Patents

Literature

83results about How to "Guaranteed mix quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

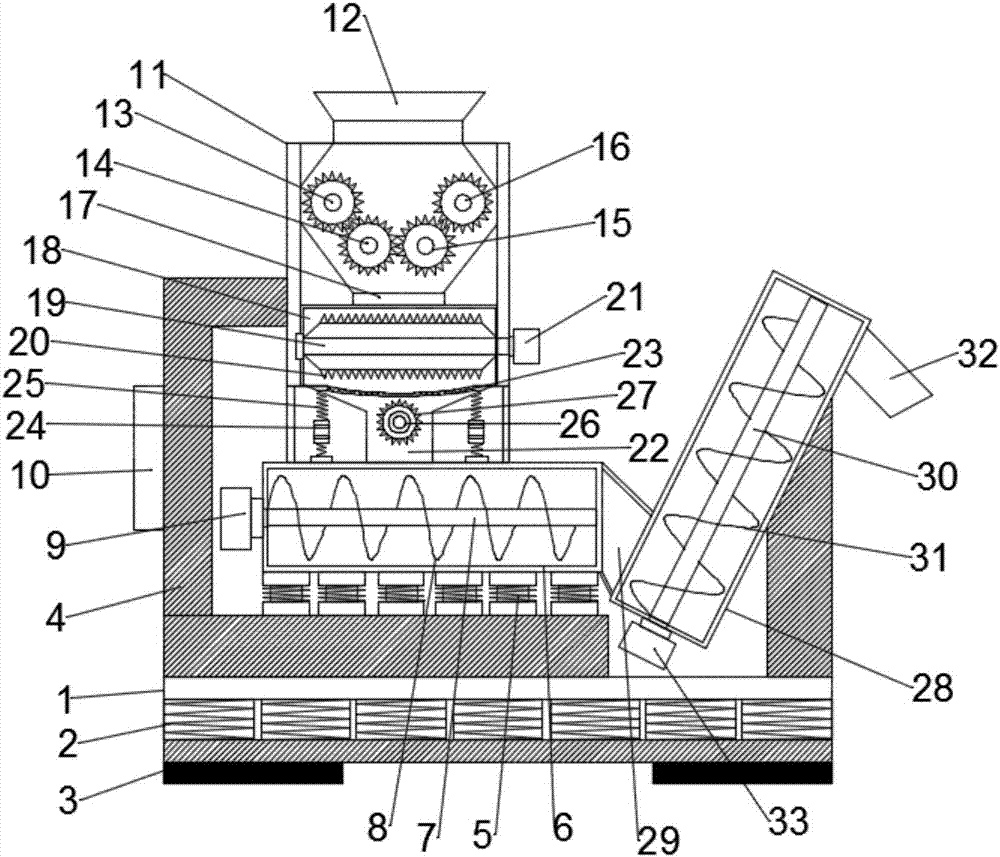

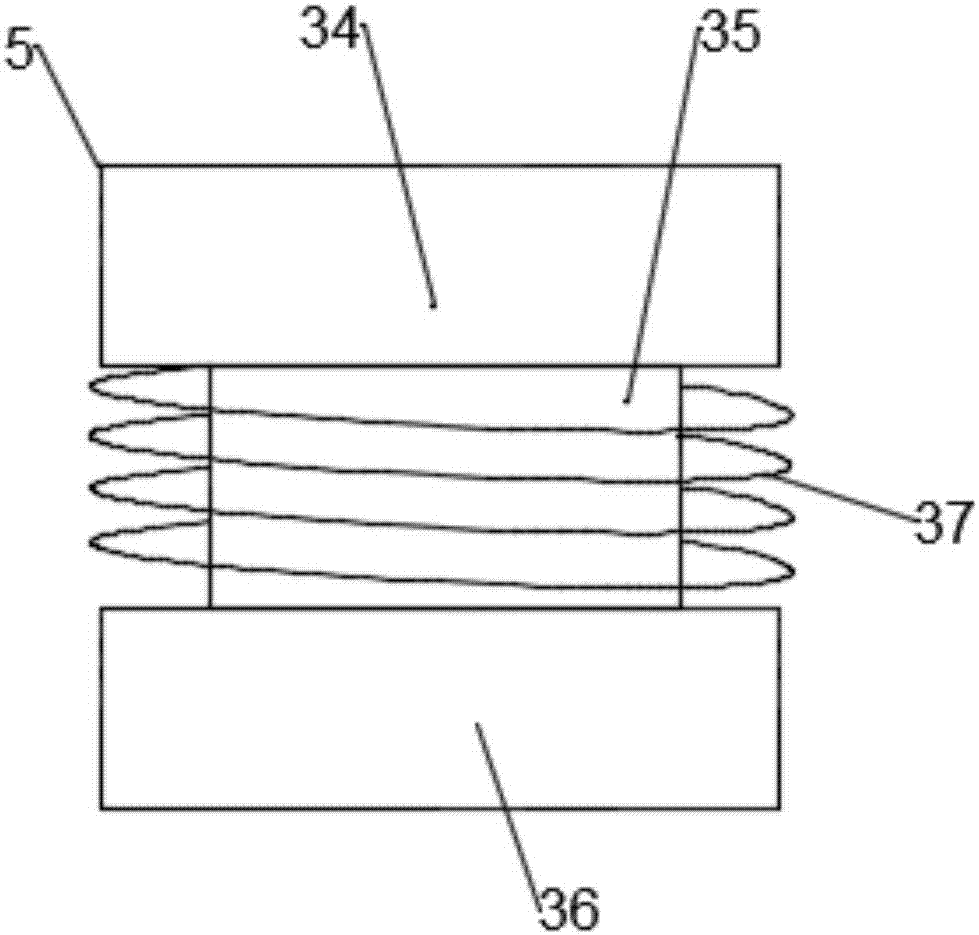

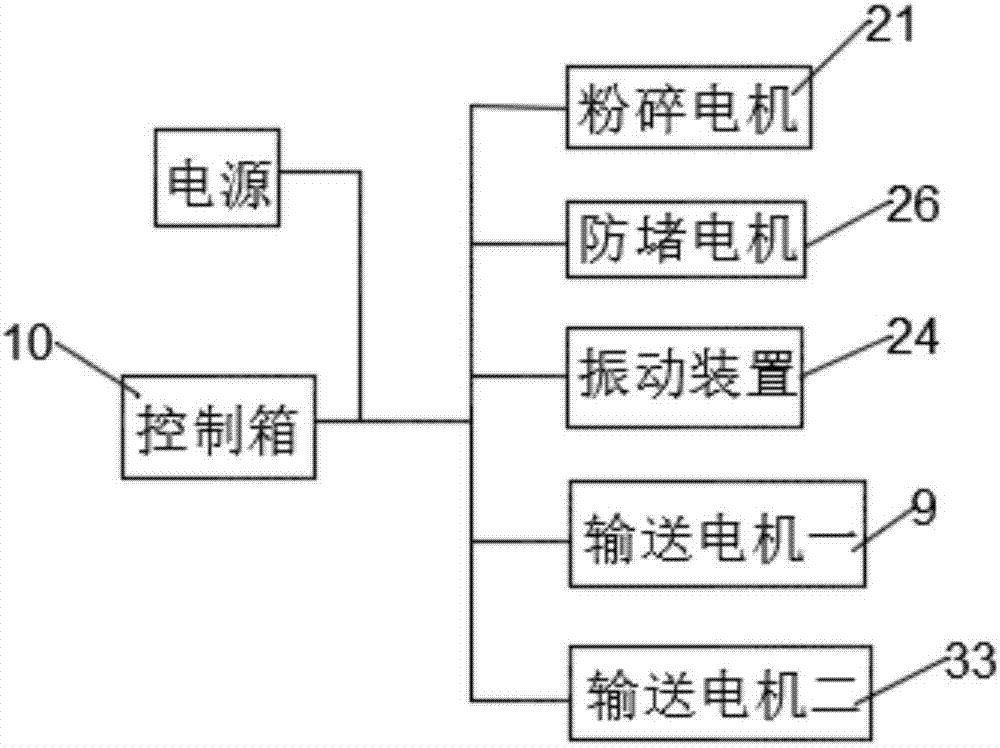

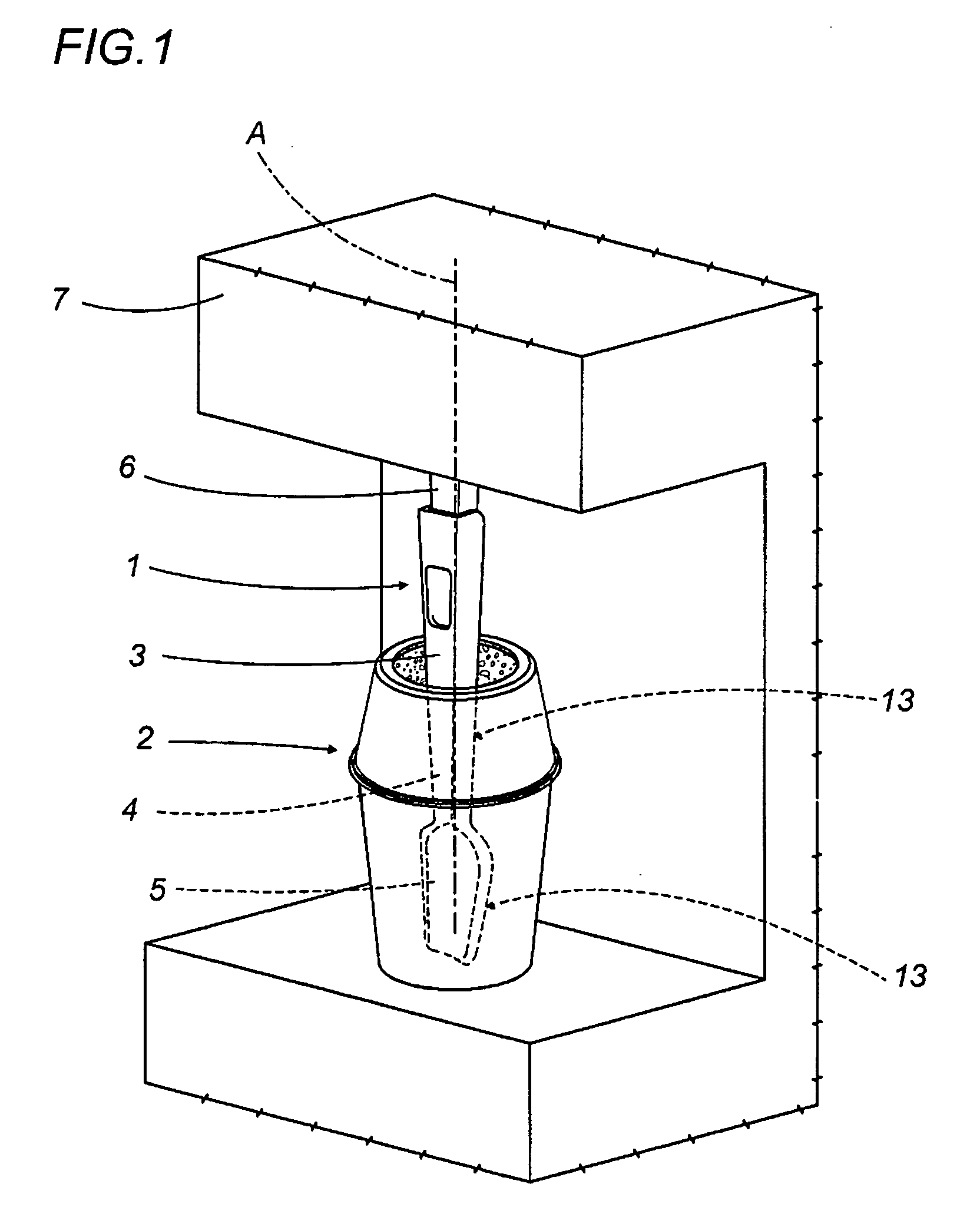

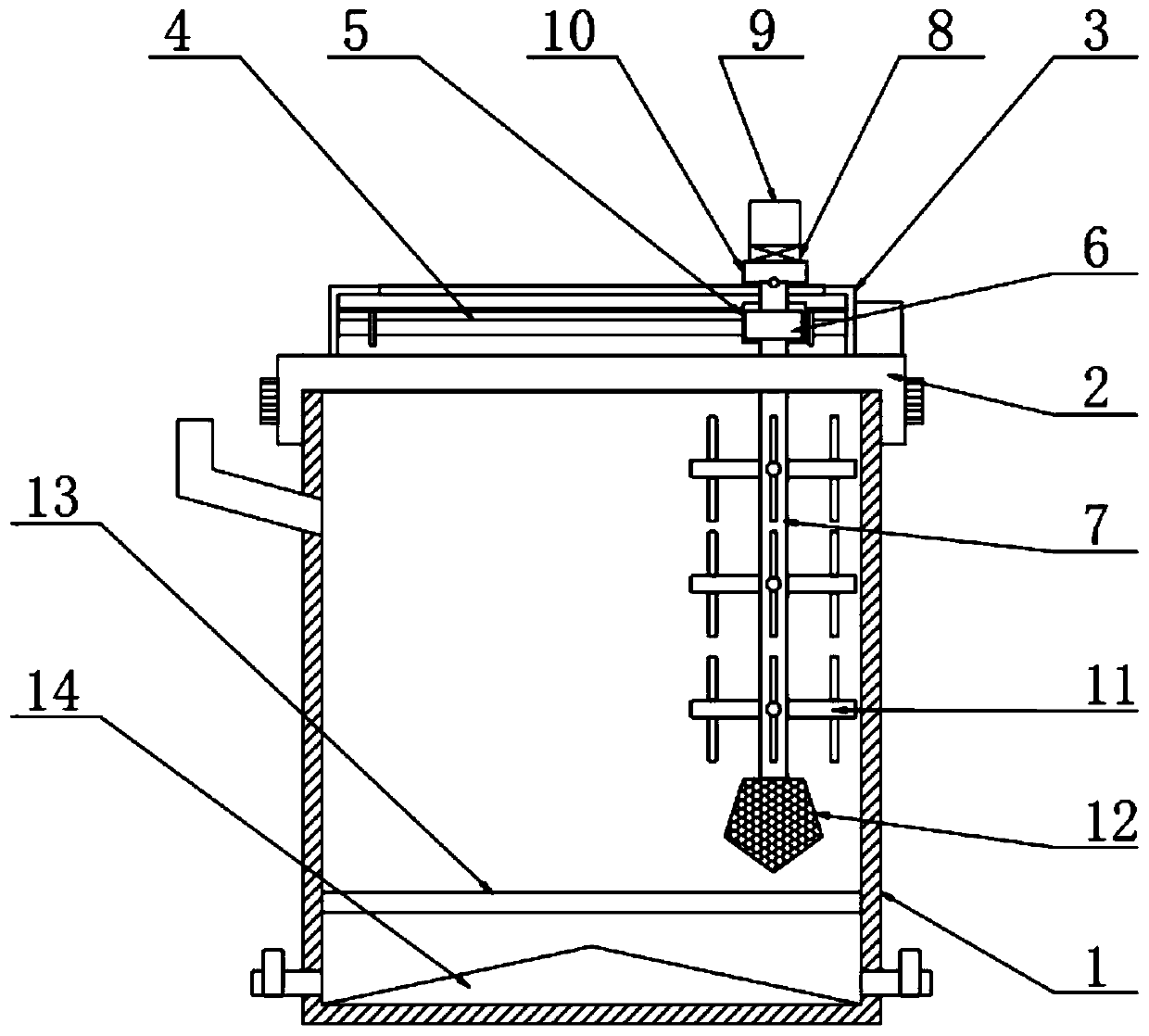

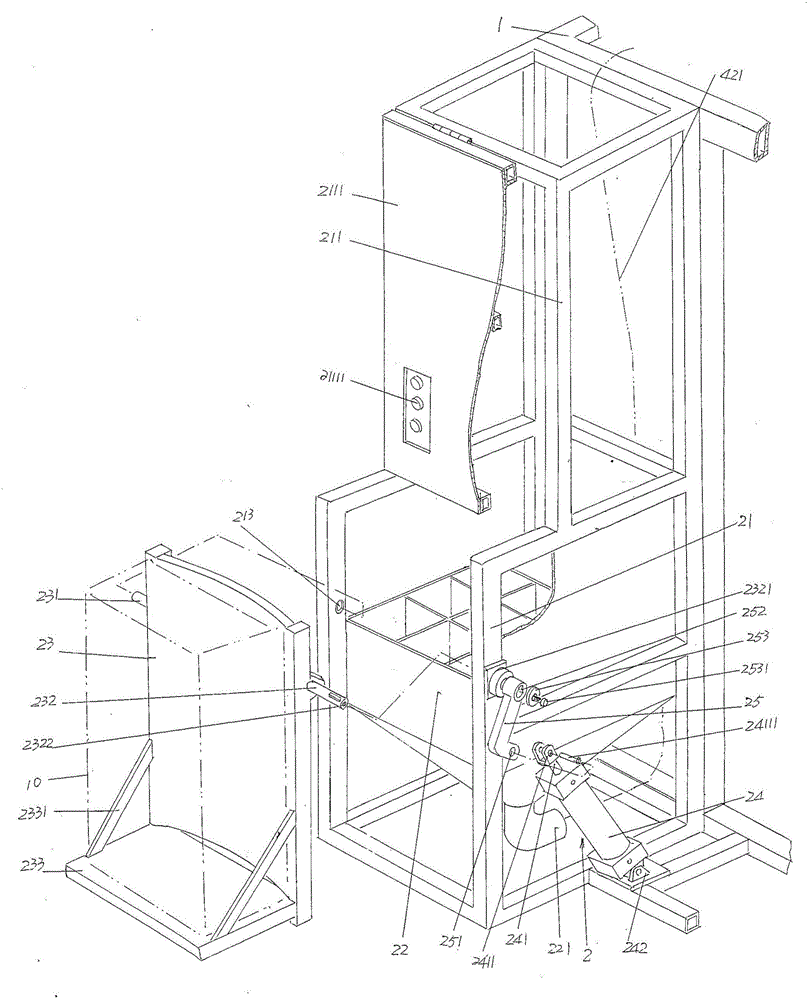

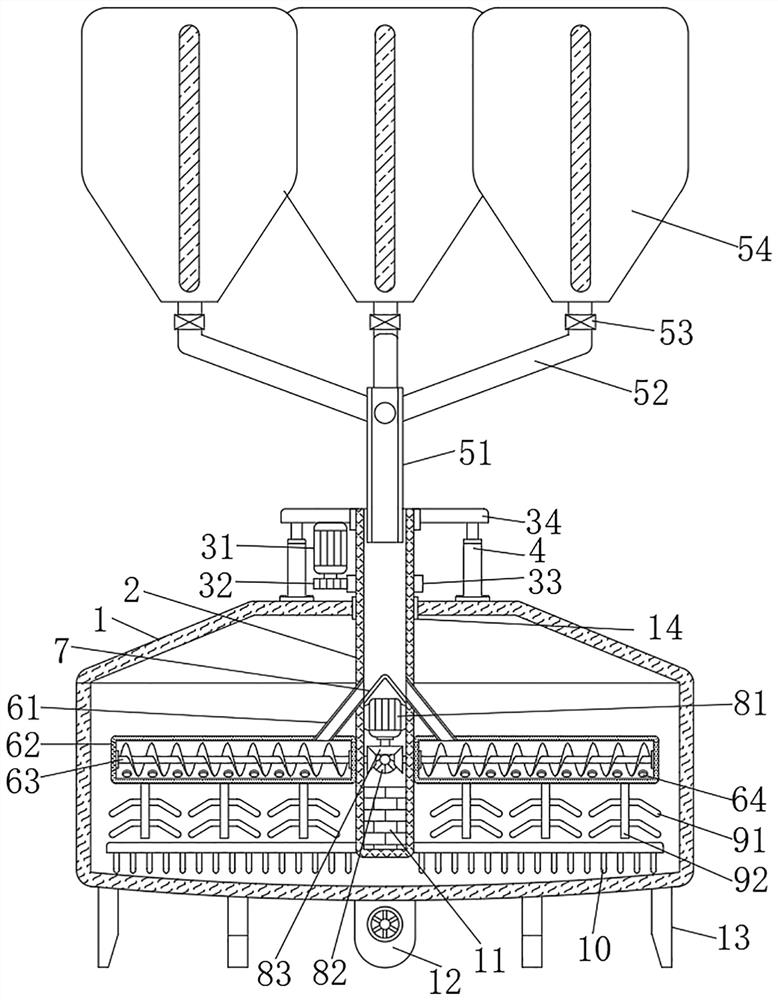

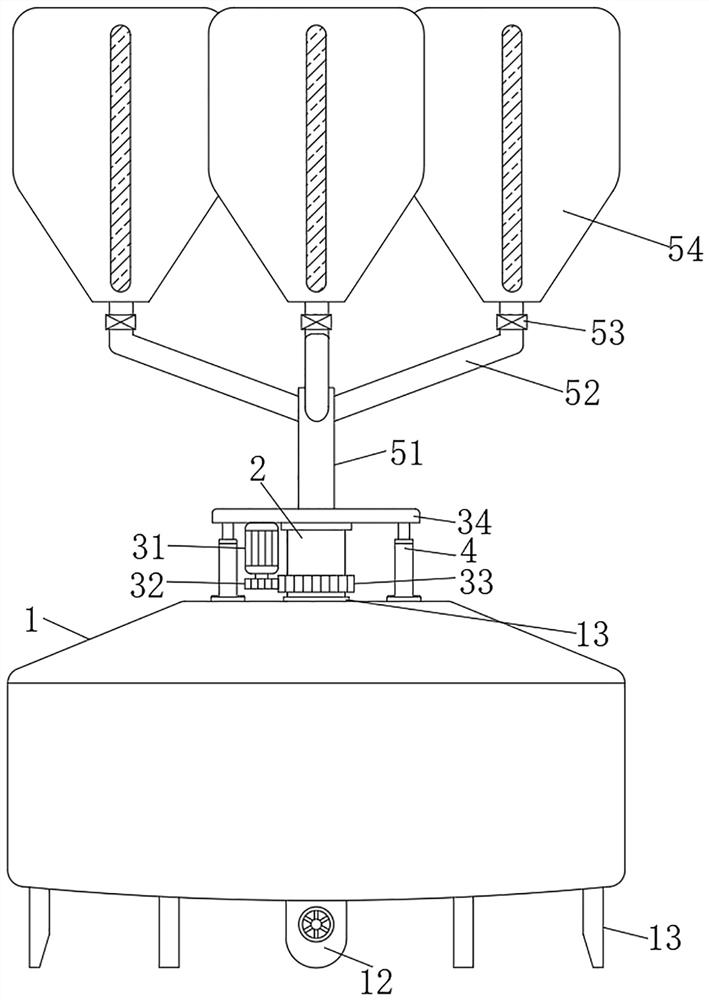

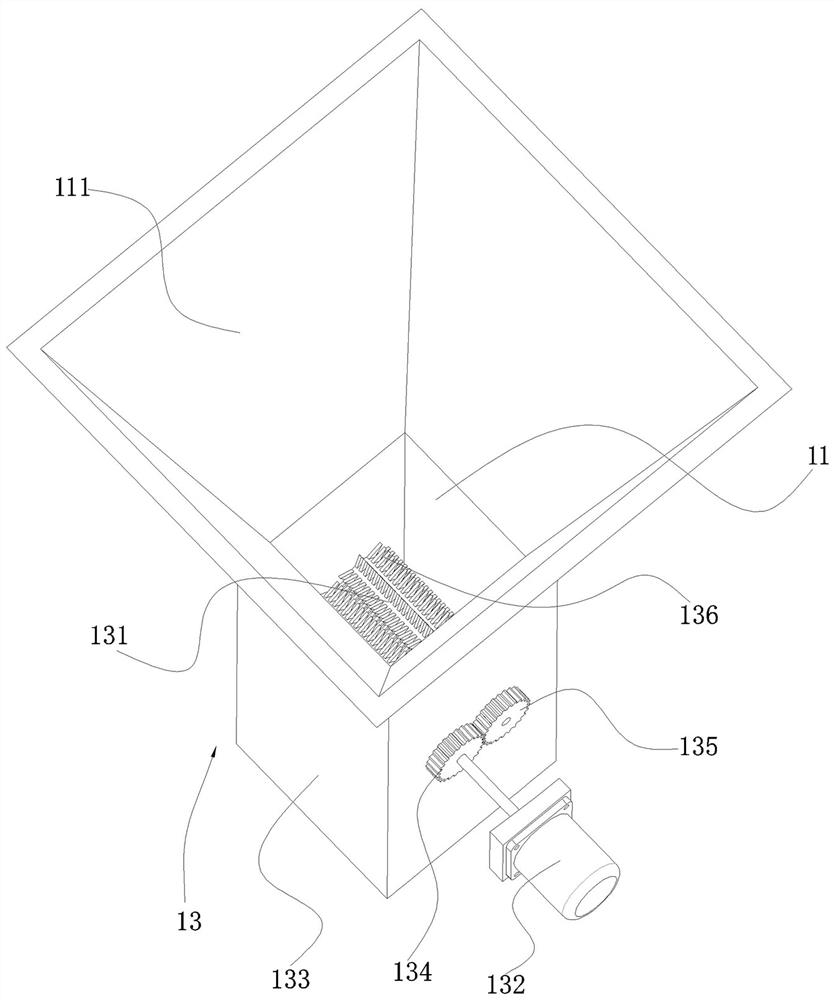

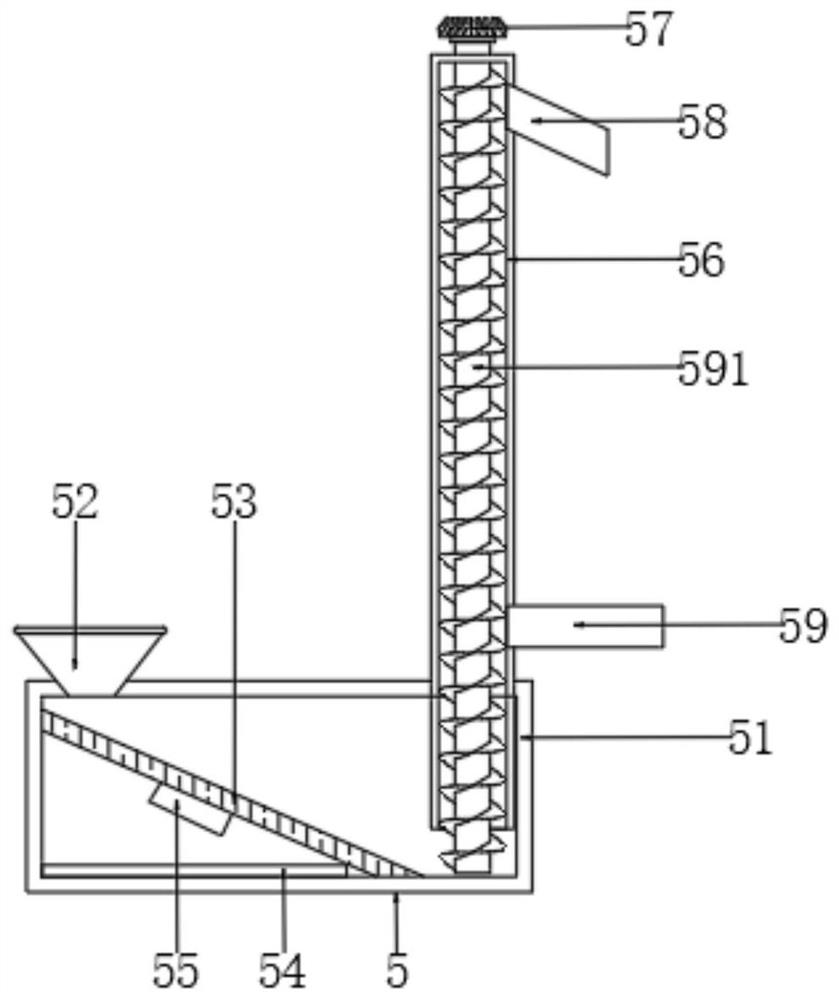

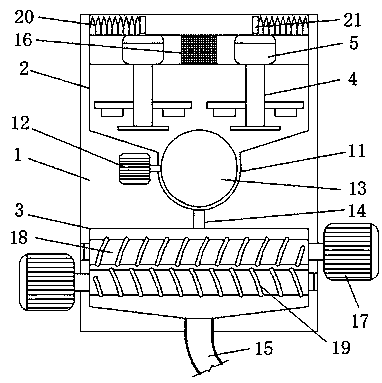

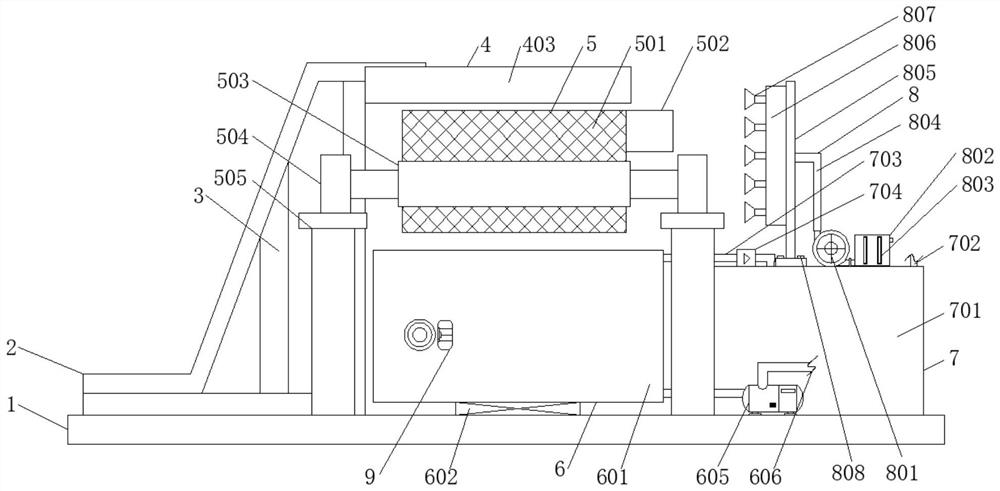

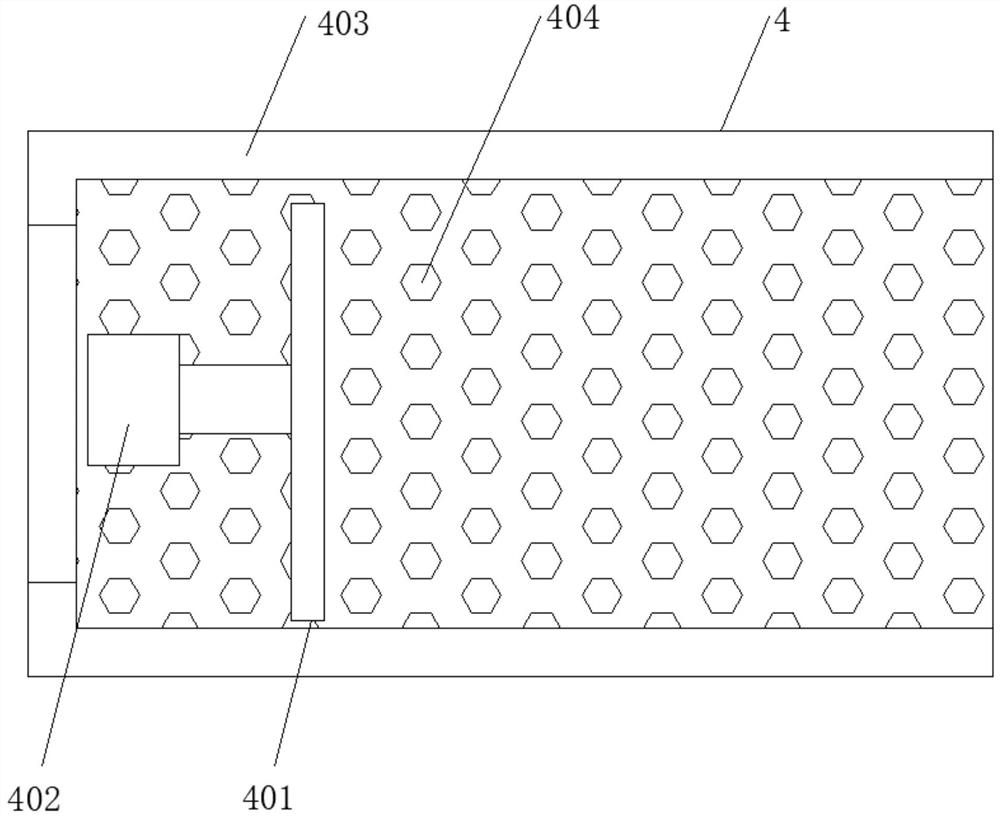

Crushing, stirring and lifting device for construction

