Apparatus and method for metering, mixing and packaging solid particulate material

A technology of solid particles and granular materials, applied in the directions of mixing methods, solid materials, transportation and packaging, etc., can solve problems such as the inability to ensure satisfactory mixing of solid granular materials, and achieve the effect of improving overall efficiency and reducing transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

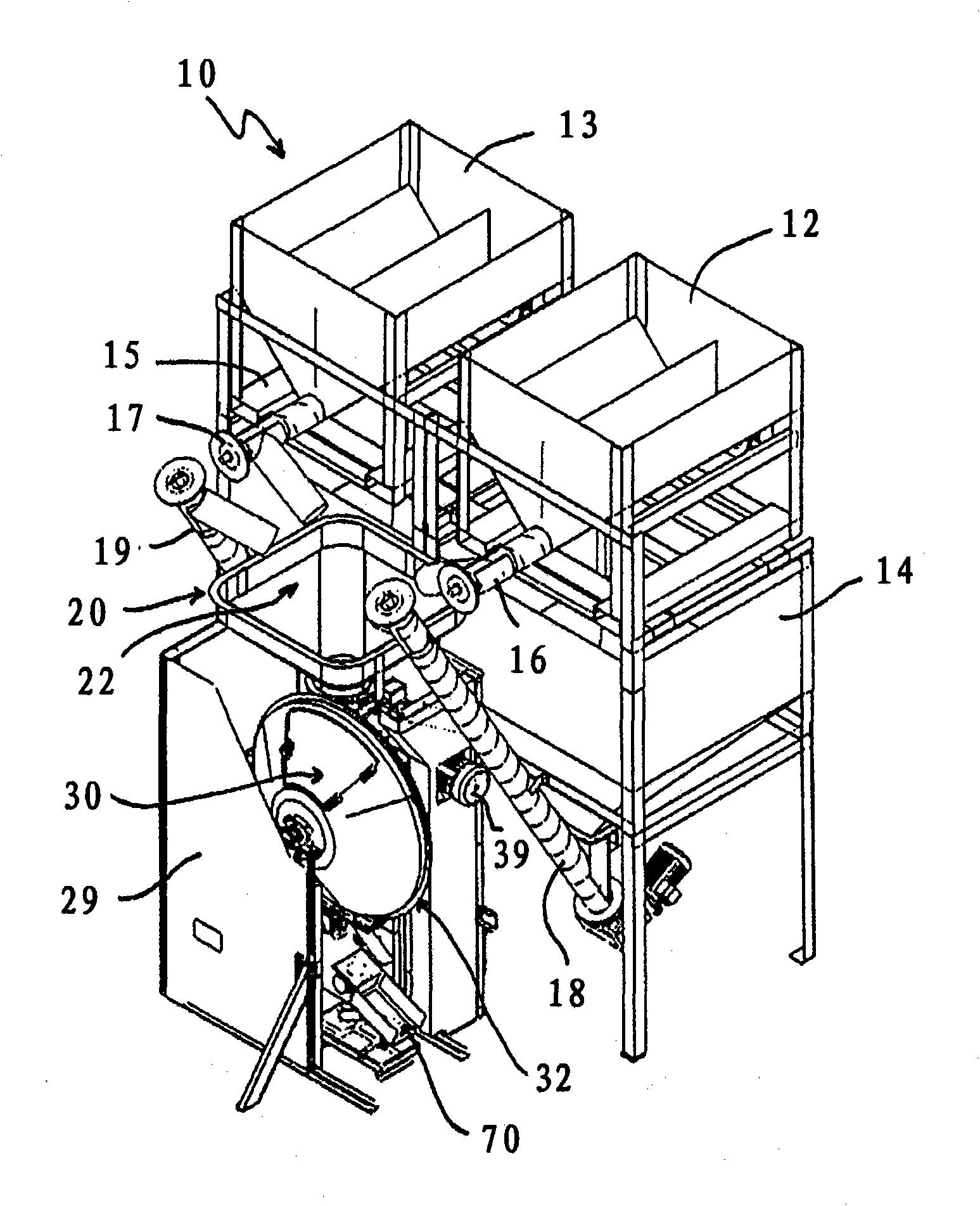

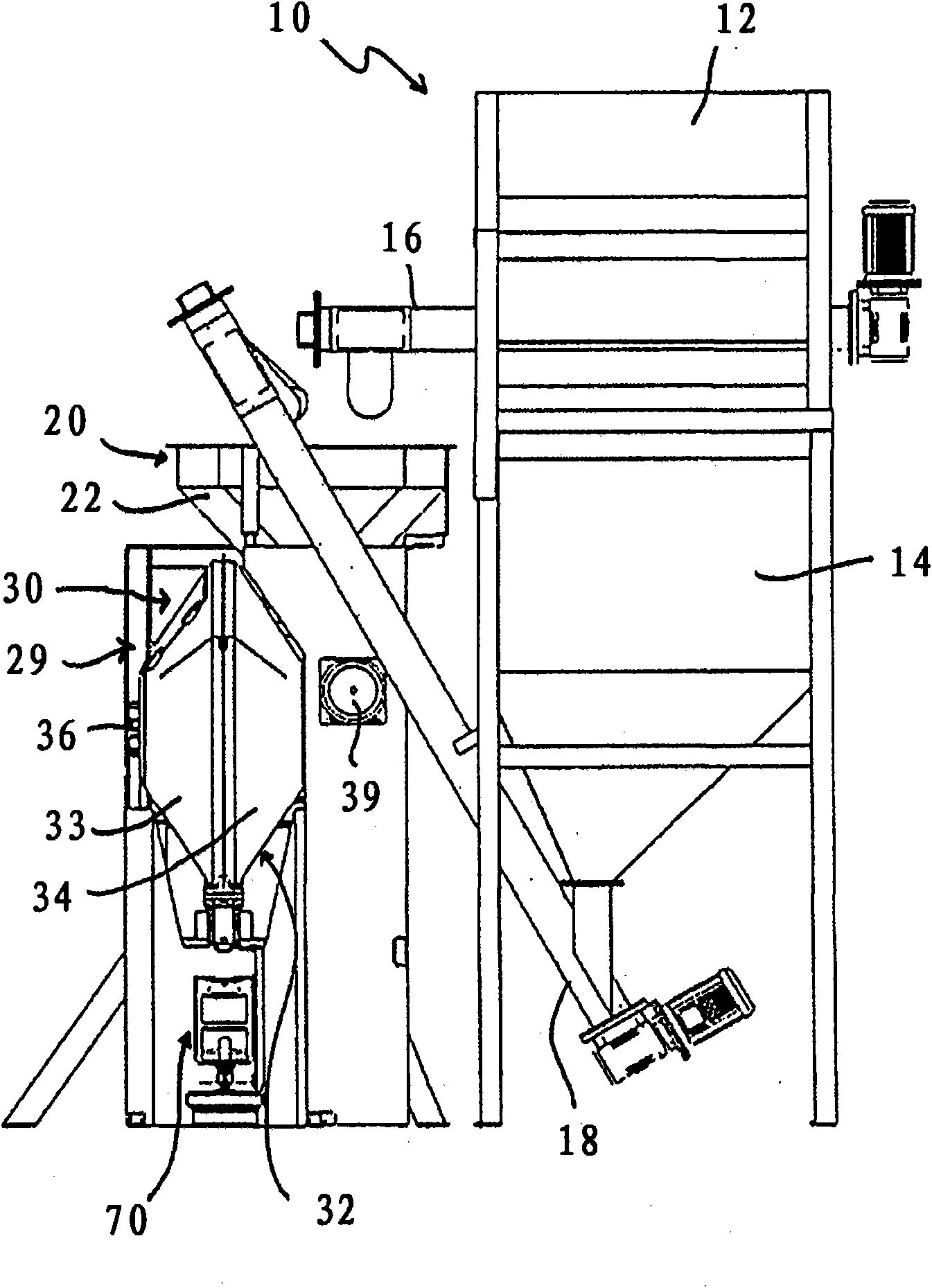

[0048] refer to figure 1 and 2, denoted by 10 according to the apparatus of the present invention. It comprises storage tanks 12, 13, 14, 15 for storing at least two different compositions of solid particulate material, respectively. In the embodiment shown in the figures, up to four components can be stored respectively in four storage tanks 12, 13, 14, 15 mounted in two superimposed rows on the support structure. The upper storage tanks 12,13 are removable, ie they can be lifted from the support structure to allow the lower tanks 14,15 to be filled. Each tank is provided with a screw conveyor 16 , 17 , 18 , 19 to withdraw the ingredients stored in the tanks 12 , 13 , 14 , 15 and feed them to the metering unit 20 . The augers are actuated by motors and controlled by a central control unit, neither said motor nor central unit control being shown.

