Patents

Literature

175results about How to "Meet the actual production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal hot rolling optimizing scheduling method and system thereof

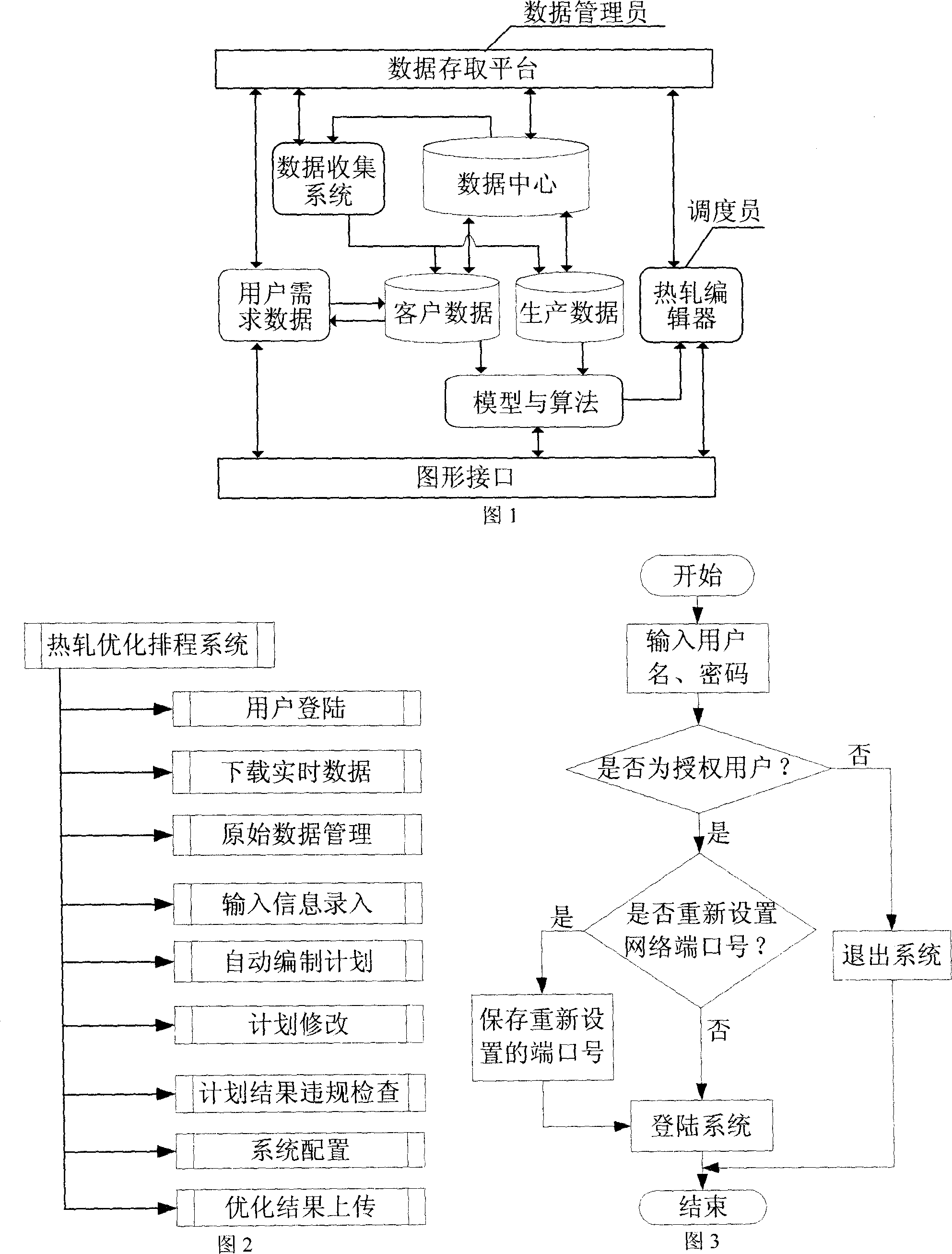

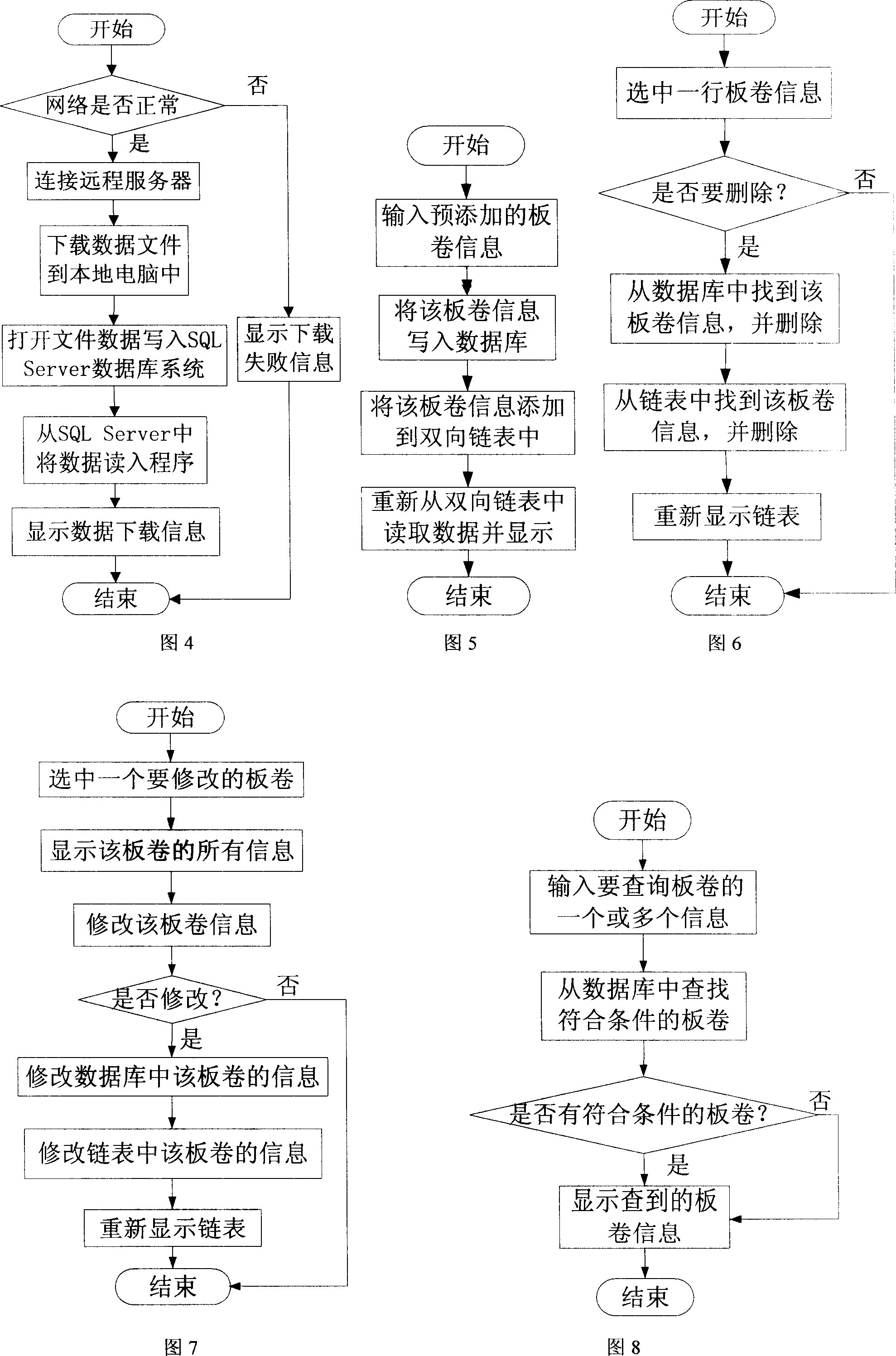

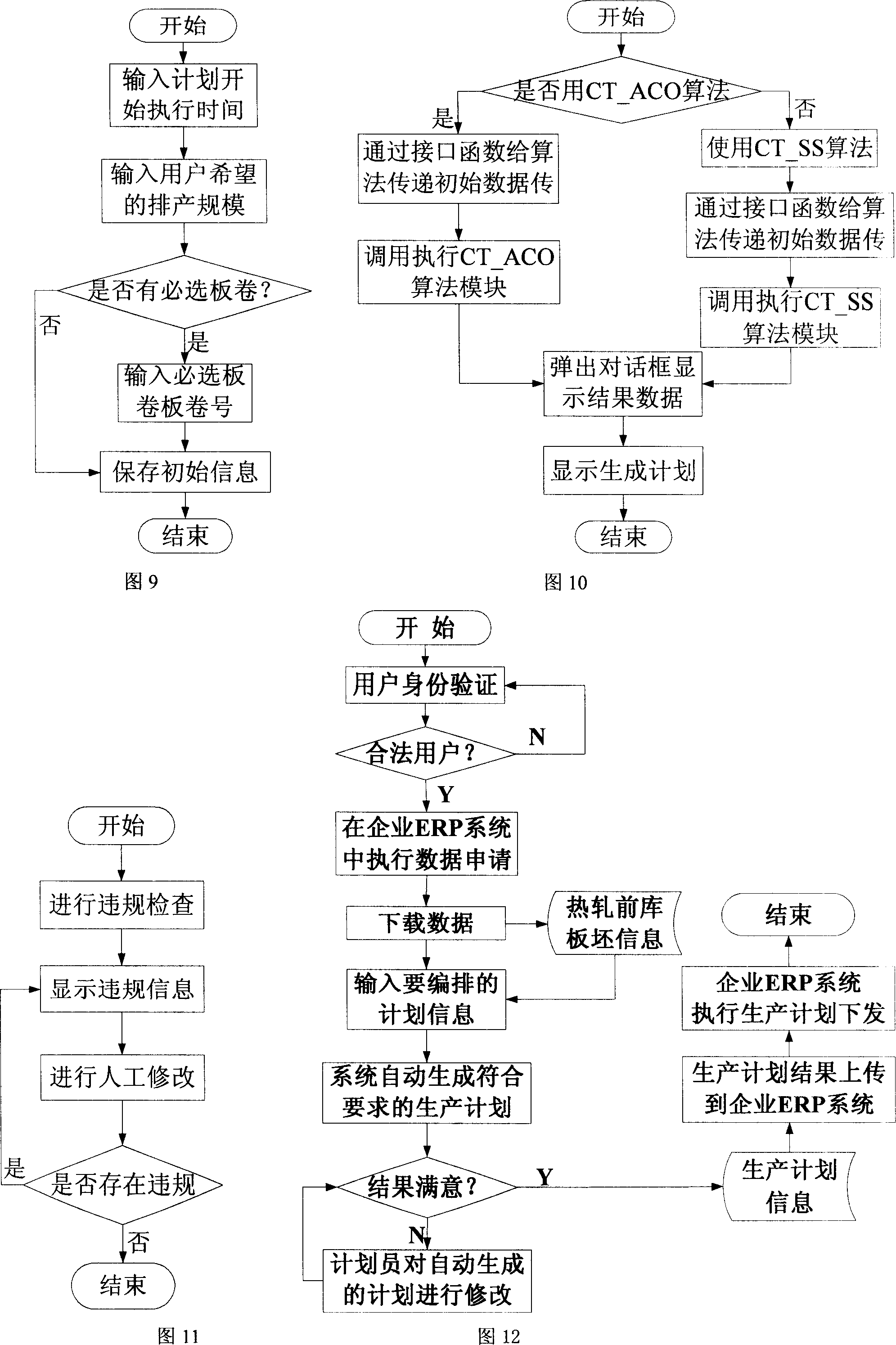

InactiveCN101097617AIncrease reflectionRealize economic schedulingForecastingSpecial data processing applicationsData centerMathematical model

A kind of optimized dispatching method for hot-rolled metal, which includes that it extracts the customer data and production data from data collection system and data center, and makes the hot-rolled production plan according to the built mathematical model of optimized production, and the characteristics are: the model is built according to the craft constraints and the hot-rolled cost, and the aims for undetermined plans and parallel hot-rolled plan is to minimize the production cost; (2)the solution of model adopts two kinds of hybrid algorism containing loop exchange algorism. It provides the hot-rolled dispatching optimized system and device based on said method, and the system is formed by combination of model design idea and graph interface, and the model construction module and model solution module are embedded in the auto production module for production plan; and the devices include PC, interface, router or switcher, and the complete software which consists of said functional module is mounted on the PC, and which is connected with the front end of hot-rolled control system by network or inner sever.