InactiveCN107127038ASimple and reasonable designEasy to operatePackagingGrain treatmentsQuality assuranceBuilding material

The invention discloses a crushing and stirring lifting device for building construction, which comprises a bottom frame, a shock-absorbing layer and a base. A second crushing box is provided, the lower end of the second crushing box is provided with a feeding channel, the lower end of the feeding channel is provided with a first conveying cylinder, the right end of the first conveying cylinder is provided with a conveying port, and the lower right end of the conveying port is provided with a second Two delivery cylinders. This device realizes double crushing and mixing of building materials, ensures the quality of material crushing and mixing, and realizes the lifting of materials from low to high, which brings great convenience to construction and can greatly reduce the labor intensity of workers , which is conducive to improving the efficiency of construction. The shock absorbing mechanism and the shock absorbing layer have a good shock absorbing and buffering effect, which can reduce the vibration caused by the equipment during operation, protect the device, and prolong the service life of the device. .

Owner:蔡政伟

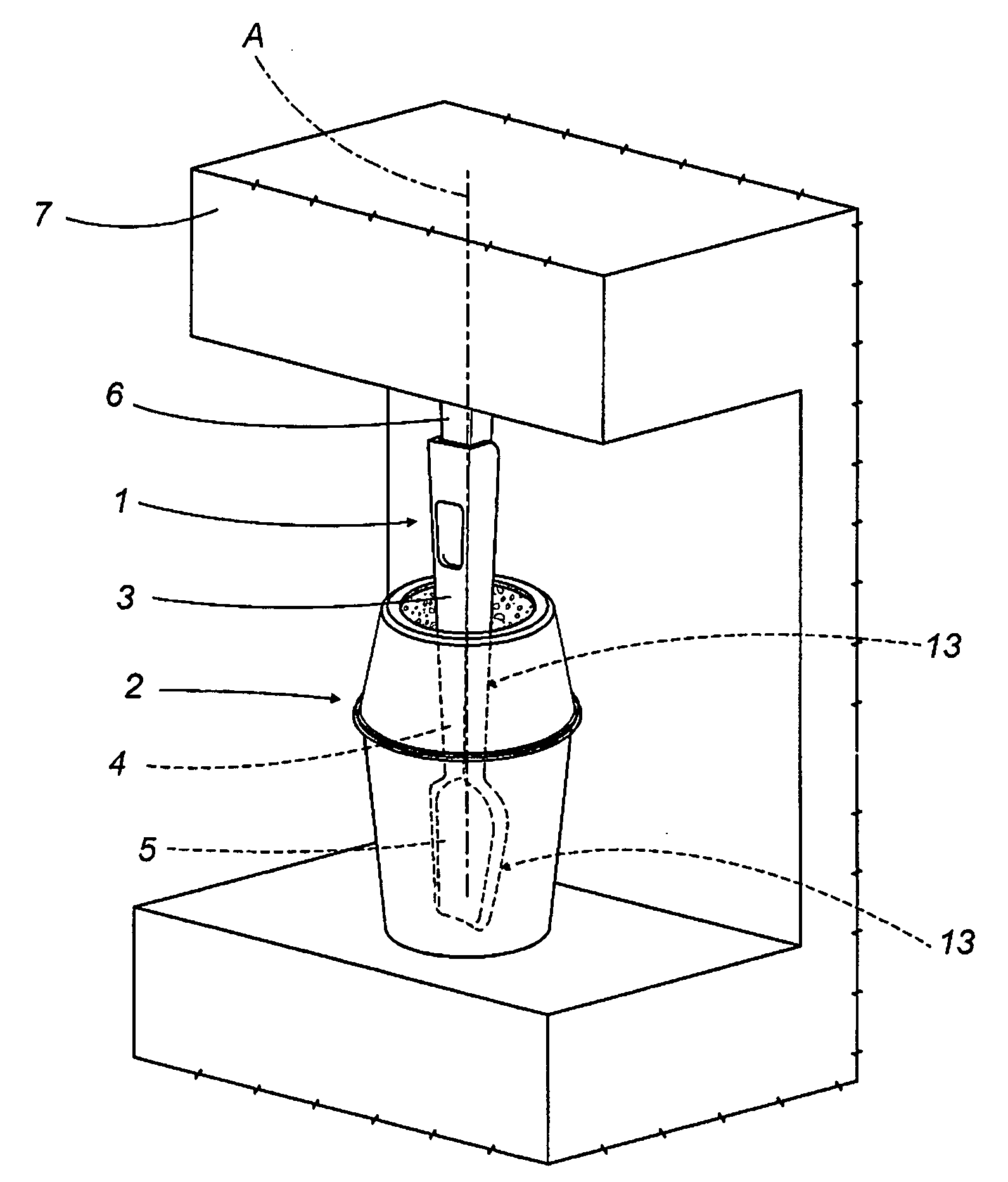

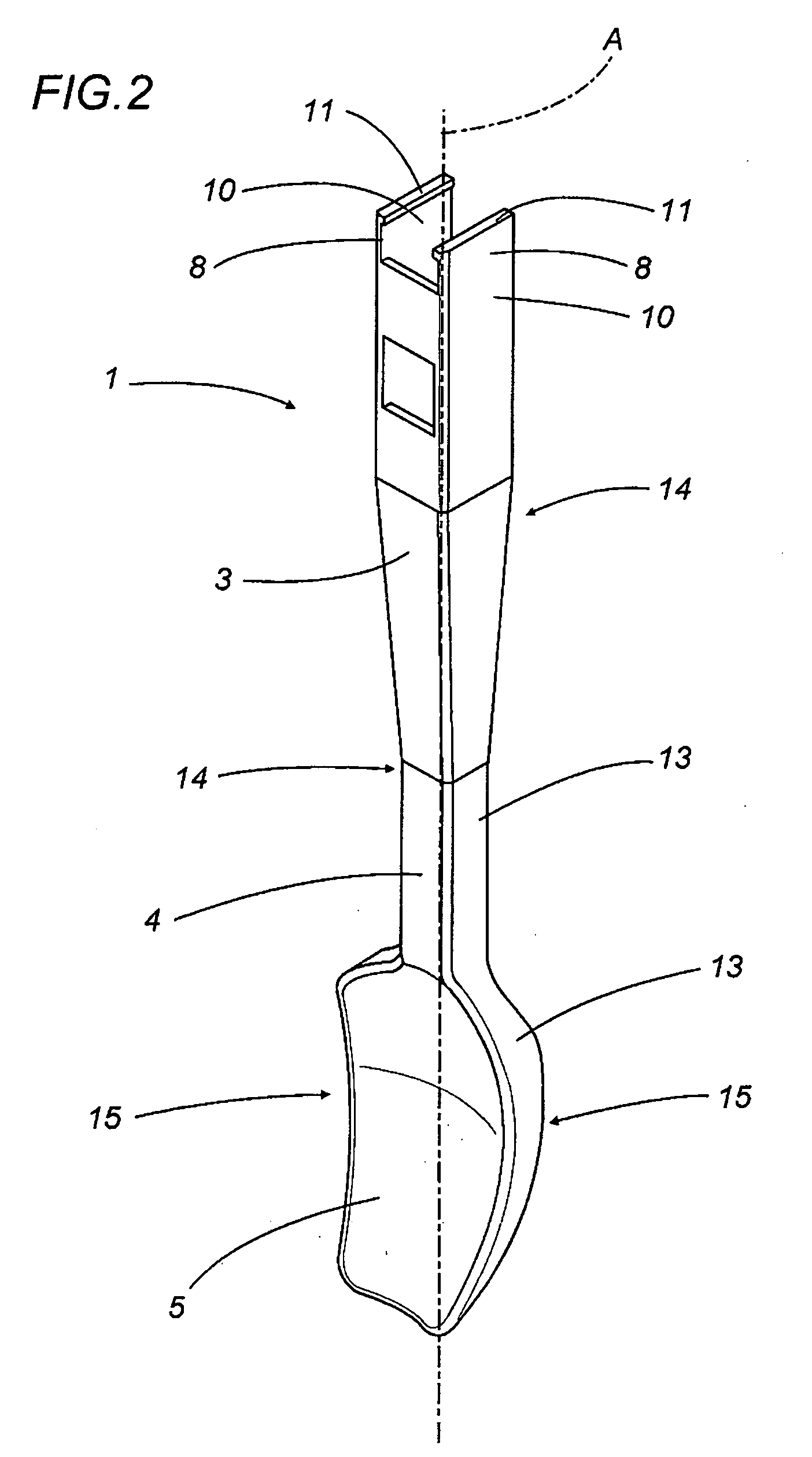

Disposable agitator for mixed food products

ActiveUS20080159070A1Guaranteed mix qualityReduce speedMixersKitchen equipmentEngineeringMechanical engineering

The disposable agitator for mixed food products has an elongated stem, which has, at a longitudinal end, an agitator blade having the shape of a spoon, and can be removably fixed to the rotary shaft of a mixer, so that the consumer can subsequently use the agitator as a utensil for eating the product previously mixed; the agitator has at least one longitudinal rib, projecting transversally from the stem and / or from the agitator blade and at the same time acting as an agitator stiffening element and an active element in the mixing action.

