System device and method for preparing calcium carbonate by using micro-nano bubbles

A technology of micro-nano bubbles and system devices, applied in the field of calcium carbonate, can solve the problems of difficulty in obtaining qualified nano-calcium carbonate products, affecting the carbonization and crystallization process, and low purity of calcium carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

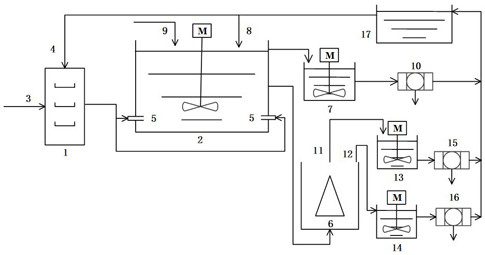

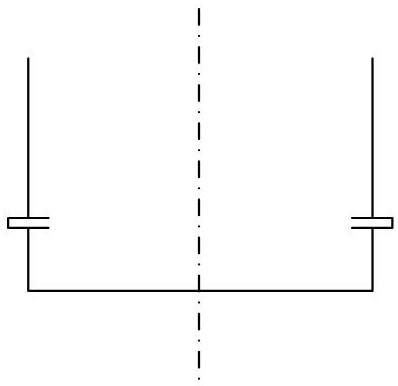

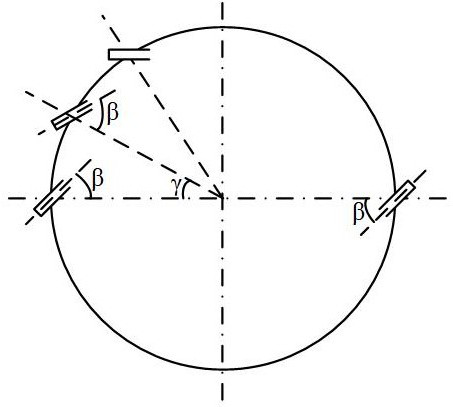

[0109] This embodiment provides a system device for preparing calcium carbonate using micro-nano bubbles, such as figure 1 As shown, the system device includes a connected micro-nano bubble generating device 1 and a reaction device 2; the micro-nano bubble generating device 1 is provided with an air source inlet 3 and a water source inlet 4; there is a stirring device in the reaction device 2, and a There are 12 injection parts 5 evenly distributed on the same level of the body, such as figure 2 As shown, the ratio of the distance between the injection part 5 to the bottom of the reaction device 2 and the height of the reaction device 2 is 1:4, the angle (β) between the center line of the injection port of the injection part 5 and the corresponding diameter of the reaction device 2 is 45°, and the included angle (γ) between any two adjacent injection parts 5 on the same horizontal plane of the shell of the reaction device 2 is 30°, such as image 3 As shown, the outlet of th...

Embodiment 2

[0119] The present embodiment provides a kind of system device that utilizes micro-nano bubbles to prepare calcium carbonate, and described system device comprises the connected micro-nano-bubble generating device and reaction device; Micro-nano-bubble generating device is provided with air source inlet and water source inlet; There is a stirring device in the device, and 6 injection parts are evenly distributed on the same horizontal plane of the shell. The ratio of the distance between the injection part and the bottom of the reaction device to the height of the reaction device is 1:3. The angle between the corresponding diameters of the reaction device is 30°, the angle between any two adjacent injection parts on the same horizontal plane of the reaction device housing is 60°, the outlet of the micro-nano bubble generating device and the reaction device The injection parts are connected;

[0120] The middle part of the reaction device is provided with a first outlet, and th...

Embodiment 3

[0129] The present embodiment provides a kind of system device that utilizes micro-nano bubbles to prepare calcium carbonate, and described system device comprises the connected micro-nano-bubble generating device and reaction device; Micro-nano-bubble generating device is provided with air source inlet and water source inlet; There is a stirring device in the device, and 4 injection parts are evenly distributed on the same horizontal plane of the shell. The ratio of the distance between the injection part and the bottom of the reaction device to the height of the reaction device is 1:5. The angle between the corresponding diameters of the reaction device is 60°, the angle between any two adjacent injection parts on the same horizontal plane of the reaction device housing is 90°, the outlet of the micro-nano bubble generating device and the reaction device The injection parts are connected;

[0130] The middle part of the reaction device is provided with a first outlet, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com