewater. The adsorbing material is prepared from polytrimethylene terephthalate, bisphenol A epoxy resin, vinylbenzyl trimethylammonium chloride, coconut shell, phenol, polyvinyl alcohol and the like. The preparation method comprises the following steps: preparing a porous carbon fiber from the coconut shell; carrying out modification treatment for multiple times to obtain a porous carbon fiber with high mechanical strength and high adsorptivity; combining the porous carbon fiber with the vinylbenzyl trimethylammonium chloride with excellent affinity to obtain an oil adsorbing elution material with good physical chemistry stability and excellent mechanical strength. With stability, the adsorbing material is suitable for being applied under various complex environmental conditions, has good environmental and economic benefits and is easy for large-scale production.

Owner:SHAANXI MAIKE TECH DEV

A kind of preparation method of organic gas adsorption purification agent

ActiveCN107970902BStable and efficient adsorption capacityLarge specific surface areaGas treatmentOther chemical processesFiberCarbon fibers

Owner:攀枝花秉扬科技股份有限公司

Method for preparing agent for adsorbing and removing organic gas

ActiveCN107970902AStable and efficient adsorption capacityLarge specific surface areaGas treatmentOther chemical processesFiberN dimethylformamide

The invention discloses a method for preparing an agent for adsorbing and removing organic gas. The agent for adsorbing and removing the organic gas is prepared from tetraethyl orthosilicate, anhydrous ethanol, N,N-dimethylformamide, coconut shells, phenol, polyvinyl alcohol and other raw materials, and according to the method, porous carbon fiber which is obtained by performing multiple modification process treatment and has high mechanical strength and high adsorbability is prepared from the coconut shells; on the basis of the porous carbon fiber, loading of silica and activation of nitrogen-containing gas are achieved through the addition of the tetraethyl orthosilicate, and a large amount of a nitrogen element is introduced on the carbon fiber, so that a strong catalytic effect on sulfur-containing and nitrogen-containing compounds in the air is achieved, and stable and efficient adsorbability of benzene, toluene and other volatile toxic gas is achieved; the skeleton of the modified carbon fiber has strong adaptability to acid, alkali, high temperature and other environments, so that a long-term stable effect of adsorption and purification is achieved; and in addition, the usage mode is flexible, and good applicability to factories, homes and public places is achieved.

