Metal hot rolling optimizing scheduling method and system thereof

A technology for optimizing scheduling and metals, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as large errors in manual scheduling, inability to realize economical scheduling, and large number of slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0301] Example 1 Optimal Scheduling of Silicon Steel Sheet Hot Rolling Production Line

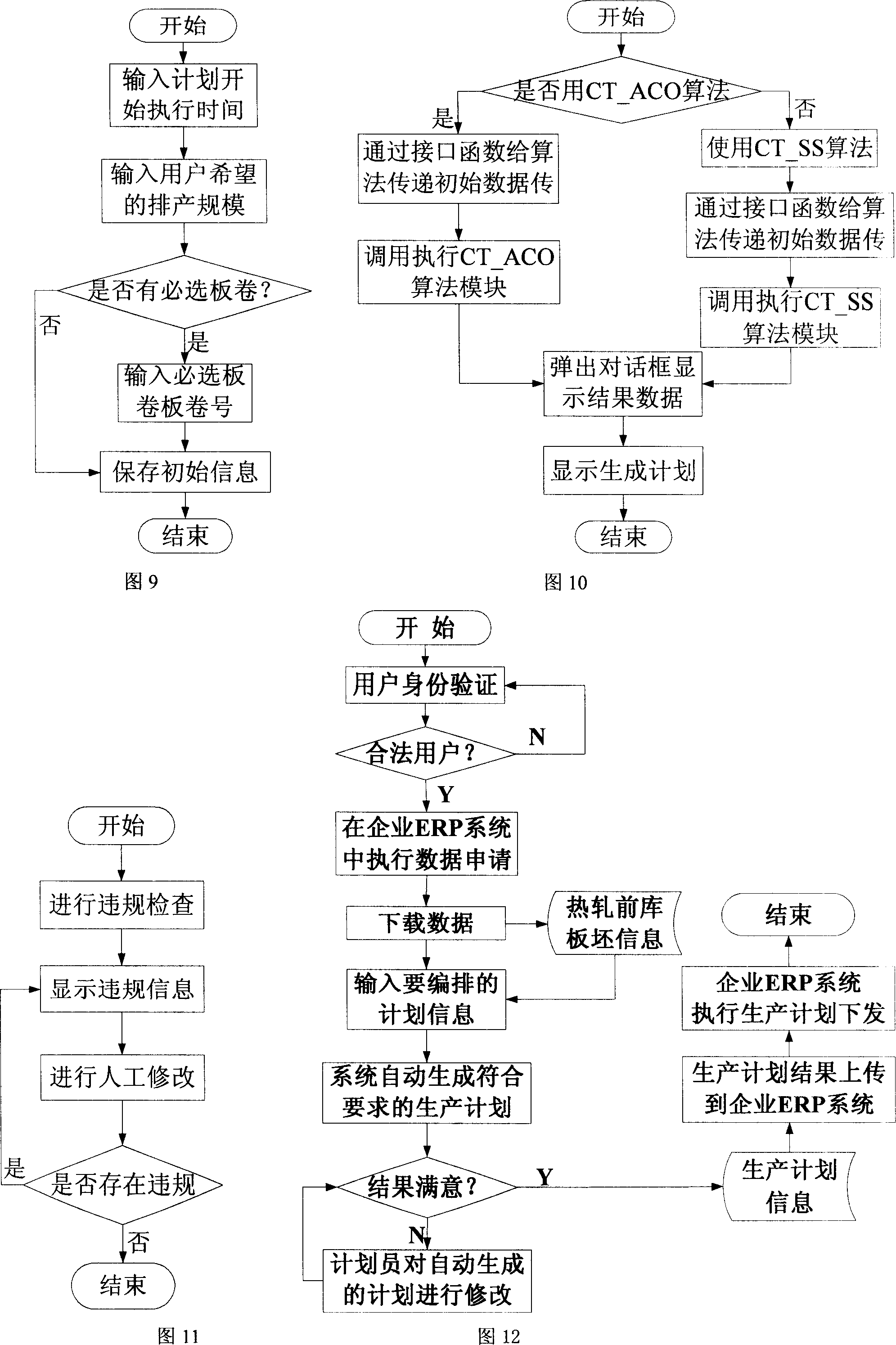

[0302] After installing the system as above. Planners complete the hot rolling plan according to the following steps, and the operation process is shown in Figure 12:

[0303] 1. After the user starts the hot rolling optimization scheduling system, firstly enter the user name and password. If the user is an illegal user, he cannot enter the system; if the user is a legitimate user, he can enter the system smoothly, as shown in Figure 13.

[0304] 2. Click the "data download" button, and the system of the present invention downloads the original data from the current information system of the enterprise. See attached drawing 14.

[0305] 3. If a new slab arrives in the warehouse before hot rolling at this time, the information of the newly arrived slab should be added into the database. At this time, click the "Add" button, and a dialog box will pop up to fill in the added slab informati...

Embodiment 2

[0331] Example 2 Optimum scheduling of medium carbon steel hot rolling production line

[0332]Same as example 1 above, first download the data, configure the calculation parameters, choose to execute the automatic arrangement algorithm, check the results for violations, and finally upload.

[0333] Authorized users log in to the system.

[0334] Click the "data download" button, and the system of the present invention downloads the original data from the current information system of the enterprise.

[0335] The planner sets the calculation parameters for the system according to the characteristics of the medium-carbon steel to be processed: click "Configuration" -> "Calculation Parameter Configuration", and set the parameters under "Slab Specifications". The other two items are the same as those of silicon steel, see Figure 28.

[0336] Execute automatic preparation of hot rolling plan. The planner chooses the algorithm to use, here the CT_SS algorithm is used. Click "CT_...

Embodiment 3

[0340] Example 3 Optimal scheduling of non-ferrous metal (aluminum) hot rolling production line

[0341] In the previous two examples, we are on the hot rolling production line of iron and steel enterprises, according to the actual production process requirements, we have established a reasonable and effective hot rolling production planning example obtained by solving the hot rolling production planning model. The system of the present invention is equally applicable to both low carbon and high carbon steels. It is proved that the system and method of the present invention can effectively solve the preparation of ferrous metal hot rolling production plan.

[0342] Provide the example of the present invention for non-ferrous metal hot rolling production plan preparation below. Take aluminum as an example.

[0343] Use the steps of the above embodiment to set calculation parameters: click "Configuration" -> "Calculation Parameter Configuration", and set parameters under "Slab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com