Method and device for producing carbon material through non-pollution biomass microwave anaerobic carbonization

A technology of biomass and carbon materials, which is applied in the direction of carbon preparation/purification, nano-carbon, graphene, etc., can solve the problems of high equipment cost, waste of biomass energy, inapplicability of large-scale promotion of biomass conversion, etc., and achieve rapid Treatment, zero-emission biomass carbonization treatment and production, and the effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

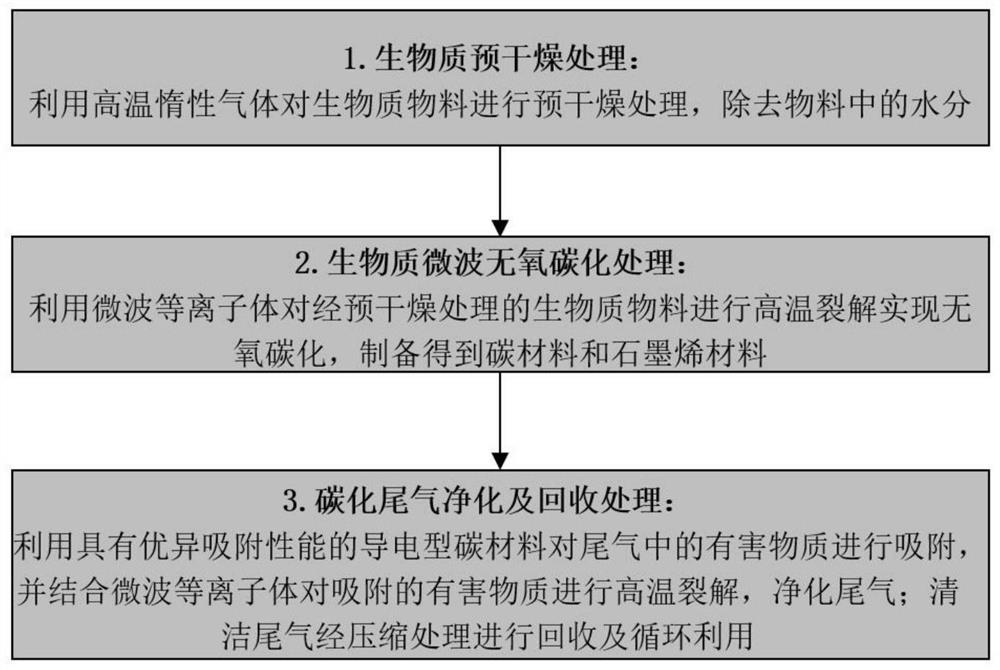

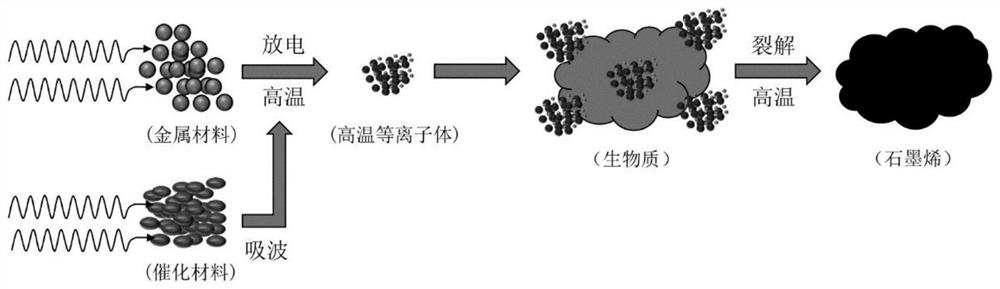

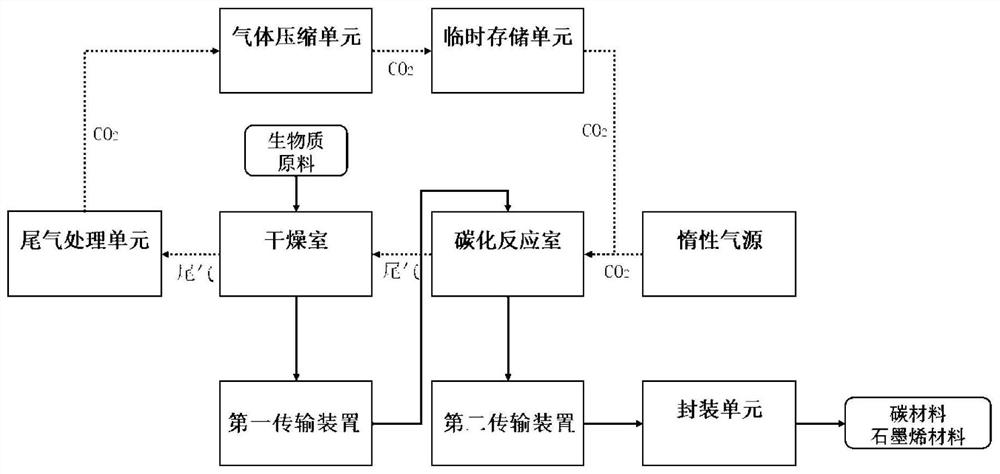

[0055] as attached figure 1 As shown, a method for producing carbon materials by microwave anaerobic carbonization of non-polluting biomass. Under the protection of inert gas environment, microwave plasma formed by microwave and metal discharge is used to pyrolyze biomass to realize oxygen-free carbonization of biomass. , and prepare carbon materials and graphene materials; then use conductive carbon materials to adsorb harmful substances in the exhaust gas generated during the oxygen-free carbonization of biomass, and use microwave plasma formed by microwave and metal discharge to reduce the harmful substances adsorbed Substances are subjected to high-temperature cracking treatment to realize the purification of tail gas.

[0056] When using the method of the present invention to treat biomass, use inert gas to form a protective environment, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com