Method for preparing humidity-sensitive switch flexible sensing material

A technology for sensing materials and switches, which is applied in the field of preparation of flexible humidity-sensitive switch sensing materials, can solve problems such as unsatisfactory measurement results, complex sensor fabrication process, and contact, and achieves a simple and convenient preparation method and constant polymer mass fraction. , the effect of uniform and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

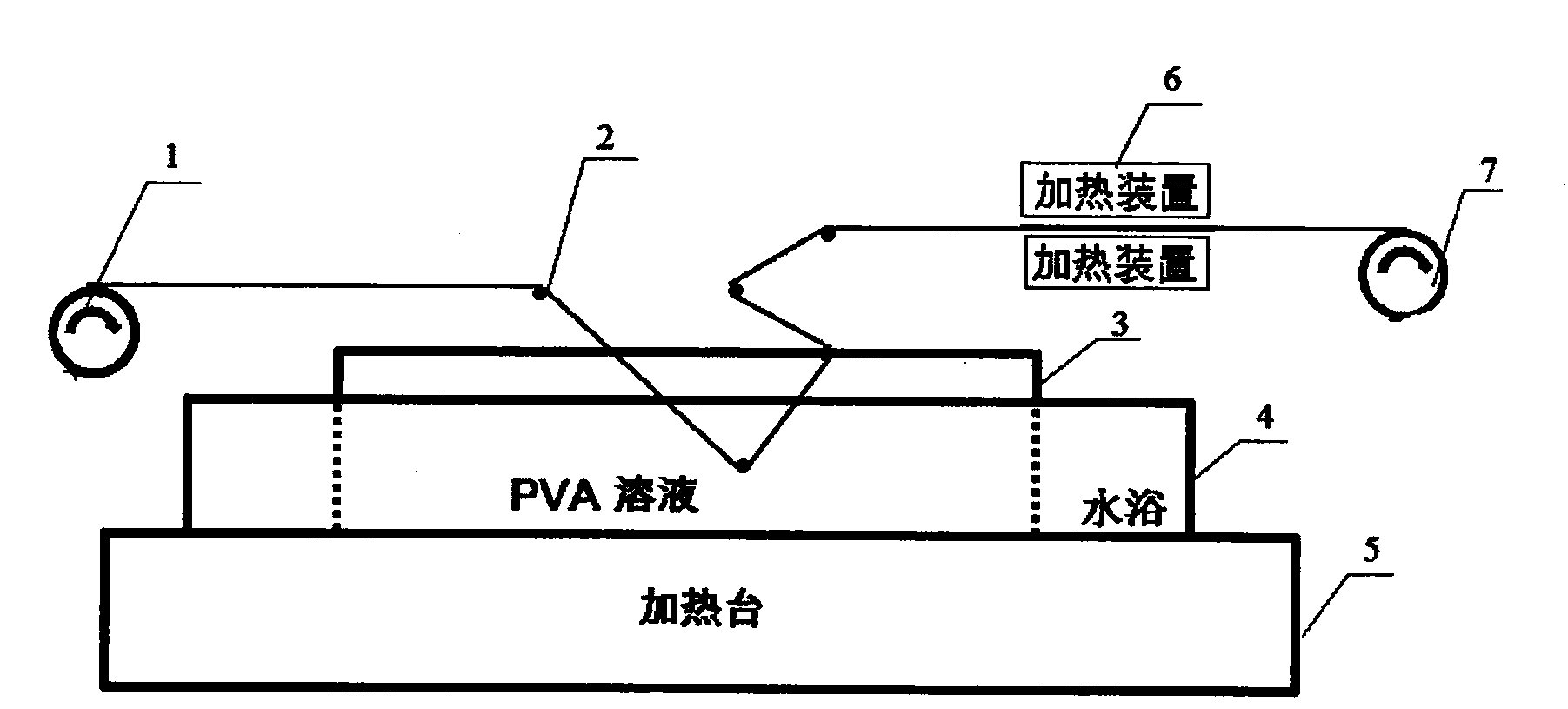

[0035] like figure 1 As shown, it is a schematic diagram of a carbon nanotube composite yarn preparation device, and the carbon nanotube composite yarn preparation device includes a winding roller 1, a yarn guide needle 2, a composite tank 3, a water bath 4, a heating table 5, and a heating device 6 and spool 7. The winding roller 1 and the bobbin 7 are respectively connected to the motor, the composite tank 3 is arranged in the water bath 4, and the water bath 4 is arranged on the heating table 5, and the carbon nanotube yarn or the carbon nanotube film is wound out from the winding roller 1, passed through the guide Guided by the yarn needle 2, it enters the compound groove 3 for compounding. The length of the carbon nanotube yarn or film in contact with the polymer solution is about 20 mm. Between two heating devices 6, drying is carried out, so that the polymer is quickly solidified on the surface of the carbon nanotube fiber, and wound on the bobbin to obtain a composite...

Embodiment 2

[0037] A method for preparing a carbon nanotube / polyvinyl alcohol composite yarn moisture-sensitive switch flexible sensing material, using the carbon nanotube composite yarn preparation device described in Example 1, the specific steps are:

[0038] (1) 2.5g of polyvinyl alcohol polymer was dissolved in 40ml of water and 10ml of alcohol to prepare a polyvinyl alcohol solution with a polymer mass fraction of 5%. Pour the polyvinyl alcohol solution into the composite tank of the carbon nanotube composite yarn preparation device described in Example 1. The composite tank is heated in a water bath, and the temperature of the water bath is 60°C;

[0039] (2) Selecting a carbon nanotube yarn with a twist angle of 20° and a diameter of about 60um. The carbon nanotube yarn is wound out from the winding roller at a winding speed of 20mm / min, guided by the yarn guide needle, and entered into the composite groove for compounding. The residence time of the carbon nanotube yarn in the co...

Embodiment 3

[0045] A method for preparing a carbon nanotube / polyvinyl alcohol composite film moisture-sensitive switch flexible sensing material, using the carbon nanotube composite yarn preparation device described in Example 1, the specific steps are:

[0046] (1) 1.5g polyvinyl alcohol polymer is dissolved in 50ml dimethyl sulfoxide (DMSO) solution and prepares the polyvinyl alcohol solution (membrane material is more compact, polymer solution concentration is lower, so that the polymer penetrates into the interior of the membrane material). Pour the polyvinyl alcohol solution into the composite tank of the carbon nanotube composite film preparation device described in Example 1. The composite tank is heated in a water bath, and the temperature of the water bath is 70°C;

[0047] (2) The carbon nanotube film is selected to be cut into narrow strips with a width of 2 cm, and wound on a winding roller for standby. The carbon nanotube film is wound out from the winding roller, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com