Owner:NORTHEASTERN UNIV

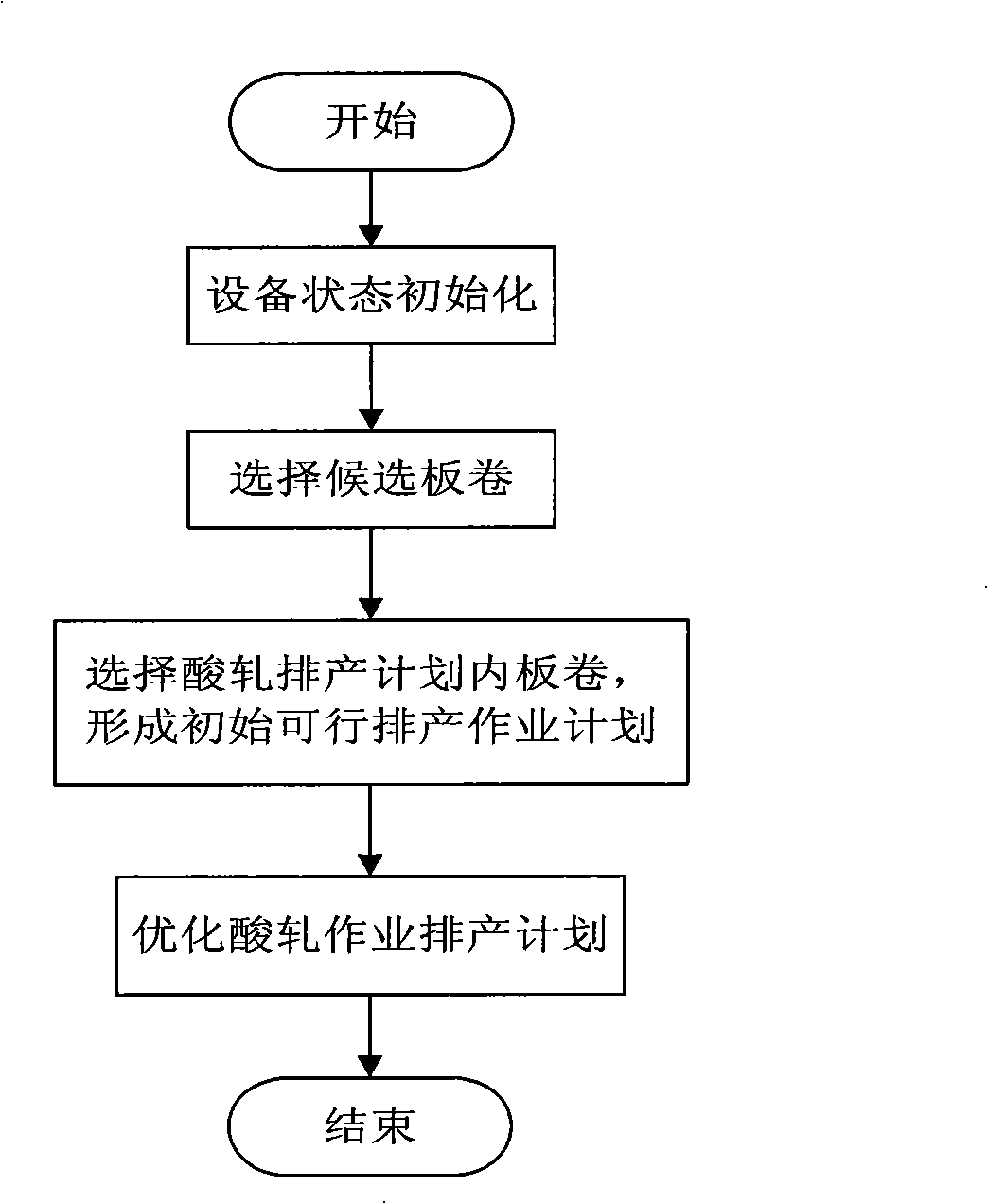

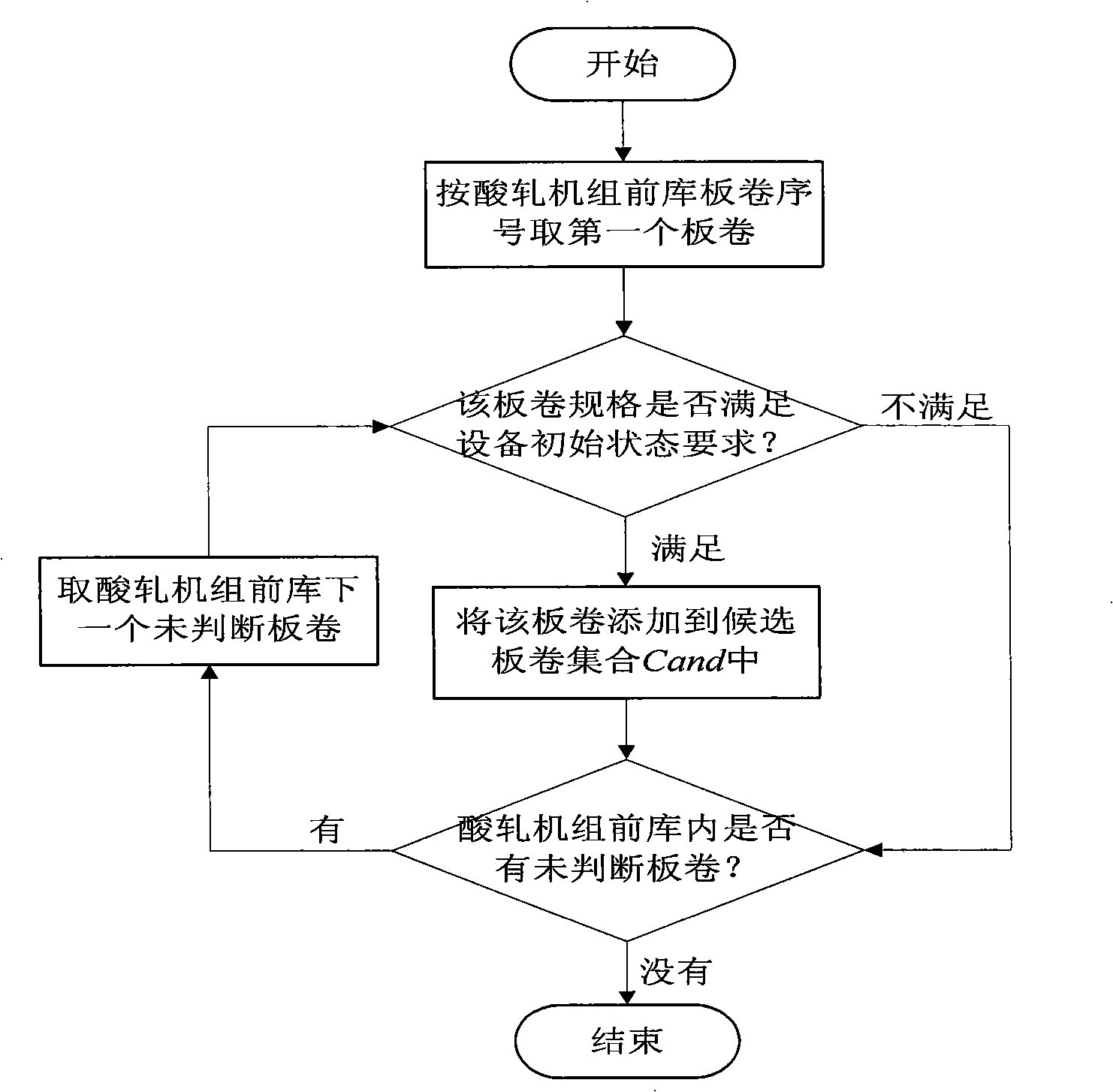

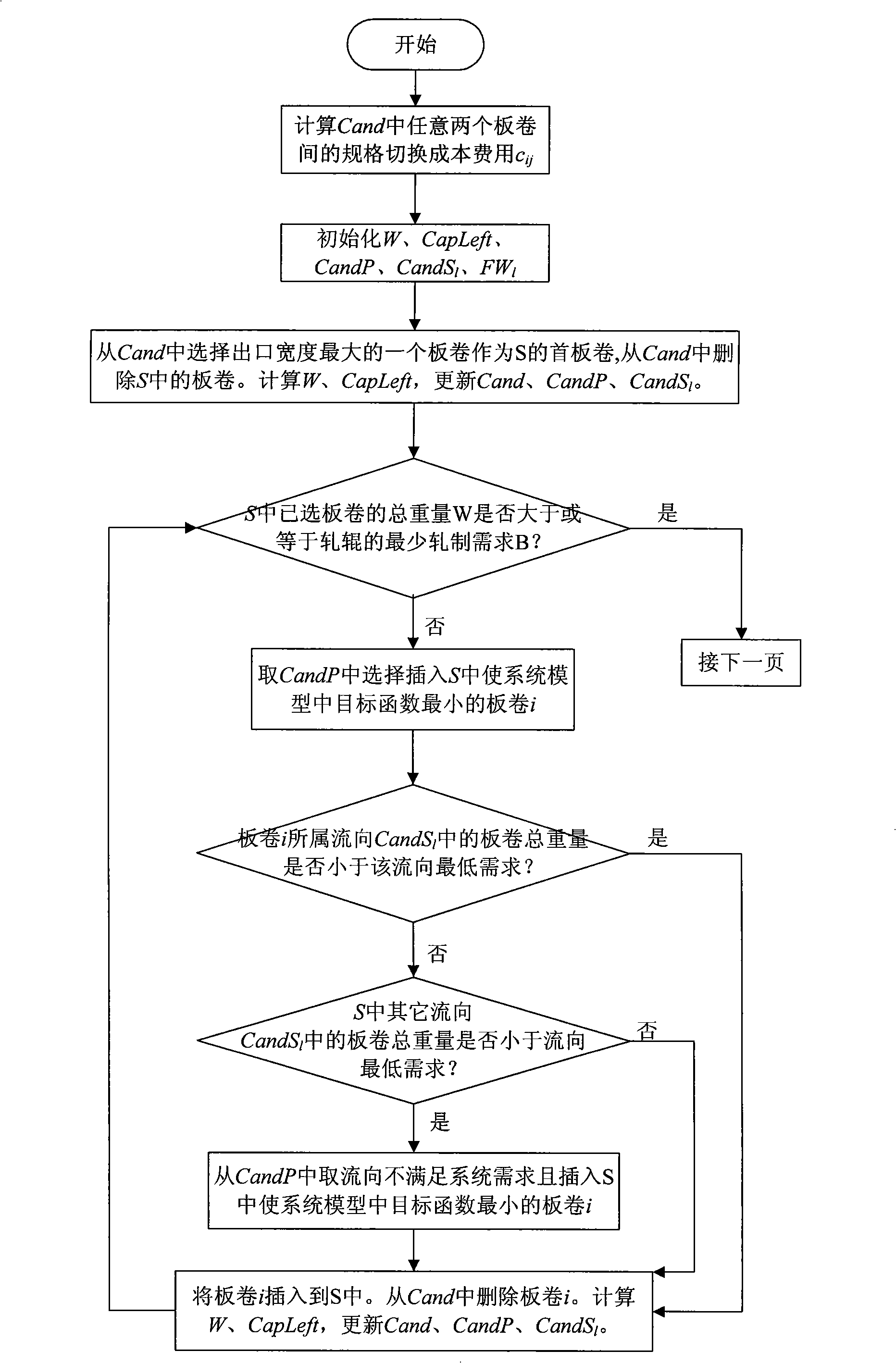

Automatic production optimizing method and system of cold rolling sulfuric acid refining and roller milling integral unit

ActiveCN101329573AOptimize production scheduleSatisfy the normal operation of productionTotal factory controlProgramme total factory controlMetallic materialsProcess engineering

The invention relates to an automatic production scheduling optimization method of an integral unit for cold rolling, acid pickling and rolling, and a system, which belong to the technical field of information of metal material processing; the method comprises the following steps of: (1) establishing initial state of equipment, setting the lower limit of flowing to the rolling quantity of a processing plate in each unit of plans, setting the biggest rolling capability and the least rolling requirement of a working roll of a rolling mill and limiting the flowing direction and the specification of acid rolling coil; (2) selecting coil which meets the requirement of specification range as acid rolling candidate coil; (3) forming an acid rolling initial feasible production scheduling plan, leading the switching cost between the adjacent coils in the plan to be little as much as possible and leading the weight of the coil in the plan to be close to the rolling capability of the roll as much as possible; (4) carrying out optimization and adjustment to the initial and feasible production scheduling plan of an acid rolling unit, carrying out adjustment of the coil and the candidate coil in the production scheduling plan and leading the objective function value of a system model to decrease under the condition of meeting the constraint condition of the system model. The method and the system of the invention reduces the production cost effectively, improves the quality of acid rolling products and gives full play to the production capability of the rolling mill.

Owner:NORTHEASTERN UNIV

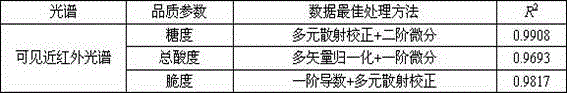

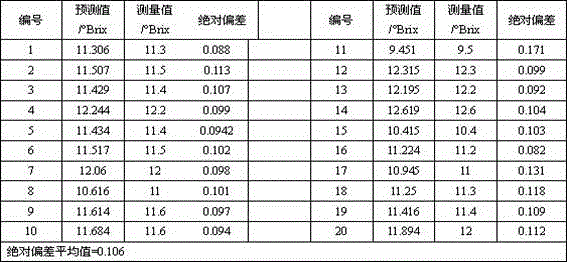

Near infrared spectrum-based Hanfu apple quality nondestructive test method

InactiveCN105527244AEasy to operateImprove detection accuracyMaterial analysis by optical meansInfraredTest platform

The invention discloses a near infrared spectrum-based Hanfu apple quality nondestructive test method. According to the method, a sample spectrum is acquired in a characteristic wave band range, an intensity spectrum under the condition of a fiber-optic probe-a reference plate distance of 24-42mm is used as a reference spectrum, an irradiation color surface is designed according to a fruit male-female face ratio, irradiation latitude is in a range of 40 degree N-40 degree S, an area with surface features is used as a spectrum collecting point and the acquired apple reflectivity information is complete and has representativeness. Through use of a spectrum technology on a detection platform, the method realizes a Hanfu apple inner quality nondestructive test, fast analysis of a sugar degree, acidity and quality of Hanfu apples, prediction of Hanfu apple quality and direct display of a quality predicted value and has a prediction precision satisfying practical production requirements. The test platform can be operated simply, can be controlled easily and has a high detection precision. The method can be used for on-line detection grading of fruit quality.

Owner:SHENYANG AGRI UNIV

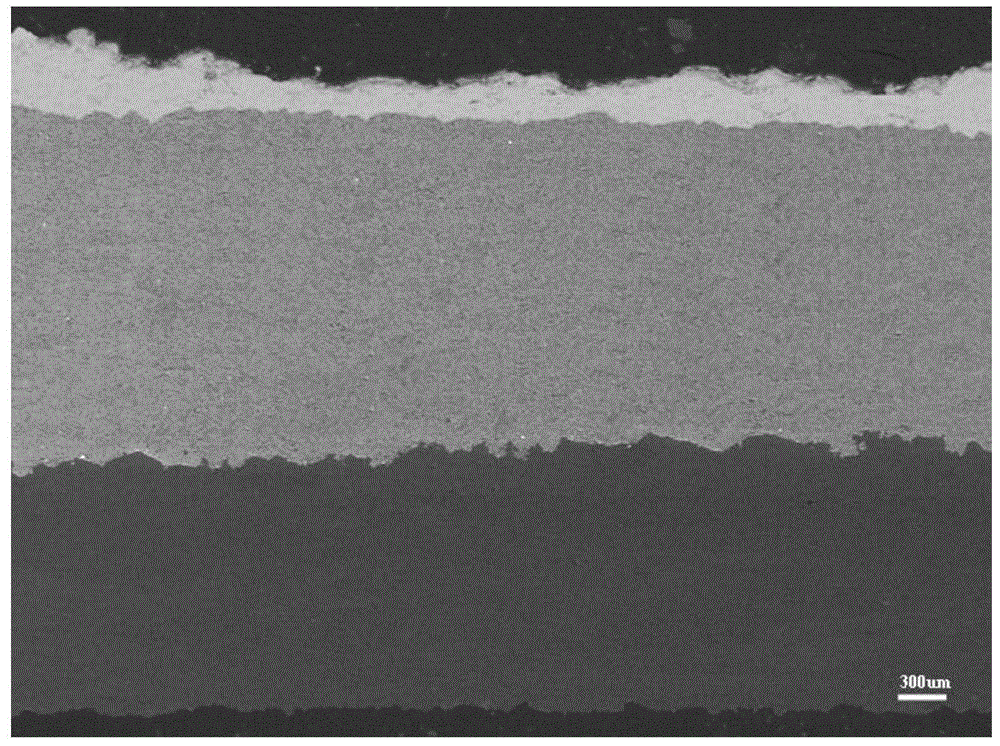

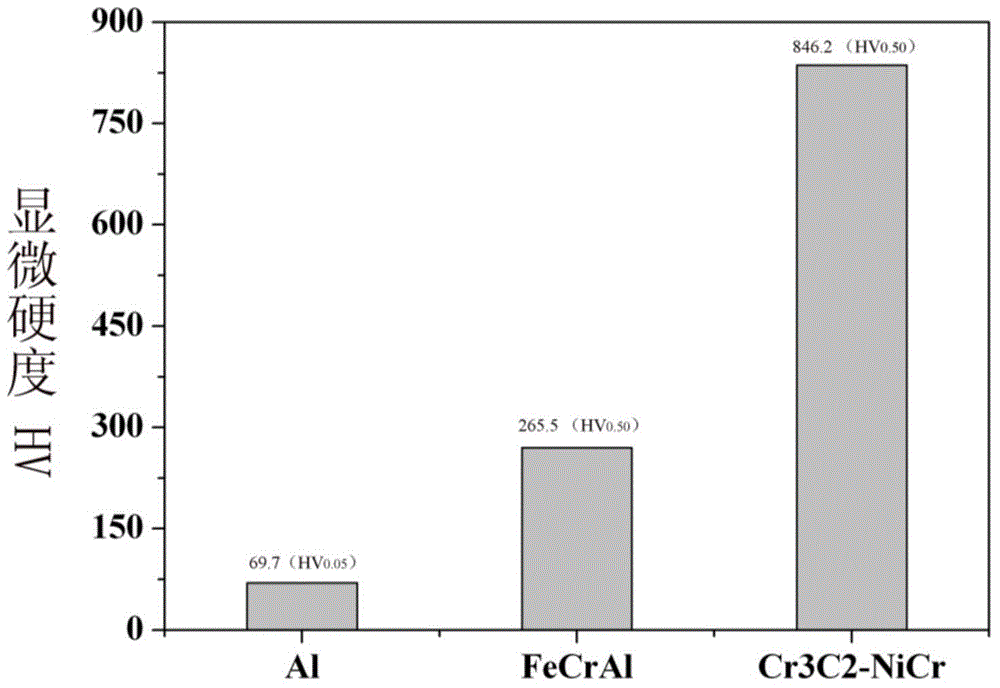

Copper casting mould rapidly moulded by hot spraying technology and manufacturing method of copper casting mould

InactiveCN104674157AWith mechanical propertiesCorrosion resistantMolten spray coatingFoundry mouldsHeat conductingMetallic materials

The invention discloses a copper casting mould rapidly moulded by a hot spraying technology and a manufacturing method of the copper casing mould. The copper casting mould sequentially comprises a heat-conducting layer, a transition layer and a heat corrosion-resistant layer from the inside to the outside, wherein the heat-conducting layer is formed by thermally spraying a high-heat conductivity metal material onto the surface of a substrate material; the transition layer is formed by thermally spraying a metal material with high deposition efficiency and corrosion resistance onto the heat-conducting layer; the heat corrosion-resistant layer is formed by thermally spraying an alloy ceramic material with high hardness and high heat corrosion resistance onto the transition layer. The copper casting mould is high in cost performance, and short in production cycle, and has excellent heat conductivity, heat corrosion resistance and hardness; by the manufacturing method, actual production requirements can be met; the manufacturing method is applicable to the field of manufacturing of a copper casting mould and other moulds; the copper casting mould has a good application prospect and economic benefits.

