High-temperature heat transfer oil processed biochar and preparation method thereof

A heat transfer oil and biochar technology, which is applied in the petroleum industry, biofuels, indirect heating and dry distillation, etc., can solve the problems of atmospheric environmental pollution, uneven heating of materials, affecting production efficiency, etc., to achieve uniform heat transfer, good adsorption performance, The effect of improving the carbonization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

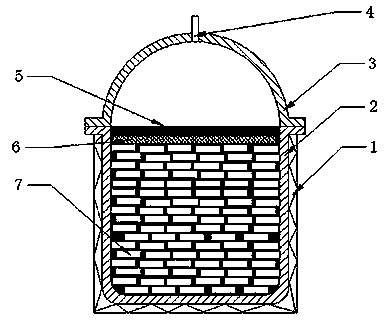

[0048] Such as figure 1 As shown, this embodiment provides a high-temperature heat transfer oil carbonization device, which can be used to prepare biochar. The carbonization device includes a base 2 and an upper cover 3 detachably connected to the base. The base 2 and the upper cover 3 are connected by a flange or a screw connection, and this embodiment may preferably be a flange connection.

[0049] The base 2 is a cavity structure with an opening, and the upper cover 3 is placed at the opening of the base to form a closed space with the base; the cavity structure is used for placing high-temperature heat transfer oil 5 and plant fiber blocks 7 .

[0050] The cavity structure is also provided with a briquetting plate 6, which is used to prevent the buoyancy of the high-temperature heat-conducting oil to make the plant fiber block float on the surface of the high-temperature heat-conducting oil layer and contact with oxygen. The thickness direction of the briquetting plate 6 i...

Embodiment 2

[0054] This embodiment provides a method for processing biochar with high-temperature heat-conducting oil, comprising the following steps:

[0055] S1. Get 100kg of rice straw and break it into rice straw fibers with an average length of 15mm. Soak it in 10% NaOH solution at a temperature of 40°C for 1 hour at 1 atmosphere, then take it out and dry it to make its moisture content 0%.

[0056] S2. After the dry rice straw fiber and 8kg of wheat starch are blended uniformly in step S1, press into a cube fiber block, and the fiber block density is 0.5kg / m 3 ;

[0057] S3. Put the fiber block prepared in step S2 into the high-temperature heat transfer oil carbonization device described in Example 1, and fix it on the bottom of the carbonization device, and then inject alkyl biphenyl type heat transfer oil. The use temperature of the heat transfer oil is 330 ° C. The amount of heat transfer oil should be able to cover the fiber block completely, and then heat the heat transfer oil...

Embodiment 3

[0061] This embodiment provides a method for processing biochar with high-temperature heat-conducting oil, comprising the following steps:

[0062] S1. Take 100kg of stalks and crush them into straw fibers with an average length of 20mm, soak in 10% KOH solution at a temperature of 40°C for 1 hour at 1 atmospheric pressure, then take out and dry to make the moisture content 0%;

[0063] S2. After blending the straw fiber dried in step S1 with 8 kg of wheat starch evenly, press it into a cube fiber block, and the fiber block density is 0.5 kg / m 3 ;

[0064] S3. Put the fiber block prepared in step S2 into the high-temperature heat transfer oil carbonization device described in Example 1, and fix it on the bottom of the carbonization device, and then inject alkyl biphenyl type heat transfer oil. The use temperature of the heat transfer oil is 330 ° C. The amount of heat transfer oil should be able to cover the fiber block completely, and then heat the heat transfer oil to keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com