Device and method for treating wastewater produced during acid process extraction of aluminium oxide from coal ash

A waste water treatment and fly ash technology, which is applied in the direction of neutralization water/sewage treatment, water/sewage treatment, natural water treatment, etc., can solve the problems such as the difficult treatment of waste water, achieve the purpose of maintaining the treatment temperature, ensuring the treatment effect, and alleviating the water pollution. Effects of Resource Scarcity Situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

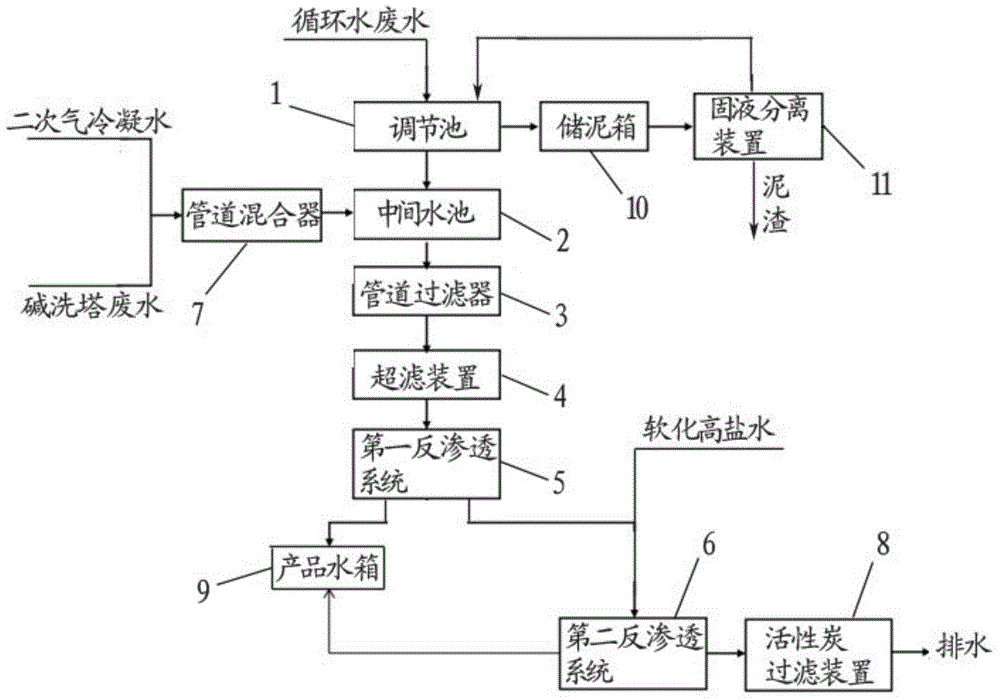

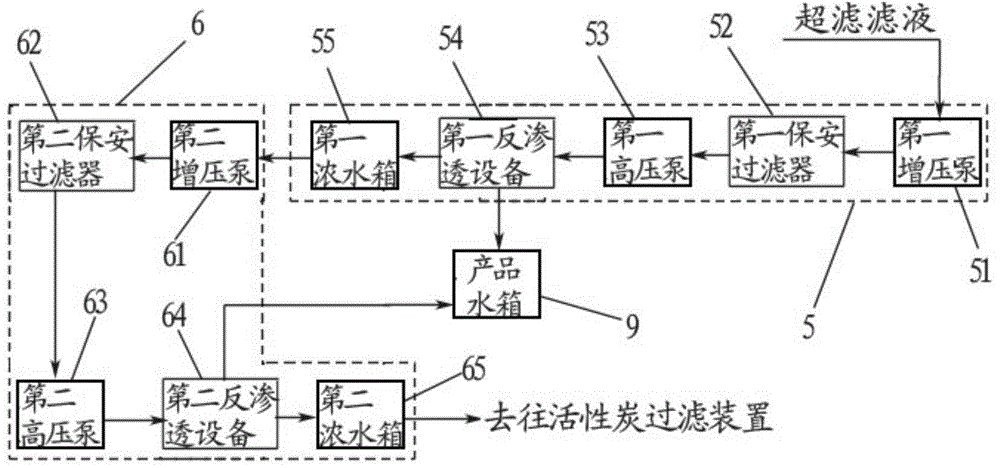

[0073] A pilot plant for extracting alumina from fly ash by acid method has an annual output of 4,000 tons of alumina, and the discharge of waste water during a certain period is 530m 3 / d, wherein, the secondary gas condensate flow rate is about 120m 3 / d, the pH value is about 2, the TDS value is less than 400mg / L, and the suspended matter content is less than 400mg / L; the temperature of the wastewater in the alkali washing tower is about 10-15°C, and the flow rate is about 10m 3 / d, the pH value is about 2, the TDS value is less than 400mg / L, and the suspended solids content is less than 400mg / L; the flow rate of the circulating water waste water is about 350m 3 / d, the pH value is 6-7, the TDS value is about 1600mg / L, the suspended matter content is about 11000mg / L; the flow rate of the softened high brine is about 50m 3 / d, the pH value is 7, the TDS value is about 12000mg / L, and the suspended matter content is less than 600mg / L.

[0074] use as figure 1 and 2 The wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com