Owner:SHAOXING SPRAY MICRONANO TECH

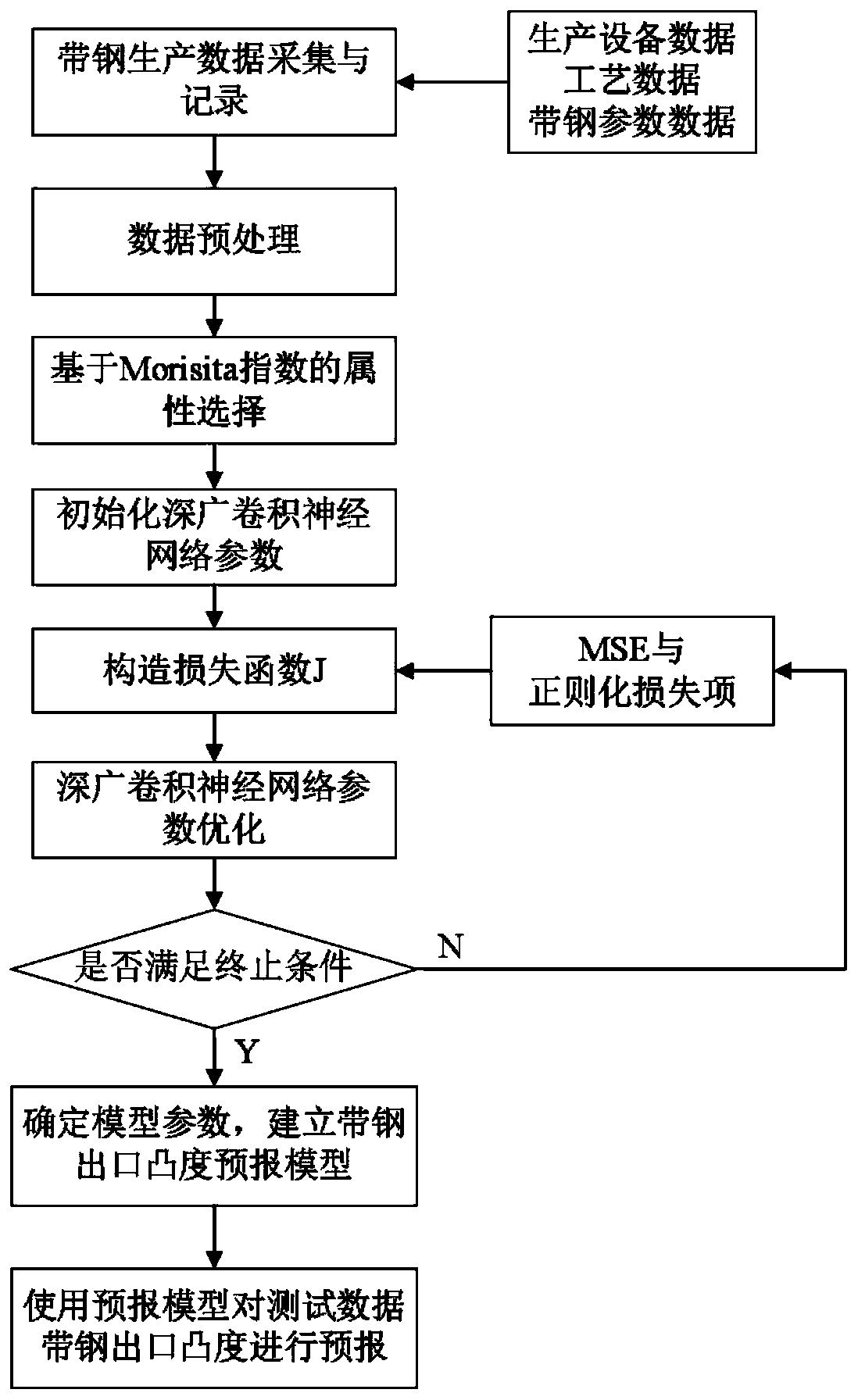

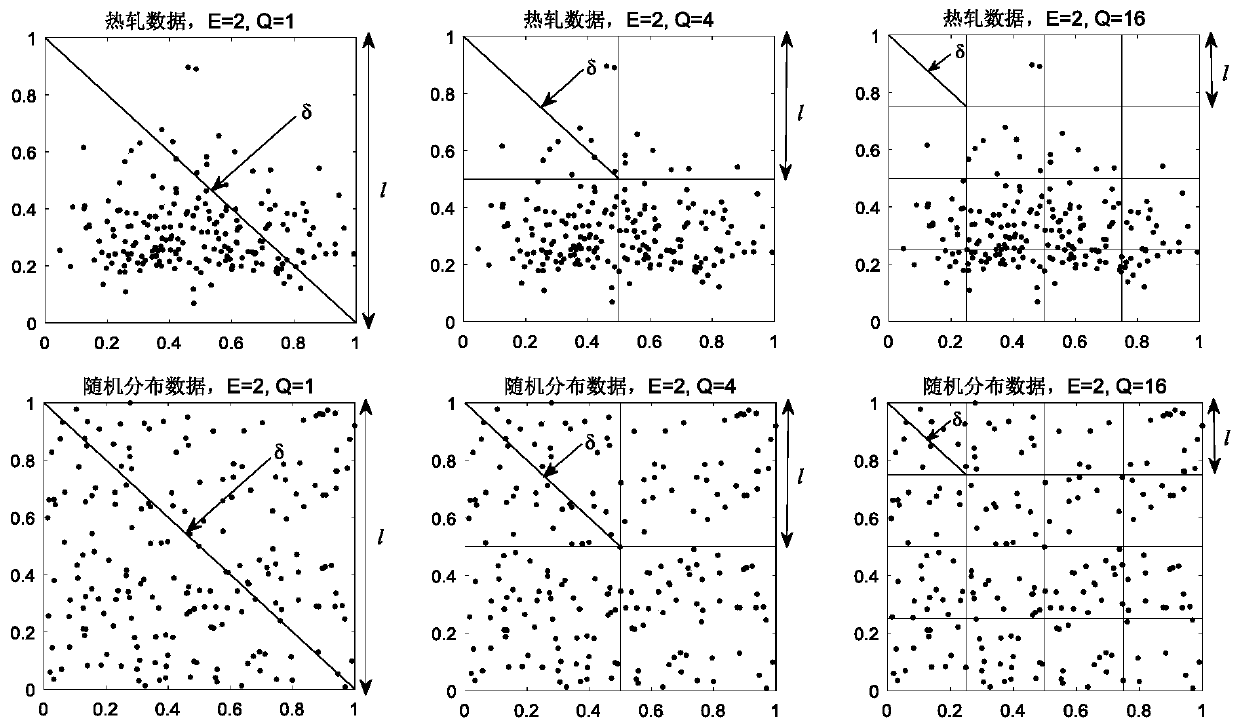

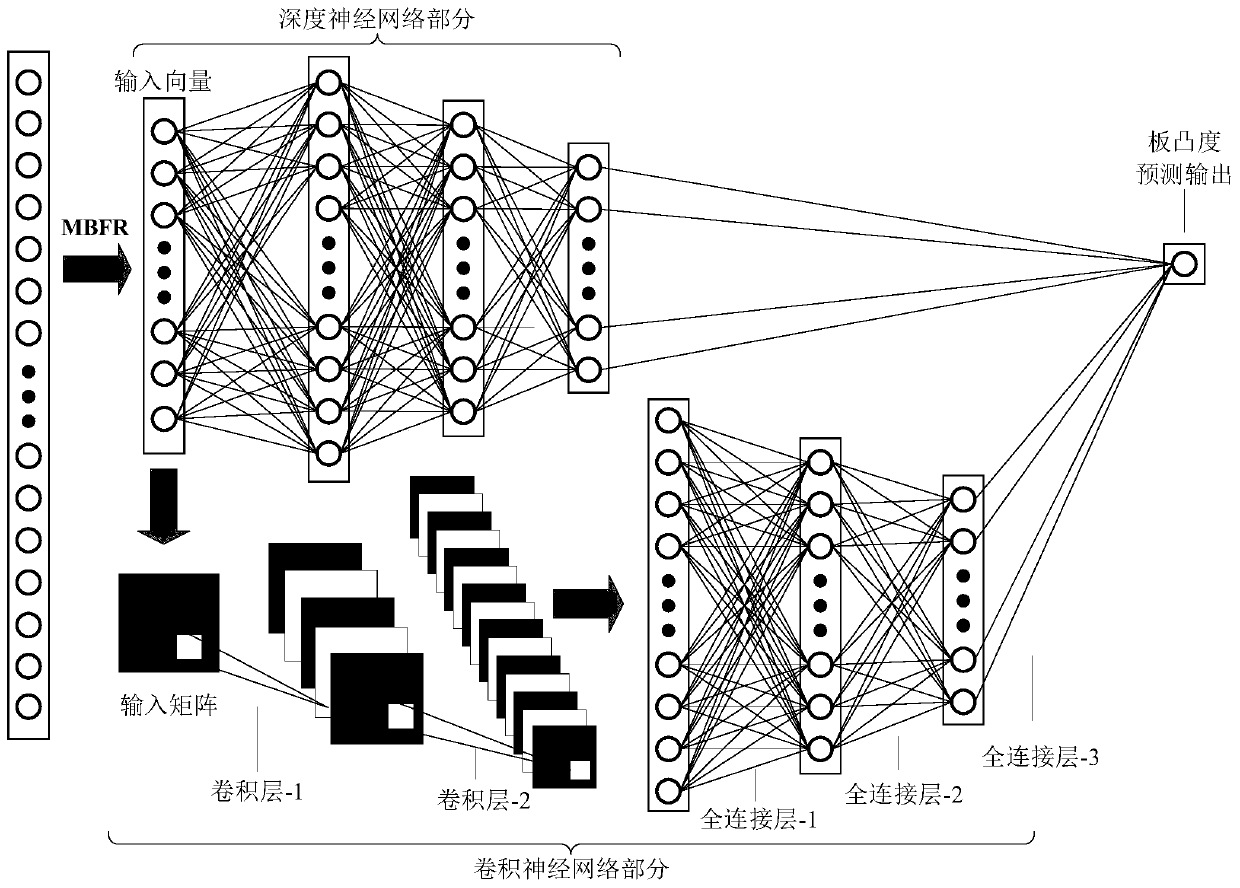

Hot-rolled strip steel plate convexity prediction method based on deep learning

ActiveCN110428175AAvoid heavy computationImprove forecast accuracyDigital data information retrievalNeural architecturesNerve networkMaterials science

The invention discloses a hot-rolled strip steel plate convexity prediction method based on deep learning, and the method comprises the following steps: S1, collecting and recording strip steel production data, and carrying out the preprocessing, including missing value deletion, abnormal value deletion and normalization, of the collected data; S2, according to the strip steel production data, removing redundant and irrelevant attributes in the collected data through an attribute selection method based on a Morita index, and screening a minimum number of attributes capable of representing plate convexity changes to form an input variable set of a forecasting model; and S3, establishing a strip steel outlet plate convexity prediction model based on the deep and wide convolutional neural network based on the input variable set so as to obtain the hot rolled strip steel outlet plate convexity. According to the method, high-order features and invariant features of the data are extracted byusing the convolutional layer in the convolutional neural network, the local correlation between the variables is learned, and the global feature learning ability of the deep neural network is combined, so that the plate convexity prediction precision is remarkably improved.

Owner:东北大学秦皇岛分校

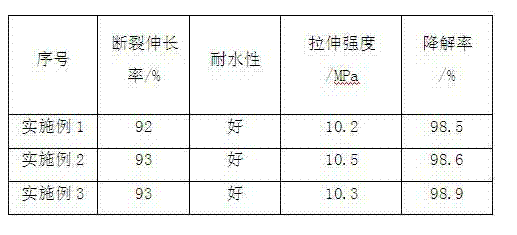

Production process of PVA (polyvinyl alcohol)-based composite packaging material

InactiveCN103540068ANo pollution in the processNo dopingFlexible coversWrappersPolyvinyl alcoholBiological materials

The invention discloses a production process of a PVA (polyvinyl alcohol)-based composite packaging material, relating to the field of film packaging materials. The production process comprises the following three technical processes: preparation of dialdehyde starch, preparation of jute fibers and preparation of a PVA-based composite film. According to the process method, in the preparation process of the dialdehyde starch, corn starch is used as a raw material, no pollution is caused, the cost is low, the raw material is sufficient, a far-infrared quick constant-temperature drying box is used as drying equipment, the dialdehyde starch is dried sufficiently, and no impurity is doped; in the preparation process of the jute fibers, the temperature control is reasonable, a right amount of reagent is added, the jute fibers are pulverized through a YSC-701 type ultrafine pulverizer, and the pulverized fibers are small in particle size and favorable in pulverization effect; and in the preparation process of the PVA-based composite film, parameters such as addition of each component, temperature, time and the like are strictly controlled, thereby ensuring that the prepared PVA-based composite film has favorable mechanical property and water resistance and can meet the requirements for practical production. By using the biological material as the raw material for production, the PVA-based composite film produced by the process is low in cost and degradable, thus greatly reducing environmental pollution.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

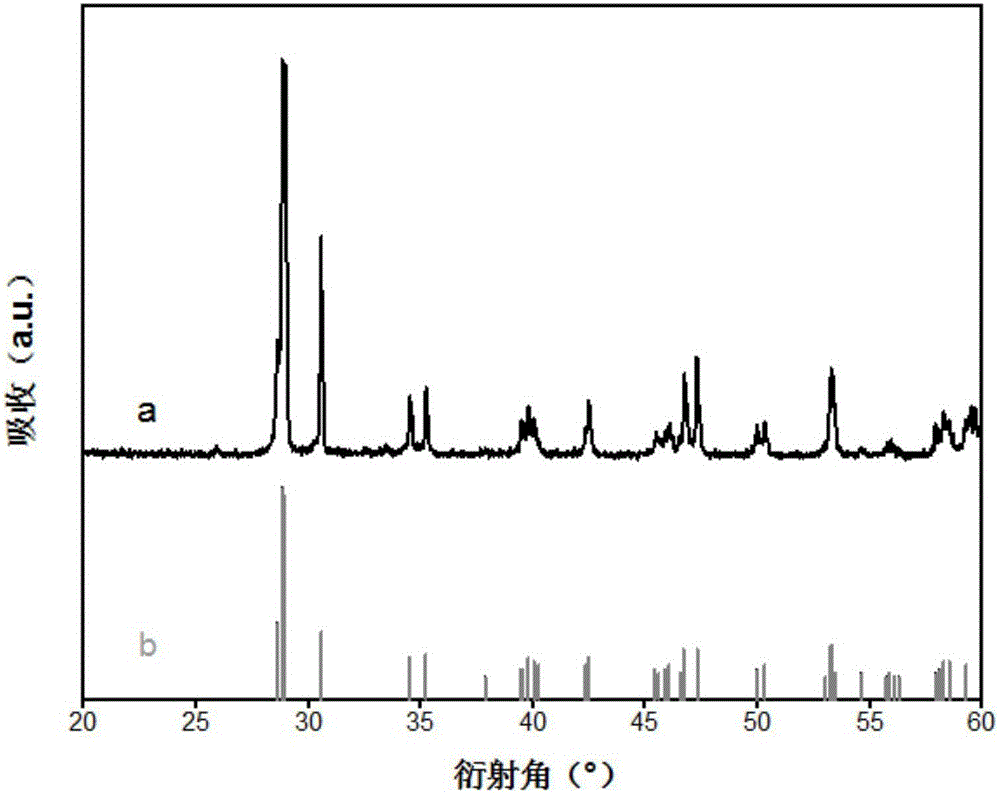

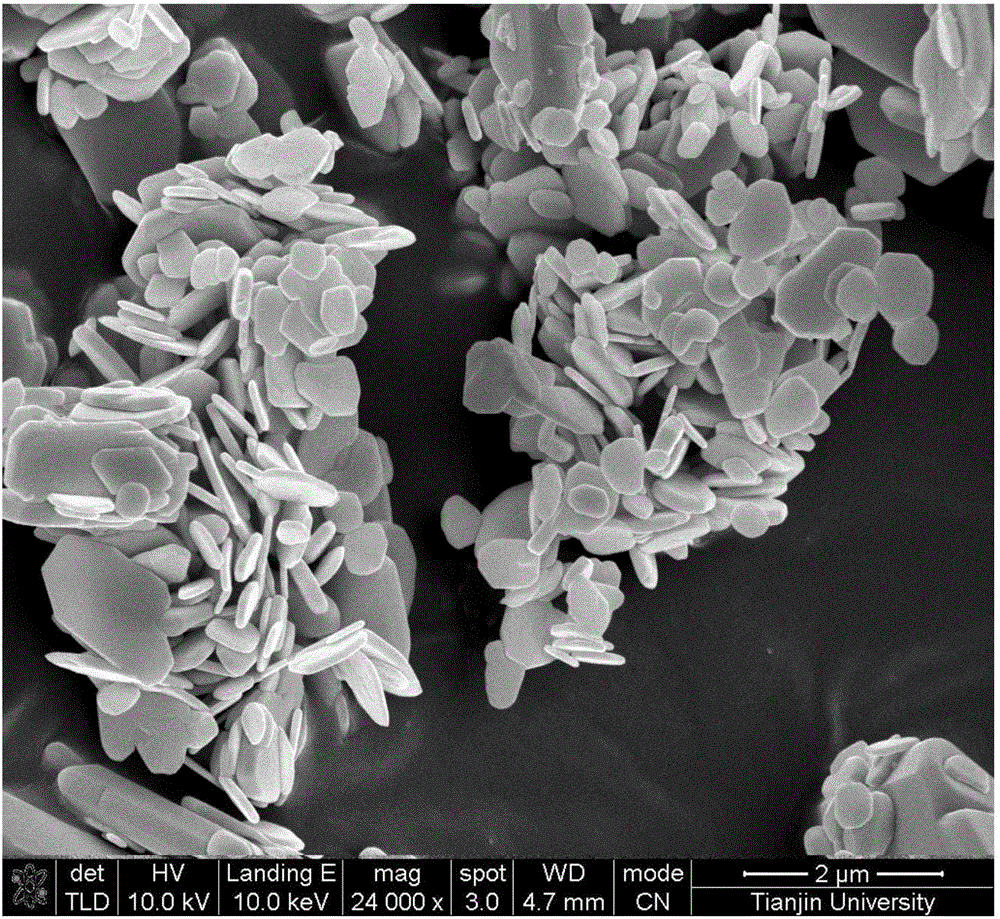

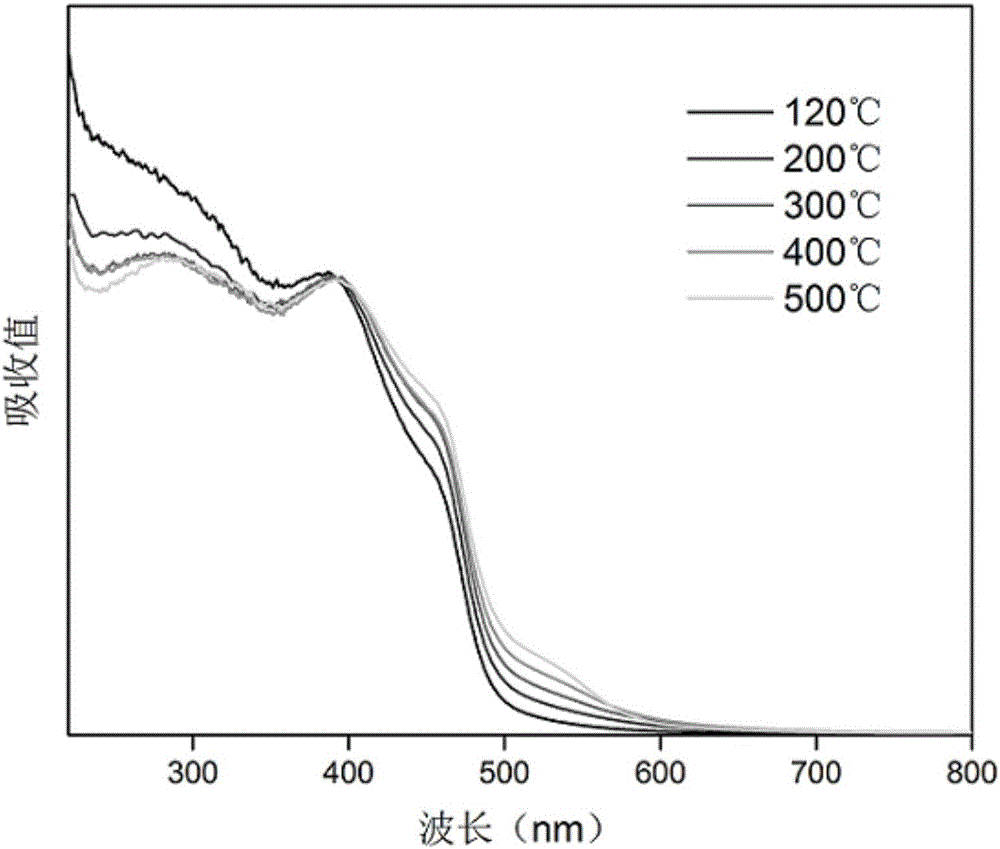

Preparation method and application of iron hydroxide/bismuth vanadate composite photocatalyst

ActiveCN105797739ASimple processEasy to operateMetal/metal-oxides/metal-hydroxide catalystsElectrodesPhotocatalytic water splittingBismuth vanadate

The invention relates to a preparation method and an application of an iron hydroxide / bismuth vanadate composite photocatalyst. Bismuth vanadate and a composite photocatalyst thereof are prepared with a hydrothermal method; the obtained bismuth vanadate powder adopts a flaky monoclinic structure phase. A template and an organic surfactant are not used, the bismuth vanadate powder in a flaky structure can be obtained by controlling the dosage of ethanolamine, and the supporting amount of iron hydroxide on bismuth vanadate can be controlled by controlling the mass ratio of bismuth vanadate to an iron salt aqueous solution; when the composite photocatalyst is applied to photocatalytic water splitting for oxygen generation, iron hydroxide and bismuth vanadate overcome the defect of high probability of recombination of photon-generated carriers of bismuth vanadate due to different conduction band positions and different valance band positions, and the composite photocatalyst has high photocatalytic water splitting activity for oxygen generation. Further, a preparation process is simple and convenient, the production cost is lower, the actual production requirement is met, and the process is simple and easy to operate.

Owner:TIANJIN UNIV

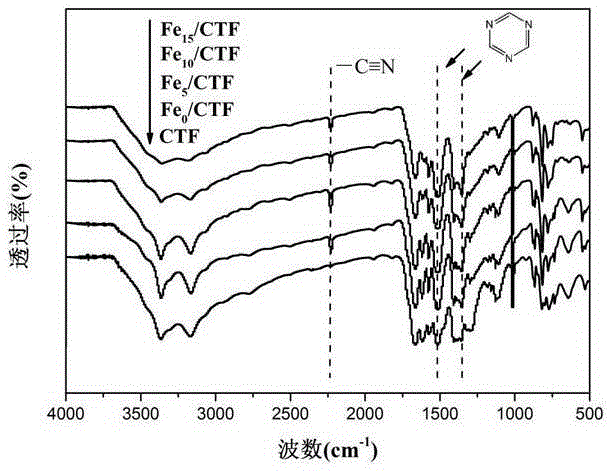

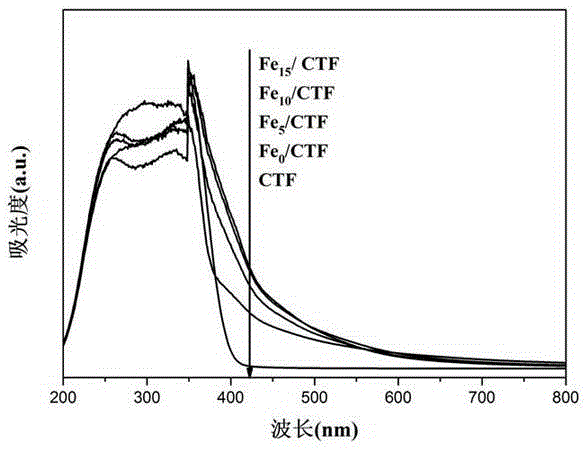

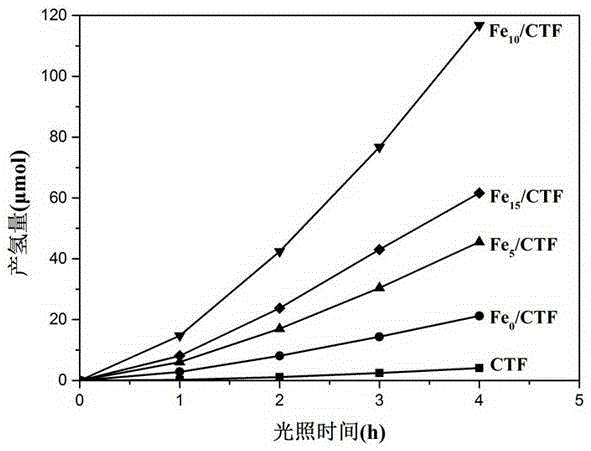

Fe-doped visible-light-driven photocatalyst of covalent triazine organic polymer and preparation and application of Fe-doped visible-light-driven photocatalyst

InactiveCN105312088ASimple and fast manufacturing methodReduce manufacturing costOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionPtru catalystTriazine

The invention discloses a Fe-doped visible-light-driven photocatalyst of a covalent triazine organic polymer and a preparation and an application of the Fe-doped visible-light-driven photocatalyst. Iron is introduced into the covalent triazine organic polymer by a solid-phase reaction sintering method; and the transition metal ion-doped visible-light-driven photocatalyst is synthesized. The catalyst has visible-light response; hydrogen is produced by photolysis of water; the adopted solid-phase reaction sintering method is simple, convenient and fast; the production cost is relatively low; and the Fe-doped visible-light-driven photocatalyst conforms to the actual production requirements, and has a relatively large application prospect.

Owner:FUZHOU UNIV

Method for preparing medium-high vinyl block-free solution-polymerized butylbenzene and product thereof

The invention discloses a method for preparing medium-high vinyl block-free solution-polymerized butylbenzene and a product thereof. The method mainly comprises the following steps of: A, undergoing a polymerization reaction on a vinyl aromatic hydrocarbon and an insufficient reacting dose of conjugated diene; and B, continually reacting the remaining reacting dose of conjugated diene. In a medium-high vinyl block-free solution-polymerized butylbenzene product, the content of a styrol block is zero, and the content of the vinyl is between 25 percent and 60 percent. In the method, n-butyl lithium is taken as an initiator for anionic polymerization, a compound product of alkyl tetrahydrofurfuryl ether and sodium alkyl benzene sulfonate is taken as a structure modifier, the alkyl tetrahydrofurfuryl ether can effectively adjust the content of vinyl in the product, the sodium alkyl benzene sulfonate can always keep high reaction activity, and further tail end functionalization is promoted; and high-temperature continuous polymerization is adopted, so that the produce efficiency of the product can be increased, and the product with wide molecular weight distribution can be produced; and the styrol block in the product is eliminated through stepwise reaction, so that practical requirements on production can be met.

