Microwave induced crosslinking polyolefin insulation material and preparation method thereof

A technology for inducing cross-linking and insulating materials, which is applied in the field of polyolefin insulating materials and its preparation, can solve the problems of polyolefin material strength, low heat distortion temperature solvent resistance, complex cross-linking process, and strict protection requirements. Enhanced water resistance, reduced production costs, and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

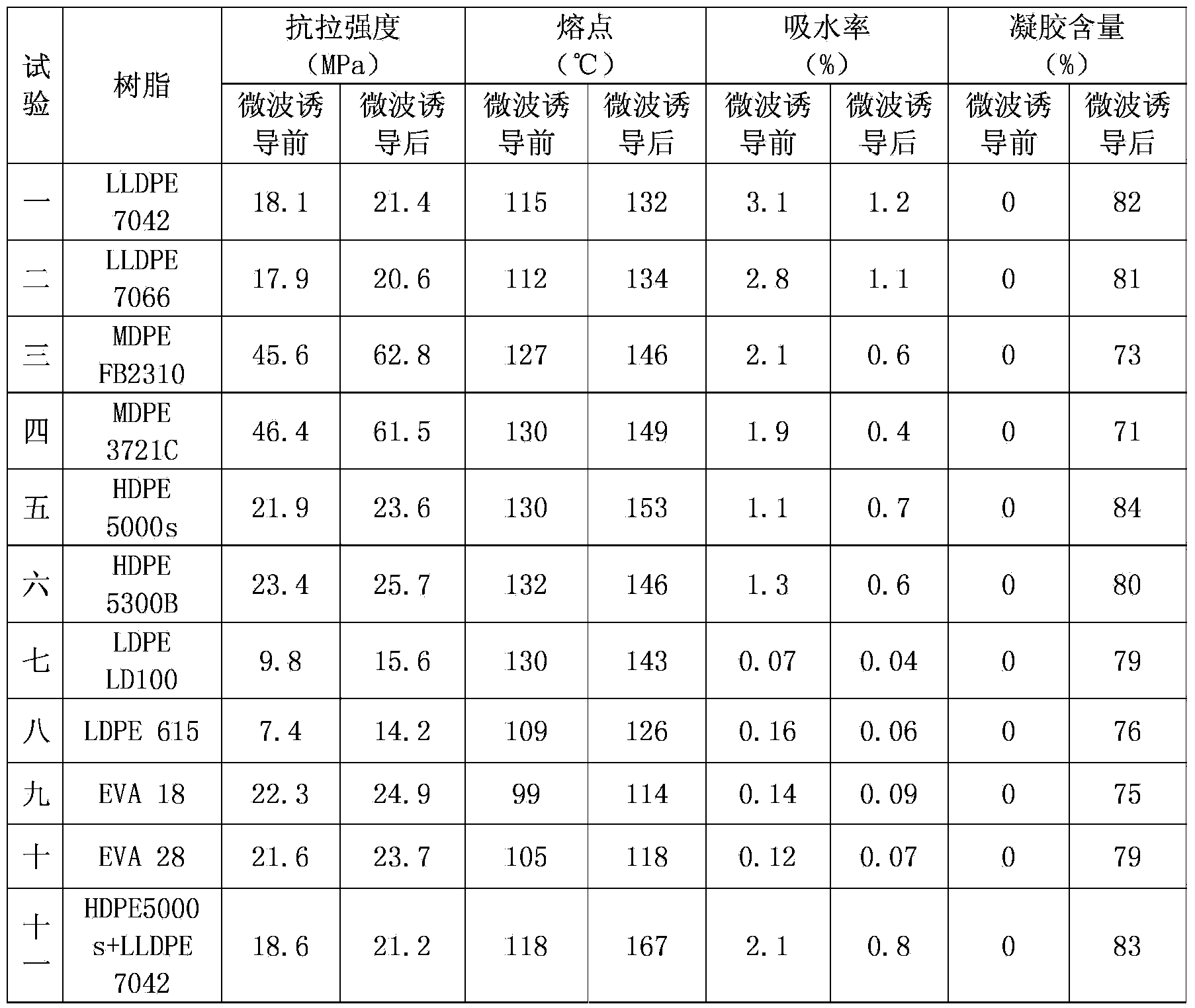

[0015] Embodiment 1: A microwave-induced cross-linked polyolefin insulating material of this embodiment is characterized in that it is composed of 100 parts of dry polyolefin resin, 0.1-4 parts of silane coupling agent, 0.1-5 parts of microwave absorbing agent, 0.1-5 parts of water producing agent, 0.1-5 parts of multifunctional cross-linking agent, 0.01-5 parts of cross-linking accelerator and 0.07-0.5 parts of antioxidant; wherein, the dry polyolefin resin is at 80- It is obtained by drying polyolefin resin at a temperature of 120°C.

specific Embodiment approach 2

[0016] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the polyolefin resin is formed by mixing one or more of HDPE, MDPE, LDPE, LLDPE and EVA polyolefin elastomers in any ratio . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the silane coupling agent is vinyltrimethoxysilane (A171), vinyltriethoxysilane (A151), γ- Aminopropyltriethoxysilane, Benzylazinomethyltriethoxysilane, γ-ethylenediazidopropyltrimethoxysilane, β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane It is mixed with one or more of γ-propylmethacrylate trimethoxysilane in any ratio. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com