Copper casting mould rapidly moulded by hot spraying technology and manufacturing method of copper casting mould

A thermal spraying and process technology, applied in the field of mold manufacturing, can solve the problems of time-consuming, high production cost, complicated processing process, etc., and achieve the effect of high surface hardness, short production cycle and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

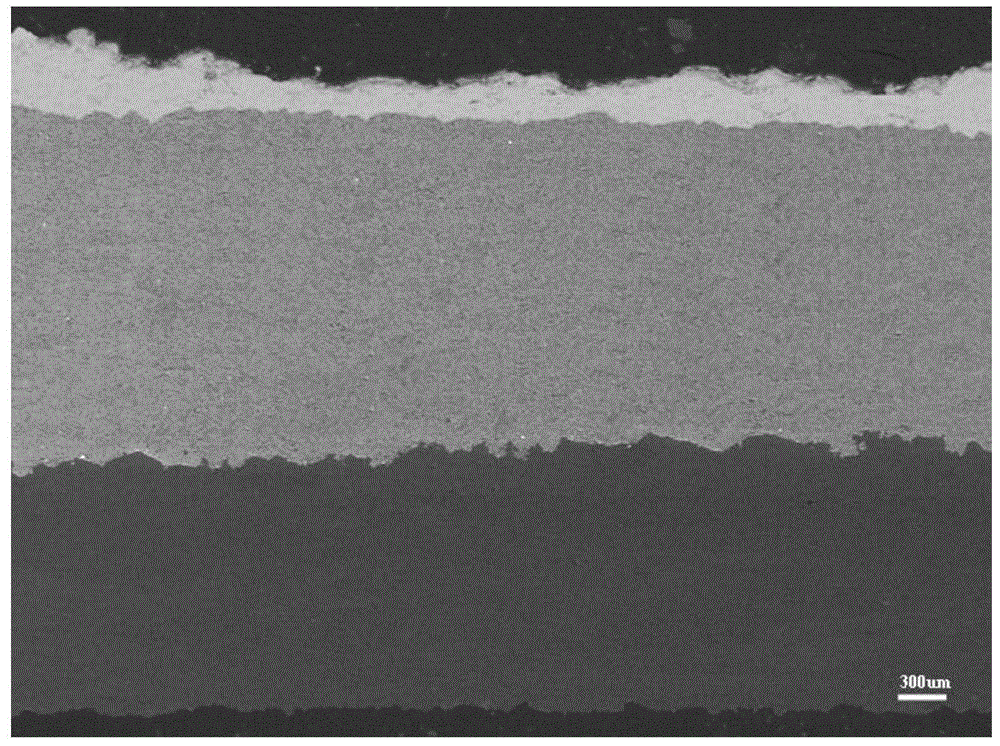

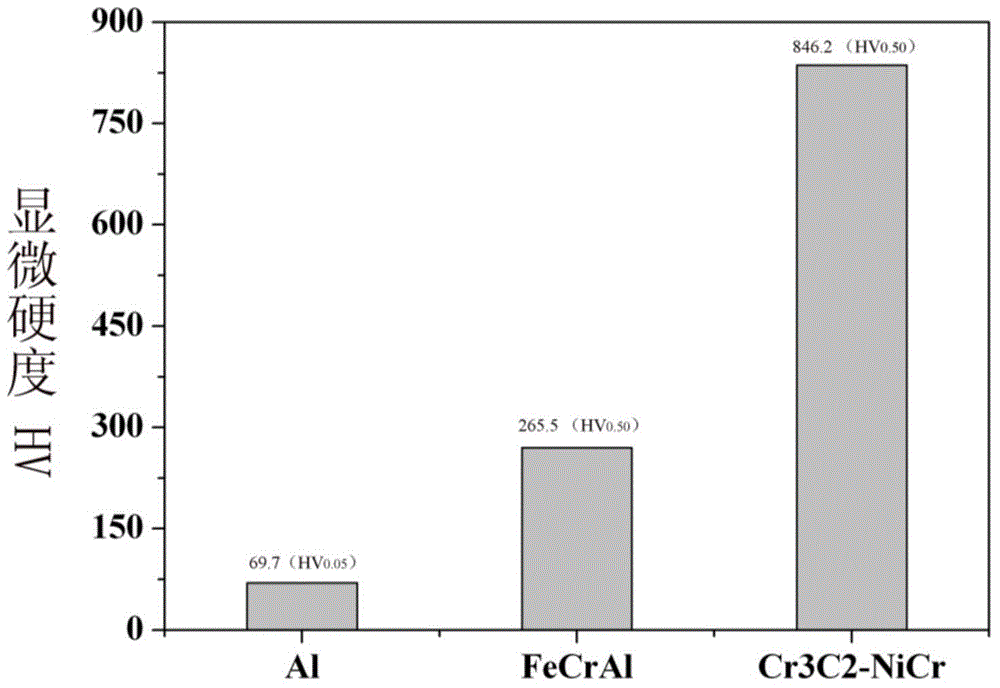

[0049] In this embodiment, the base material is water-soluble gypsum, and the surface of the base material is thermally sprayed to prepare a copper casting mold, which is composed of a heat-conducting layer metal Al coating, a transition layer metal FeCrAl coating and a heat-resistant layer cermet Cr3C2-25NiCr coating ; Among them, the heat conduction layer is 1600 μm, the transition layer is 2200 μm, and the heat-resistant corrosion layer is 300 μm.

[0050] The preparation of the above-mentioned copper casting mold adopts thermal spraying rapid prototyping process, and the specific method is as follows:

[0051] 1. According to the size of the copper casting mold, water-soluble gypsum is used as the base material, and 60 mesh brown corundum sand is used for surface blasting pretreatment to make the roughness meet the spraying requirements.

[0052] 2. Metal Al was sprayed on the surface of the substrate by arc spraying method to obtain a heat conduction layer with a thicknes...

Embodiment 2

[0060] In this embodiment, the base material is water-soluble gypsum, and the surface of the base material is thermally sprayed to prepare a copper casting mold. The mold is composed of a heat-conducting layer metal Al-Zn alloy coating, a transition layer metal stainless steel coating and a heat-resistant corrosion layer cermet Cr3C2-7NiCr The composition of the coating; the heat conduction layer is 2000 μm, the transition layer is 3500 μm, and the heat-resistant layer is 300 μm.

