High-efficiency carbonization furnace

A technology of carbonization furnace and furnace body, which is applied in the field of high-efficiency carbonization furnace, and can solve the problems of low carbonization rate, inability to cool rapidly, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

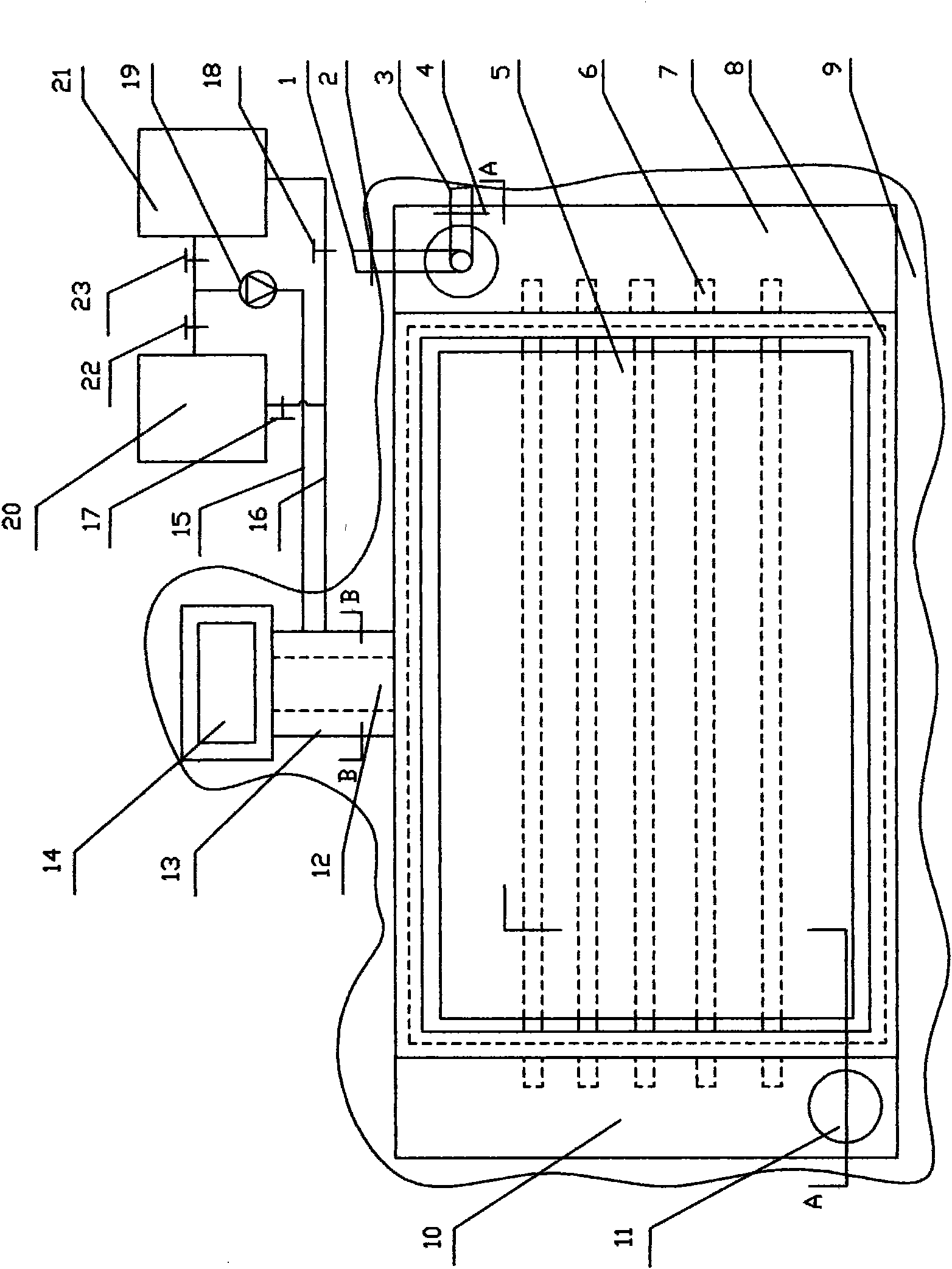

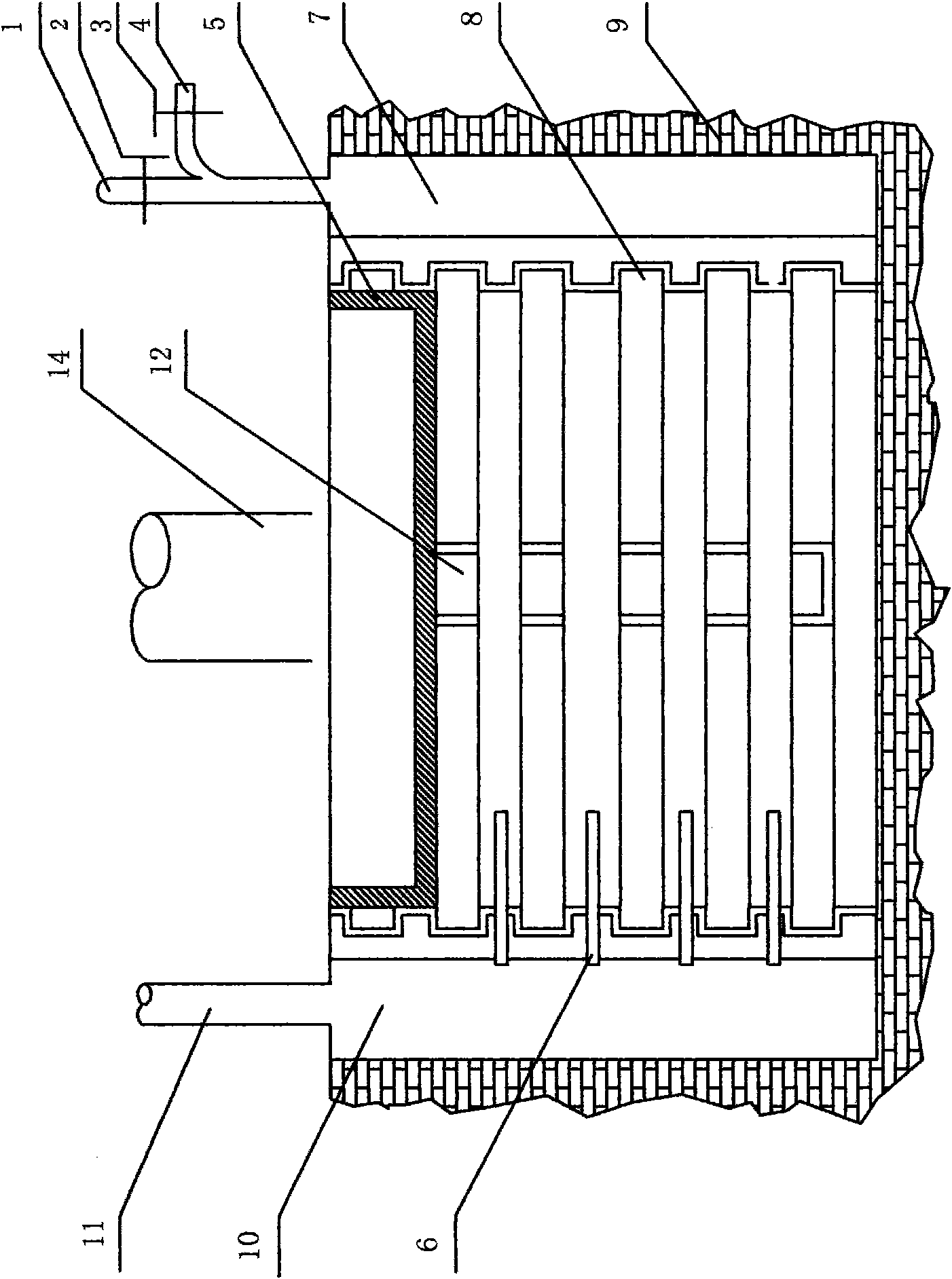

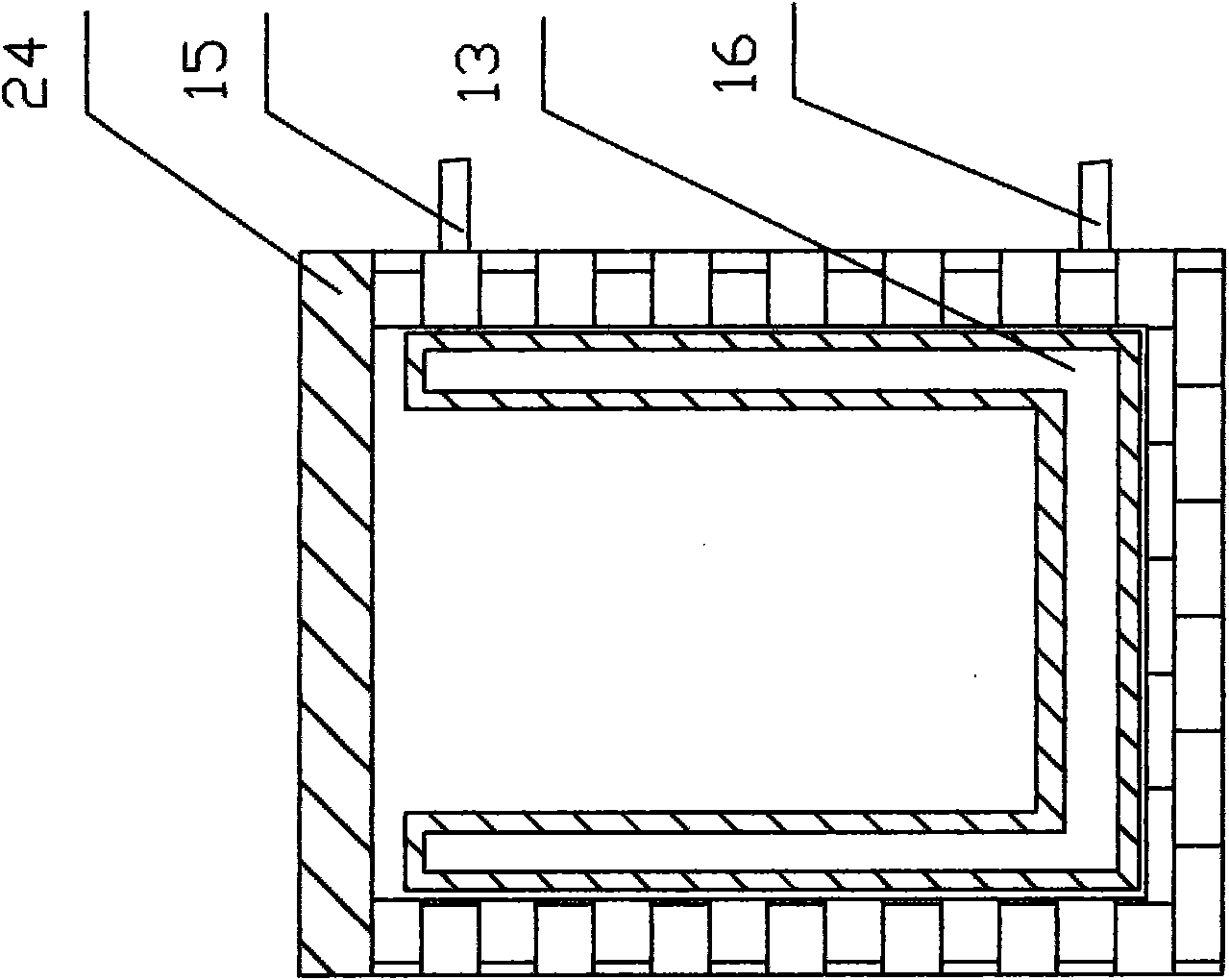

[0012] Reference attached figure 1 ——attached image 3

[0013] The high-efficiency carbonization furnace consists of a large fire pipe 1, a fire pipe switch 2, a cold air pipe 3, an air pipe switch 4, a furnace cover plate 5, a small fire pipe 6, a fire inlet 7, a U-shaped groove 8, a furnace body 9, and an outlet. Flue 10, smoke outlet pipe 11, wood gas flue 12, water jacket 13 (or snake hollow pipe 25), flue cover plate 24, wood gas chimney 14, water inlet pipe 15, water outlet pipe 16, valve 17, valve 18 , Water pump 19, water tank 20, water tank 21, valve 22, and valve 23 etc. are formed.

[0014] The walls around the body of heater 9 have multiple horizontal U-shaped grooves 8, and between the two U-shaped grooves 8 is a boss, which wears a plurality of fire tubes 6 in the boss, and the small fire tube 6 is made of a metal material. One end of the fire pipe 6 communicates with the fire inlet 7, and the other end communicates with the flue 10, and a U-shaped groove 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com