Drilling fluid prepared from oilfield produced water, and preparation method thereof

A technology for producing water and drilling fluid, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as environmental pollution, waste of water resources, etc., to delay corrosion rate, reduce drilling costs, and prevent sticking accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

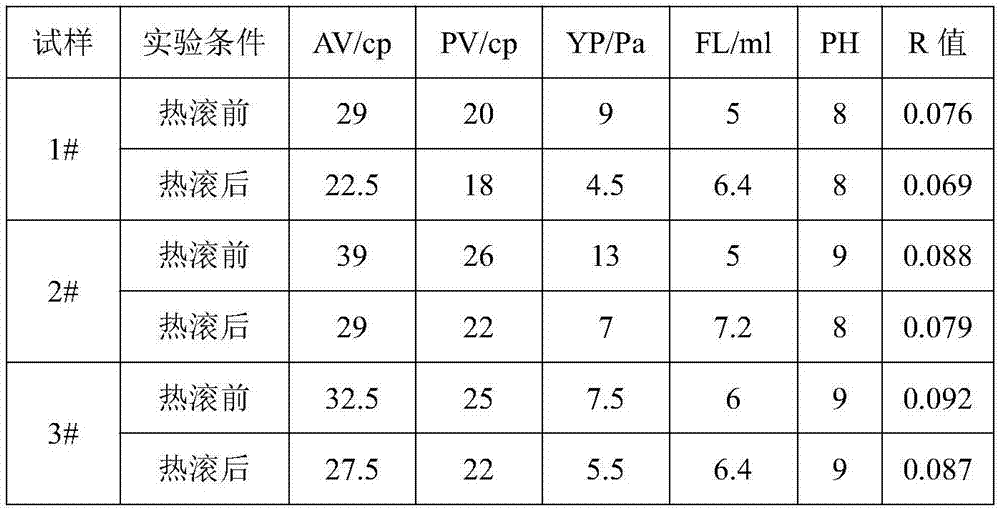

Embodiment 1

[0024] In order to reduce the waste of oilfield produced water, this embodiment provides a kind of drilling fluid prepared from oilfield produced water, including water and the following components in terms of mass percentage of water: 0.1~0.3% desulfurizer, 0.1~0.3% % calcium and magnesium ion remover, 0.3-0.5% anti-salt corrosion inhibitor, 0.2-0.3% viscosity raising agent, 0.2-0.5% flow pattern regulator, 0.2-0.3% flocculation coating agent, 0.8-1.1% dehydration reduction Agent, 1-2% anti-collapse agent, 2-5% liquid lubricant, 20-50% solid weighting agent, all of the above materials are commercially available.

[0025] A method for preparing drilling fluid prepared from oilfield produced water, characterized in that it at least includes the following steps:

[0026] Step 1: Pretreatment of oilfield produced water: including the following steps:

[0027] Step 1) Gradually add 0.1 to 0.3% desulfurizer in the produced water of the oilfield, stir evenly, and detect the hydroge...

Embodiment 2

[0035] This embodiment provides a drilling fluid prepared from oilfield produced water, including water and the following components in terms of mass percentage of water: 0.1 to 0.3% desulfurizer, 0.1 to 0.3% calcium and magnesium ion remover, 0.3 ~0.5% anti-salt corrosion inhibitor, 0.2~0.3% viscosity increasing agent, 0.2~0.5% flow pattern regulator, 0.2~0.3% flocculation coating agent, 0.8~1.1% fluid loss reducer, 1~2% anti-slump Agent, 2~5% liquid lubricant, 20~50% solid weighting agent, all above materials are commercially available.

[0036] A method for preparing drilling fluid prepared from oilfield produced water, characterized in that it at least includes the following steps:

[0037] Step 1: Pretreatment of oilfield produced water: including the following steps:

[0038] Step 1) Gradually add 0.1 to 0.3% desulfurizer in the produced water of the oilfield, stir evenly, and detect the hydrogen sulfide content with lead acetate test paper during the addition process. ...

Embodiment 3

[0050] This embodiment provides a drilling fluid prepared from oilfield produced water, including water and the following components in terms of mass percentage of water: 0.1 to 0.3% desulfurizer, 0.1 to 0.3% calcium and magnesium ion remover, 0.3 ~0.5% anti-salt corrosion inhibitor, 0.2~0.3% viscosity increasing agent, 0.2~0.5% flow pattern regulator, 0.2~0.3% flocculation coating agent, 0.8~1.1% fluid loss reducer, 1~2% anti-slump Agent, 2-5% liquid lubricant, 20-50% solid weighting agent.

[0051] A method for preparing drilling fluid prepared from oilfield produced water, characterized in that it at least includes the following steps:

[0052] Step 1: Pretreatment of oilfield produced water: including the following steps:

[0053] Step 1) Gradually add 0.1 to 0.3% desulfurizer in the produced water of the oilfield, stir evenly, and detect the hydrogen sulfide content with lead acetate test paper during the addition process. When the hydrogen sulfide content is zero, stop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com