Automatic wire and steel bar conveying device

A technology for transportation device and steel bar, applied in the field of automatic feeding device for wire rods, can solve the problems of low efficiency, large workload, high labor intensity, etc., and achieve the effects of simple assembly and disassembly, improving work efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Aiming at the aforementioned problems of heavy workload, low efficiency, and high labor intensity due to manual handling of wire rods, the present invention provides an automatic feeding device for wire rods and steel bars.

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

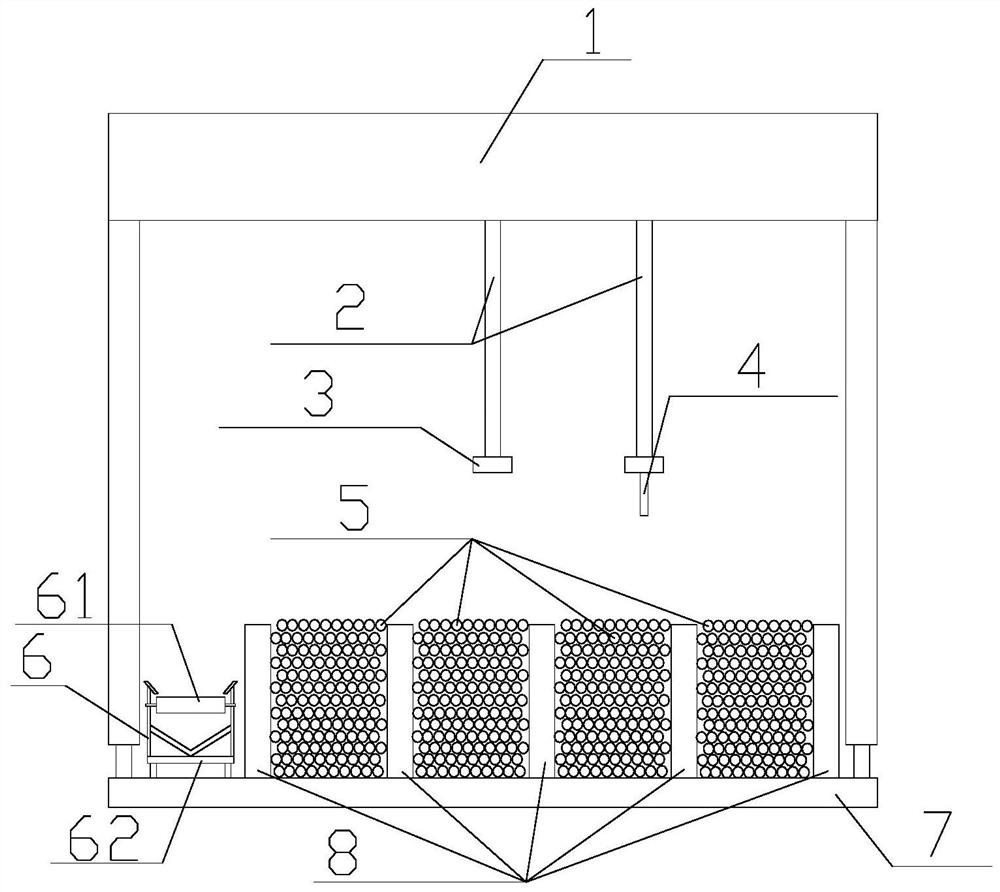

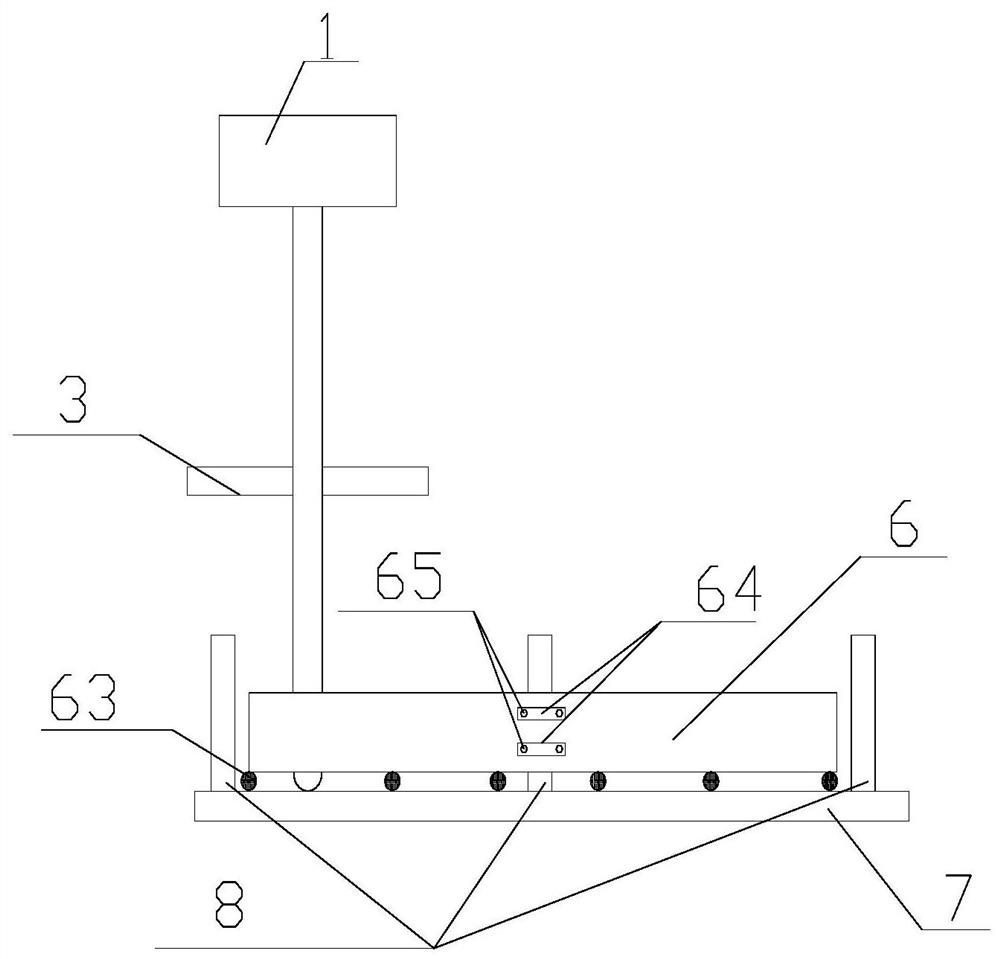

[0029] In order to illustrate the structure of the wire rod reinforcement automatic feeding device provided by the present invention, figure 1 and figure 2 The structure of the automatic feeding device for wire rod and steel bar is exemplarily marked from different angles. specifically, figure 1 It shows the cross-sectional structure of the wire rod and steel bar automatic feeding device according to the embodiment of the present invention; figure 2 It shows the side structure of the automatic feeding device for wire rod and steel bar according to the embodiment of the present invention.

[0030] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com