Fe-doped visible-light-driven photocatalyst of covalent triazine organic polymer and preparation and application of Fe-doped visible-light-driven photocatalyst

A covalent triazine and polymer technology, applied in the field of photocatalysis, can solve the problems of narrow photoresponse range of CTFs and high recombination rate of photogenerated carriers, achieve high practical value and application prospects, simple and convenient preparation method, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

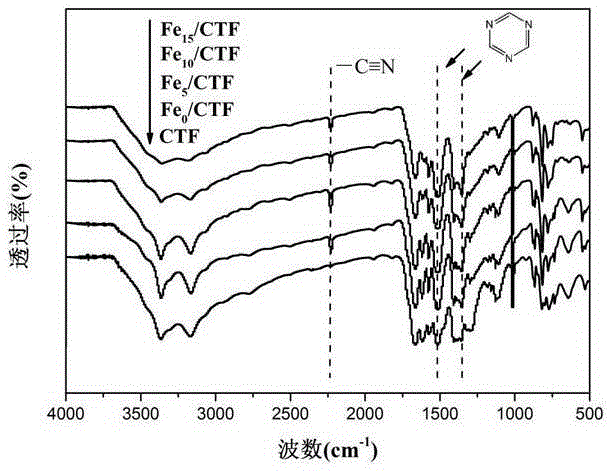

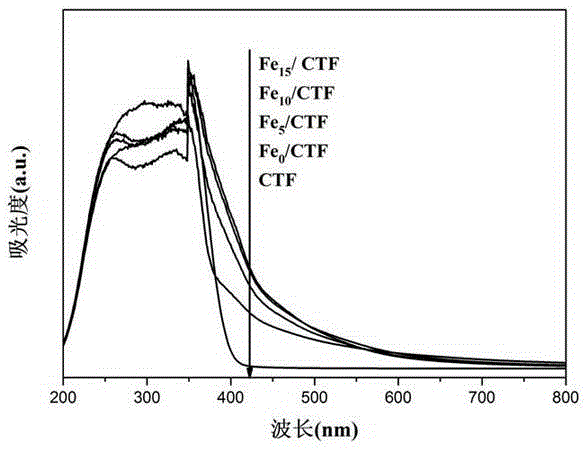

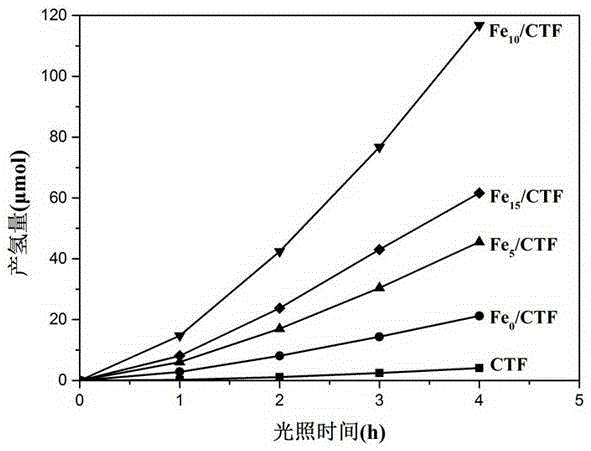

[0027] Weigh 0.01g of ferric chloride and 0.2g of covalent triazine organic polymer and mix them in 20mL of distilled water. After ultrasonication for 30min, heat and stir in a water bath at 80°C until the water is evaporated to dryness. Collect the solid and place it in a muffle furnace. Calcined at 250°C for 1 hour in an air atmosphere to obtain a solid sample; grind the obtained solid sample thoroughly, reflux it with methanol at 90°C for 12 hours, collect the solid and dry it at 60°C for 12 hours to obtain a 5% iron-doped covalent triazine Organic polymer visible light catalyst, denoted as Fe 5 / CTF.

Embodiment 2

[0029] Weigh 0.02g of ferric chloride and 0.2g of covalent triazine organic polymer and mix them in 20mL of distilled water. After ultrasonication for 30min, heat and stir in a water bath at 80°C until the water is evaporated to dryness. Collect the solid and place it in a muffle furnace. Calcined at 250°C for 1 hour in an air atmosphere to obtain a solid sample; grind the obtained solid sample thoroughly, reflux it with methanol at 90°C for 12 hours, collect the solid and dry it at 60°C for 12 hours to obtain 10% iron-doped covalent triazine Organic polymer visible light catalyst, denoted as Fe 10 / CTF.

Embodiment 3

[0031] Weigh 0.03g of ferric chloride and 0.2g of covalent triazine organic polymer and mix them in 20mL of distilled water. After ultrasonication for 30min, heat and stir in a water bath at 80°C until the water evaporates to dryness. Collect the solid and place it in a muffle furnace. Calcined at 250°C for 1 hour in an air atmosphere to obtain a solid sample; grind the obtained solid sample thoroughly, reflux it with methanol at 90°C for 12 hours, collect the solid and dry it at 60°C for 12 hours to obtain a 15% iron-doped covalent triazine Organic polymer visible light catalyst, denoted as Fe 15 / CTF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com