Hot-rolled strip steel plate convexity prediction method based on deep learning

A deep learning, hot-rolled strip technology, applied in the field of metallurgy, can solve the problems of low model prediction accuracy and generalization ability, and achieve the effect of avoiding a huge amount of calculation and improving prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

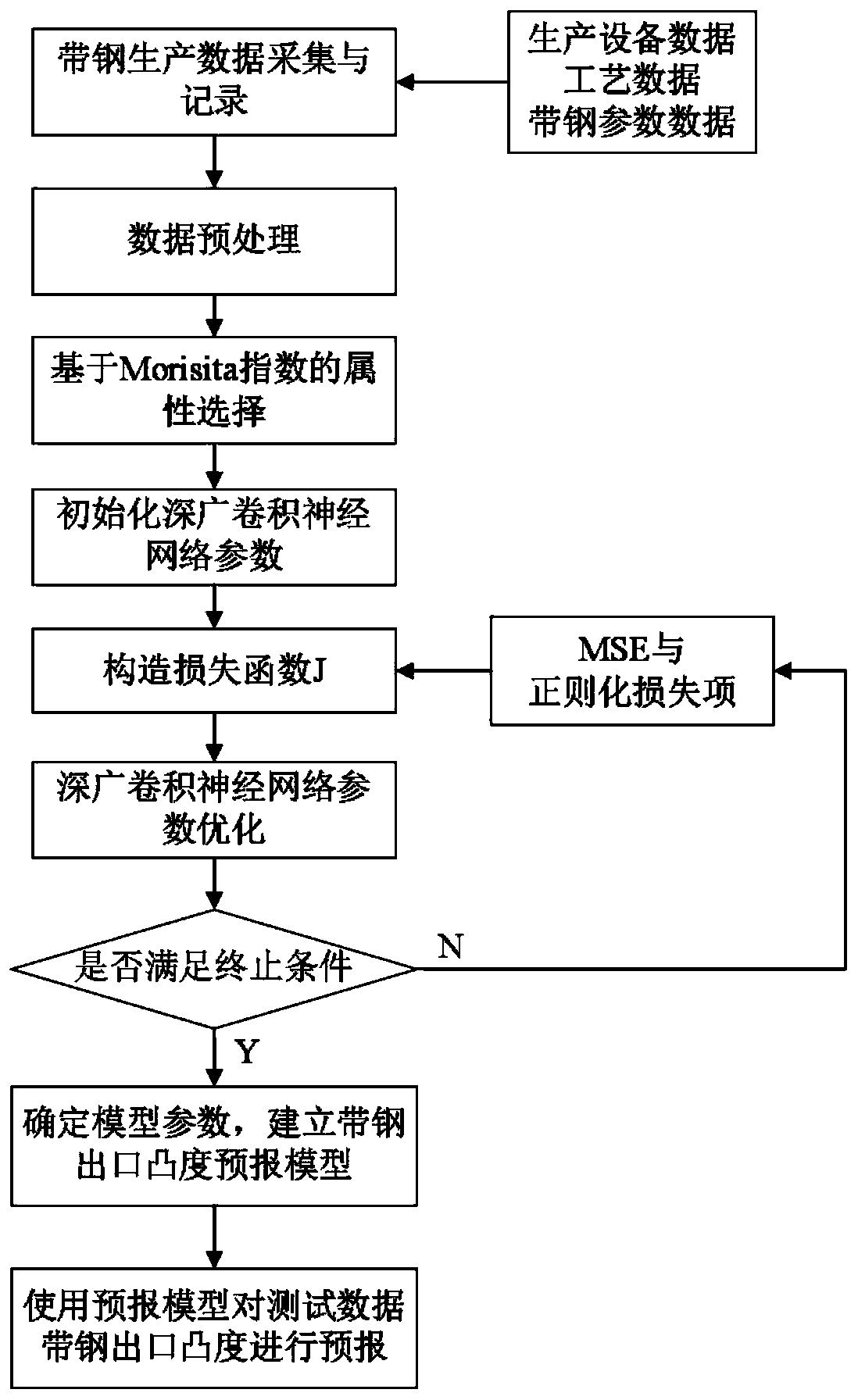

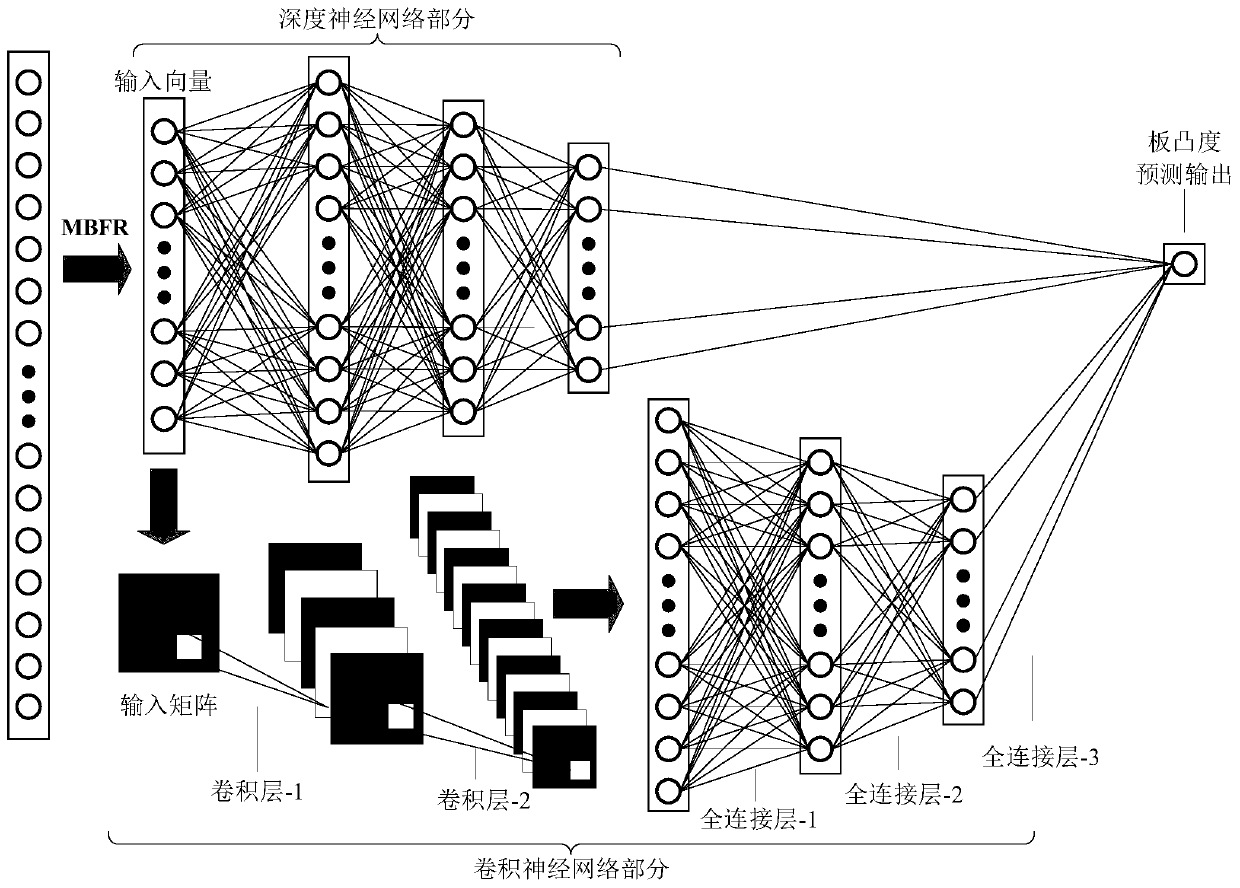

[0107] Experimental example: A method for predicting the convexity of hot-rolled strip steel plates based on deep learning, such as figure 1 shown, including the following steps:

[0108] (1) Data collection and recording: Collect historical rolling data of a 2160 hot continuous rolling mill, including: the