A kind of silicon-containing reactive flame-retardant nylon resin and preparation method thereof

A reactive flame retardant, nylon resin technology, applied in the field of silicon-containing flame retardant nylon resin and its preparation, can solve the problems of affecting the application range of materials, affecting mechanical properties, low flame retardant efficiency, etc., and achieving good industrial application prospects, Good mechanical properties and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

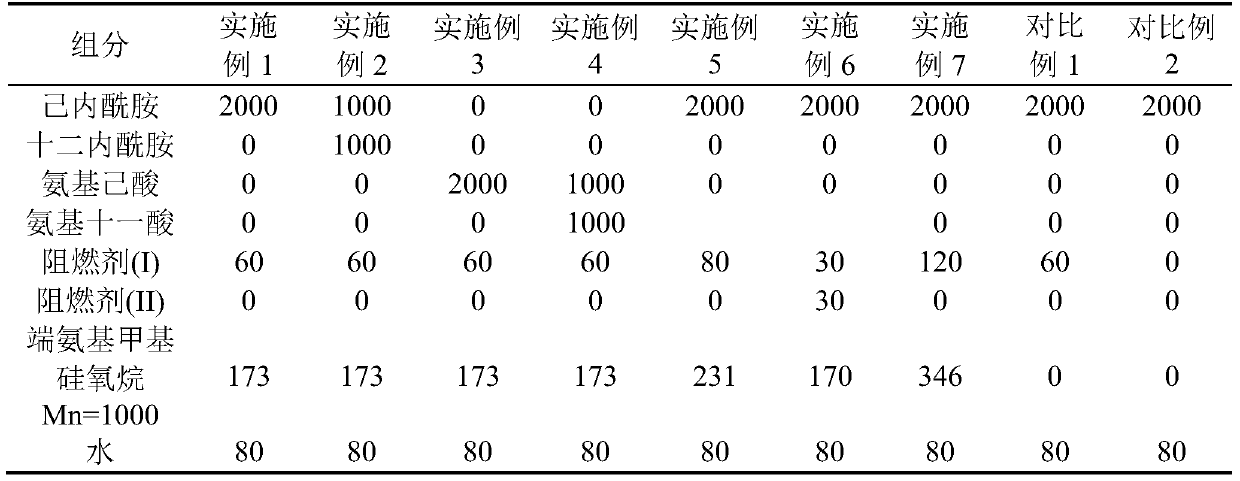

Examples

Embodiment

[0032] A preparation method of the silicon-containing reactive flame-retardant nylon resin of the present invention comprises the following steps:

[0033] (1) The reactive phosphorus-containing flame retardant containing two carboxyl groups is mixed with amino silicone oil in a molar ratio of 1:1;

[0034] (2) Add the mixed reactive phosphorus-containing flame retardant and amino silicone oil into the autoclave, and simultaneously add nylon polymerized monomer and catalyst (the amount of catalyst is 4% of the mass of nylon polymerized monomer), close the feeding cap, Repeat three times to replace the air in the autoclave with nitrogen;

[0035] (3) Heating the high-pressure reactor filled with materials, so that the temperature reaches 200°C-280°C, and the pressure of the kettle is 0.2Mpa-2.0Mpa, and the reaction is 2-6h;

[0036] (4) Open the pressure relief valve, slowly reduce the high-pressure reactor to normal pressure, stop for 30 minutes and then vacuumize for 3 to 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com