Manufacturing system comprehensive evaluation method based on improved data envelopment analysis

An envelope analysis and manufacturing system technology, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of the production system being difficult to meet, the DEA method is no longer applicable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

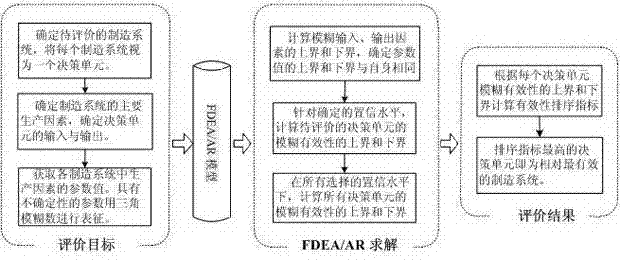

Method used

Image

Examples

Embodiment

[0069] The existing manufacturing system evaluation of the automobile lamp production industry is used as an example to verify the effectiveness of the method provided by the present invention. The production data of each manufacturing system are shown in Table 1.

[0070] Table 1 Manufacturing system production data

[0071]

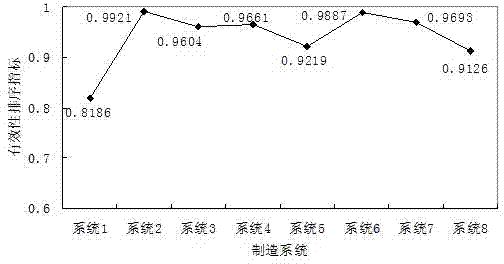

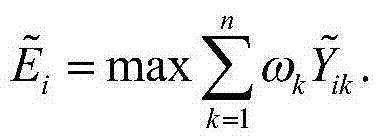

[0072] According to the expert scoring method to determine the weight ranges of production cost, floor area and production time input, respectively: ω 1 =[0.3523,0.3835],ω 2 =[0.1318,0.1996] and ω 3 =[0.4547,0.4838], the ranges of the weights of quality, output and profit are: U 1 =[0.6105,0.6895],υ 2 =[0.0855,0.1895] and U 3 =[0.2013,0.2387]. Let α=0.1,0.2,...,1.0, calculate the relative effective of each manufacturing system upper and lower bounds of . Table 2 shows the performance of 8 manufacturing systems under 10 discrete values of α and

[0073] Table 2 Fuzzy effectiveness of eight manufacturing systems based on α-cut sets

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com