Owner:周铁生

Ethylene-propylene-diene monomer material used for electric wire and preparation method of ethylene-propylene-diene monomer material

ActiveCN104448664AHigh strengthGood anti-aging performanceRubber insulatorsSodium stearateEthylene-propylene-diene-monomer

The invention relates to an ethylene-propylene-diene monomer material used for an electric wire and a preparation method of the ethylene-propylene-diene monomer material. The ethylene-propylene-diene monomer material comprises the following components in parts by weight: 85-115 parts of an ethylene-propylene-diene monomer, 2.5-10 parts of acrylic acid, 1.5-7 parts of sodium stearate, 1.5-6 parts of an initiator, 2.5-8 parts of an antiager, 0.5-1.5 parts of an inorganic filler and 1-2 parts of a fire retardant. According to the preparation method, a mixture is added to a double-screw extruder to carry out extrusion pelleting. The ethylene-propylene-diene monomer material used for the electric wire is high in strength, good in anti-aging, good in flame retardant property, stable in power supply property and convenient to process.

Owner:JIANGSU LONG E CABLE

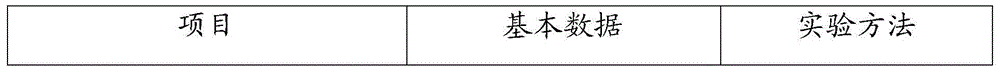

Butenedioic acid resin, preparation method thereof, and preparation of aluminum-casted crystallizer demoulding oil therewith

The invention provides butenedioic acid resin, a preparation method thereof, and preparation of a degradable micro-scale lubricant therewith. The butenedioic acid resin is characterized by being prepared from following raw materials: butenedioic acid or butenedioic acid anhydride and fatty alcohol, wherein the molar ratio of the butenedioic acid or the butenedioic acid anhydride to the fatty alcohol is 1:1.9-2. Raw materials for preparing aluminum-casted crystallizer demoulding oil include the butenedioic acid resin. The aluminum-casted crystallizer demoulding oil is stable, is uniform in dispersion and is low in kinematic viscosity.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

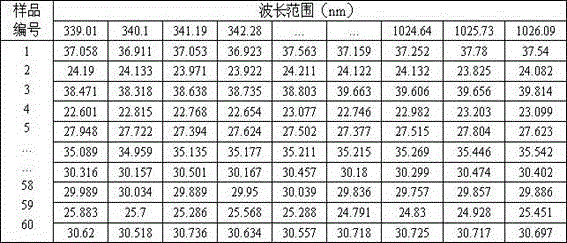

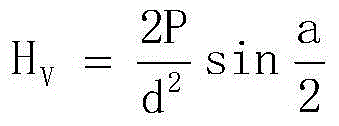

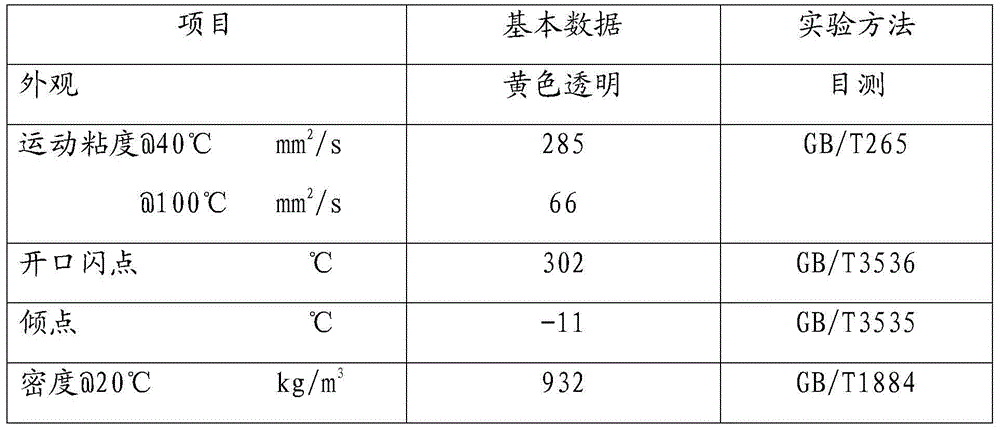

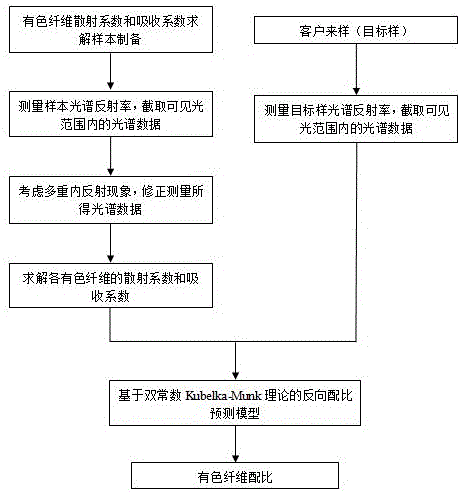

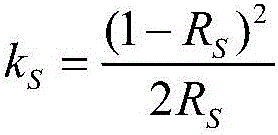

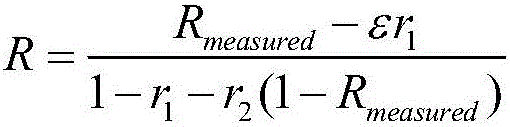

Colored fiber mixed color matching method based on double-constant Kubelka-Munk theory

InactiveCN106469258AImprove the accuracy of ratio predictionEasy to implementFibre mixingScattering properties measurementsFiberComputer science

The invention relates to a colored fiber mixed color matching method based on the double-constant Kubelka-Munk theory and belongs to the technical field of dyed spinning. The method includes the steps that a colored fiber scattering coefficient and absorption coefficient solving sample is prepared; sample spectral reflectance is measured, and visible spectral data is intercepted; multiple internal reflection correction is conducted on actually measured spectral reflectance data; a colored fiber scattering coefficient and an absorption coefficient are solved; target spectral reflectance is measured, and visible spectral data is intercepted; ratio prediction of colored fibers matched with target colors is conducted. By means of the method, an ideal ratio prediction result can be obtained on the premise hat the number of samples is reduced, implementation is convenient, and the method is high in practicality in the field of dyed-spun colored fiber mixed color matching.

Owner:WUHAN UNIV

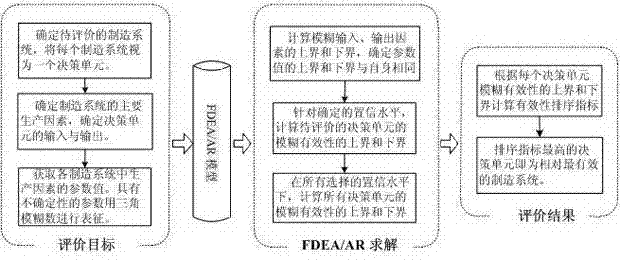

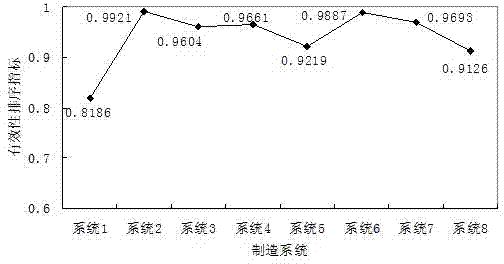

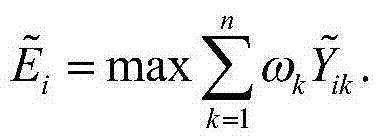

Manufacturing system comprehensive evaluation method based on improved data envelopment analysis

InactiveCN104123447AMeet the actual production requirementsEnsure objectivitySpecial data processing applicationsDomain modelFuzzy data envelopment analysis

The invention discloses a manufacturing system comprehensive evaluation method based on improved data envelopment analysis. On the basis of a traditional data envelopment analysis model, uncertainty and fuzziness of production factors in a complex manufacturing system are taken into account, triangular fuzzy numbers are introduced to represent the production factors, and a fuzzy data envelopment analysis and evaluation model is built. In order to avoid the situation that certain input / output factors are depended on excessively or neglected during the manufacturing system evaluation process, the concept of a guarantee domain is introduced into the model, as a result, it is guaranteed that the weight values of all the production factors are within a reasonable range, and a fuzzy data envelopment analysis / guarantee domain model is built. An alpha cut set is introduced to calculate the upper bound and the lower bound of manufacturing system fuzzy effectiveness, a sorting method is disclosed to sort the upper bound and the lower bound, and it is the most effective manufacturing system that has the highest ordering index. The manufacturing system comprehensive evaluation method based on improved data envelopment analysis breaks the restraint of constant returns to scale in the production process of the manufacturing system, and has practical significance in actual production systems.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

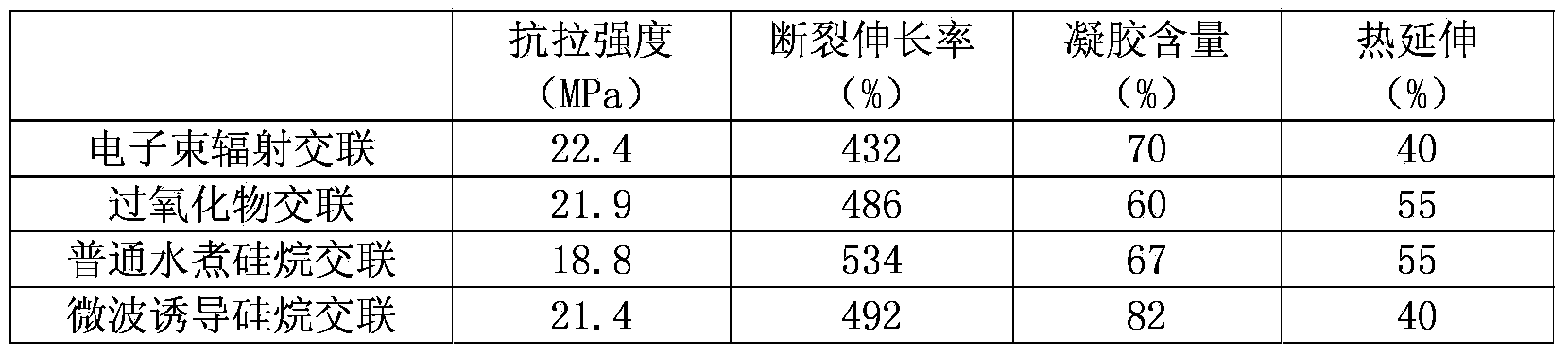

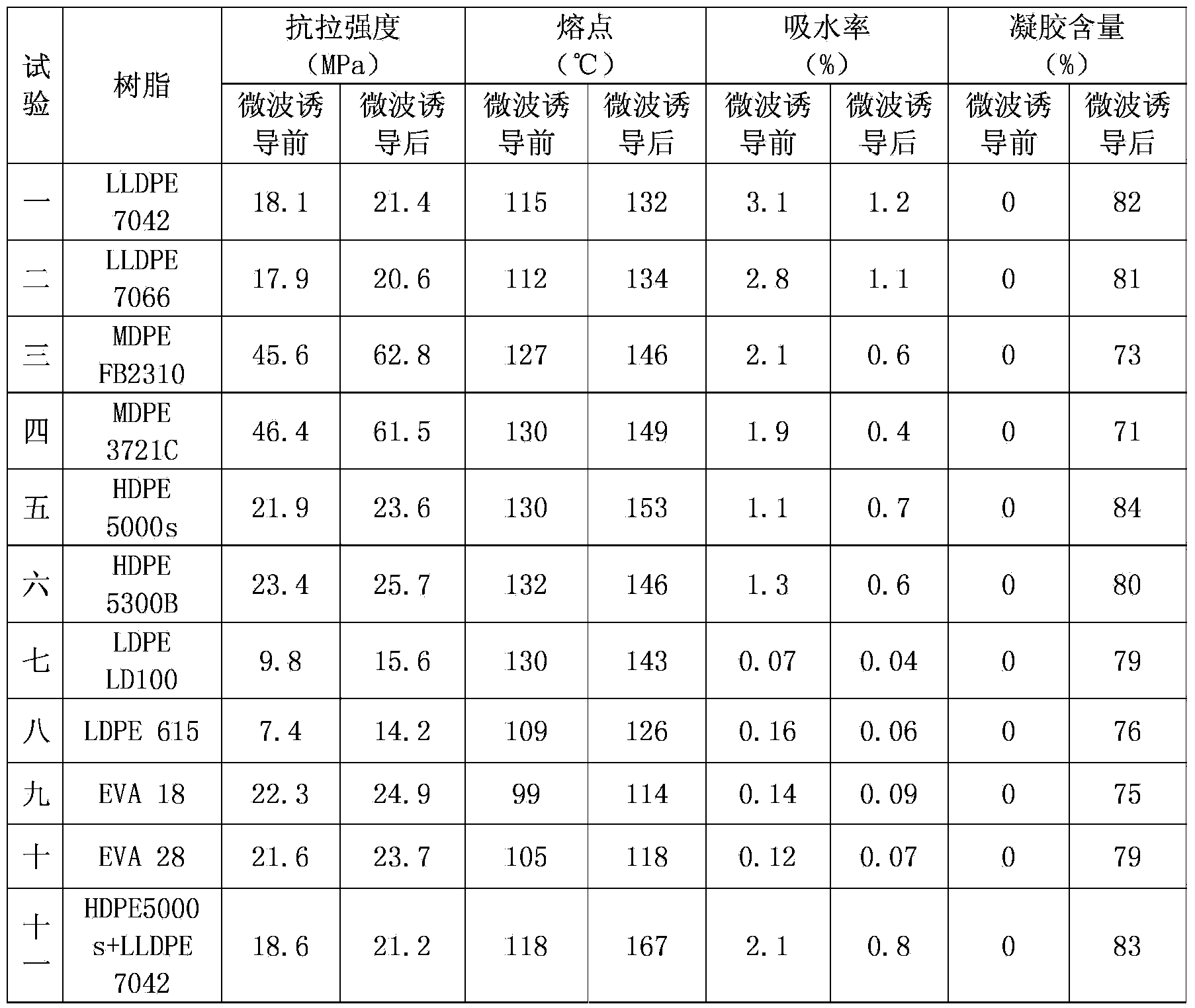

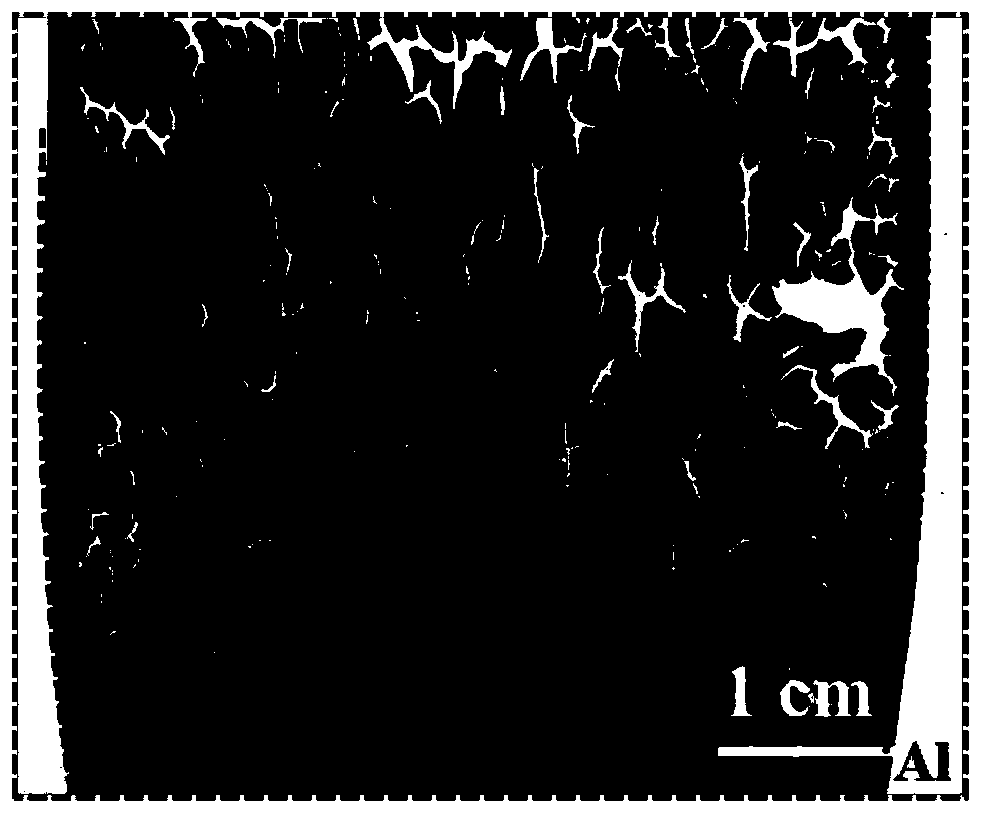

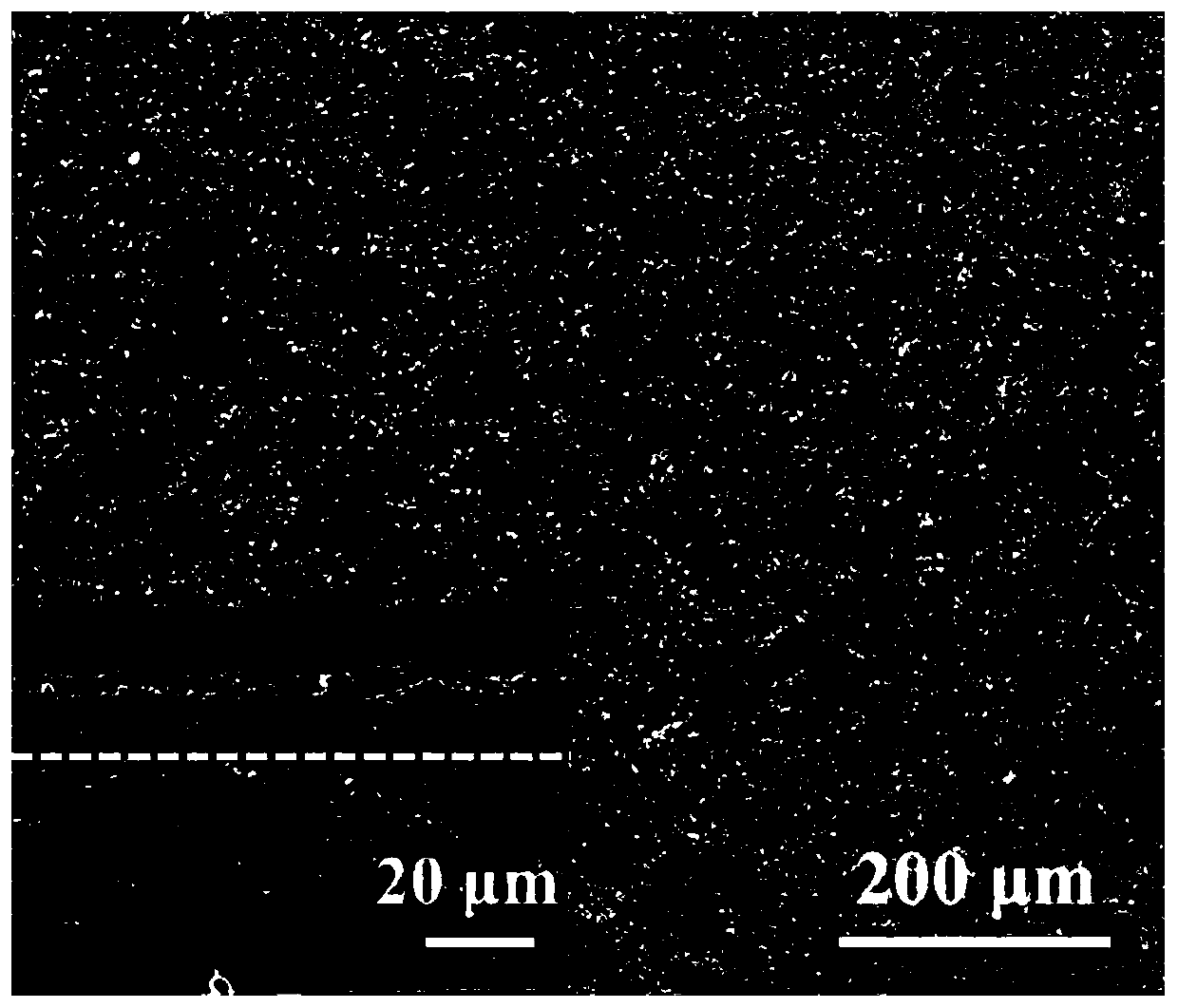

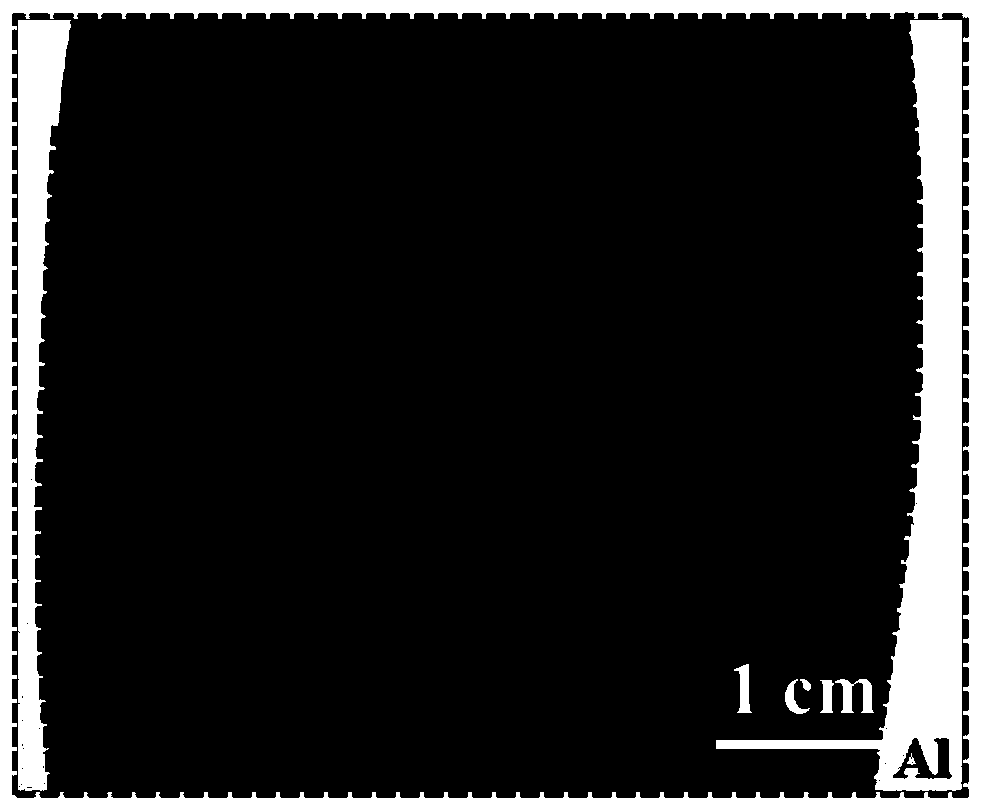

Microwave induced crosslinking polyolefin insulation material and preparation method thereof

