Automatic production optimizing method and system of cold rolling sulfuric acid refining and roller milling integral unit

A technology of combined unit and optimization method, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as rising costs, increasing the number of roll changes, affecting the normal production of subsequent units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The optimization process method for the production operation system of the acid rolling group proposed by the present invention has been realized and embedded in the production operation optimization system of the acid rolling group for iron and steel enterprises developed by MicrosoftVisual Studio 6.0. The system is based on the information platform (Enterprise Resource Planning (ERP) system, data warehouse system) of iron and steel enterprises, with Windows as the supporting platform, using Visual C++6.0 to develop the program, and the background database is developed using Microsoft SQL Server 2000 database system Optimize the system.

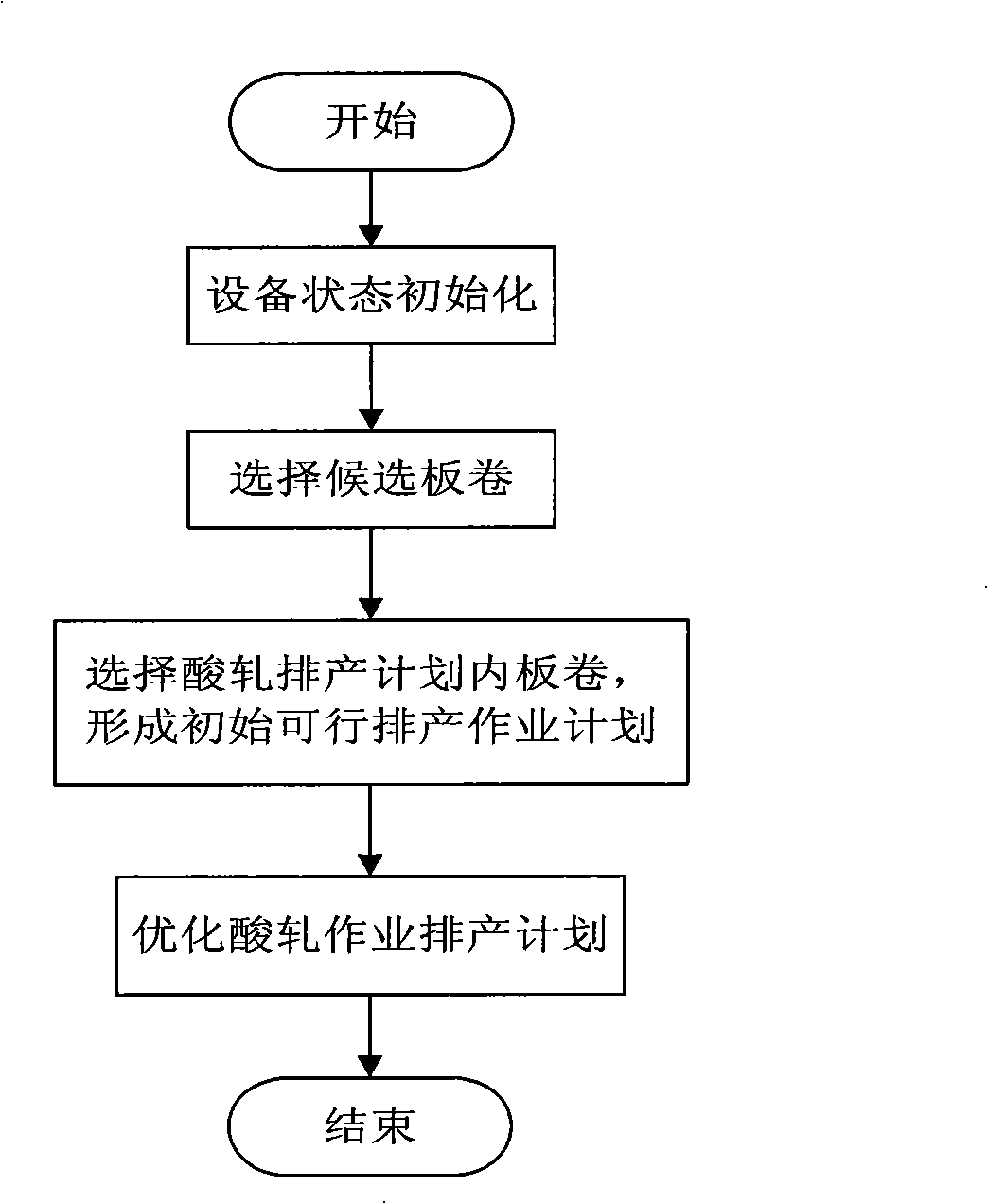

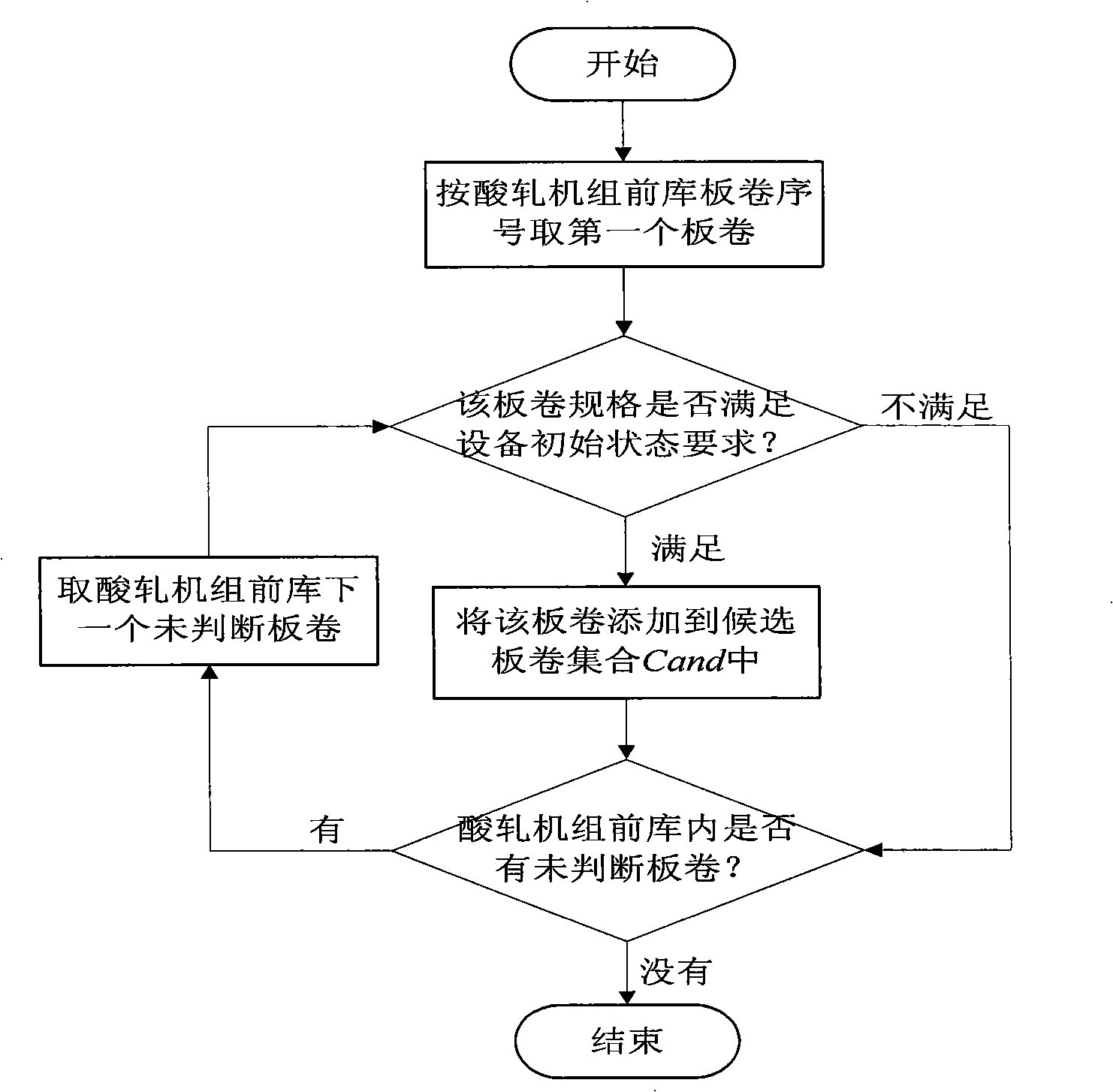

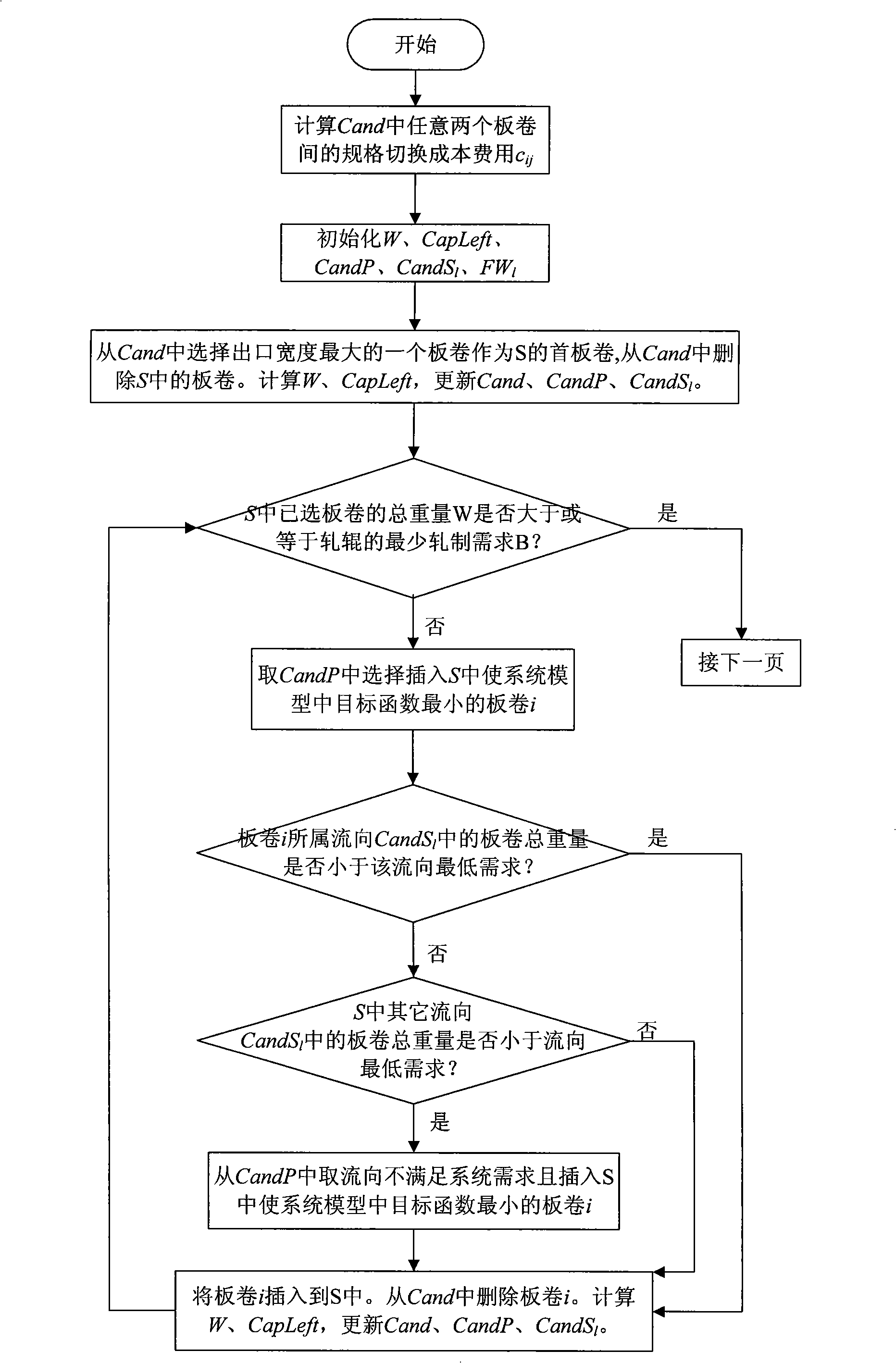

[0103] Use the iron and steel enterprise pickling mill production operation optimization system developed by the present invention according to the following steps:

[0104] Step 1. Enter the system according to the authorization, and download the coil data information from the enterprise ERP data server (information fields include: c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com