Owner:攀枝花秉扬科技股份有限公司

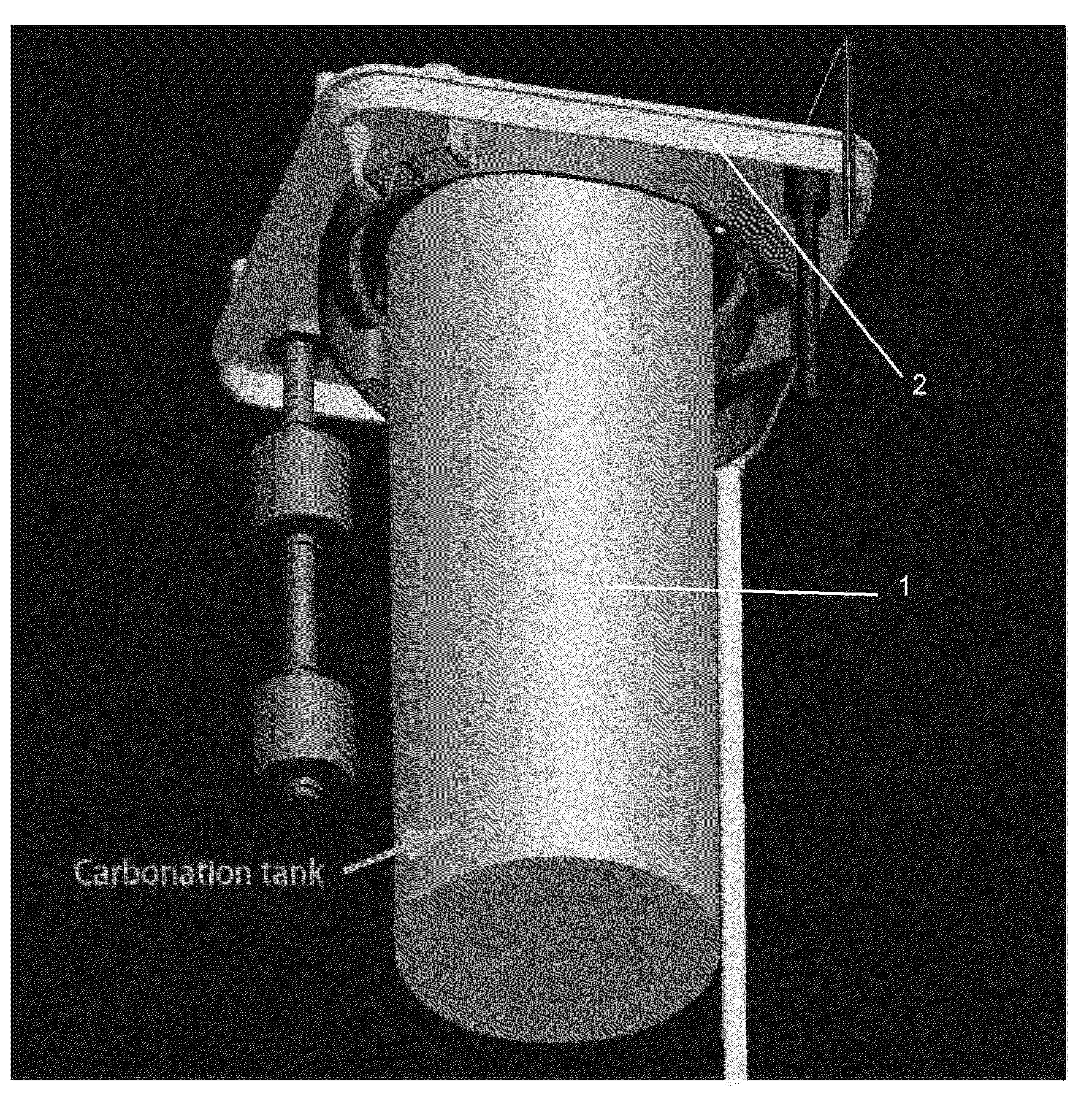

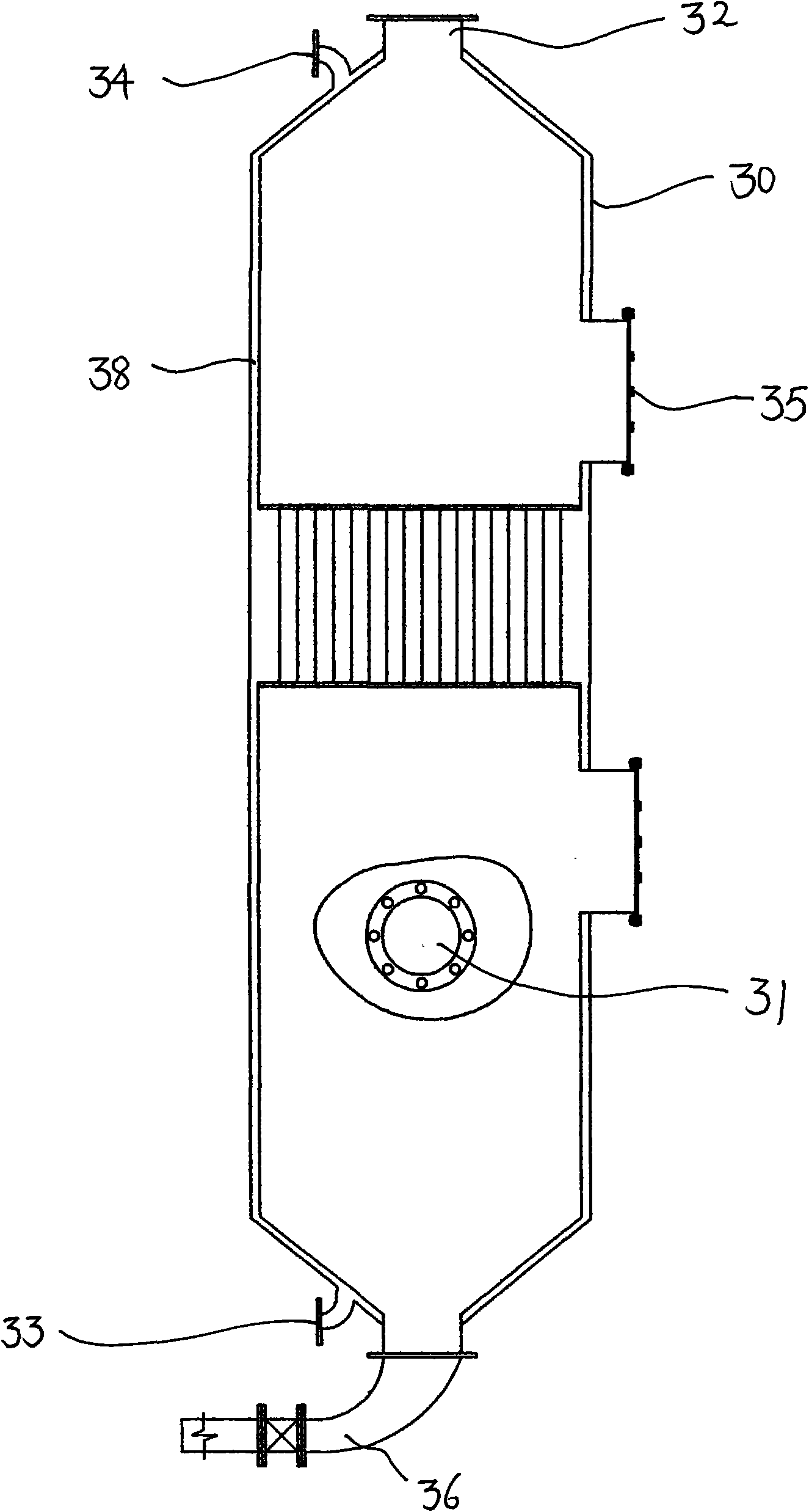

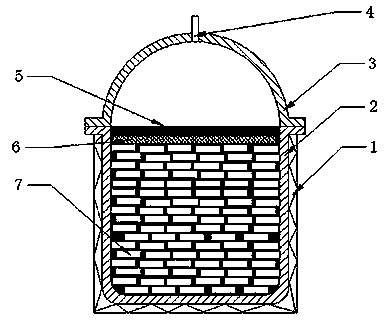

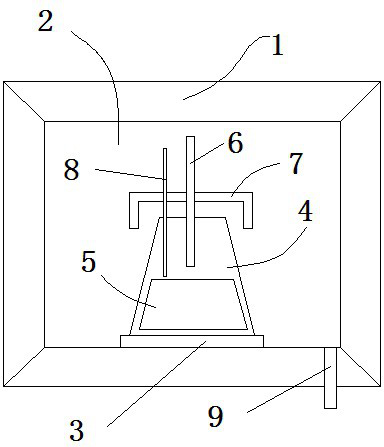

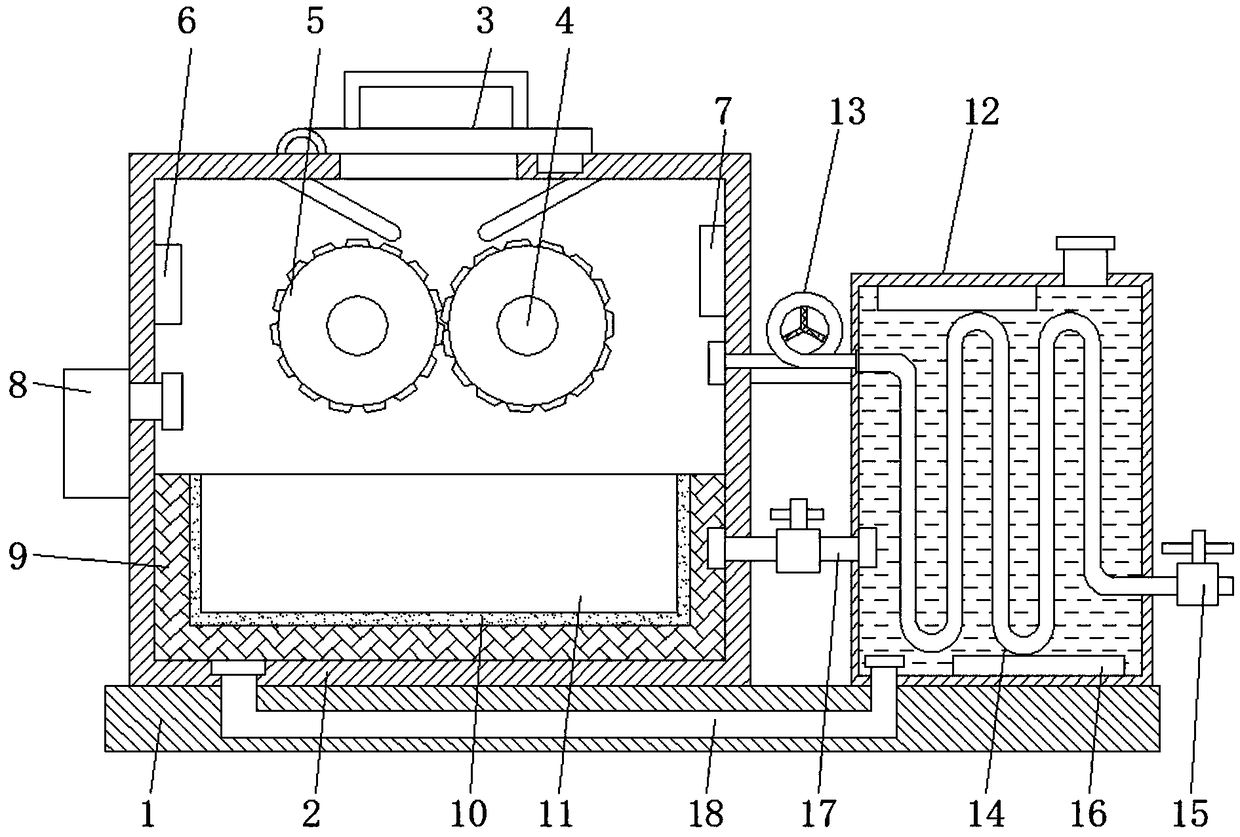

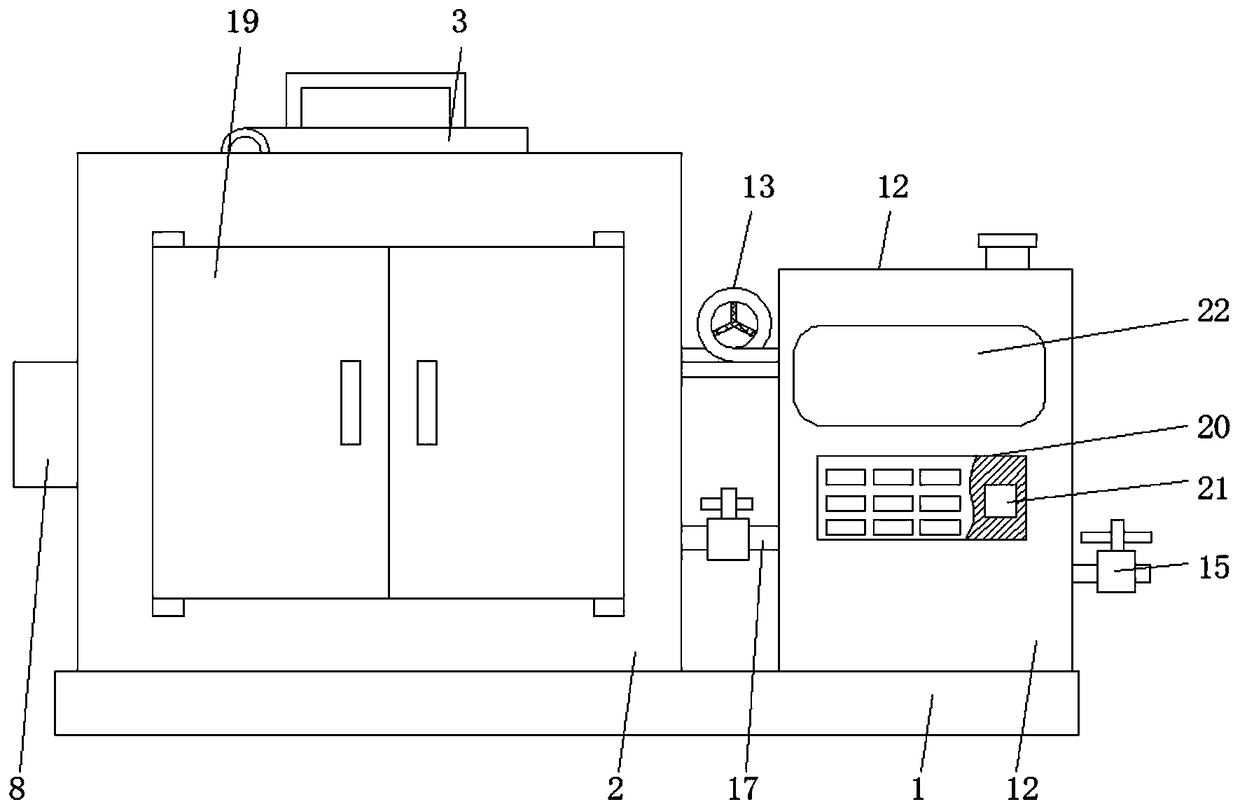

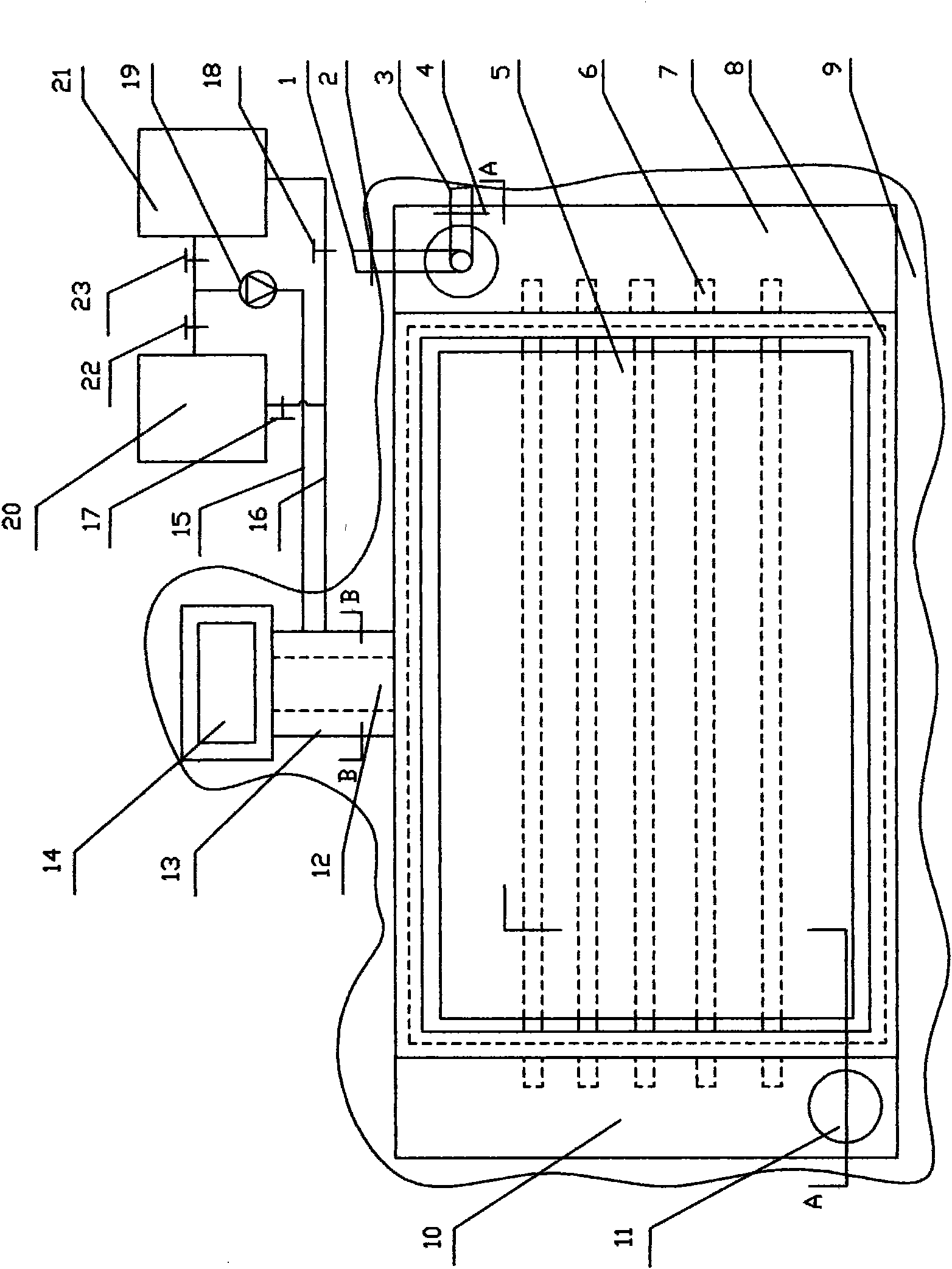

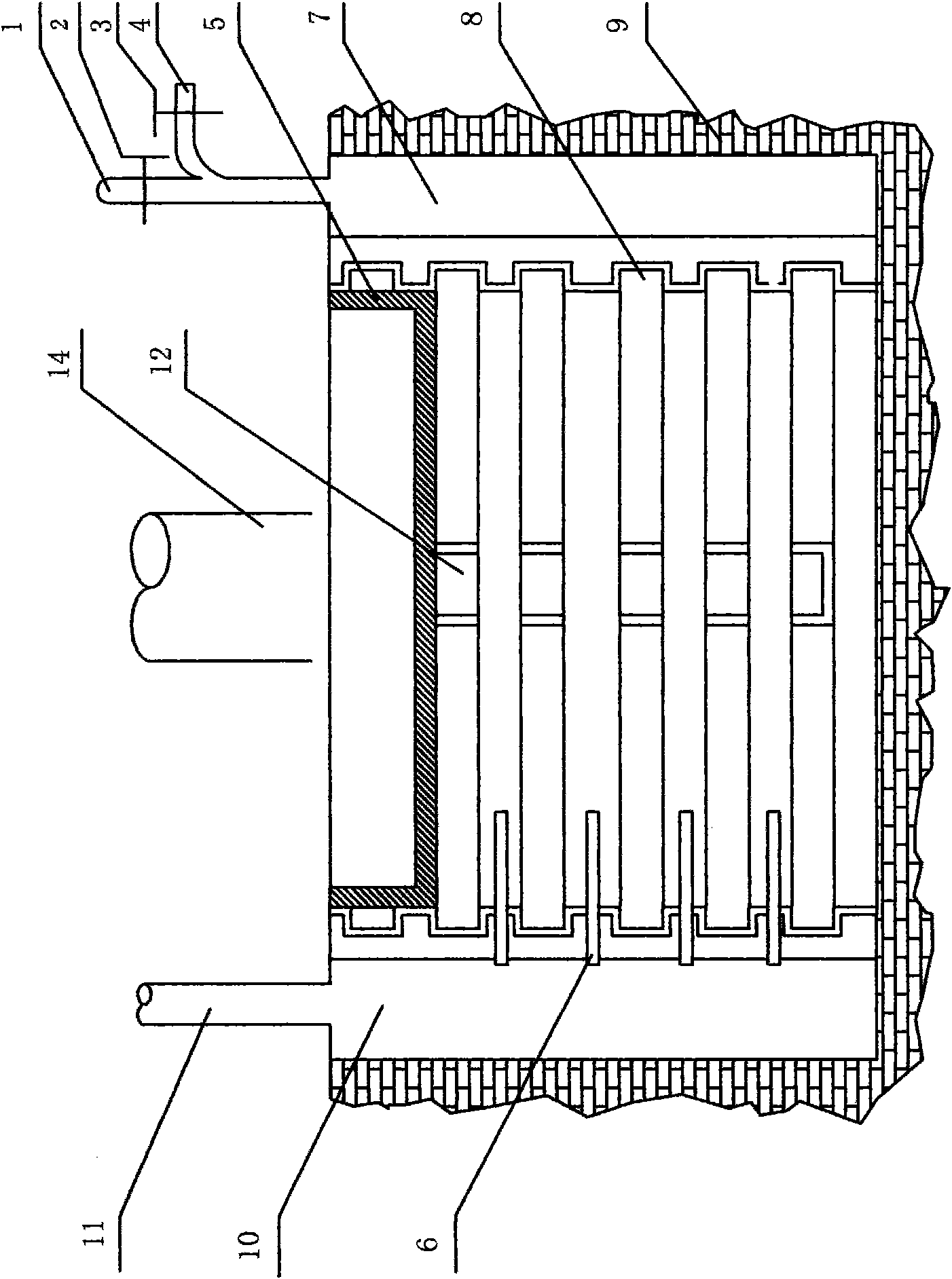

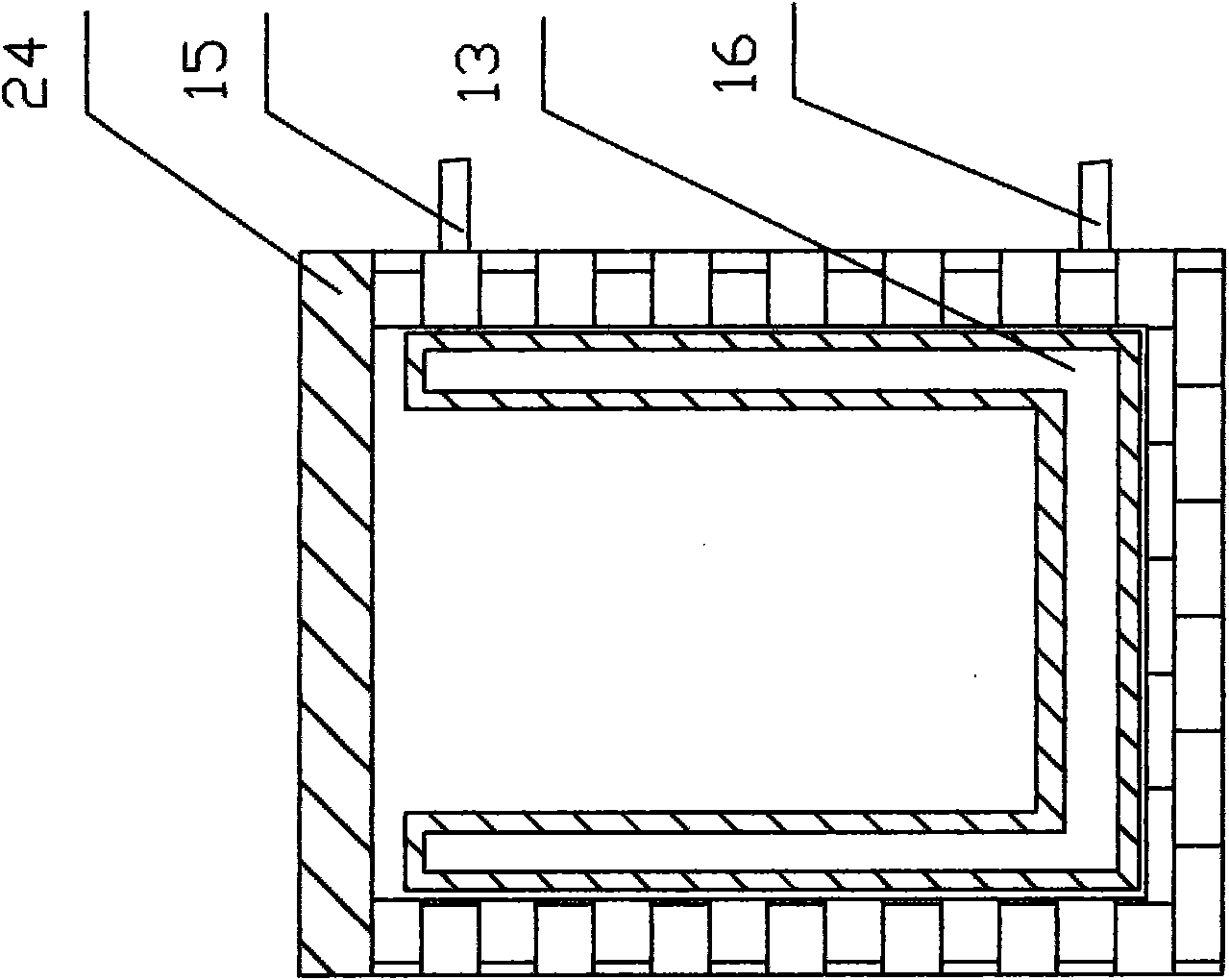

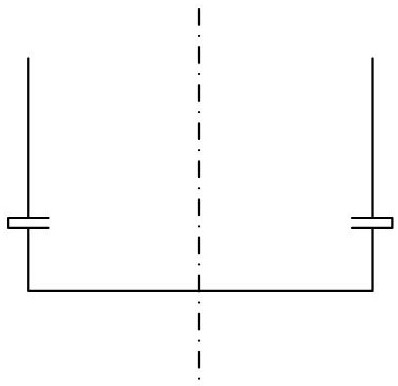

Microwave vacuum device for drying and charring lumber

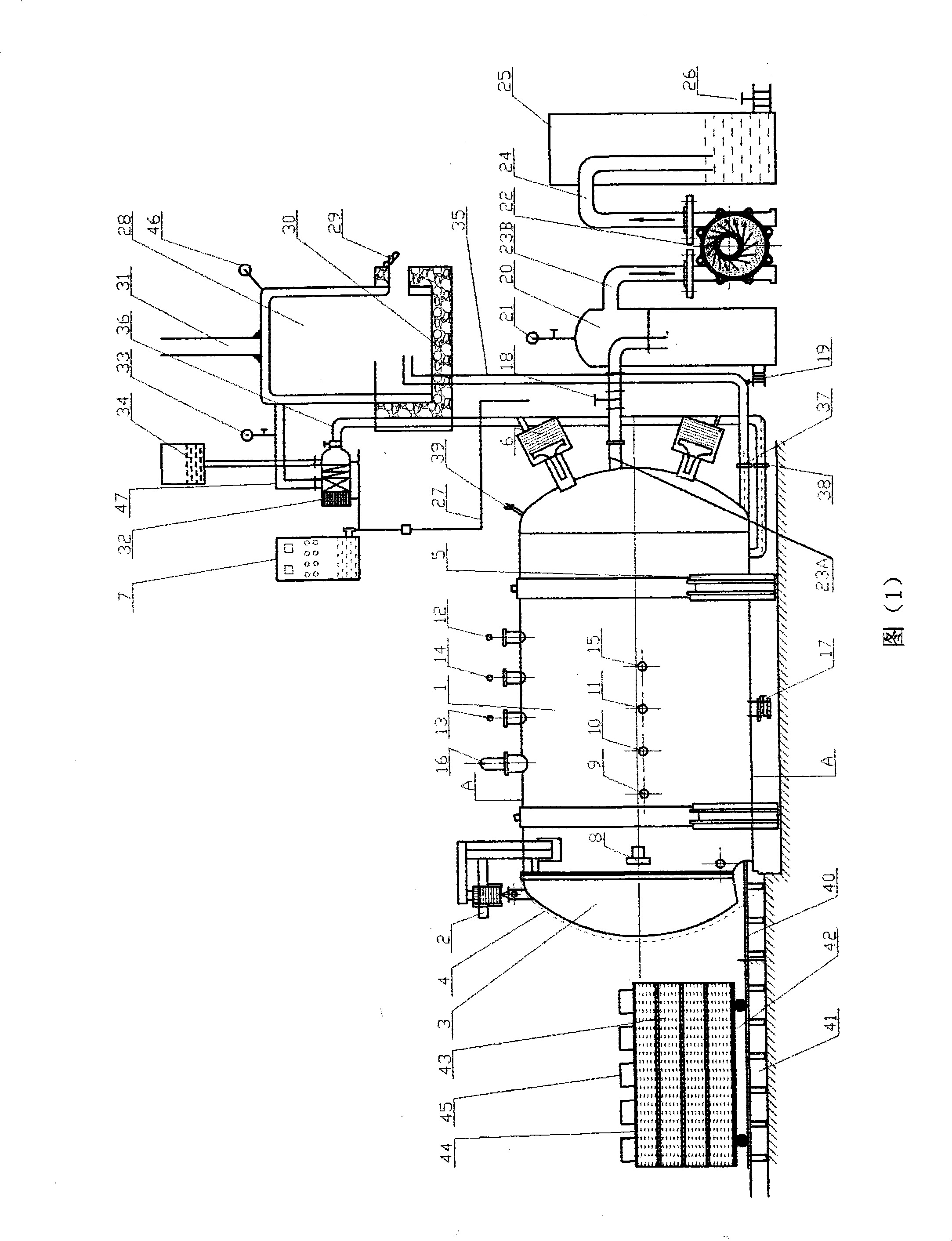

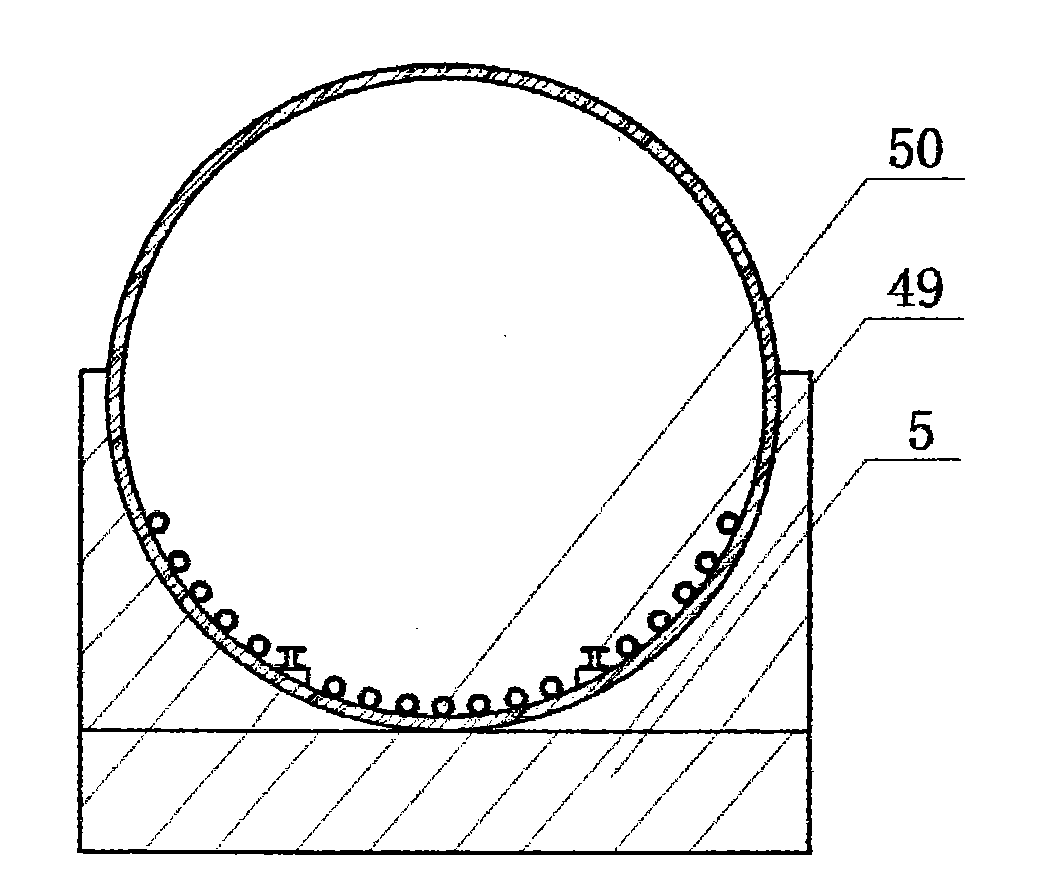

ActiveCN101439529BConsistent heating inside and outsideDry evenlyWood treatment detailsWood dampingAir cycleFurnace temperature

The invention relates to a wood microwave vacuum drying and charring device and a drying and charring method thereof. The device comprises one charring tank (box) with a tank door (3), a tank door opener (2) and a charring chamber (1), a vacuum system, and one or more microwave sources (6) generating the microwave, a heat-conducting oil furnace system and a material preparation and feed system. The drying and charring method comprises the