Pure niobium purification process

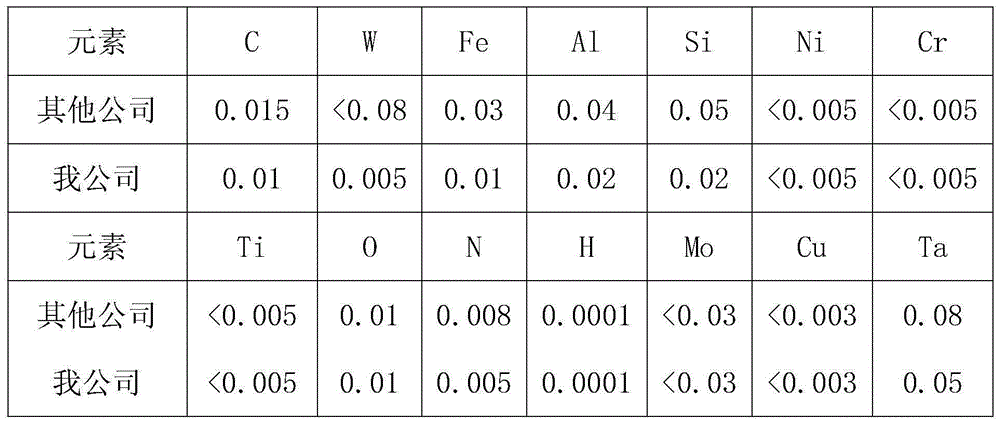

A process, pure niobium technology, applied in the field of purification process, can solve the problems of low work efficiency, high purification cost, and many impurities, and achieve the effects of controlling production costs, high purification efficiency, and less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The purification process of pure niobium of the present invention, it comprises the following steps,

[0025] (1) Ingredients: calculated in parts by weight, get 150 parts of industrial niobium oxide and 60 parts of aluminum powder;

[0026] (2) Mixing: put industrial niobium oxide and aluminum powder into a V-shaped mixer and mix for 40 minutes, fully contact and mix;

[0027] (3) Reduction furnace cleaning: clean the reduction furnace body before reduction to ensure a good reduction atmosphere;

[0028] (4) Reduction: Put the mixed material into the reduction furnace for reduction reaction, that is, Al+Nb 2 o 5 →Nb+Al 2 o 3 , the reduction vacuum is controlled within 50 Pascals, and the furnace temperature is controlled within 300 °C;

[0029] (5) Out of the furnace: reduce the temperature of the reduced material to within 80°C to prevent the material from nitriding and other reactions;

[0030] (6) Crushing: Put the material after being baked into the jaw crush...

Embodiment 2

[0042] The purification process of pure niobium of the present invention, it comprises the following steps,

[0043] (1) Ingredients: calculated in parts by weight, get 160 parts of industrial niobium oxide and 65 parts of aluminum powder;

[0044] (2) Mixing: put industrial niobium oxide and aluminum powder into a V-shaped mixer and mix for 45 minutes, fully contact and mix;

[0045] (3) Reduction furnace cleaning: clean the reduction furnace body before reduction to ensure a good reduction atmosphere;

[0046] (4) Reduction: Put the mixed material into the reduction furnace for reduction reaction, that is, Al+Nb 2 o 5 →Nb+Al 2 o 3 , the reduction vacuum is controlled within 50 Pascals, and the furnace temperature is controlled within 300 °C;

[0047] (5) Out of the furnace: reduce the temperature of the reduced material to within 80°C to prevent the material from nitriding and other reactions;

[0048] (6) Crushing: Put the material after being baked into the jaw crush...

Embodiment 3

[0060] The purification process of pure niobium of the present invention, it comprises the following steps,

[0061] (1) Ingredients: calculated in parts by weight, get 170 parts of industrial niobium oxide and 70 parts of aluminum powder;

[0062] (2) Mixing: put industrial niobium oxide and aluminum powder into a V-shaped mixer and mix for 50 minutes, fully contact and mix;

[0063] (3) Reduction furnace cleaning: clean the reduction furnace body before reduction to ensure a good reduction atmosphere;

[0064] (4) Reduction: Put the mixed material into the reduction furnace for reduction reaction, that is, Al+Nb 2 o 5 →Nb+Al 2 o 3 , the reduction vacuum is controlled within 50 Pascals, and the furnace temperature is controlled within 300 °C;

[0065] (5) Out of the furnace: reduce the temperature of the reduced material to within 80°C to prevent the material from nitriding and other reactions;

[0066] (6) Crushing: Put the material after being baked into the jaw crusher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com