Active self-healing cement slurry system in response to oil and gas

A self-healing, cement slurry technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as failure of interlayer isolation, damage to the wellbore integrity of the cement sheath, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

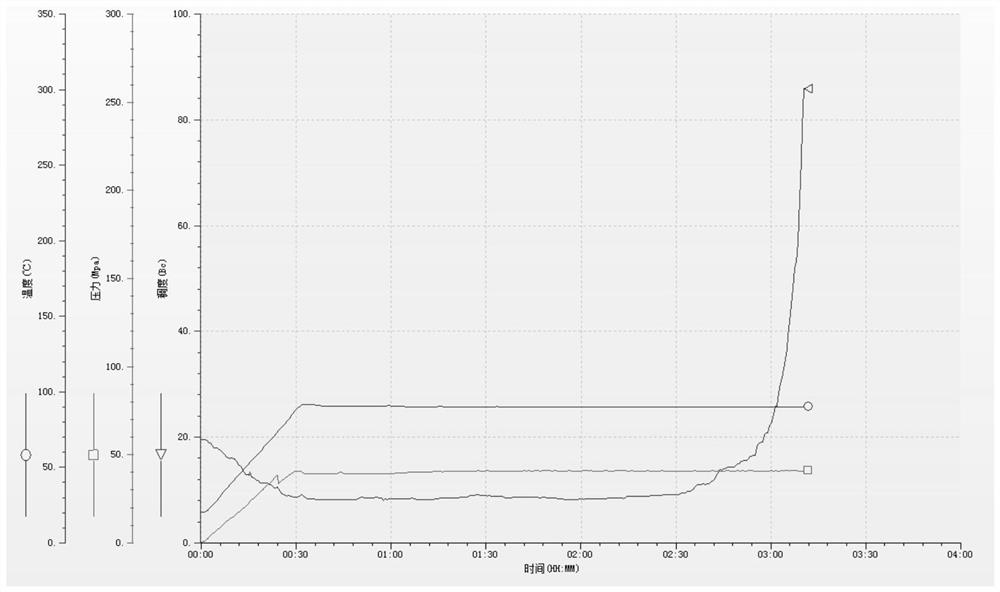

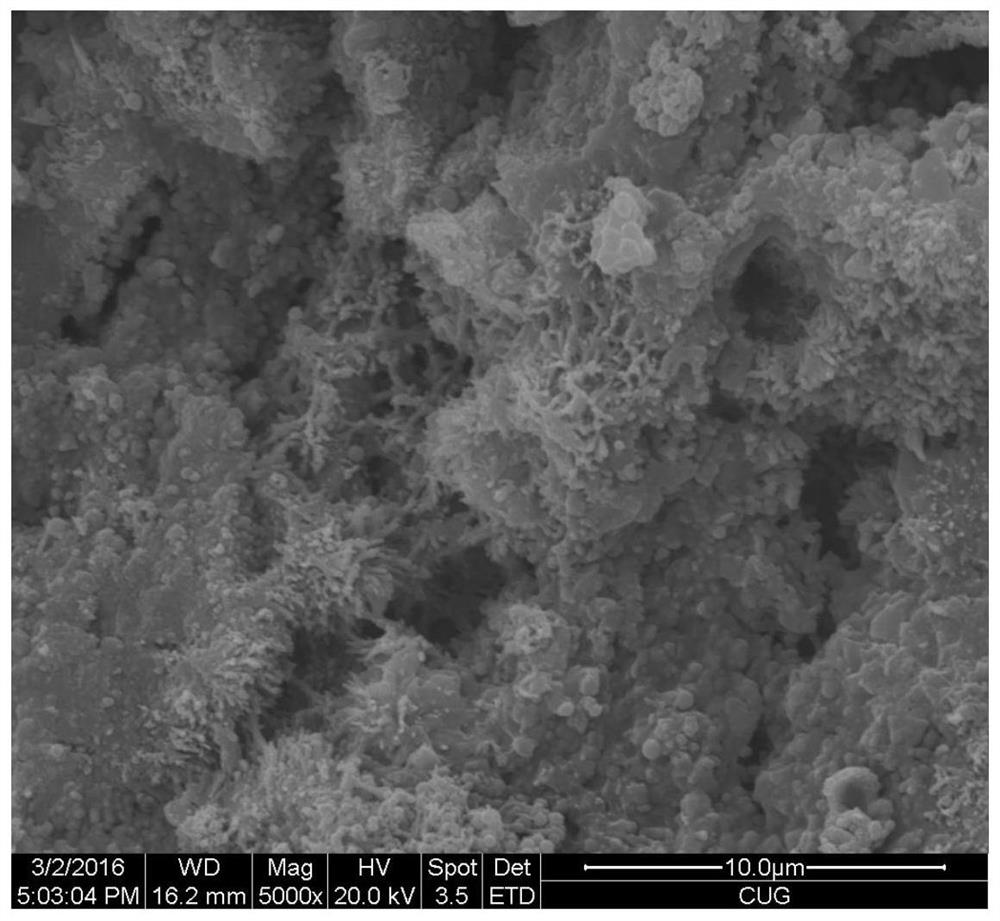

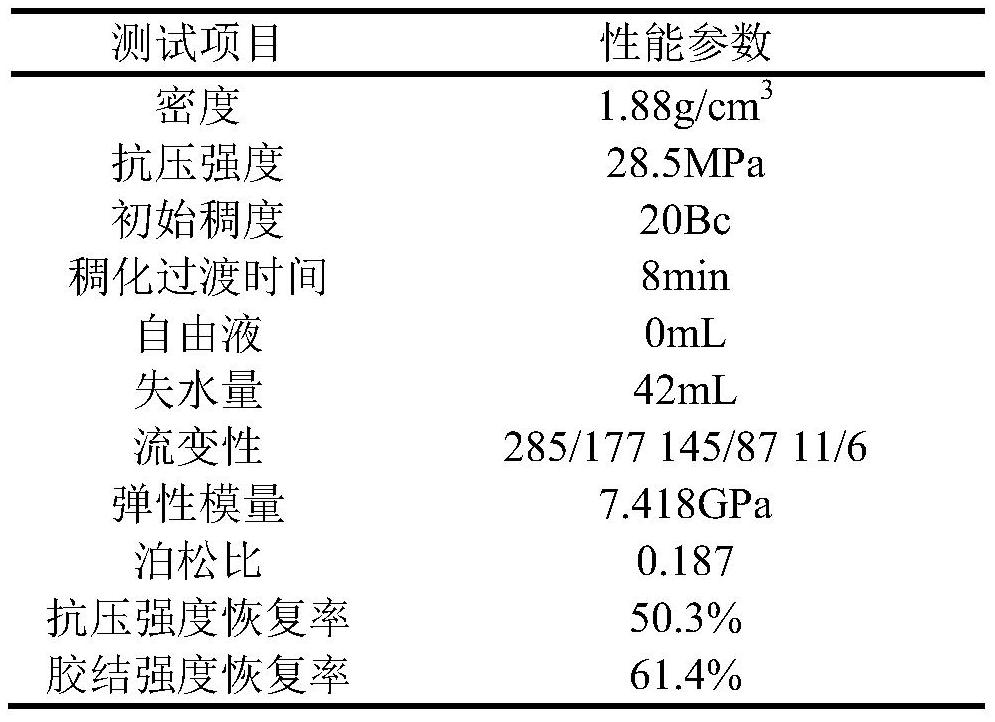

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0026] The present invention is an active self-repairing cement slurry system that responds to oil and gas, according to the cement slurry density of 1.88g / cm 3 Prepared, which included Jiahua G grade oil well cement 800g, fresh water 360mL, modified polyvinyl alcohol polymer self-healing agent 20g, carboxypropyl methylcellulose fluid loss reducer 18g, polycarboxylic acid dispersant 4g, gluconic acid Sodium retarder 6mL and polyvinyl ether defoamer 4mL.

[0027] The preparation method of the above-mentioned active self-healing cement slurry system that responds to oil and gas: Weigh 800g of Jiahua G-grade oil well cement in a sample bag, add 20g of modified polyvinyl alcohol polymer self-healing agent, and mix well; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com