InactiveCN103435896ALittle influence on mechanical and physical propertiesImprove mechanical propertiesHeat deflection temperaturePolymer science

The invention relates to a microwave induced crosslinking polyolefin insulation material and a preparation method thereof. The invention aims to solve the problems of low strength, low heat-deformation temperature and low solvent resistance in the common polyolefin material, and the problems of complex technique, harsh protecting requirements, low production efficiency, high product cost and poor stability in the existing crosslinking method. The microwave induced crosslinking polyolefin insulation material provided by the invention is prepared from dry polyolefin resin, silane coupling agent, microwave absorber, water bringing agent, polyfunctional group crosslinking agent, crosslinking accelerator and antioxidant. The preparation method comprises the following steps: 1. weighing the components; 2 banburying the components in a Banbury mixer, melting and mixing, and granulating in a single screw extruder to obtain sample granules; and 3. tabletting the obtained sample granules in a vulcanizer, and carrying out microwave induced crosslinking reaction in microwave equipment to obtain the microwave induced crosslinking polyolefin insulation material. The invention is applicable to the fields of wire cable insulation, polyolefin boards and tube products.

Owner:HONGLONGJIANG ORIENT SCI & TECH

Preparation method of lithium-sulfur battery positive electrode

InactiveCN110752349AHigh specific capacityAvoid local agglomeration of materialsElectrode manufacturing processesLi-accumulatorsElectrical batteryElectrically conductive

The invention provides a preparation method of a lithium-sulfur battery positive electrode. The preparation method comprises the following steps: uniformly mixing an active substance sulfur, a conductive agent and a binder to obtain a mixture, then adding a dispersing solvent into the mixture, and uniformly mixing to obtain electrode slurry; uniformly coating a positive electrode current collectorwith the electrode slurry to obtain a wet electrode coated with the slurry; freezing the wet electrode coated with the slurry in a low-temperature environment of -80 to -5 DEG C for 1-5 hours until the wet electrode is frozen and formed, so that the dispersing solvent in the wet electrode is solidified and crystallized to obtain a solidified electrode; placing the solidified electrode in a vacuumenvironment with the vacuum degree of 0.1-100Pa for 1-5 hours, so that solid-phase sublimation of ice crystals in the solidified electrode is carried out to obtain a solid-phase sublimated electrode;and carrying out rolling treatment on the solid-phase sublimated electrode, and controlling the porosity of the electrode to be 50-70% to obtain the lithium-sulfur battery positive electrode. The preparation method is simple, and the problem of electrode cracking in the preparation of a high-sulfur-carrying positive electrode by adopting a traditional hot drying method is effectively solved.

Owner:TONGJI UNIV

Chain plate material for pipeline chain plate conveyor

The invention relates to a chain plate material for a pipeline chain plate conveyor. The chain plate material for the pipeline chain plate conveyor is prepared from the components in parts by weight:67-90 parts of alloy steel, 20-35 parts of manganese, 5-11 parts of silicon carbide, 4-10 parts of zinc fluoride, 1-3 parts of magnesium fiber filaments with 1-5 mesh and 1-2 parts of mineral castinggrains. The chain plate material for the pipeline chain plate conveyor is excellent in performance, high in strength, high in wear resistance and easy to process.

Owner:宜兴市乐华冶金辅助材料有限公司

Method for preparing work layer on surface of process roller of cold rolling unit

InactiveCN101798685AMeet the actual production requirementsExtended service lifeMolten spray coatingLiquid/solution decomposition chemical coatingChemical platingMetallic Nickel

The invention discloses a method for preparing a work layer on the surface of a process roller of a cold rolling unit, which comprises the thermal spraying of a metal ceramic coating on the surface of the process roller. The method comprises the following steps: firstly, cleaning and activating a thermal spraying coating on the surface of the process roller; secondly, chemically plating a Ni-P layer, wherein chemical plating solution comprises 30g / l of nickel sulfate, 25g / l of sodium hypophosphite, 15ppm of activator, 5g / l of accelerator, 10g / l of lactic acid and 15g / l of citric acid; thirdly, immersing the process roller into the plating solution, wherein the temperature of the plating solution is between 80 and 100 DEG C, the nickel content is 88 to 92 percent, and the phosphorus content is 8 to 12 percent; and finally, when the thickness of the chemical plating layer reaches 0.01 to 0.02mm, stopping the chemical plating, performing thermal treatment at the temperature of between 50 and 450 DEG C, and preserving the heat for 0.5 to 5 hours. The work layer on the surface of the process roller prepared by the method has abrasion resistance, impact resistance, roughness retention capacity and excellent anti-adhesion performance, meets the operating requirement of long term and stability of the process roller, and prolongs the service life of the process roller.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

Method for preparing cold-rolled titanium roll with high surface roughness

ActiveCN110560482AImprove surface roughnessEasy accessRollsWork cleaning devicesEmulsionSurface roughness

The invention provides a method for preparing a cold-rolled titanium roll with high surface roughness. The method comprises the steps that a raw material titanium roll is rolled on a cold-rolling millthrough a cold-rolling working roller first, so that the raw material titanium roll is rolled to a target thickness, and a thickness allowance is reserved; the rolled raw material titanium roll is subjected to degreasing treatment and cover annealing, so that a non-roughened titanium roll is obtained; then, the non-roughened titanium roll is subjected to roughening rolling through a laser roughening roller, wherein the unit tension for roughening rolling is controlled to 2.5kg / mm<2>-10.5kg / mm<2>; an emulsion is added in the roughening rolling process, wherein the rolling force and the flow ofthe emulsion are controlled according to the yield strength of the titanium roll; the non-roughened titanium roll is rolled to a target thickness through 1-3 passes of rolling, so that a roughened titanium roll is obtained, wherein the adopted laser roughening roller is a roughening roller obtained after the cold-rolling working roller is subjected to disordered laser roughening treatment; and the roughened titanium roller is subjected to degreasing treatment, so that the cold-rolled titanium roll with the surface roughness of 1-3 [mu]m is obtained. By adoption of the method, the cold-rolledtitanium roll with high surface roughness can be directly obtained when a titanium roll is rolled, and actual production requirements can be met.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Preparation method of water-soluble chitosan-oligosaccharide

InactiveCN102786607AControl weight average molecular weightControl the degree of degradation reactionHydrolysateWater soluble

A preparation method of water-soluble chitosan-oligosaccharide comprises the following steps: (1) dissolving chitosan in an acetic acid solution to prepare a chitosan acetic acid solution with a concentration of 2.0-4.0 g / ml; (2) heating to 55-65 DEG C, adding a 1-5% H2O2 solution according to a molar ratio of the chitosan to hydrogen peroxide of 1:1.5-1:2.5, adjusting the pH to be 5.5-6.5, continuously stirring for hydrolyzation to obtain a hydrolysate; (3) sampling, adding strong alkali liquor till no flocculent precipitate is generated so as to determine the hydrolysate; (4) continuously performing hydrolyzation for not more than 2 hours; (5) adding a degradation reaction terminator to obtain a preliminary product; (6) processing the preliminary product by a spray-drying process to obtain the water-soluble chitosan-oligosaccharide. Compared with the prior art, the invention has the advantages that: the degradation reaction terminator is used for controlling the degree of the degradation reaction so as to control the weight average molecular weight of the obtained chitosan-oligosaccharide; real production requirements are met; and large scale production requirements are met.

Owner:ZHEJIANG OCEAN UNIV

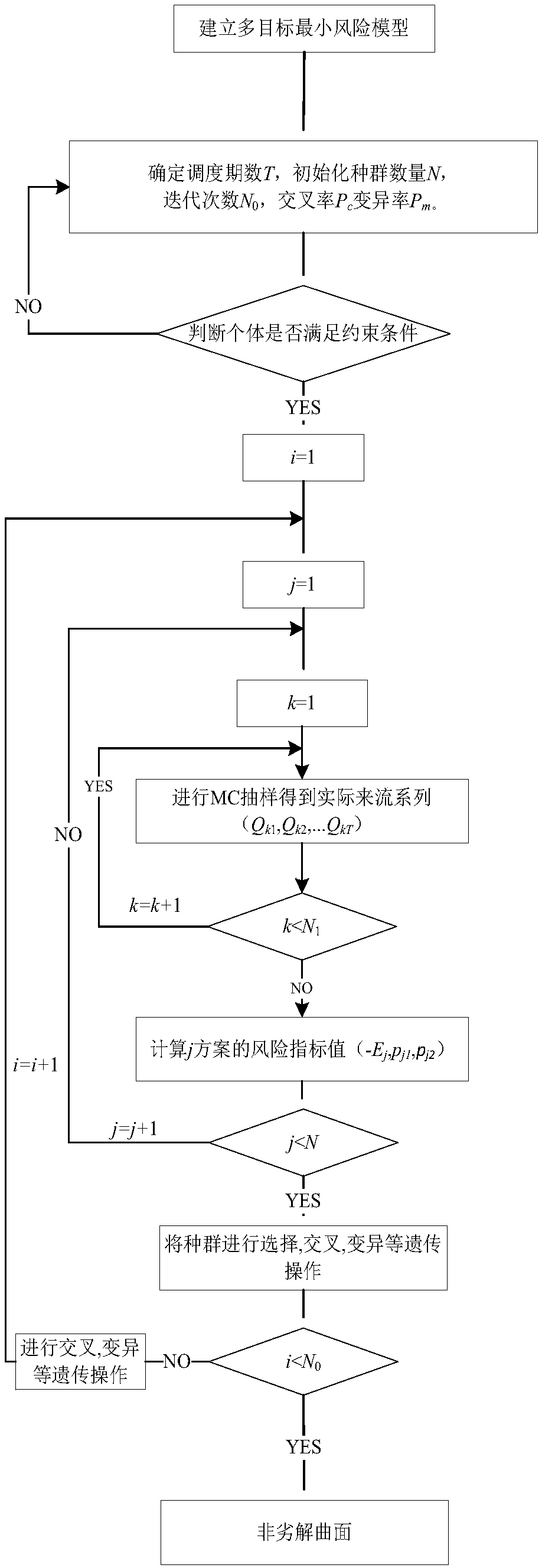

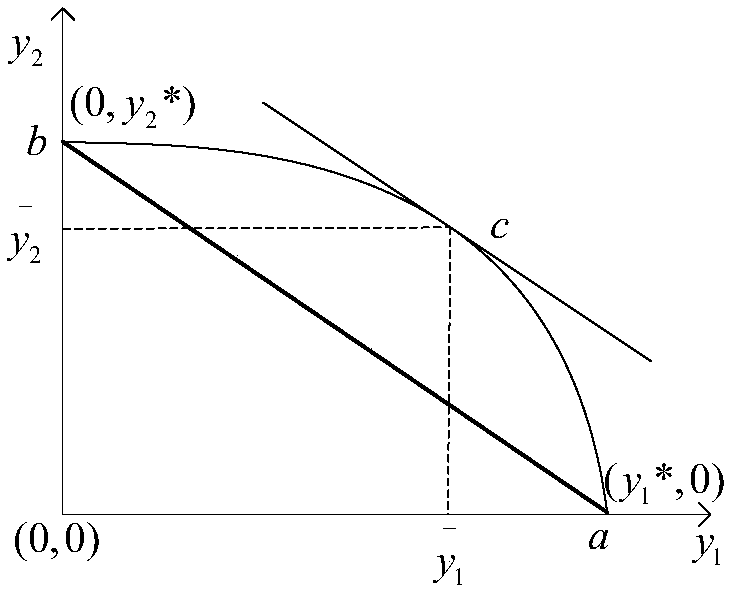

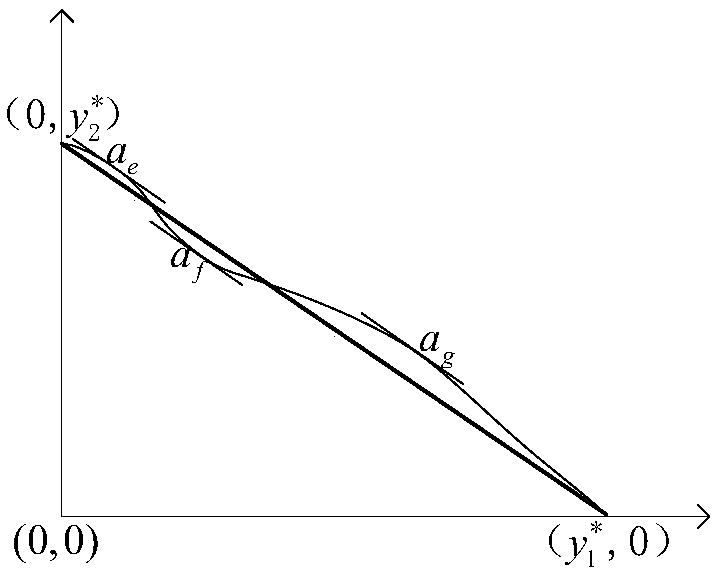

Method for obtaining reservoir group multi-objective scheduling risk analysis optimal equilibrium solution

InactiveCN107392460ASimple methodImprove portabilityArtificial lifeResourcesRisk profilingRisk model

The invention discloses a method for obtaining a reservoir group multi-objective scheduling risk analysis optimal equilibrium solution. The method comprises the acquisition of a multi-objective scheduling risk analysis noninferior solution, the calculation of a uniformity rate decision method of multi-objective scheduling risk analysis, and the calculation of a risk and benefit conversion relation and a threshold determination process in multi-objective scheduling. In the acquisition of the multi-objective scheduling risk analysis noninferior solution, firstly a cascade reservoir combined dispatching multi-objective minimum risk model is established, then a scheme is obtained through a selection operation in a genetic algorithm to carry out non-dominated sorting, and through the continuous renewal and elimination of crossover and variation operations in the algorithm, finally a solution curve or curve surface formed by a solution set is outputted. In the calculation process of the uniformity rate decision method of the multi-objective scheduling risk analysis, and based on a uniformity rate, a decision mode of the optimal equilibrium solution is determined. In the process of the calculation of a risk and benefit mutual conversion relation and a threshold determination process in multi-objective scheduling, based on the bifurcation theory, the threshold of a risk and benefit conversion relation between objectives is analyzed and determined.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