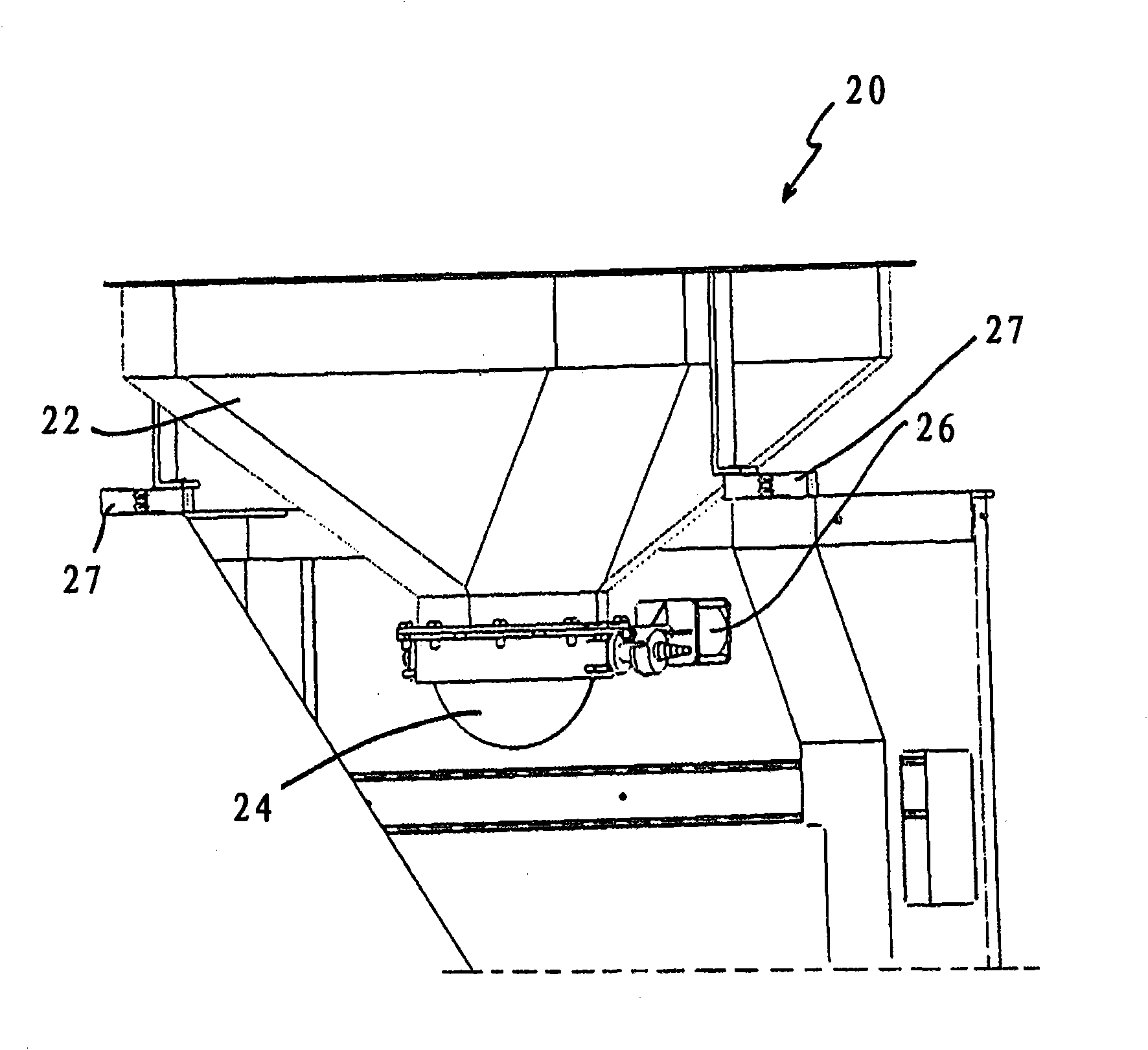

[0049] The metering unit 20 includes a feeder 22, which is image 3 is also displayed. The feeder 22 has an opening at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com