following steps: A. rising the temperature inside the tank to 30-50 DEG C, and then to 80-130 DEG C at the rate of 2-8 DEG C / h; B. preserving the temperature for 2-100 hours; C. vacuumizing the tank for 4-100 hours; D. starting a hot recycle pump to control the oil furnace temperature, the oil flow rate and the pressure inside the tank for 4-100 hours: E. turning off the microwave source and a heat source, opening an intake and exhaust valve (39) to discharge the pressure inside the tank to 0 and lower the temperature to 70-130 DEG C, and then closing the intake and exhaust valve (39); and F. starting a vacuum pump (22) to lower the temperature inside of the tank by air circulation and removing the wood from the tank when the temperature decreases to 30-70 DEG C. The device and the method help char the wood evenly, shorten the production cycle by 60% compared with the conventional method, and lower the energy consumption by 70%, thus greatly reducing the production cost.

Owner:罗玉成

A preparation method of modified porous carbon fiber loaded calcium chloride hygroscopic material

ActiveCN107938313BReduce contact surfaceImprove stabilityCarbon fibresElectro-spinningCelluloseFiber

The invention discloses a preparation method of a modified-porous-carbon-fiber-loaded calcium chloride hygroscopic material. The hygroscopic material is made from calcium chloride, sodium carboxymethylcellulose, diatomite powder, coconut shell, phenol, and polyvinyl alcohol. Porous carbon fiber made from coconut shell undergoes multiple modification treatment. The obtained porous carbon fiber is high in mechanical strength and good in adsorbability. The porous carbon fiber itself can adsorb a large amount of water vapour from air, and the porous structure is beneficial for loading calcium chloride. The composite material is good in moisture absorption, and a small amount of added nanometer diatomite provides components with better adhesion and support after moisture absorption, which is beneficial for reuse of the hygroscopic material after high-temperature drying. The hygroscopic material is non-pollution to the environment, is low in application cost, and is super high in economic value and environmental value.

Owner:MAANSHAN XINZHOU GRAPES PROFESSIONAL COOP

A preparation method of modified porous carbon fiber for flue gas desulfurization and denitrification

ActiveCN107983302BHigher than the tableGreat reactivityNitrous oxide captureGas treatmentFiberCarbon fibers

The invention discloses a preparation method of modified porous carbon fiber for smoke gas desulfurization and denitrification. The modified porous carbon fiber is prepared from raw materials including tris(hydroxymethyl)methyl aminomethane, aminopropionic acid, sodium hydroxide, coconut shell, phenol, polyvinyl alcohol and the like. The carbon fiber uses coconut shell for preparing the porous carbon fiber; after the multi-time modified process treatment, the surface of the carbon fiber is subjected to great-amount amino modification; meanwhile, the structure advantages of high specific surface area and multiple micropores of the active carbon fiber are maintained; greater saturation adsorption volume can be shown through the surface high reaction activity; great amount adsorption on nitric oxide and sulfur oxide in the smoke gas can be realized; meanwhile, the preparation method is simple; the conditions are mild; the method is suitable for scaled production and use.

