Preparation method and application of iron hydroxide/bismuth vanadate composite photocatalyst

A technology of iron hydroxide and bismuth vanadate, which is applied in the field of photocatalysis, can solve the problems of rare, expensive, and limited precious metal elements, and achieve the effects of low production cost, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of bismuth vanadate: Add bismuth chloride and ammonium metavanadate with a molar ratio of 1:1 into a beaker containing deionized water and mix evenly, add dropwise 1mol / L ethanolamine solution, the corresponding mole of ethanolamine and bismuth chloride The ratio is 400:1, and the precursor is obtained by mixing and stirring; the precursor is placed in the reactor, and BiVO is synthesized by hydrothermal method at 160 °C 4 , the bismuth vanadate was centrifugally settled, washed with distilled water and absolute ethanol, dried and ground to obtain yellow bismuth vanadate powder.

Embodiment 2

[0037] Preparation of bismuth vanadate: Add bismuth chloride and ammonium metavanadate with a molar ratio of 1:1 into a beaker containing deionized water and mix evenly, add dropwise 1mol / L ethanolamine solution, the corresponding mole of ethanolamine and bismuth chloride The ratio is 500:1, and the precursor is obtained by mixing and stirring; the precursor is placed in the reaction kettle, and BiVO is synthesized by hydrothermal method at 180°C 4 , the bismuth vanadate was centrifugally settled, washed with distilled water and absolute ethanol, dried and ground to obtain yellow bismuth vanadate powder.