Owner:SEAT PLASTIC SRL

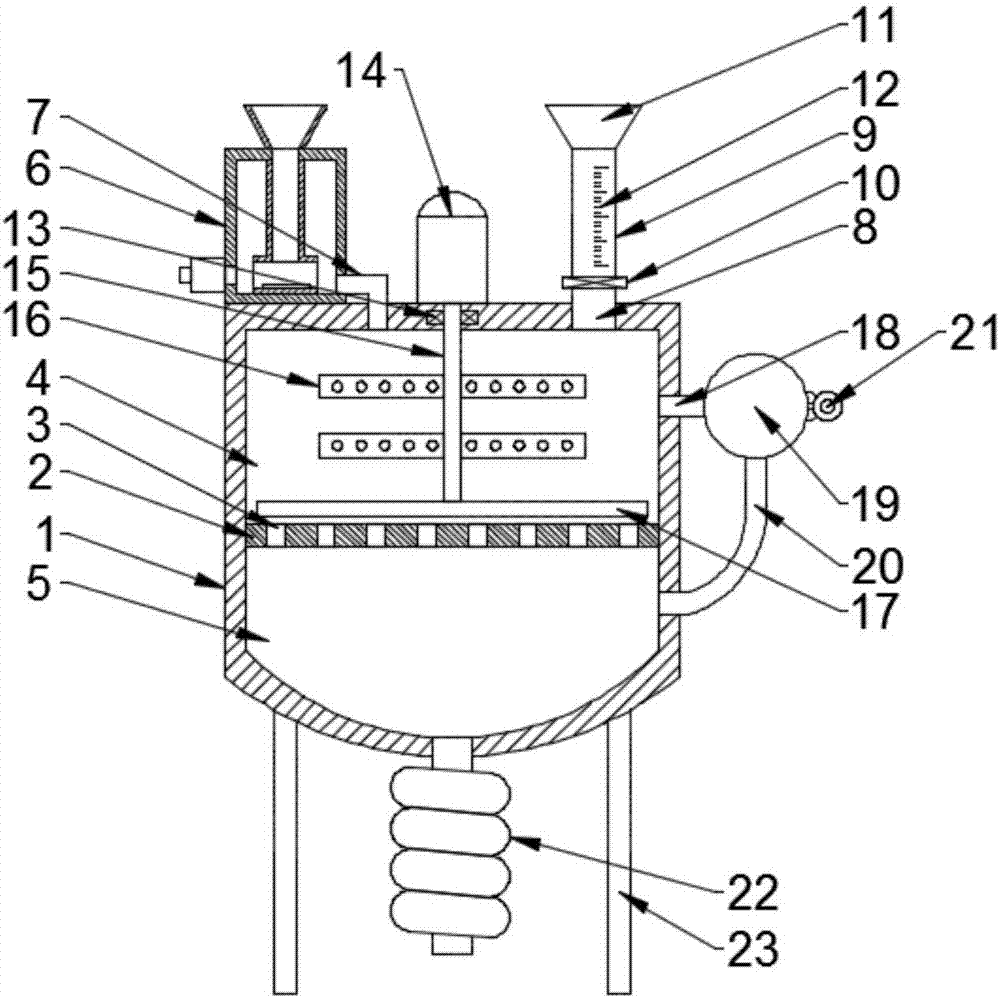

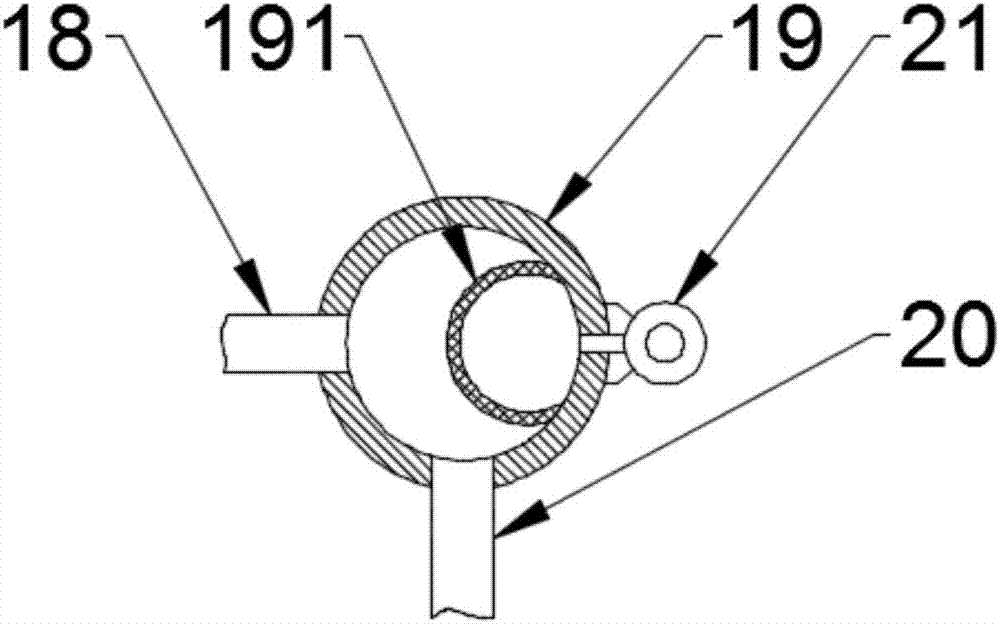

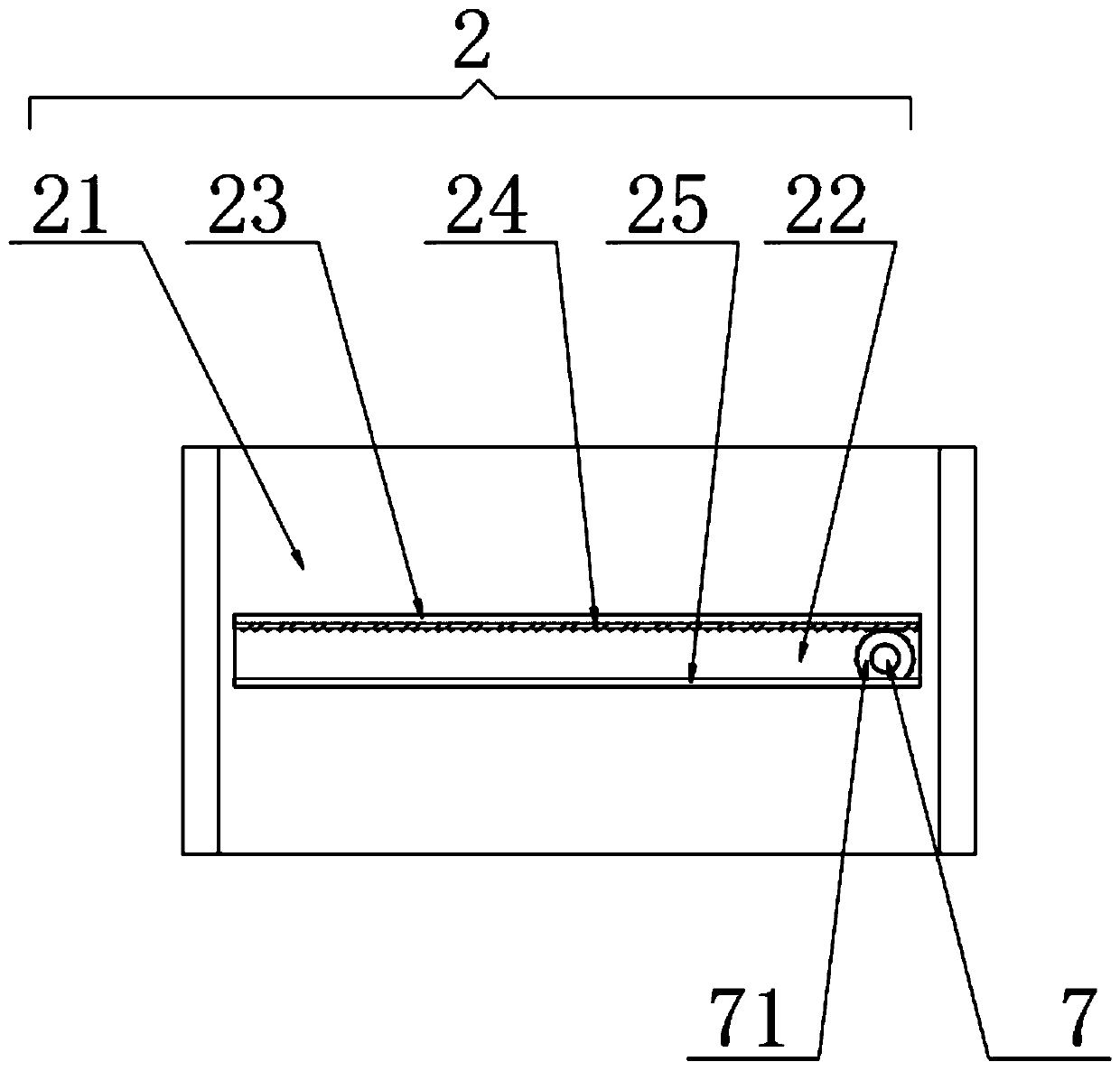

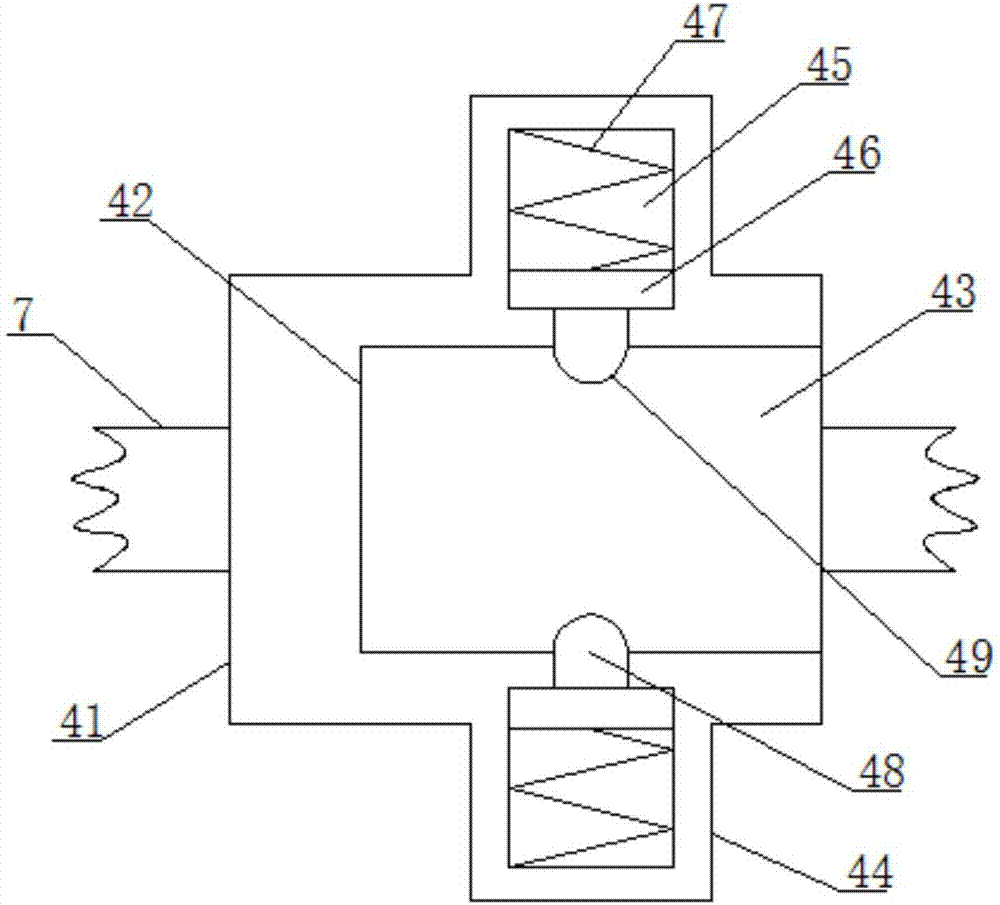

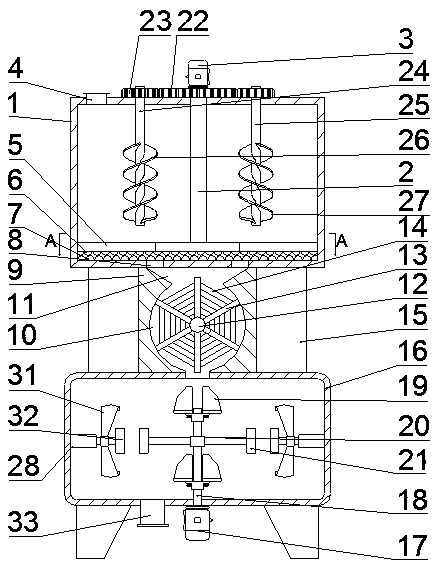

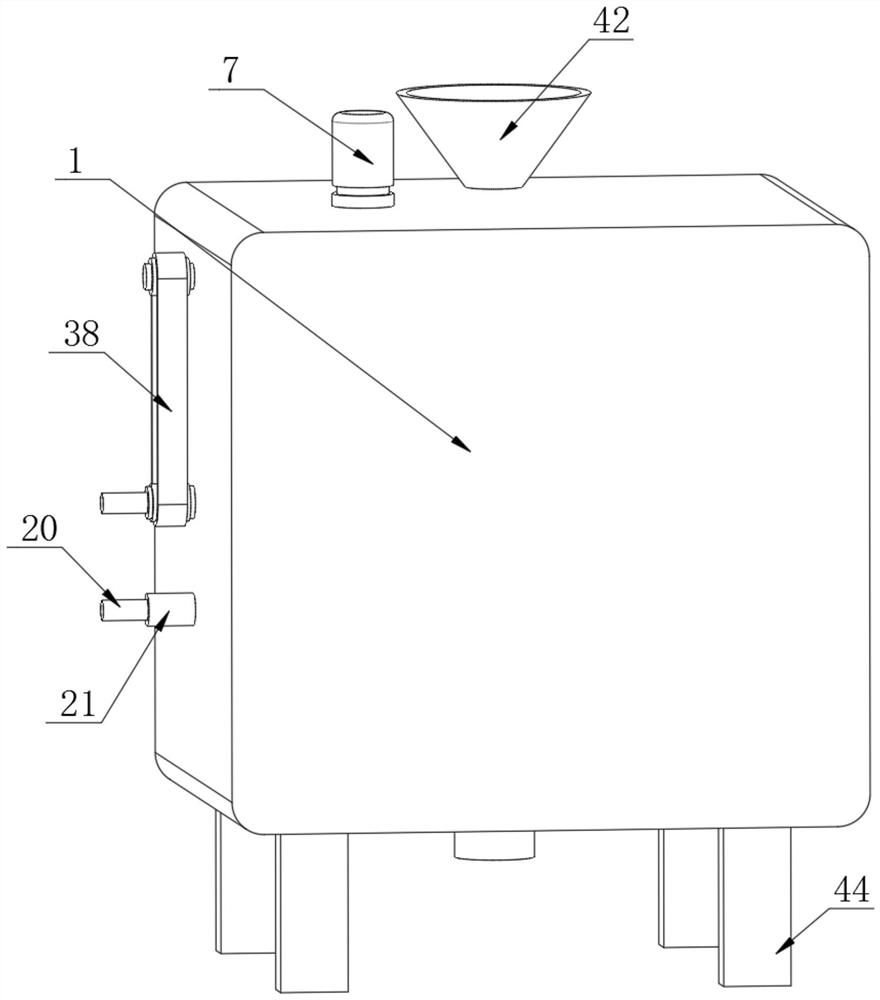

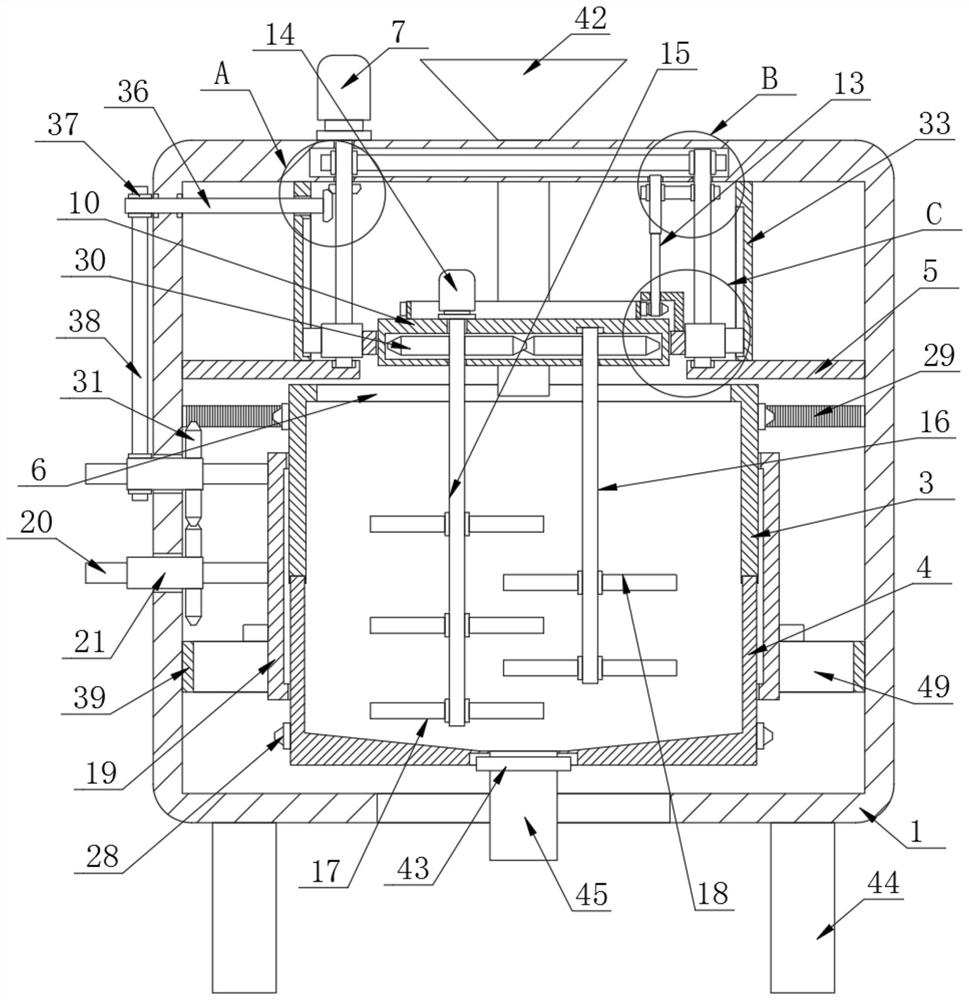

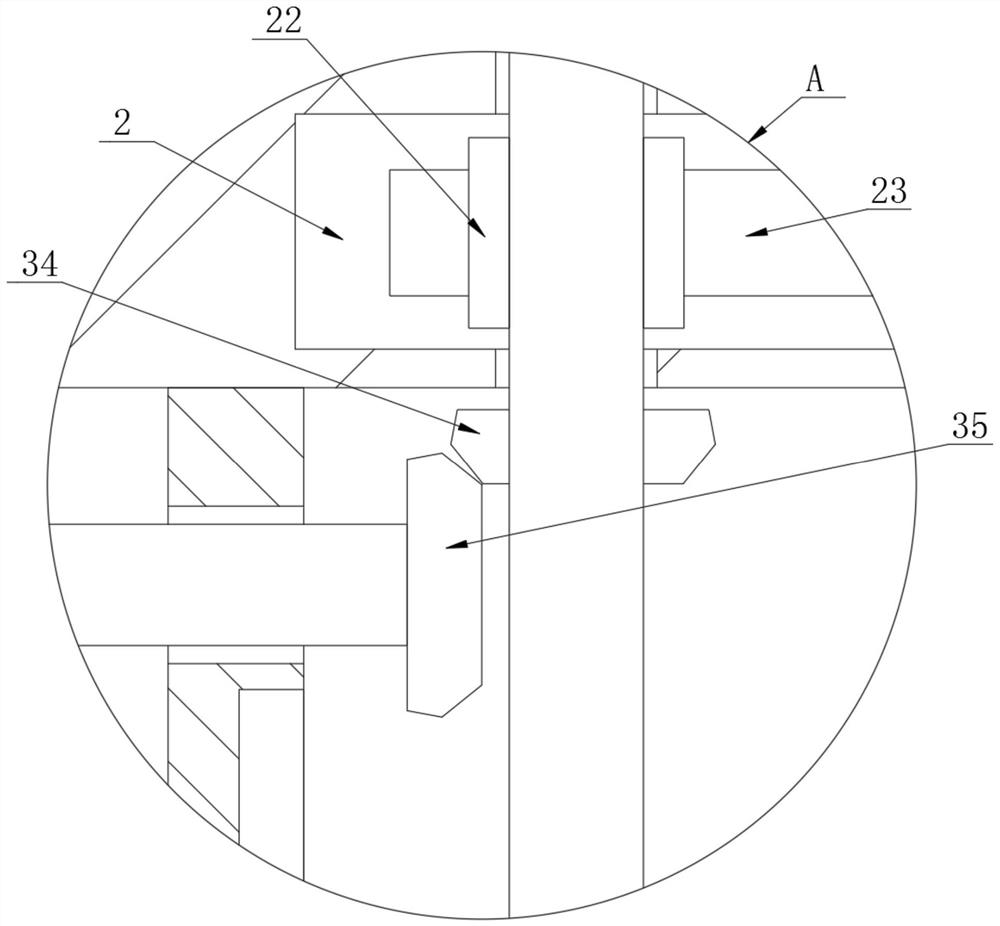

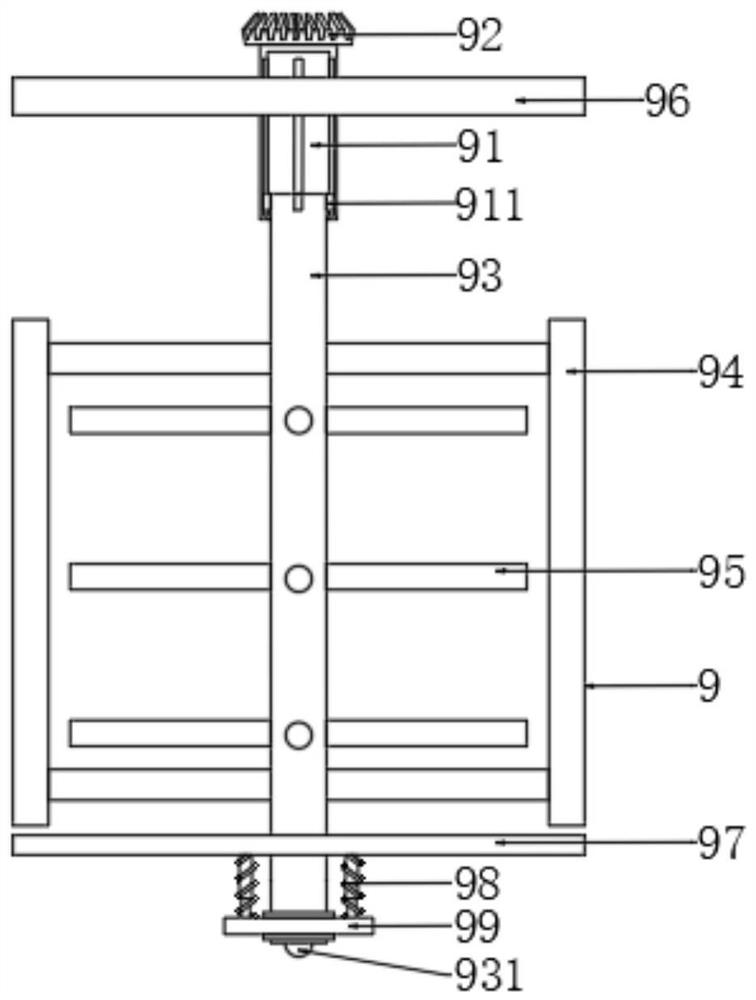

Feed additive dosing device

PendingCN107224933AMeet the needs of useAdd accurateFeeding-stuffRotary stirring mixersEngineeringFeed additive

The invention discloses a feed additive dosing device. The feed additive dosing device comprises a mixing box, a feeding box and a dust collection box, wherein a separating baffle plate is arranged at the middle part of an inner cavity of the mixing box; the separating baffle plate is used for separating the inner cavity of the mixing box into a mixing cavity and a discharging cavity; the mixing cavity is internally provided with a stirring shaft; the top end of the stirring shaft penetrates through the top wall of the mixing box and is fixedly connected to a motor shaft of a motor; the bottom end of the stirring shaft is fixedly connected with a second stirring blade which is matched with the separating baffle plate; a plurality of first stirring blades are uniformly arranged at the middle part of the stirring shaft; a first feeding hole is formed in one side of the top wall of the mixing cavity; the top part of one side wall of the mixing cavity is in through connection with the dust collection box through an air inlet pipe. According to the feed additive dosing device disclosed by the invention, two weighing and dosing modes of the feeding box and a weighing drum are arranged, the using demands of different additives are met, and accurate adding of various additives is ensured; due to the arrangement of the dust collection box, flying dust generated by stirring the additives can be collected, and meanwhile, the collected flying additive smoke dust can return to the discharging cavity again, so that accurate proportioning of all the additives is ensured.