Owner:MAANSHAN XINZHOU GRAPES PROFESSIONAL COOP

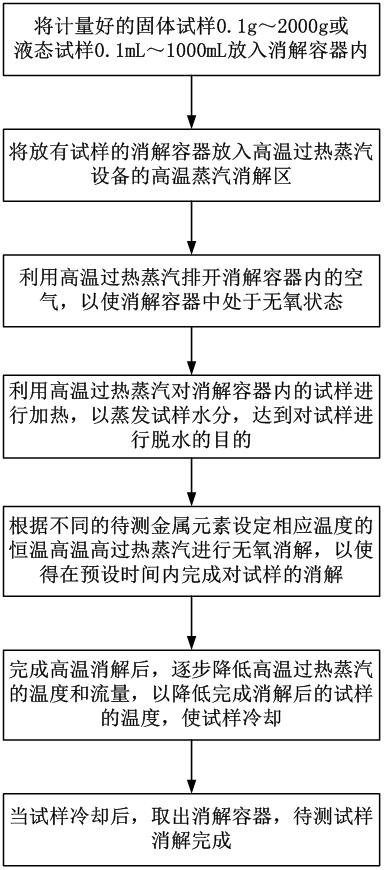

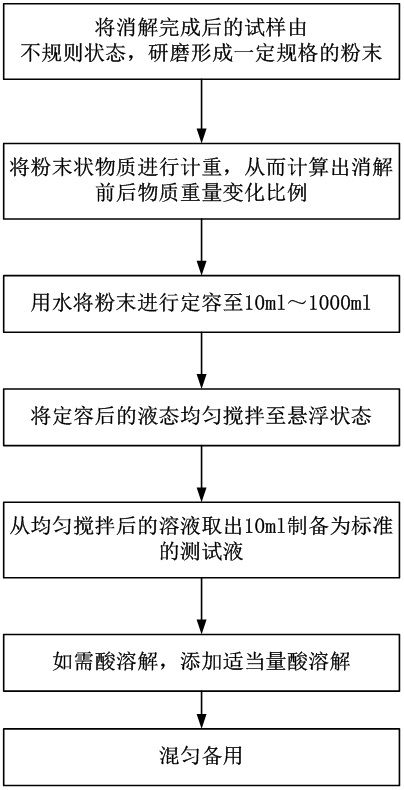

A digestion processing method for detection of metal element content in food

ActiveCN108776058BFast carbonizationReduce dosagePreparing sample for investigationDigestion TreatmentTest sample

The invention discloses a digestion processing method for detecting the content of metal elements in food. The method comprises: measuring or weighing samples of objects to be digested into a digestion container, and putting the digestion container into high-temperature superheated steam digestion equipment high-temperature steam digestion zone; in the high-temperature superheated steam digestion equipment, high-temperature superheated steam is used to digest the samples in the digestion vessel, wherein the digestion process includes: exhaust step, dehydration step, high-temperature digestion steps and sample cooling steps. The digestion treatment method provided by the present invention has the advantages of a large amount of processed samples and a fast carbonization speed of organic matter, and in an oxygen-free, normal-pressure environment, the metal elements of the tested sample will not be oxidized, and no carbonization will occur after carbonization. Large-grained carbon does not produce carbon particles to wrap metal compounds, and the amount of soluble acid used in the whole process is extremely low, which will not cause the risk of experimental accidents caused by strong acids, and will not cause environmental pollution risks.

Owner:林丽琴

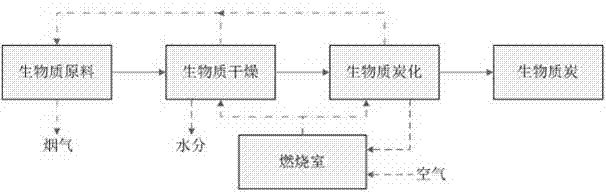

Low-consumption straw carbonization device

InactiveCN109401772AGuaranteed circulating flowCirculating flow guarantees guaranteedBiofuelsSpecial form destructive distillationCombustionHigh energy

The invention discloses a low-consumption straw carbonization device, and relates to the technical field of straw carbonization. The low-consumption straw carboniation device comprises a bottom plate,a heating box is fixedly mounted on the upper surface of the bottom plate, and a cover plate is hinged to the upper surface of the heating box; a feeding port is formed in the upper surface of the heating box, the cover plate is located above the feeding port, and two drive motors are fixedly mounted on the inner wall of the heating box. According to the low-consumption straw carbonization device, an electric heater is arranged and can heat water in a fuel box, and accordingly a storage plate is heated; an air pump is adopted to collect high-heat gas produced after straw combustion, the high-heat gas enters a guide tube and exchanges heat with the water in the fuel box, and in combination with a return pipe, the water can flow circularly so that it can be guaranteed that the water is always heated circularly; therefore, required energy consumption in the heating process is reduced, the low-consumption advantage is achieved, and the problem of excessively high energy consumption is solved.

Owner:吕博轩

Biomass carbonizing and vaporizing equipment and technology thereof

ActiveCN101570691BThe amount of extraction is easy to controlEasy extractionChemical industryBiofuelsCarbonizationEngineering

The invention belongs to the technical field of biomass comprehensive utilization and discloses biomass carbonizing and vaporizing equipment and a technology thereof. The invention has the following main technical characteristics: the biomass carbonizing and vaporizing equipment comprises a furnace body with a control valve; the furnace body is orderly connected with a condensing tower, a screening tower, a centrifugal tower and a purifying tower, wherein, a frequency conversion fan is arranged between the centrifugal tower and the purifying tower; the condensing tower, the screening tower and the centrifugal tower are connected with a separation cell and a water cooling tower with a temperature control circulating pump; and the furnace body is also connected with a gas separation unit which is used for rapidly extinguishing fire. The biomass carbonizing and vaporizing equipment and the technology thereof have high mechanization degree; the biomass carbonization and smoke-gas separating, extracting and purifying process are carried out in a fully-closed environment; all raw materials are converted into products; the whole process has no pollution or waste; and the invention realizes energy saving and environmental protection and changes wastes into valuables. The invention has the advantages of safe performance, high carbonizing speed, high extraction quantity and good quality.

Owner:河北序然环保工程有限公司

High-efficiency carbonization furnace

The invention discloses a high-efficiency carbonization furnace, which comprises a furnace body, a main fire pipe, a cold air pipe, a fire accessible duct, fire tubes, a flame inlet passage, an fume outlet duct, a fume outlet pipe, U-shaped grooves, a wood gas flue, a water jacket (or snaking hollow section), wood gas chimney and the like. The periphery of the carbonization furnace is provided with a plurality of the U-shaped grooves, and the inside of the carbonization furnace is provided with a plurality of the fire tubes of which two ends are connected with the fire accessible duct and the fume outlet duct respectively. Biomass fuels are placed in the carbonization furnace, the cover board of the furnace body is covered, flue gas passes through the small fire tube to heat the biomass fuels, and the carbonization is started and speeds up with the continuous rise of the temperature. When the carbonization of wood charcoals is finished, an air blower is started; and cool air enters the cold air pipe and the small fire tube 6 to absorb heat of the wood charcoals and flows out from the fume outlet duct to enter a heat drying chamber for drying the raw materials of the biomass fuels. Wood tar and the wood gas generated during the carbonization flow into the wood gas fuel along the U-shaped grooves, and the wood tar is cooled by the water jacket (or snaking hollow section) and changed into solid.