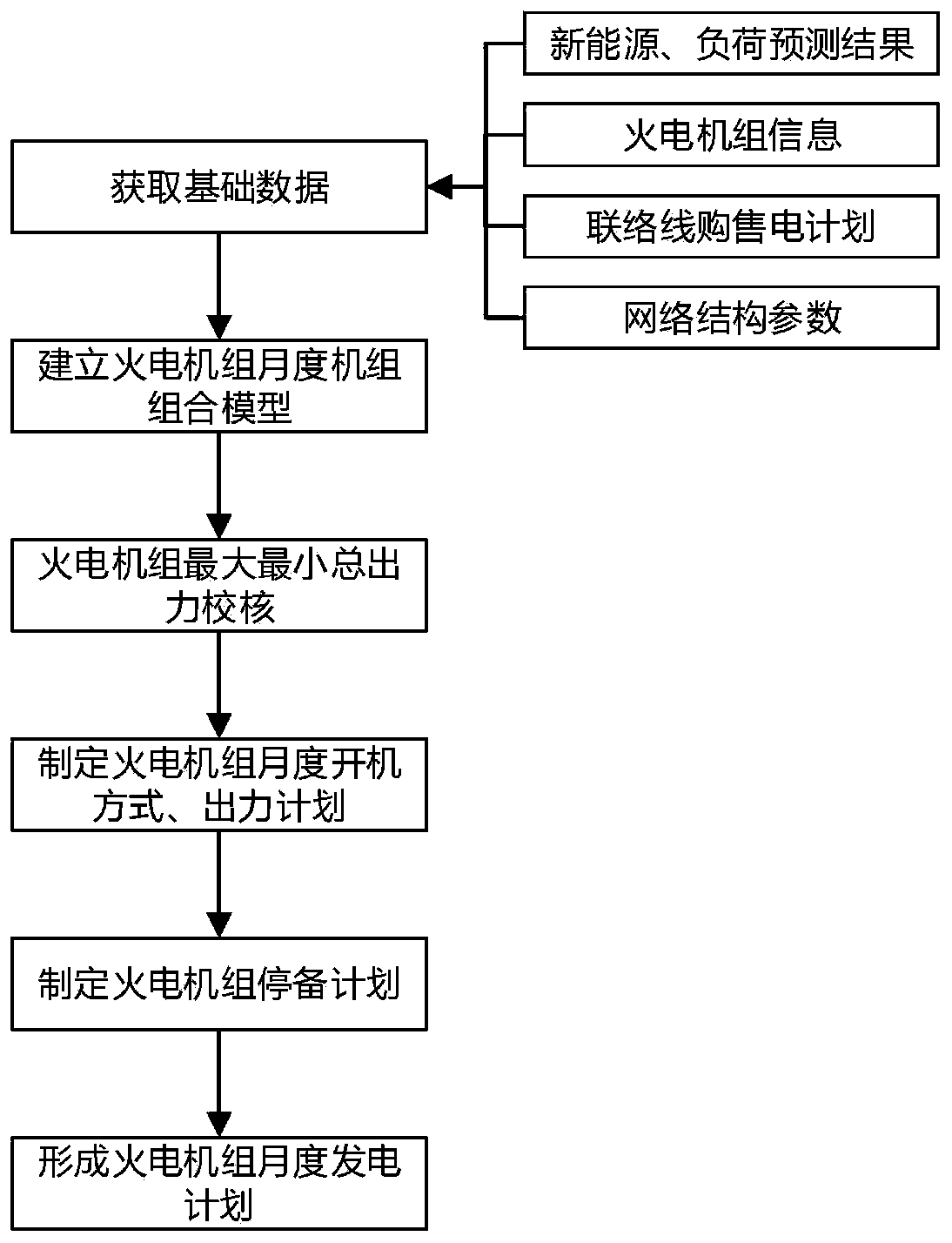

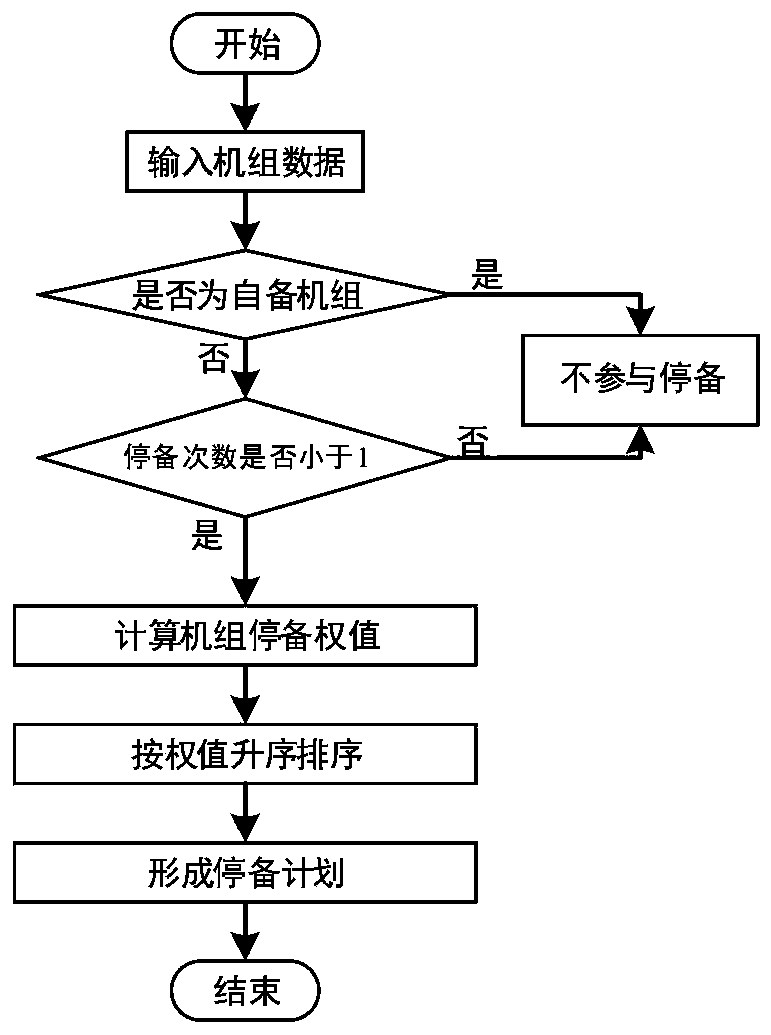

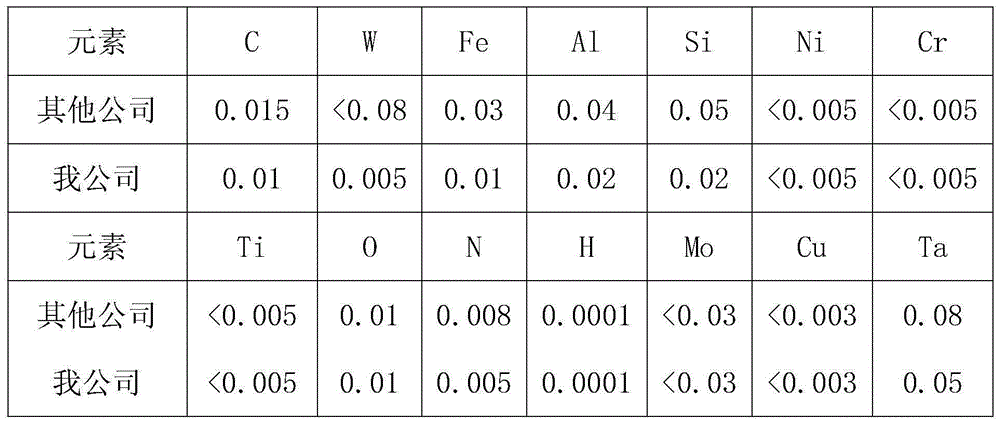

Thermal power generating unit monthly power generation plan optimization method considering new energy access

ActiveCN110826773AReasonable load rateMeet the actual production requirementsForecastingResourcesNew energyControl engineering

The invention provides a thermal power generating unit monthly power generation plan optimization method considering new energy access, and relates to the field of power generation scheduling of a power system. The method comprises the following steps: firstly, acquiring information of each thermal power generating unit in a provincial power system, and establishing a monthly thermal power generating unit combination optimization model; making a monthly startup rule of the thermal power generating unit, and checking the maximum and minimum total output of the thermal power generating unit to obtain a monthly startup plan of the thermal power generating unit; solving the model to obtain a monthly output plan of the thermal power generating unit; optimizing a unit shutdown plan based on a monthly shutdown rule of the thermal power unit; and finally, obtaining a monthly power generation plan optimization scheme of the thermal power generating unit composed of the three plans. According tothe method, the monthly power generation plan meeting the actual engineering requirements can be efficiently calculated, the actual production requirements of power dispatching under tens of thousands of variable levels of provincial power companies are effectively met, and the method has important practical significance.

Owner:INNER MONGOLIA POWER GRP +2

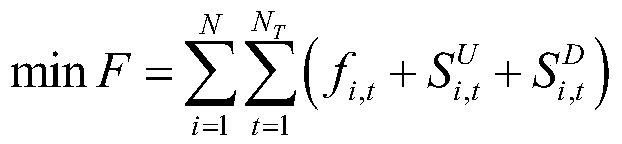

Pure niobium purification process

The invention relates to a pure niobium purification process including the steps of material preparation, material mixing, reduction furnace cleaning, reducing, discharging, crushing, screening, vacuum electron beam furnace cleaning, charging, primary smelting with a vacuum electron beam furnace, primary cooling, secondary smelting with the vacuum electron beam furnace, secondary cooling, discharging, sampling analysis and finished product obtaining. The process is rigorous in steps, the purification efficiency is high, and the purification purity is high.

Owner:江苏圣亚有色金属材料有限公司

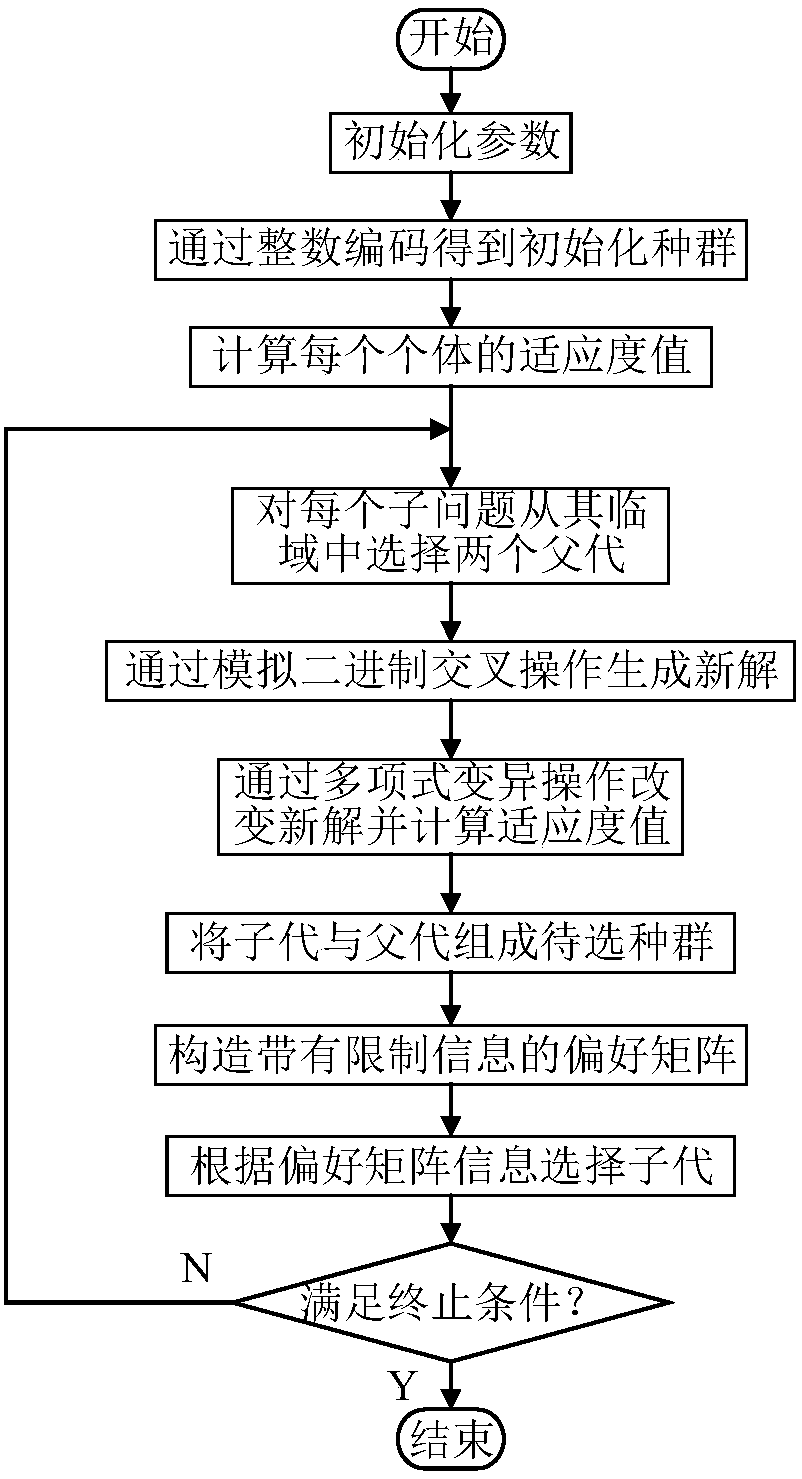

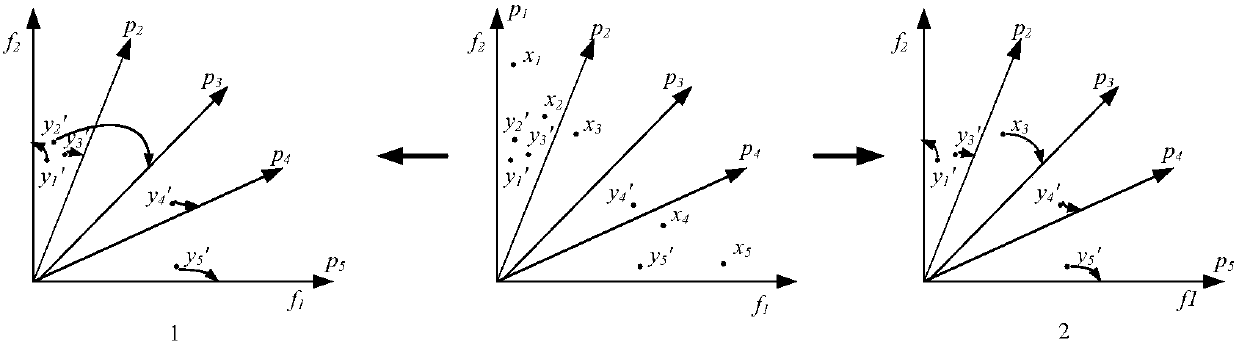

Flexible job-shop scheduling method based on limited stable pairing strategy

ActiveCN108320057AIncrease the probability of being selectedGood varietyProgramme controlMathematical modelsJob shop schedulingJob shop scheduling problem

The invention provides a flexible job-shop scheduling method based on a limited stable pairing strategy, and belongs to the field of job-shop scheduling. The method comprises step of a, generating aninitial chromosome population by integer coding, and initializing related parameters; b, crossing and mutating a parent chromosome to obtain a progeny chromosome; c, constituting a chromosome set withthe progeny chromosome and the parent chromosome, and selecting a next-generation chromosome by a limited stable pairing operation; and d, stopping the algorithm if a cutoff condition is satisfied, otherwise returning to step b. The method solves the multi-objective flexible job-shop scheduling problem by introducing the limited stable pairing strategy into the process of selecting the progeny chromosome, overcomes the insufficient population distribution and insufficient convergence of a conventional multi-objective flexible job-shop scheduling problem solving method, can obtain a better scheduling scheme, good real-time performance and high reliability.

Owner:JIANGNAN UNIV

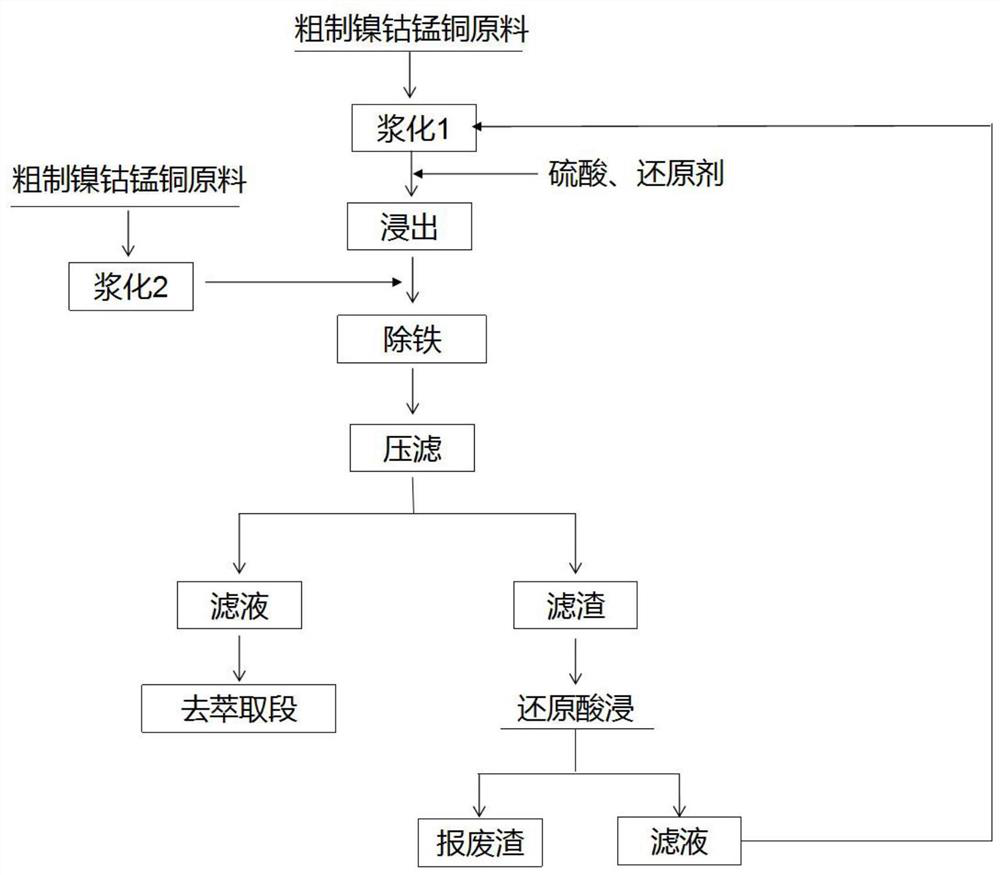

Method for removing iron, aluminum and silicon from nickel-cobalt-manganese-copper solution under normal pressure

ActiveCN112779419AAcid Utilization BreakthroughAvoid enrichmentProcess efficiency improvementSlagManganese

The invention discloses a method for removing iron, aluminum and silicon from a nickel-cobalt-manganese-copper solution under normal pressure. The method comprises the following steps that 1) a rough nickel-cobalt-manganese-copper raw material is taken and mixed with water to form slurry, then acid and a reducing agent are added for leaching, the pH value at the leaching end point is smaller than or equal to 2.5, and the Fe<2+> content is controlled to be proper; (2) after the leaching slurry is subjected to dense separation, supernate and a precipitator are added, in a parallel flow mode, into liquid which contains nickel, cobalt, manganese and copper without iron, aluminum and silicon at the temperature of 70-100 DEG C, and heat preservation is conducted, wherein the precipitator is a rough nickel-cobalt-manganese-copper raw material with the solid content being 1-50%, and the pH value of the liquid without iron, aluminum and silicon ranges from 3.0 to 4.0; and 3) the slurry is subjected to solid-liquid separation, filtrate is as an extraction stock solution, water is added into removed iron-aluminum-silicon slag and leaching slag to prepare slurry with the solid content being smaller than or equal to 50%, acid is added to regulate the pH value to 2.0-3.5, a reducing agent is added to enable the Fe<2+> concentration to be greater than or equal to 0.1g / L, the removed iron-aluminum-silicon slag and the filtrate are obtained after solid-liquid separation, and the filtrate is fed to a leaching section for leaching raw materials. According to the method, auxiliary materials and hazardous chemicals do not need to be used for removing iron, aluminum and silicon, other elements are not introduced either, the purposes of lowering the cost of the auxiliary materials and the salinity of wastewater are achieved, and the sewage treatment pressure is lowered.

