Method for preparing regenerative road material by using waste concrete and construction method thereof

A technology of waste concrete and construction method, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as the inability to guarantee construction quality and road service life, save natural sand and gravel materials, ensure the use of effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

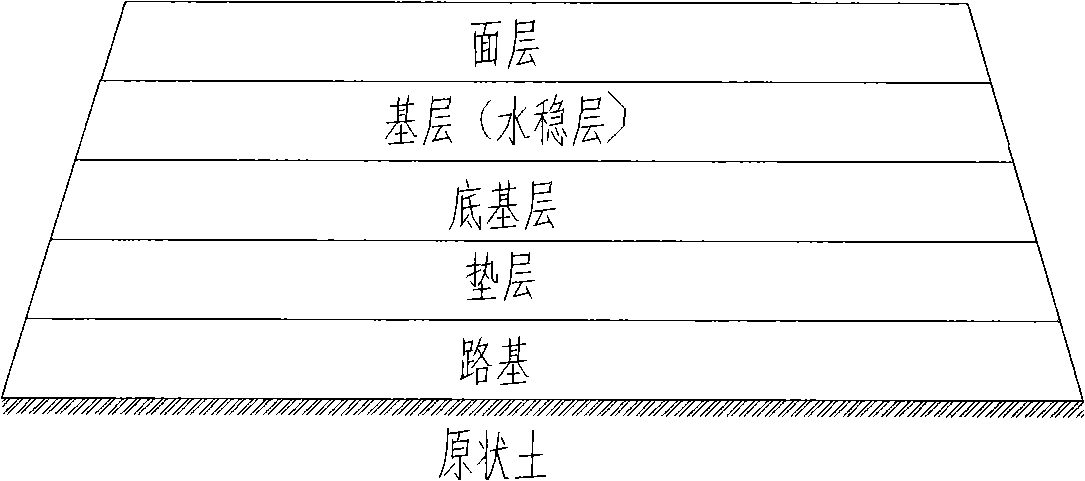

[0028] Recycled road construction material prepared from waste concrete used as subbase material for municipal roads and construction access roads and its preparation method and construction method

[0029] 1. Sorting waste concrete, removing metal, wood and impurities, and removing waste concrete contaminated by radioactive, heavy metal and other harmful impurities;

[0030] 2. The crushing of waste concrete in the project adopts the principle of centralized crushing, and the waste concrete is crushed and screened to obtain waste concrete particles with a maximum particle size of less than 32mm;

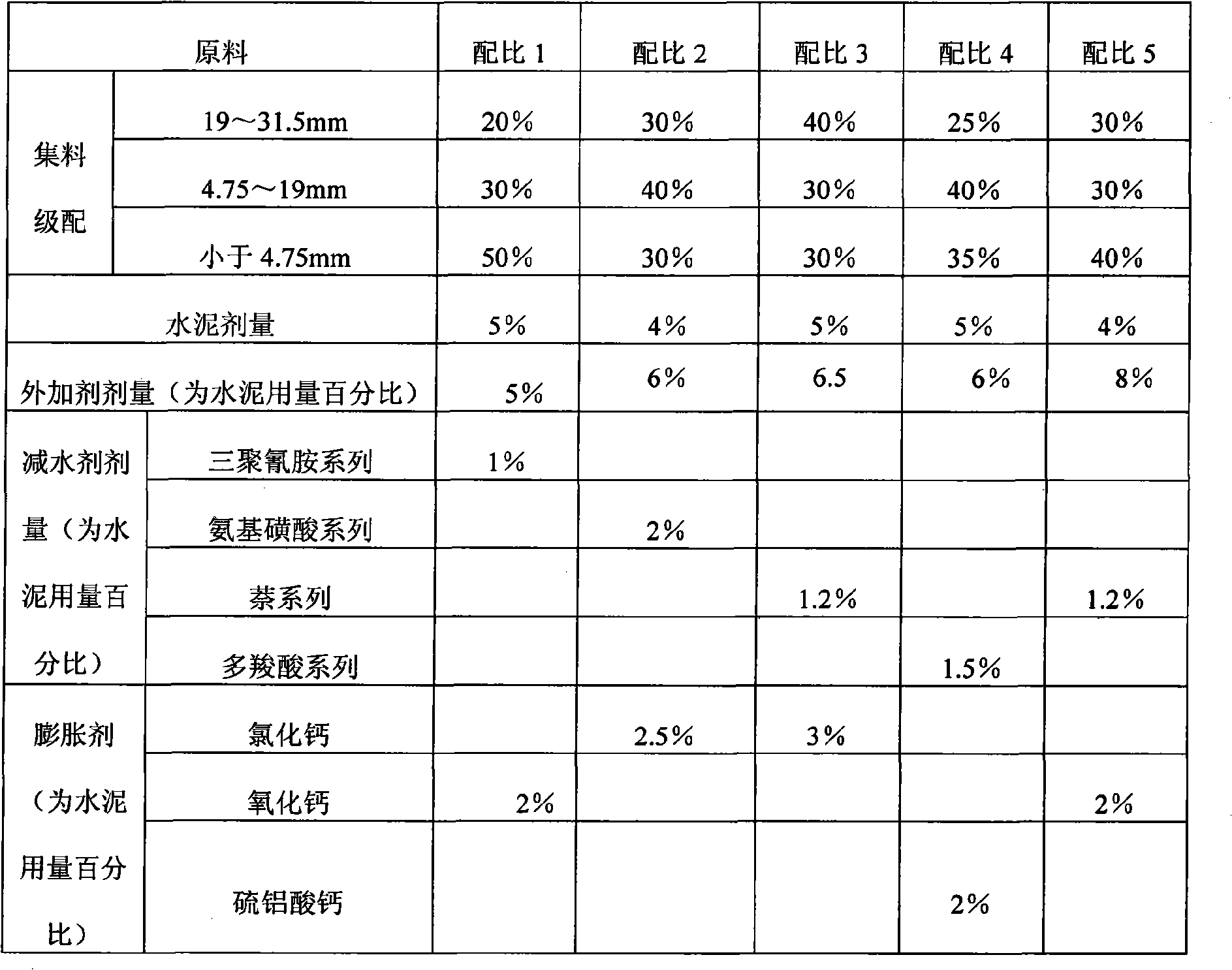

[0031] 3. Prepare materials,

[0032] (1) Prepare waste concrete pellets according to the design requirements, the maximum particle size is less than 32mm, and should not be greater than one-third of the construction layer thickness;

[0033] (2) 32.5, 42.5, 52.5, 62.5 grade ordinary Portland cement, slag Portland cement and pozzolanic Portland cement with initial setting time ≥ 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com