Owner:肖国雄 +1

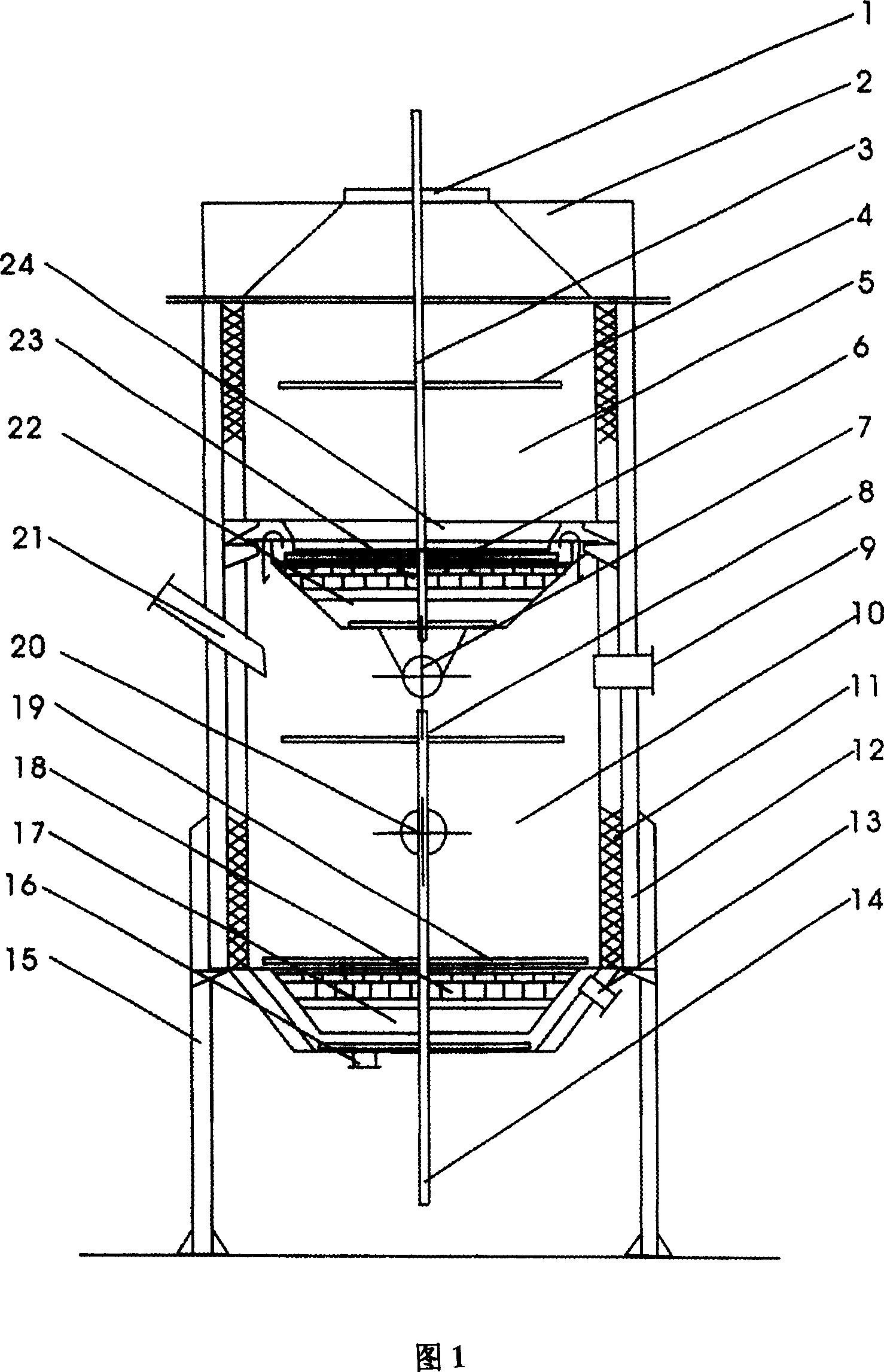

Method for producing biomass carbonized gas and back fire-biomass carbonated gas generating stove

InactiveCN100340634CIncrease incomeImprove protectionBiofuelsSpecial form destructive distillationBack-fireCarbonization

Its craft steps are: respectively cut material into pieces, comminute, and filtrate, add material unsuitable to produce carbonization into the upper layer converse fire gasifying stove cavity as its gasifying fuel; add gasifying material suitable for producing biomass charcoal into the carbonizing stove cavity equipped on the nether layer; produce biomass fuel gas and get biomass carbonized products. Its main structure is: there equips upper layer converse fire gasifying stove cavity and nether layer carbonizing stove cavity in the stove body. Its advantages are: its biomass carbonized fuel gas value can get to 5000 - 6000 KJ / h, add the produced biomass charcoal into water-soluble macromolecule cementing agent after comminuted to process into machine-made charcoal by mechanism extrusion; it can replace the carbonized produces of previous wood charcoal; its structure is simple and reasonable, and is convenient to operate; besides its processing material quantity is large, carbonization speed in stove is high and its efficiency is high.

Owner:韩连恩 +1

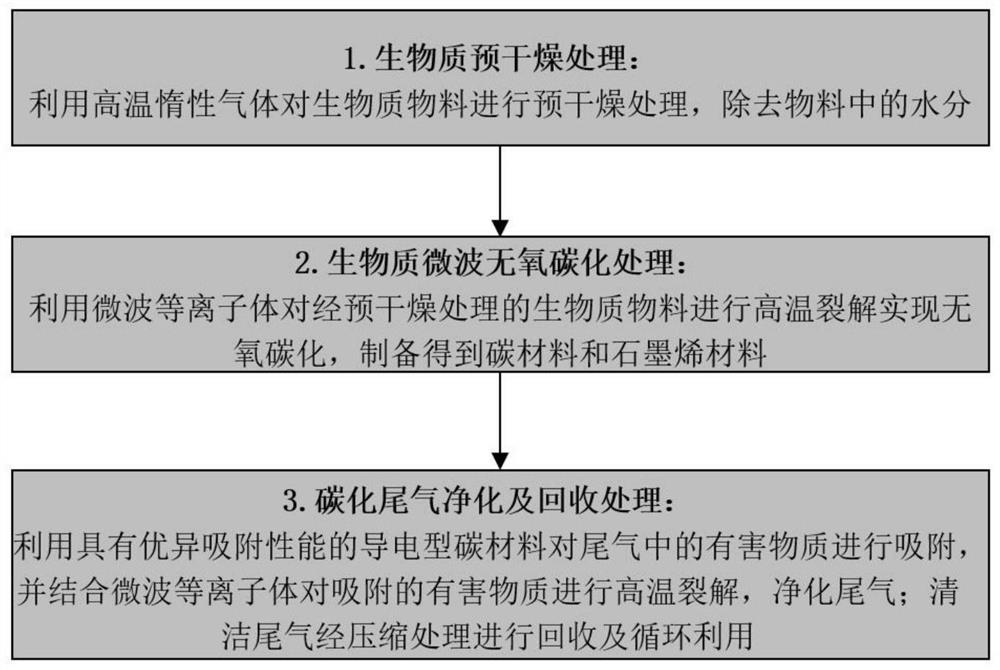

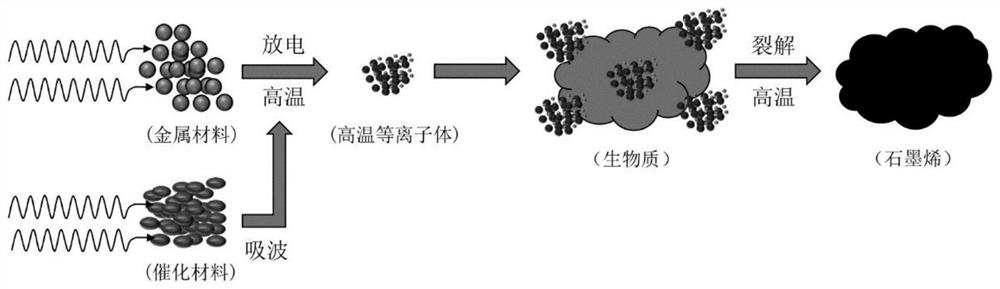

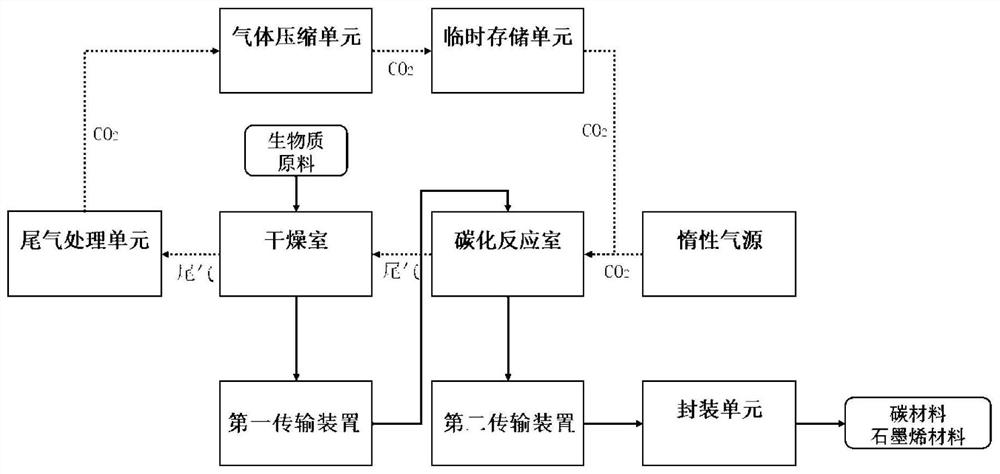

Method and device for producing carbon material through non-pollution biomass microwave anaerobic carbonization