Owner:ZHEJIANG HUAYOU COBALT +1

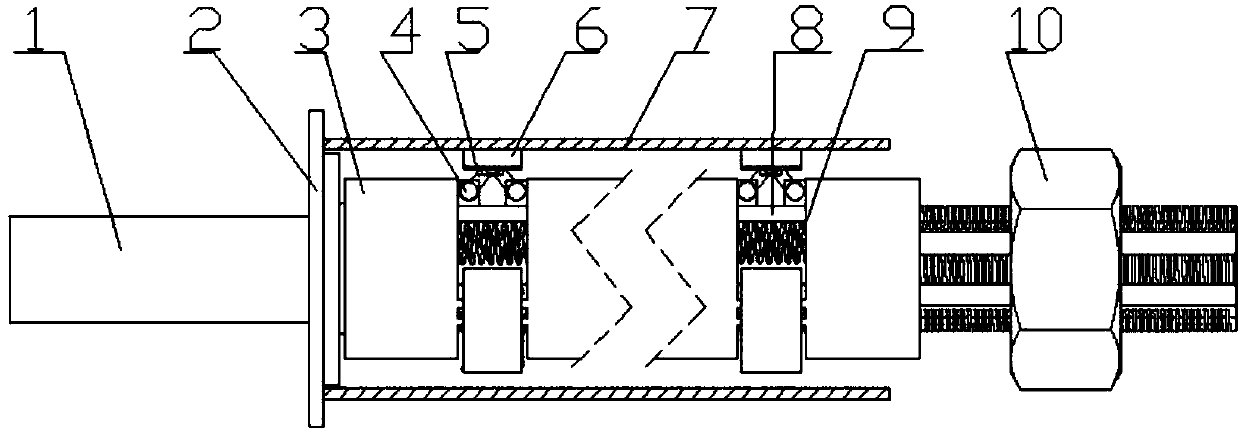

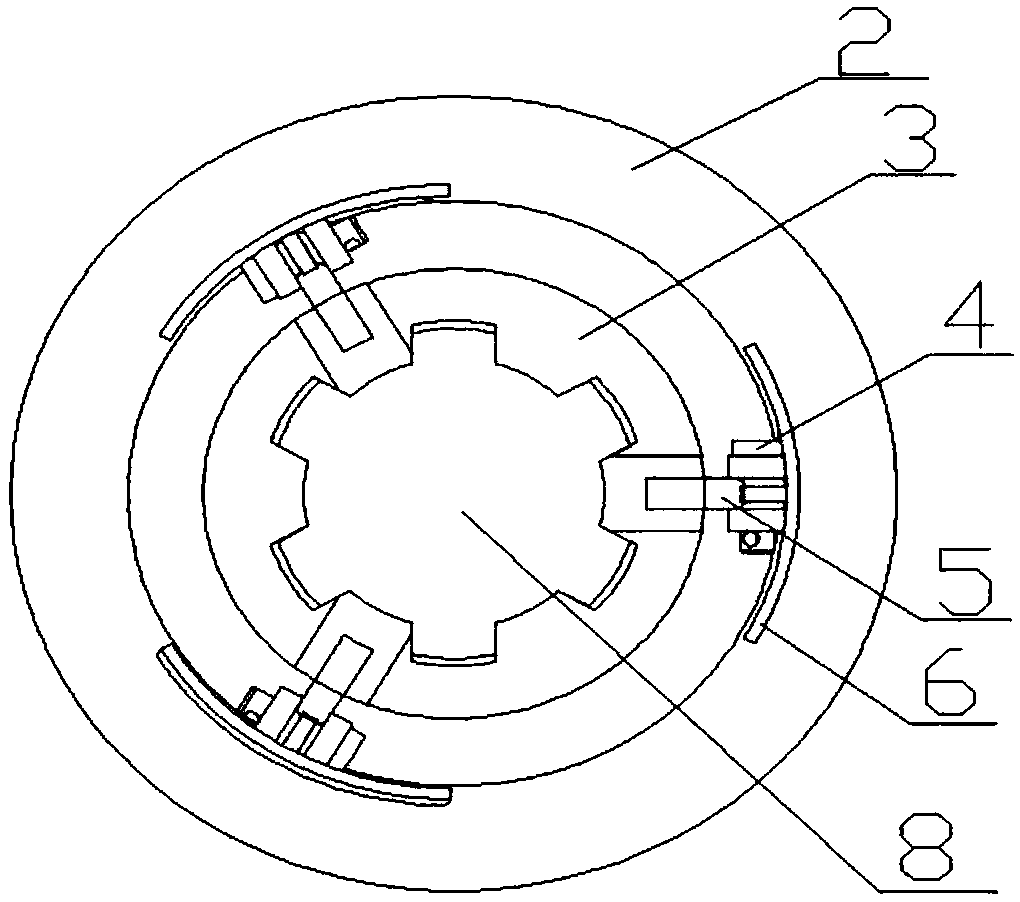

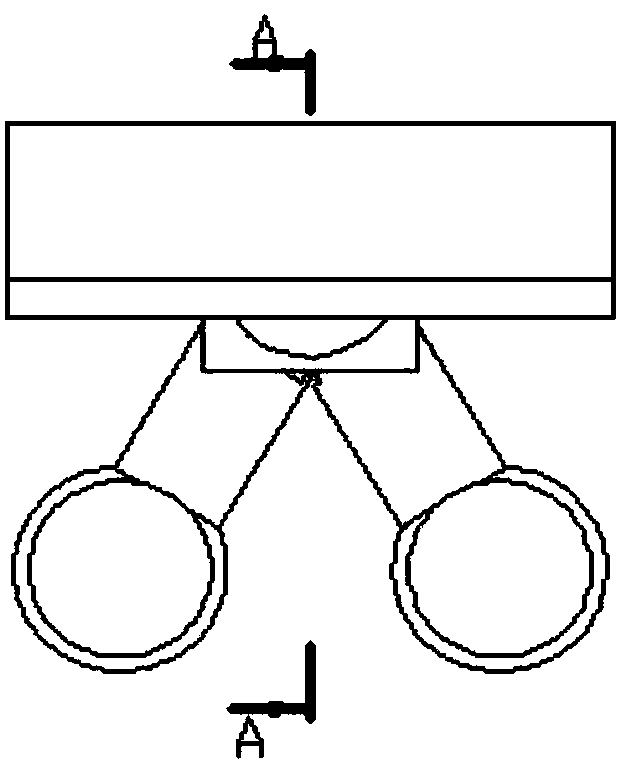

Novel circular tube fixture

PendingCN109513988AHigh degree of automationCompact structureShearing machine accessoriesEngineeringScrew thread

The invention relates to the technical field of machine manufacturing and machining, in particular to the technical field of mechanical circular tube manufacturing and machining fixtures, and discloses a novel circular tube fixture to achieve the technical purpose of providing a fixture which can clamp from the interior of a circular tube to achieve multi-section cutting. The novel circular tube fixture comprises a connecting shaft, a positioning disc, an inner spline, connecting pins, a connecting rod, a friction piece, an outer spline, and a clamping nut. The inner spline is matched with theouter spline. The inner spline is hinged to the connecting rod by the connecting pin. The friction piece is hinged to the connecting rod by the connecting pin. The clamping nut is in threaded fit with the right end of an outer spline shaft. The positioning disc is connected with the left side of the outer spline shaft. The fixture can clamp and position a workpiece, and can achieve multi-sectioncutting of the workpiece. The structure is simple, and universality is high. The fixture is used for cutting cylindrical workpieces. Machining quality and machining efficiency can be greatly improved.The production cost is lowered.

Owner:ZHENGZHOU UNIV

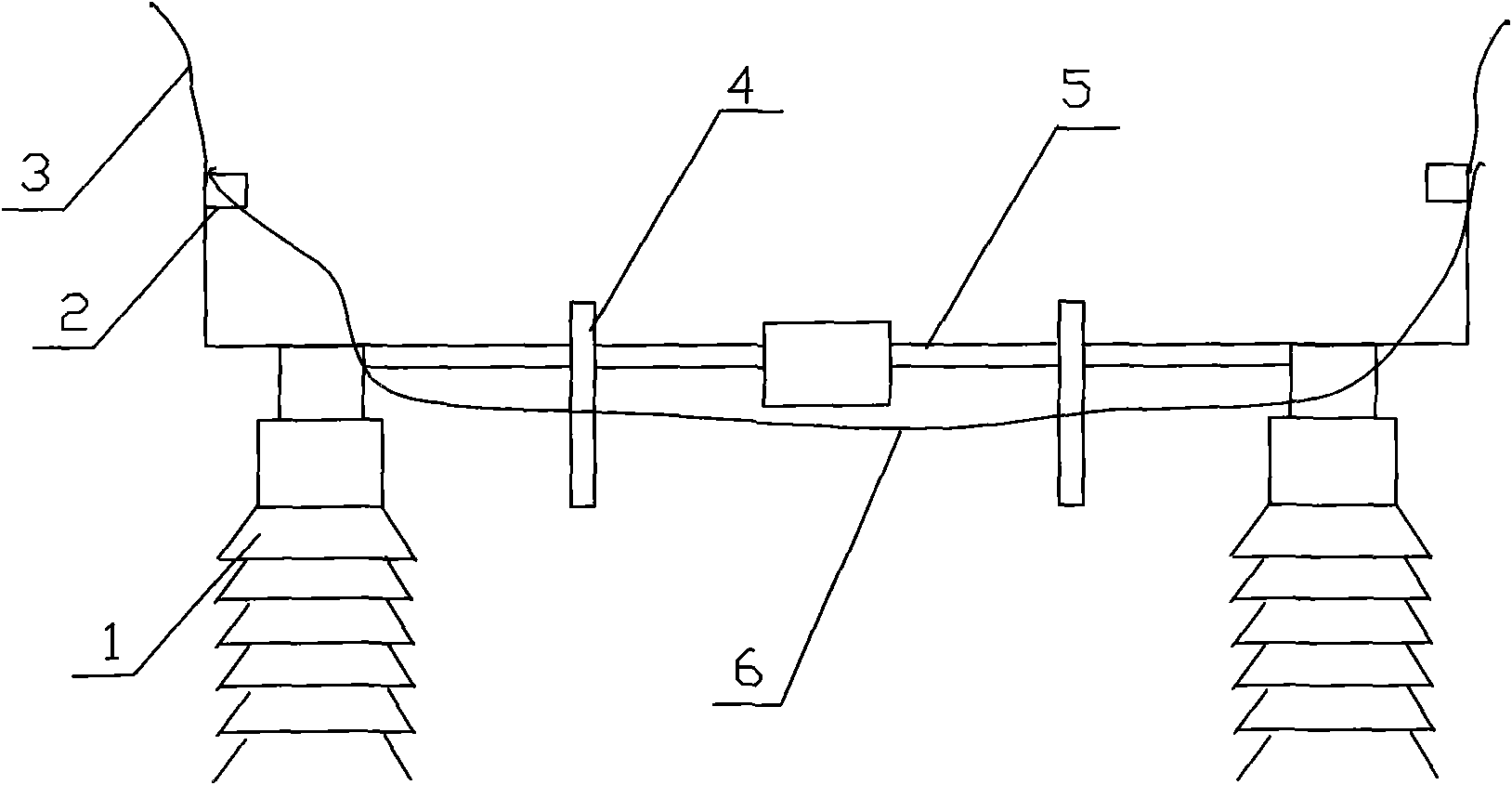

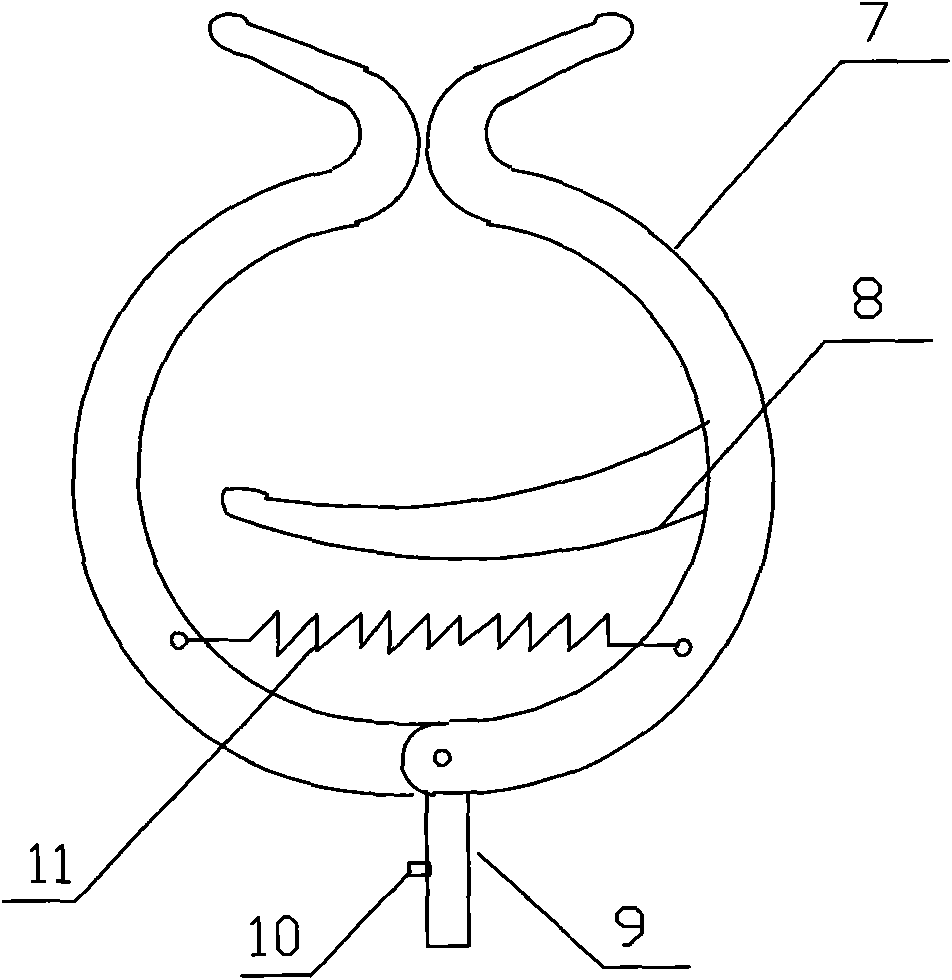

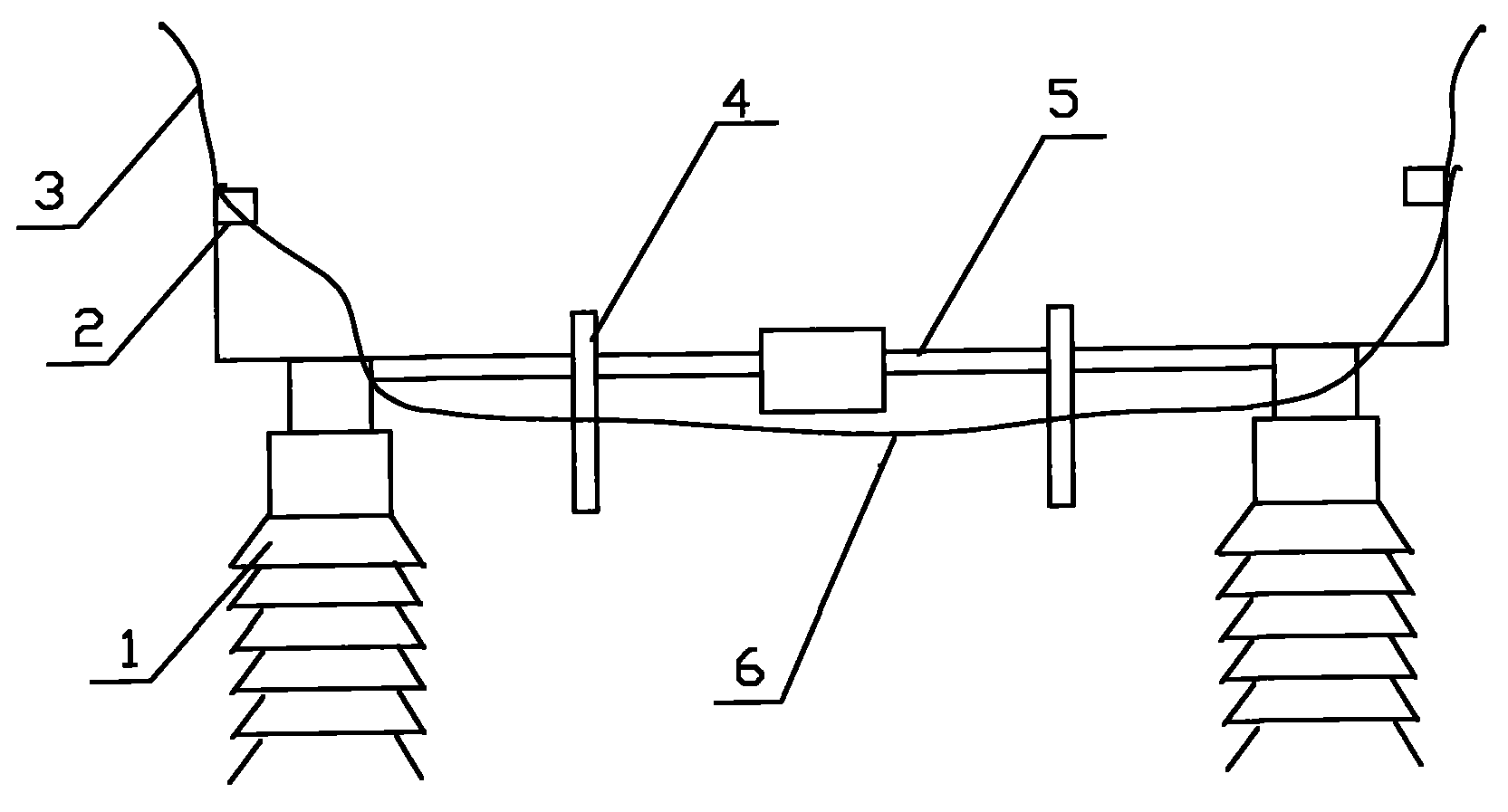

Isolating switch heating-preventing device

ActiveCN102044374AAvoid overheatingMeet the actual production requirementsAir-break switch detailsPower equipmentTemperature control

The invention belongs to the technical field of power equipment units, in particular discloses an isolating switch heating-preventing device composed of a shunt short jumper and 2-4 shunt wire fixing rings, wherein the two ends of the shunt short jumper are respectively provided with a lead wire clamp. By adopting the device, overheating of parts of a conducting loop of an isolating switch can be effectively avoided, and the temperature thereof is controlled to be within the range of normal operation, thus reducing frequency of power cut for repairing and improving power supply reliability, and the device has the advantages of low labour intensity, safety and reliability, simple structure as well as economy and practicability, and is rapid in mounting, convenient to use, easy to implement.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