Owner:邹铁梅

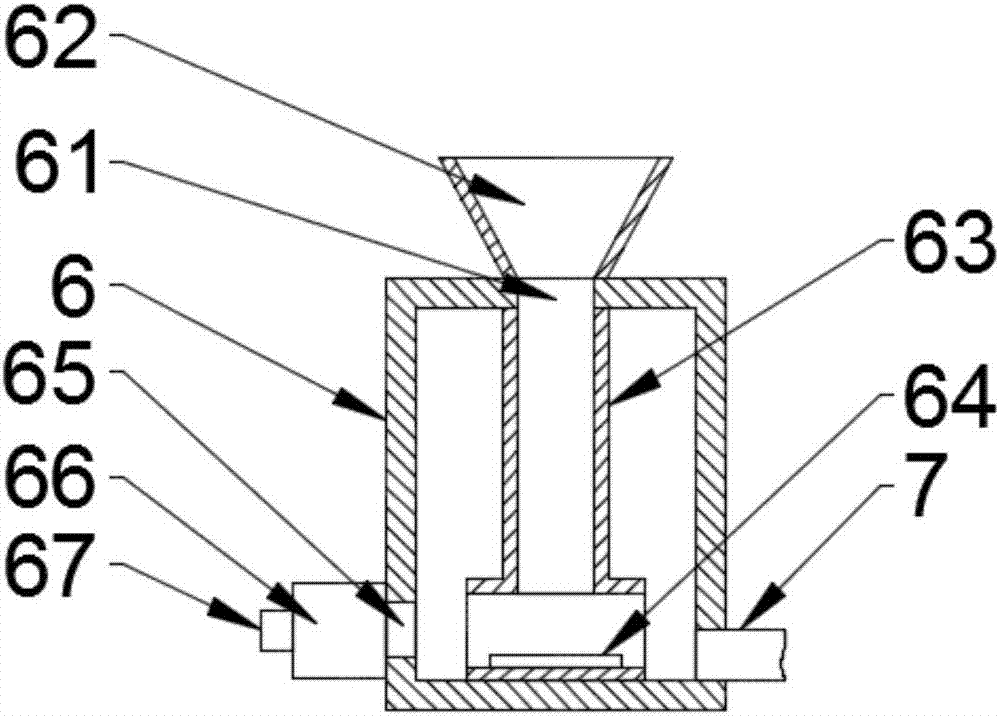

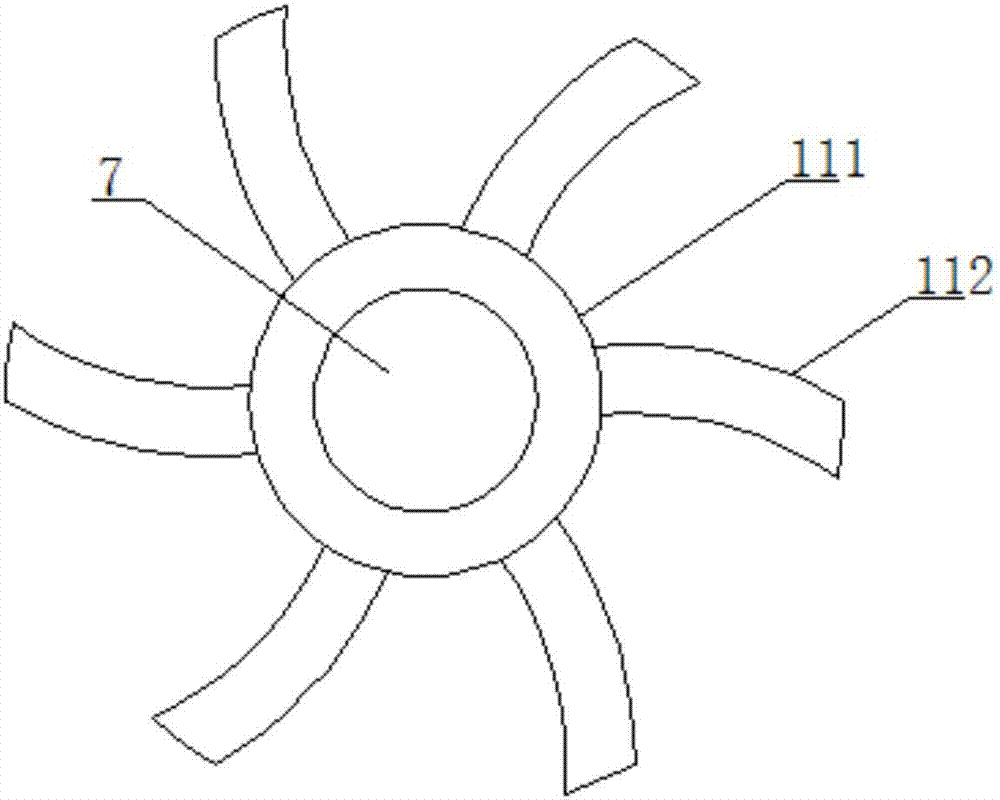

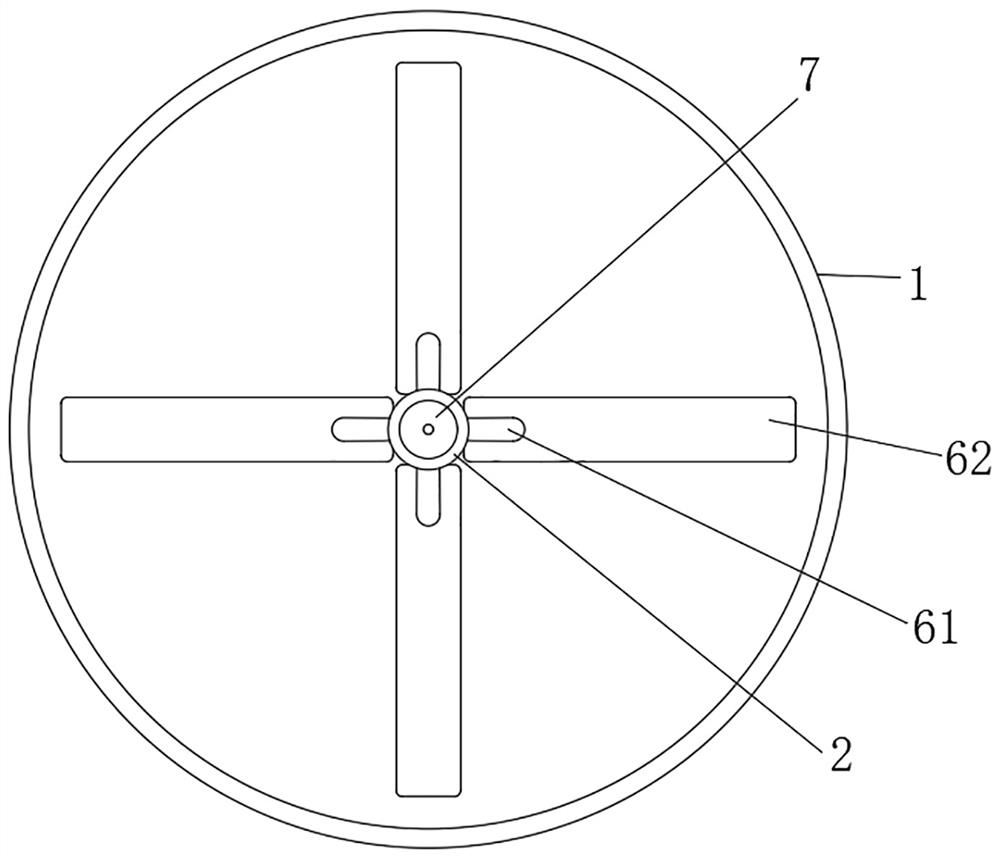

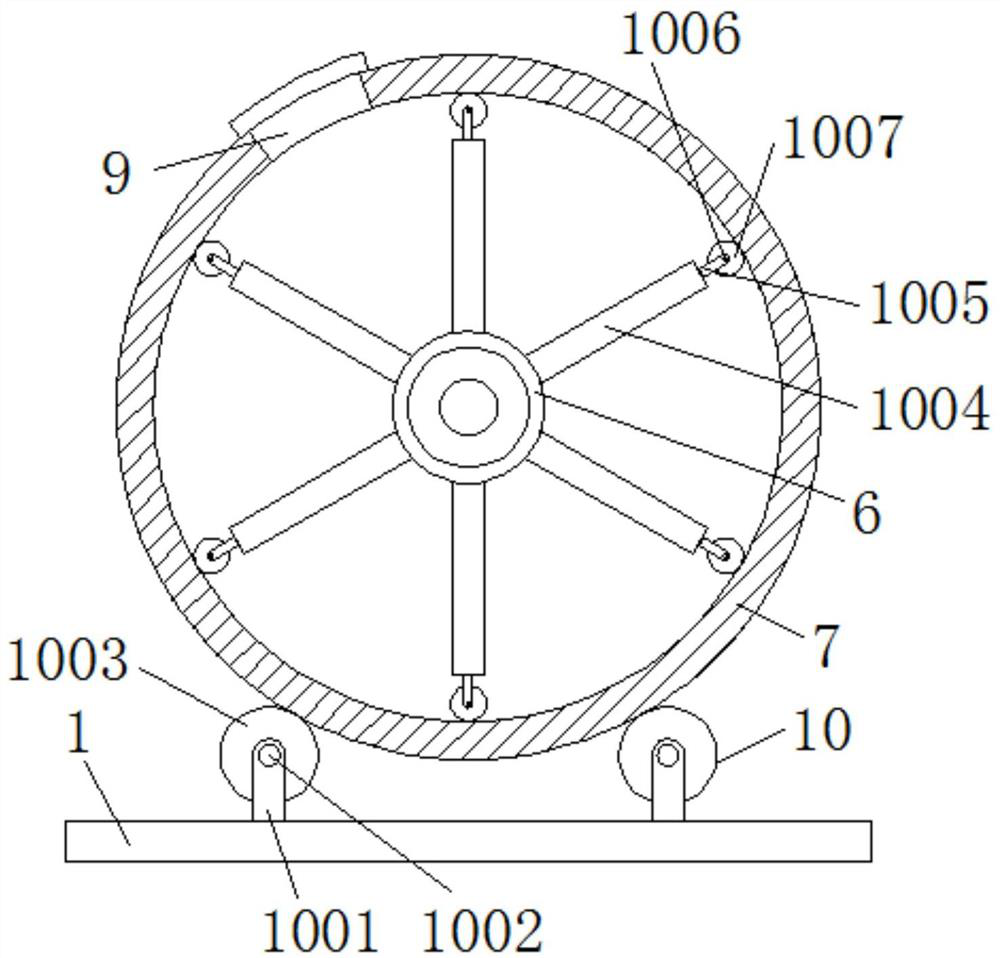

Novel brine stirring machine for ice maker

InactiveCN109847627AIncrease the mixing areaImprove uniformityShaking/oscillating/vibrating mixersRotary stirring mixersPulp and paper industry

The invention discloses a novel brine stirring machine for an ice maker, and belongs to the technical field of stirring machines. The brine stirring machine comprises a shell and a quantitative discharging device; a lead screw is movably arranged between the left inner wall and the right inner wall of a mounting shell through bearings; the outer wall of the screw rod is sleeved with a movable block; the outer wall of a stirring rod is uniformly provided with branched stirring rods; a hollow block communicating with the bottom end of the stirring rod is arranged at the bottom end of the stirring rod; a material placing cylinder is arranged at the top of the quantitative discharging device; and a filter screen plate is transversely arranged in the inner cavity of the shell. The brine stirring machine is provided with the lead screw, the movable block, an assembly block, the stirring rod and the branched stirring rods, so that the branched stirring rods can move left and right, the stirring area of liquid inside the shell is increased, and uniformity is improved. Meanwhile, a gear and a gear rack are arranged to be matched with each other, so that the stirring rod can rotate during moving, the liquid located at each position in the shell can be mixed, and mixing quality is improved.

Owner:FOCUSUN REFRIGERATION JIANGSU

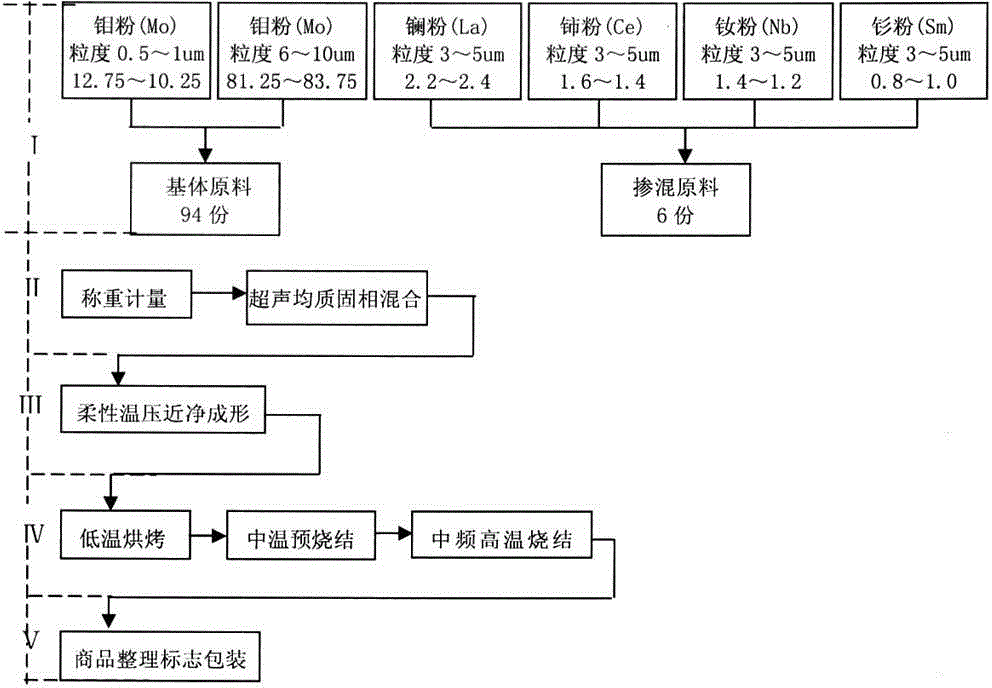