ActiveCN113942996ATake advantage ofNo pollution in the processGrapheneCarbon preparation/purificationHazardous substanceCarbonization

The invention discloses a method and device for producing a carbon material by non-pollution biomass microwave anaerobic carbonization. The method comprises the following steps that: in an inert gas protection environment, high-temperature pyrolysis treatment is performed on biomass by using microwave plasma formed by microwaves and metal discharge to realize anaerobic carbonization of the biomass, and a carbon material and a graphene material are prepared; and harmful substances in tail gas generated in the anaerobic carbonization treatment process of the biomass are adsorbed by utilizing a conductive carbon material, and the adsorbed harmful substances are subjected to high-temperature cracking treatment by utilizing microwave plasma formed by microwaves and metal discharge, so that the purification of the tail gas is realized. According to the method and device of the invention, not only can high-efficiency, pollution-free and zero-emission treatment of the biomass be realized, but also recycling of the biomass can be realized.

Owner:YUNNAN HUAPU QUANTUM MATERIAL CO LTD +6

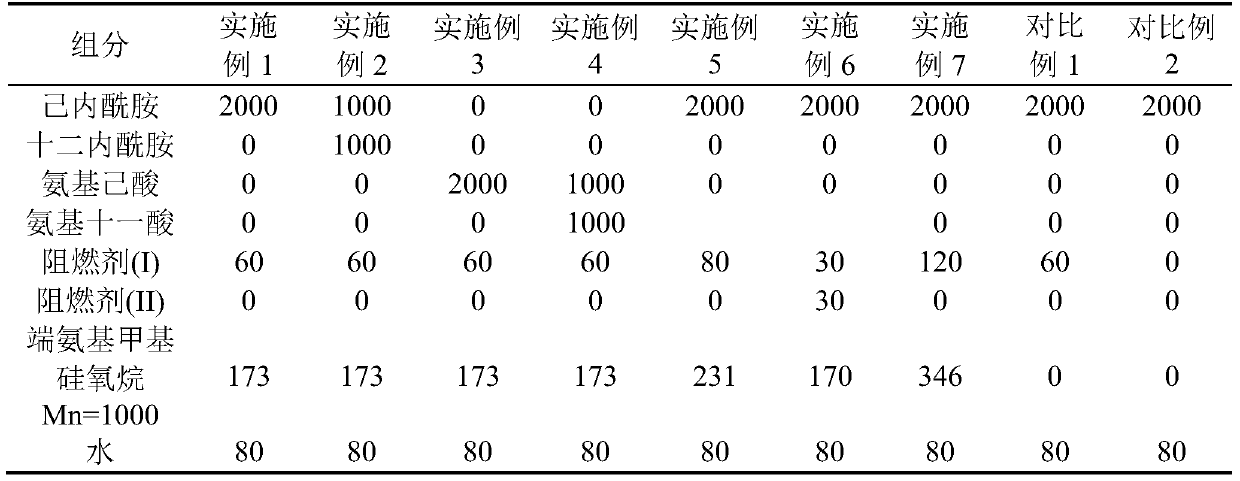

A kind of silicon-containing reactive flame-retardant nylon resin and preparation method thereof

ActiveCN106700067BSolve the problem of flammable drippingFast carbonizationPolymer sciencePtru catalyst

Silicon-containing reactive flame retardant nylon resin and a preparation method thereof are disclosed. The preparation method comprises the following steps: a phosphorus-containing reactive flame retardant with two end carboxyl groups is mixed with amino silicone oil to obtain a mixture; the obtained mixture, a nylon monomer and a catalyst are mixed in a certain ratio into a material, and after polymerization reaction of the material, the silicon-containing reactive flame retardant nylon resin can be obtained. The silicon-containing reactive flame retardant nylon resin has permanent flame retardant property, the flame retardant grade reaches to UL94V-0, the oxygen index is 25-45, and the product has the advantages of good mechanical properties, high oxygen index, high flame retardant grade and better adaptability, and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A system device and method for preparing calcium carbonate using micro-nano bubbles

ActiveCN112897561BContinuous operationEasy to operateCalcium/strontium/barium carbonatesMaterial nanotechnologyMicro nanoPhysical chemistry

The invention provides a system device and method for preparing calcium carbonate using micro-nano bubbles. The system device includes a connected micro-nano bubble generating device and a reaction device, and also includes a first separation device and a centrifuge device respectively connected to the reaction device. device, and the second separation device and the third separation device respectively connected to the centrifugal device; the method for preparing calcium carbonate by the micro-nano bubbles carried out in the system device comprises utilizing the micro-nano-bubble generating device to generate micro-nano-bubbles, entering The reaction device is mixed with calcium carbide slag for carbonization reaction, and then passed into the centrifugal device for separation, so as to obtain calcium carbonate particles. The present invention controls the grain size of calcium carbonate by carbonizing calcium carbide slag with micro-nano bubbles, avoids the use of crystal form control agents, can realize continuous operation, and can also be intermittent operation, and has the advantages of large processing capacity, fast carbonization speed, and low cost. advantage.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of preparation method of modified carbon fiber thermal insulation composite material

ActiveCN108017362BImprove thermal insulation performanceImprove adsorption capacityPhysical treatmentCarbon fibresFiberCarbon fibers

The invention discloses a preparation method of a modified carbon fiber thermal insulation composite material. The modified carbon fiber thermal insulation composite material is prepared from raw materials of silicon powder, coconut shell, phenol, polyvinyl alcohol, etc. The preparation method is characterized in that the coconut shell is used to prepare porous carbon fiber and undergoes a plurality of modification processes to obtain porous carbon fiber with high mechanical strength and high adsorption; and then the porous carbon fiber is impregnated with alkaline silica sol, so that the well-developed mesoporous structure of the silica sol makes the carbon fiber have high temperature resistance and extremely low thermal conductivity, and further strengthens the thermal insulation capacity of the carbon fiber. The obtained composite material is not only light in weight, but also has high thermal insulation ability and low thermal conductivity, so that use cost of the thermal insulation material is greatly reduced, and the modified carbon fiber thermal insulation composite material is suitable for the needs of thermal insulation materials in various fields.

Owner:嘉兴德毅新材料有限公司

A preparation method of modified carbon fiber friction particles

ActiveCN107936916BLarge specific surface areaIncrease elasticityOther chemical processesCarbon fibresEpoxyFiber

The invention discloses a preparation method of a modified carbon fiber friction particle. The modified carbon fiber friction particle is prepared from asphalt powder, epoxy resin, styrene butadiene rubber, nitrile butadiene rubber, coconut shell, phenol, polyvinyl alcohol and other raw materials. The method provided by the invention employs coconut shell to prepare porous carbon fiber, and by means of multiple modification process treatment, porous carbon fiber with high mechanical strength and high abrasion resistance can be obtained, then the porous carbon fiber is subjected to sizing withnitrile butadiene rubber, and then kneading is carried out. The modified carbon fiber friction particle has a stable hollow structure inside, also has high elasticity, high porosity and high temperature performance stability, and has a wider application range than traditional friction materials. At the same time, the raw materials involved in the invention have wide sources, the preparation methodis simple, and the obtained friction particle is wear resistant and high temperature resistant, and has good market prospects.

Owner:南京赛富汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com