speed of each stand of the finishing mill, rolling force, roll bending force, roll shifting amount, side press press quantity, rough rolling centerline position, and strip steel type, temperature, length, width, thickness, weight, etc., each strip collects the above 50 production variable data and convexity data as a sample, and uses a 51-dimensional vector To represent;

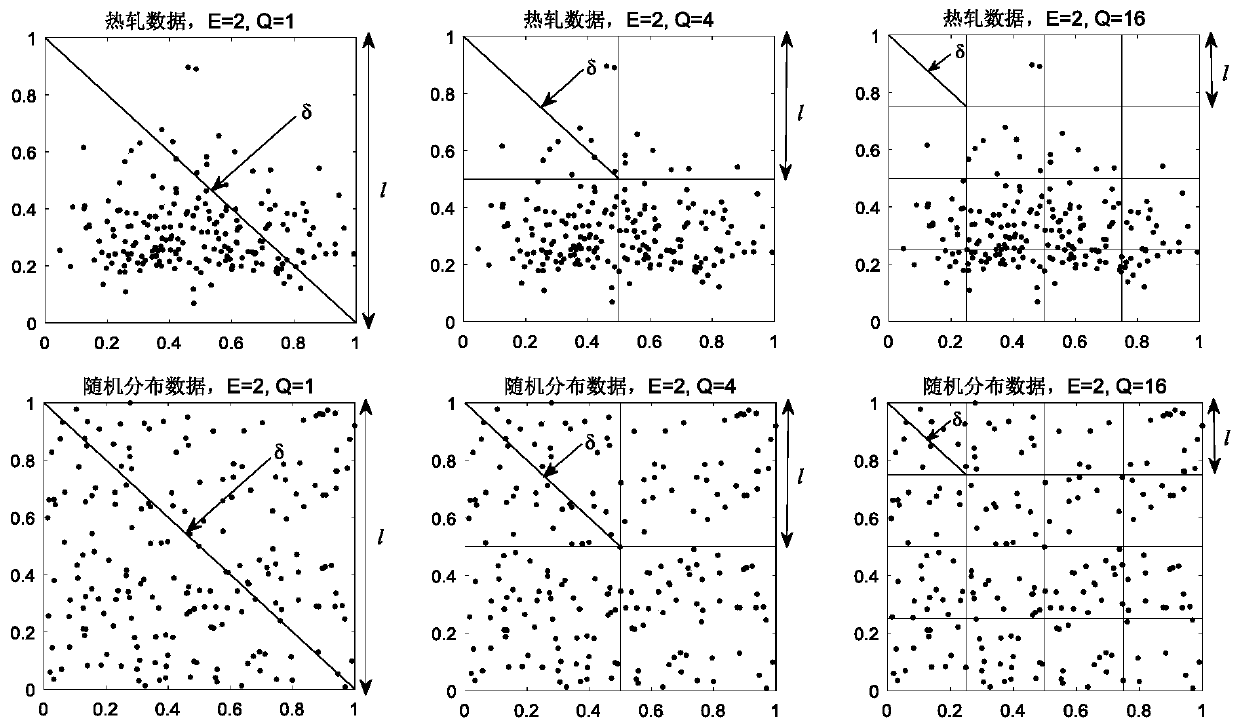

[0109] (2) Data preprocessing: data cleaning and transformation of the original data, including deletion of missing values, deletion of outliers using the 3σ criterion, and normalization, to obtain production parameters of 11,544 steel strips for training and testing of the prediction model . The datas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com