[0061] The preparation of the above-mentioned copper casting mold adopts thermal spraying rapid prototyping process, and the specific method is as follows:

[0062] 1. According to the size of the copper casting mold, water-soluble gypsum is used as the base material, and 60 mesh brown corundum sand is used for surface blasting pretreatment to make the roughness meet the spraying requirements.

[0063] 2. The Al-Zn alloy is sprayed onto the surface of the substrate by arc spraying to obtain a heat c...

Embodiment 3

[0071] In the present embodiment, base material water-soluble gypsum, base material surface thermal spraying prepares copper casting mold, and this mold is made up of heat-conducting layer metal Al coating, transition layer metal NiCr coating and heat-resistant layer cermet CoMoCrSi coating; Wherein The heat conduction layer is 2000 μm, the transition layer is 4000 μm, and the heat-resistant corrosion layer is 300 μm.

[0072] The preparation of the above-mentioned copper casting mold adopts thermal spraying rapid prototyping process, and the specific method is as follows:

[0073] 1. According to the size of the copper casting mold, water-soluble gypsum is used as the base material, and 60 mesh brown corundum sand is used for surface blasting pretreatment to make the roughness meet the spraying requirements.

[0074] 2. Al is sprayed on the surface of the substrate by an arc spraying method to obtain a heat conducting layer with a thickness of 2000 μm. Among them, the sprayi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com