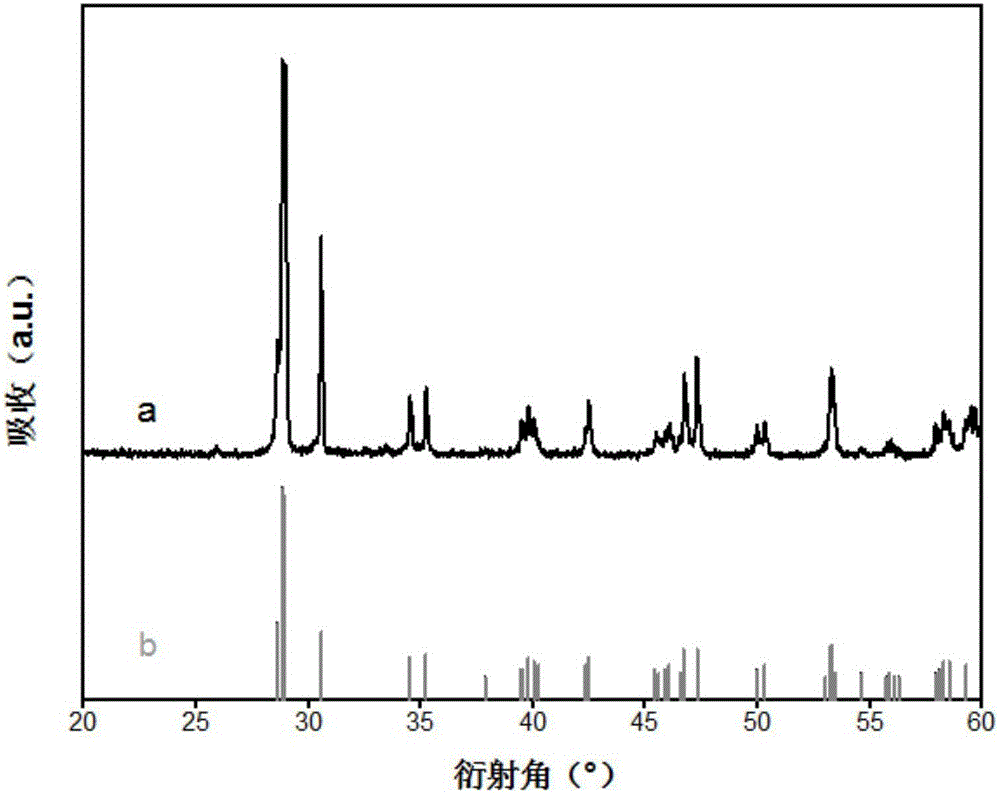

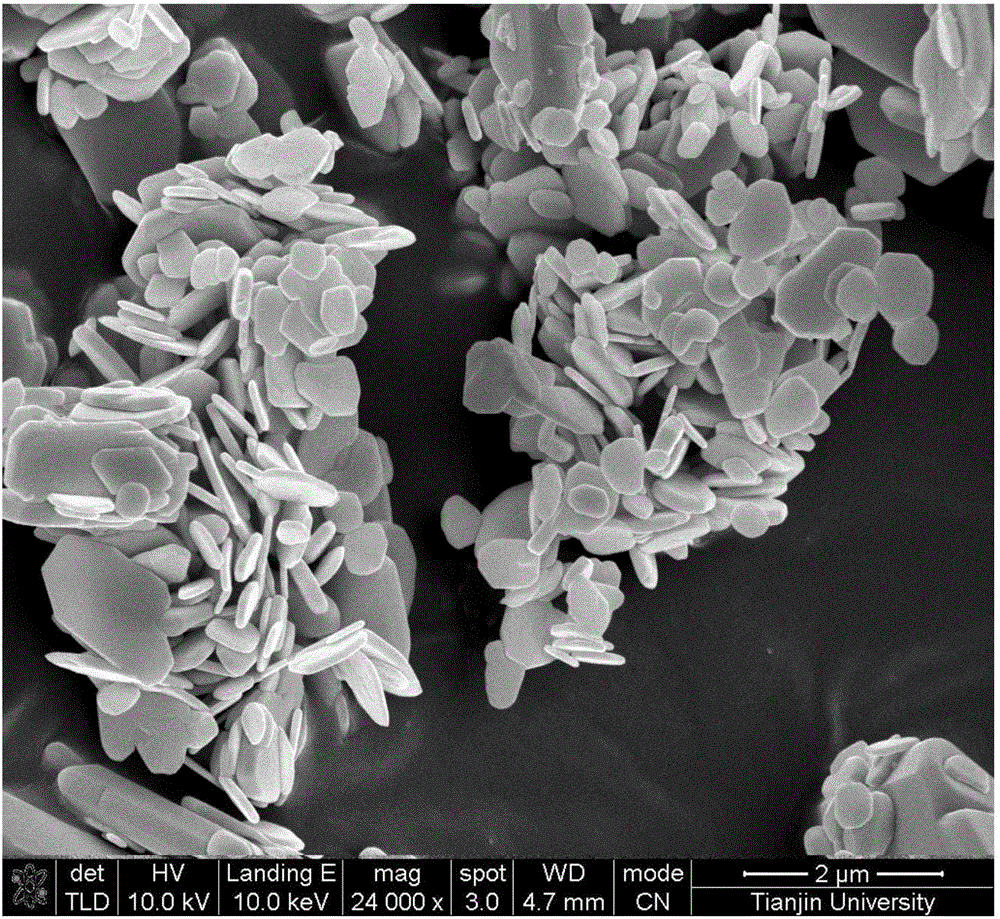

[0038] Some crystal structure studies were performed on the bismuth vanadate product prepared by the method described above. figure 1 figure 2 XRD diffraction pattern and SEM pattern of bismuth vanadate under hydrothermal conditions at 160°C, a is the XRD diffraction pattern of bismuth vanadate prepared in the experiment, b is the diffraction pattern of #14-1688#PDF card. ...

Embodiment 3

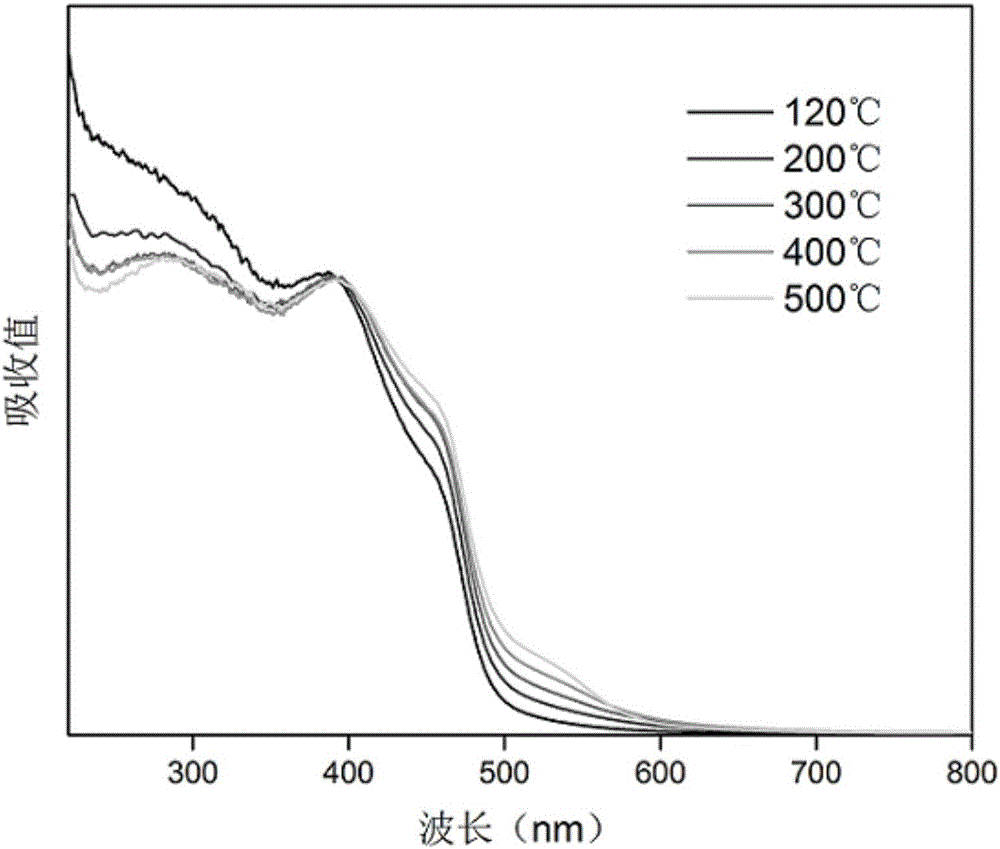

[0040] Preparation of iron hydroxide / bismuth vanadate composite material: Mix yellow bismuth vanadate powder, urea, and distilled water evenly in a molar ratio of 1:40:4000, add concentrated nitric acid, concentrated nitric acid, and vanadic acid to the mixed solution drop by drop The molar mass ratio of bismuth is 1:7, which provides an acidic environment and prevents Fe 3+hydrolysis. Then add ferric nitrate nonahydrate solution, so that the molar ratio of iron and bismuth vanadate is 0.01:1; heat in an oil bath at 80°C for 4h, and react under stirring conditions. Let the heated liquid stand for 30 minutes. Pour off the supernatant, divide the yellow powder at the bottom into centrifuge tubes, add deionized water, oscillate evenly and put it in the centrifuge for centrifugation (centrifuge at 9000r / min for 5min), pour off the supernatant, and repeat the above steps , washed 4 times with water, and washed 4 times with alcohol at the same time to obtain a yellow precipitate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com