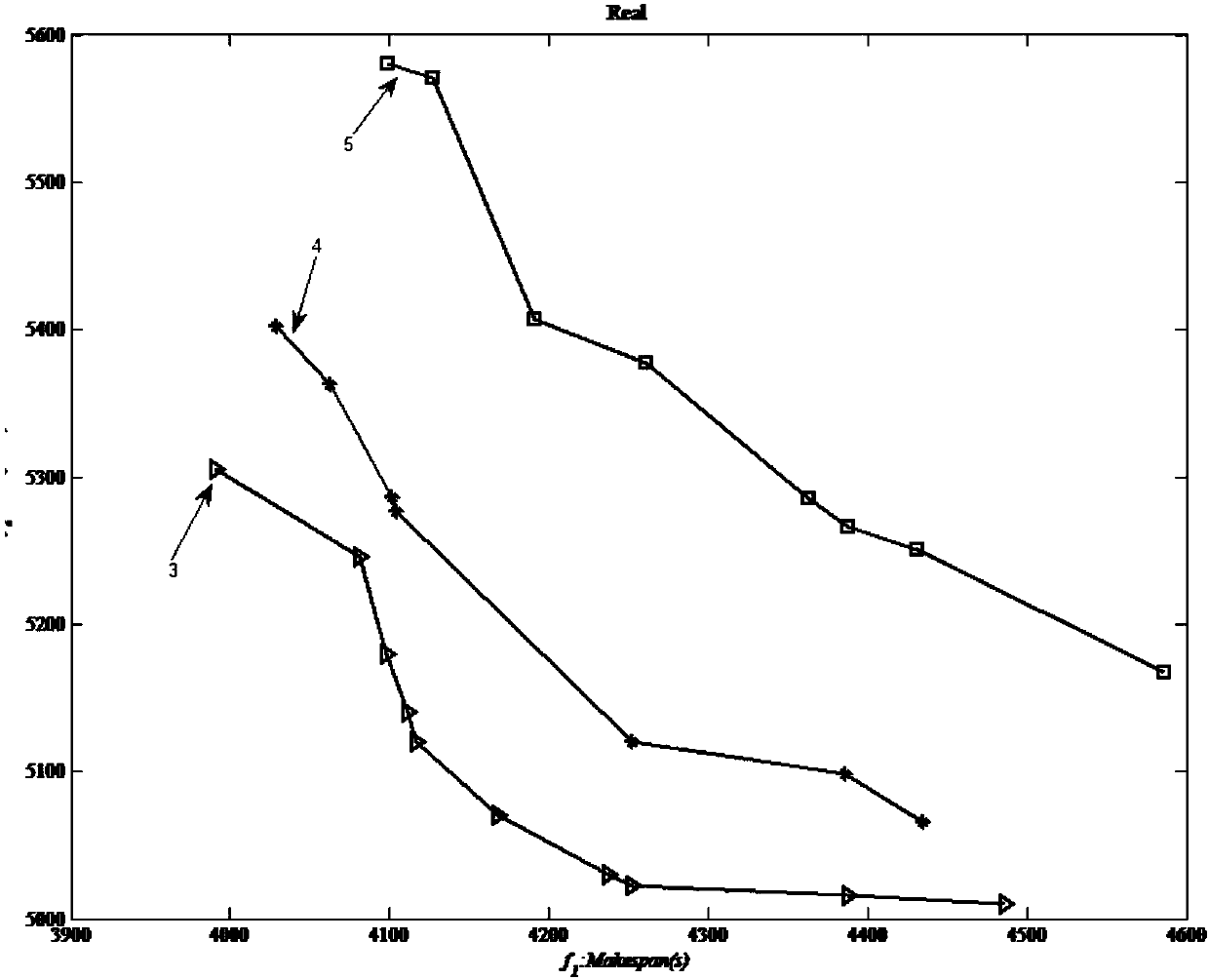

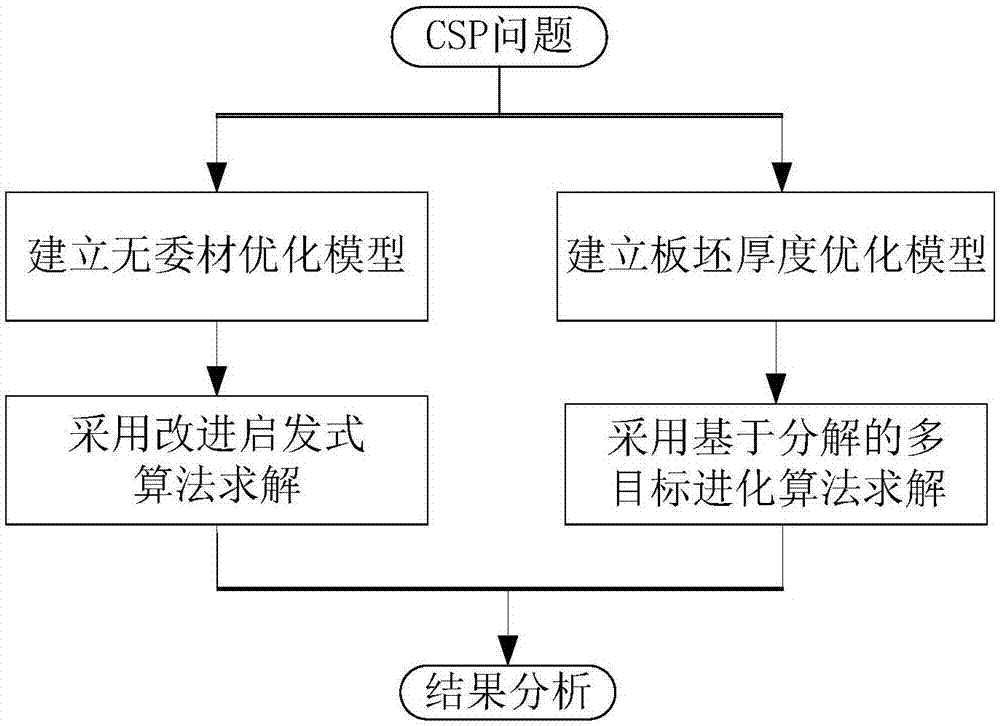

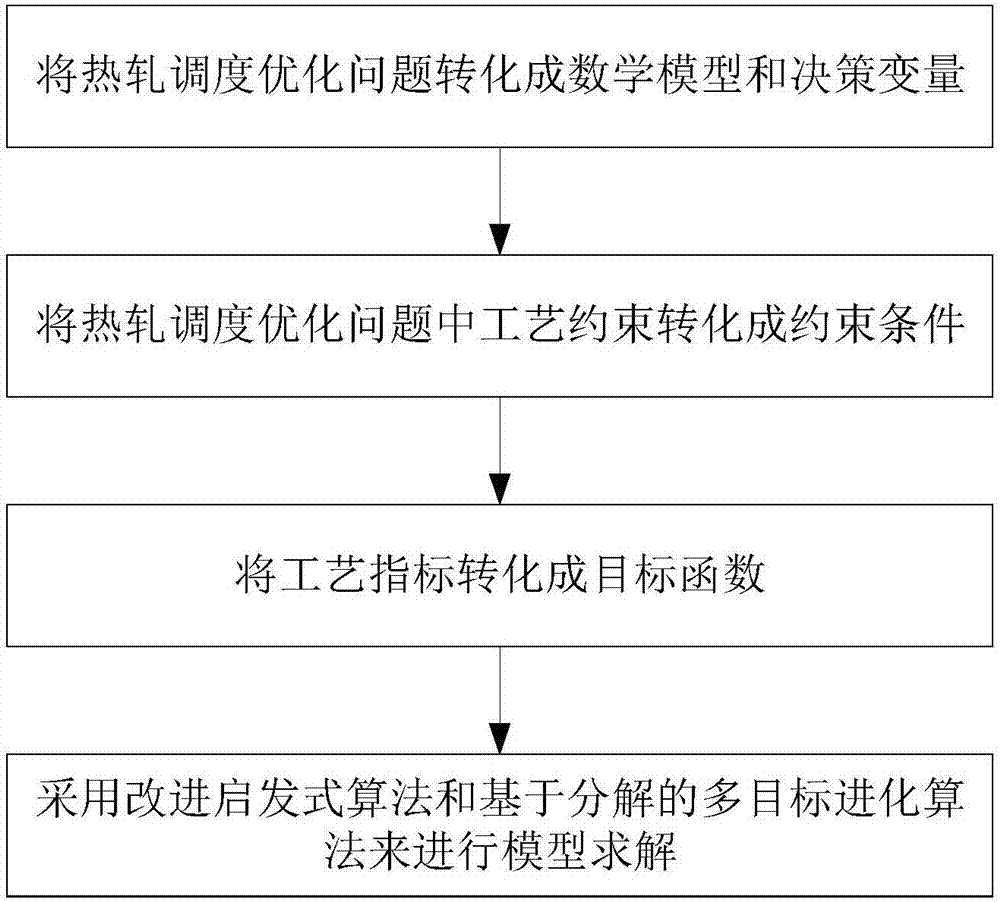

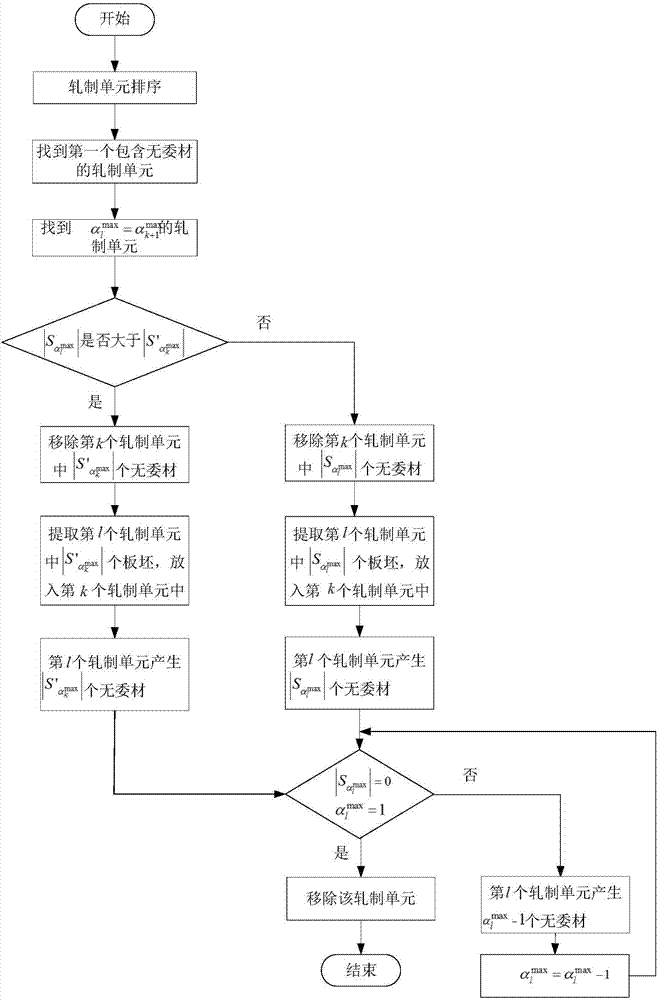

Hot-rolling scheduling method for compact strip production

InactiveCN107256317APursue maximizationReduce manufacturing costDesign optimisation/simulationSpecial data processing applicationsDecompositionMaterials science

The invention discloses a hot-rolling scheduling method for compact strip production. The method comprises the steps of constructing a hot-rolling production scheduling model including a non-outsourcing material optimization model and a plate blank thickness optimizing model with the target of minimizing the quantity of non-outsourcing materials, minimizing the maximum thickness change amount of two adjacent plate blanks in the same rolling unit, and minimizing the changing time of the thickness of the plate blanks; determining the constraint conditions of the non-outsourcing material optimization model and the plate blank thickness optimizing model according to technological constraints in an actual hot-rolling production process; adopting an improved heuristic algorithm to solve the non-outsourcing material optimization model to obtain the quantity of optimal rolling units and the quantity of the non-outsourcing materials; adopting a multi-objective evolutionary algorithm based on decomposition to solve the plate blank thickness optimizing model to obtain the optimal change value of the thicknesses of adjacent plate blanks and the optimal thickness changing time. According to the comparison between a scheduling plan obtained through the hot-rolling scheduling method and a production plan which is worked out manually, the plate blank specification skip cost and roll replacement cost can be effectively reduced, and thus the production cost is lowered.

Owner:HUAZHONG UNIV OF SCI & TECH

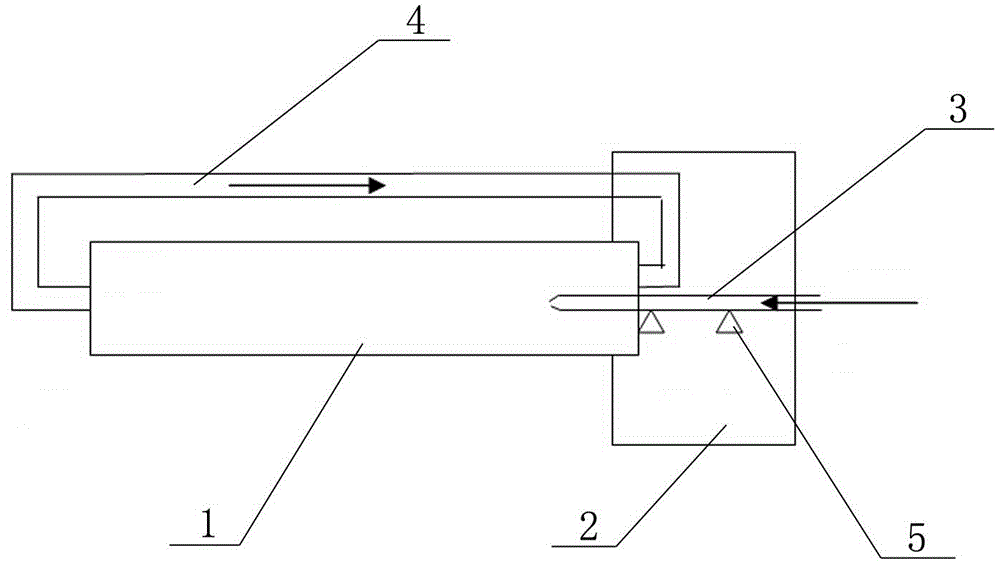

Preparation method and device for rapidly-activated active coke

InactiveCN104386689AReasonable designReduce energy consumptionCarbon compoundsEnergy inputCombustion chamberCarbonization

The invention provides a preparation method and device for rapidly-activated active coke and particularly provides a preparation method of rapidly-activated active coke. The preparation method comprises the following steps of firstly, improving the existing rotary furnace for carbonization as follows: a, additionally arranging a steam pipeline in the furnace, namely necking a pipe head of a 310S stainless steel pipe with the pipe head of DN50 to DN15, inserting the stainless steel pipe from a combustion chamber at the head of the furnace to a discharging hole formed in the head of the furnace, and carrying out two-point support on the middle of the stainless steel pipe by using 310S angle iron; b, conveying combustible substances released by low-temperature carbonization of raw materials in a furnace body in the carbonization process from the tail to the head of the furnace through an underground flue by virtue of an injection pump so as to combust and furthermore increase the carbonization temperatures of the raw materials at the head of the furnace from 650 DEG C to 850 DEG C; and then, introducing steam from a waste heat boiler to the steam pipeline, conveying the steam to the discharging hole formed in the head of the furnace to carry out activating treatment on the raw materials for 15 minutes, and next, discharging. The invention provides a carbonization and activation integrated preparation technology for active coke, which is favorable in market application prospect.

Owner:SHANXI XINHUA CHEM

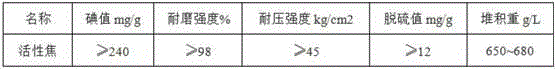

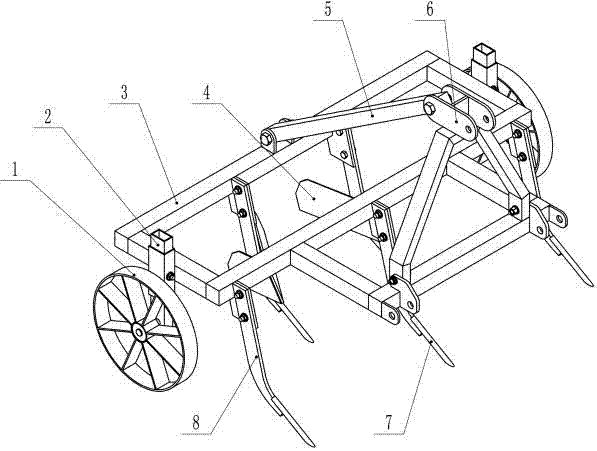

Soil loosing ridging machine

PendingCN107960165ASimple structureMeet the actual production requirementsSpadesPloughsSoil scienceStructural engineering

Provided is a soil loosing ridging machine. The ridging machine comprises a machine frame and a suspension frame, the suspension frame is arranged at the front end of the machine frame, depth limitingwheels are arranged on two sides of the middle of the machine frame, a plurality of shovels are arranged at the lower portions of the front and rear parts of the machine frame, soil loosing ridging shovels are arranged on the shovels arranged at the lower portion of the rear part of the machine frame, and two adjacent soil loosing ridging shovels cooperate to turn soil to form a ridge surface. According to the soil loosing ridging machine, soil loosing is conducted by using staggered shovel tips and handles arranged from front to back, the shovel tips in a front row can loosen soil in furrows, the shovel tips arranged on a rear row cooperate with the soil loosing shovels to turn the soil to form the ridge surface, furrows are formed by the soil loosened by the shovel tips arranged on thefront row, and the shovel tips can loose the soil in the furrows, and break plough pans to improve plough structure. The soil loosing ridging machine has the advantages of being simple in structure, easy to process and manufacture and high in practicability.

Owner:GANSU TAOHE TRACTOR MFG

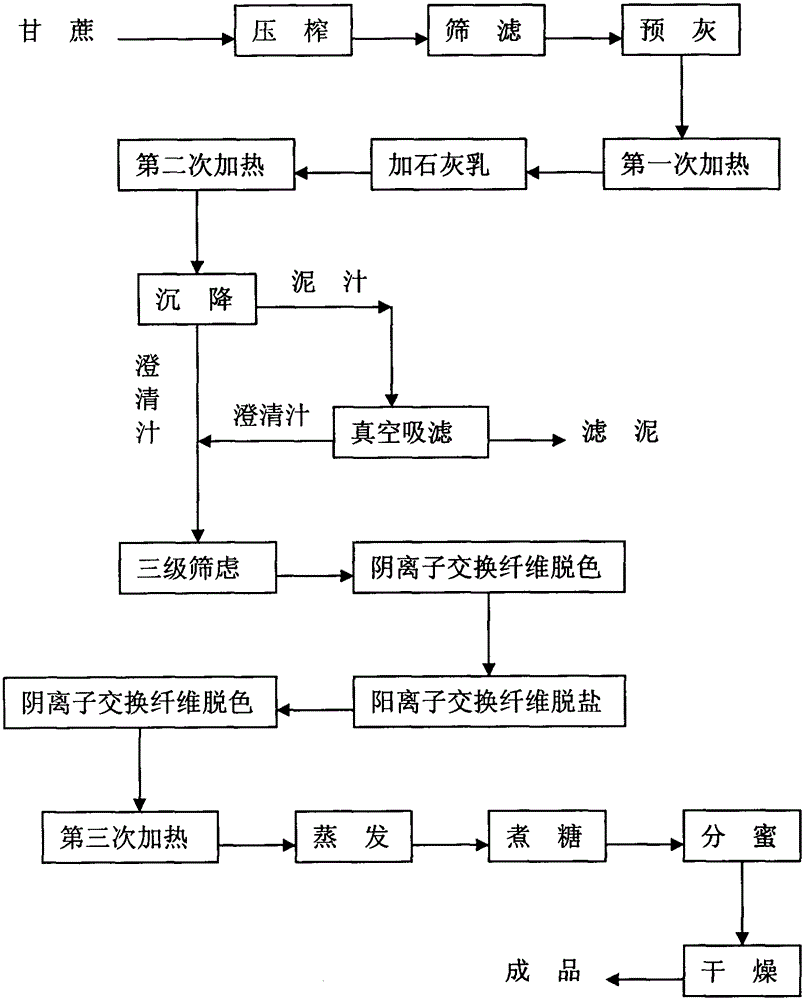

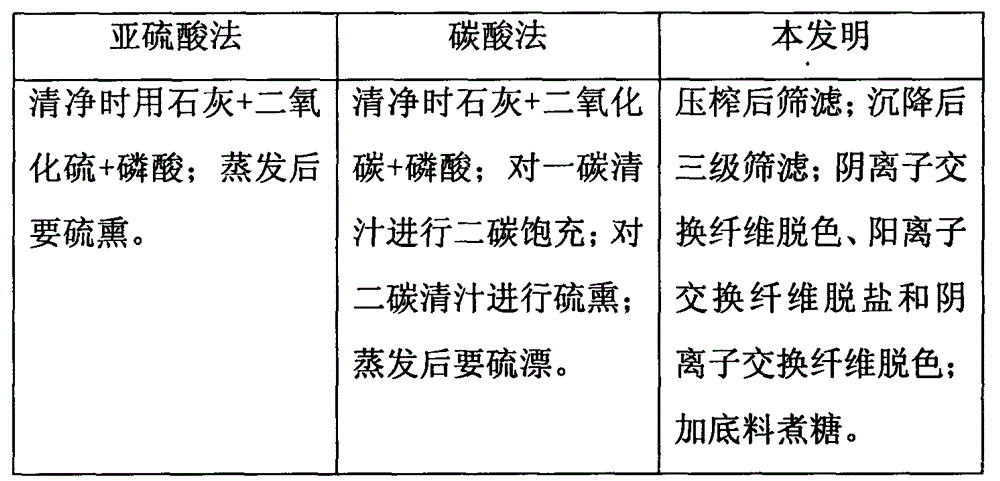

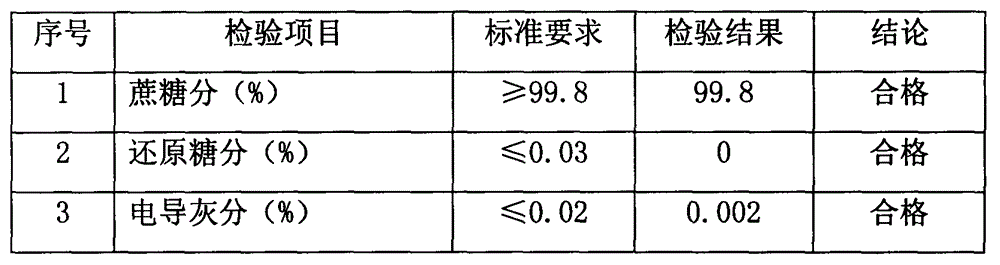

New highly efficient ion-exchange fiber decoloring sulfur-free phosphorus-free sugar-making technology

InactiveCN105002307AShort processEasy to controlSugar productsPurification using ion-exchange materialsFiberSulfur

A new highly efficient ion-exchange fiber decoloring sulfur-free phosphorus-free sugar-making technology comprises the following steps: 1) squeezing, screening, pre-liming, first heating, addition of lime milk and second heating; 2) settlement and tertiary screening; 3) anion-exchange fiber decoloring, cation exchange fiber desalination and anion-exchange fiber decoloring; and 4) third heating, evaporation, sugar boiling, sugar separating and drying. Finally, a finished production is obtained. According to the new technology, sulfur-free and phosphorus-free purposes are realized by advantages of ion-exchange fiber. The technology is simple and is adopted to raise quality index of sugar juice. Quality of the product is good. In addition, energy is saved and environmental pollution is minimized.

Owner:GUANGXI HUAZHENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com