A kind of cement slurry for hydrate cementing and its preparation method

A kind of cement slurry and hydrate technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of long thickening time and inability to guarantee, and achieve the effect of reducing waiting time and fast strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the second aspect, the embodiment of the present invention also provides a method for preparing cement slurry for hydrate cementing related to the first aspect, the preparation method comprising the following steps:

[0042] Step a, mixing the oil well cement, lightening reinforcement material, drag reducer, and expansion agent evenly to form a dry mixture,

[0043] Step b, mixing the enhancer and water to form a mixed liquid;

[0044] Step c. Uniformly mixing the dry mixture and the mixing solution to form cement slurry.

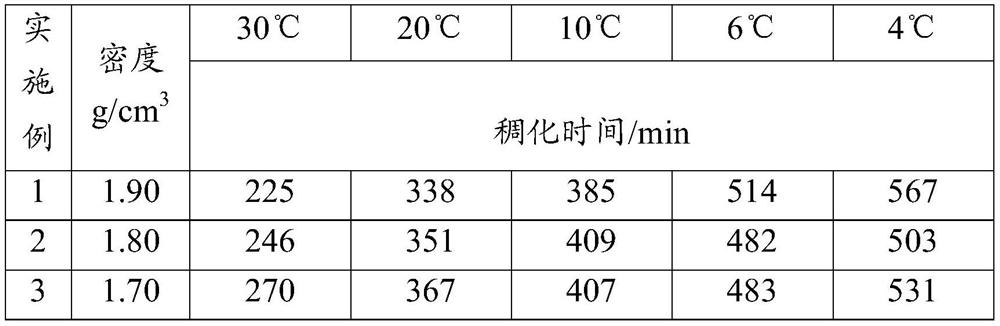

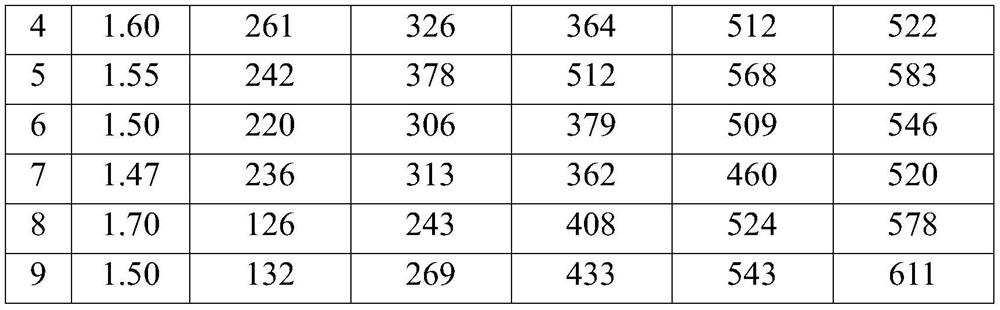

[0045]The cement slurry prepared by the method provided in the embodiment of the present invention can be used for the cementing of hydrates in sea areas with a temperature of 4-30°C through the synergistic compounding of the above-mentioned components. The thickening time of the cement slurry is It can meet the safety construction requirements at 30°C, and the strength develops faster at a low temperature of 4°C, reducing the waiting time for se...

Embodiment 1

[0048] This example provides a cement slurry for hydrate cementing, which is prepared by the following components in weight ratio: 100 parts of oil well cement, 0.5 part of drag reducer, 0.5 part of expansion agent, 3 parts of reinforcing agent and 43 parts of water. The density of the cement slurry prepared by this formula is 1.90g / cm 3 .

Embodiment 2

[0050] This example provides a cement slurry for hydrate cementing, which is prepared by the following components in weight ratio: 100 parts of oil well cement, 10 parts of lightening and reinforcing materials, 0.3 parts of drag reducer, 1.5 parts of expansion agent, 2 parts enhancer and 45 parts water. The density of the cement slurry prepared by this formula is 1.80g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com