Powder warm-compaction near-net molded molybdenum-based rare earth alloy top and manufacturing technology thereof

The invention discloses a powder warm-compaction near-net molded molybdenum-based rare earth alloy top and a manufacturing technology thereof. The manufacturing technology comprises key technologies of scientific proportioning of multi-element composite materials, ultrasonic homogenous solid-phase blending, flexible warm-compaction near-net molding, continuous successive sintering shaping and the like, and special technological devices matched with the key technologies in use, an operation technology procedure and technology parameters are also involved in the manufacturing technology. Hot piercing molding operation adopted in the seamless steel pipe manufacturing industry, especially the high-nickel-chromium thick-wall stainless steel seamless tube manufacturing industry is provided with the new high-tech powder metallurgy warm-compaction near-net molded molybdenum-based rare earth alloy top product which has the beneficial effects of good high-temperature red hardness, high strength, high cold and hot fatigue resistance stability, long service life, good working quality and the like. The manufacturing technology has the outstanding beneficial effects that the system is complete and comprehensive, the technology is advanced and reliable, the number of configured devices is less, and the operation cost is low. By the adoption of the manufacturing technology, industrial volume production can be achieved. After the manufacturing technology is applied and popularized, a large amount of precious resources such as rare precious metals molybdenum and rare earth can be greatly saved.

Owner:SIPING BEIWEI METAL TECH RES DEV

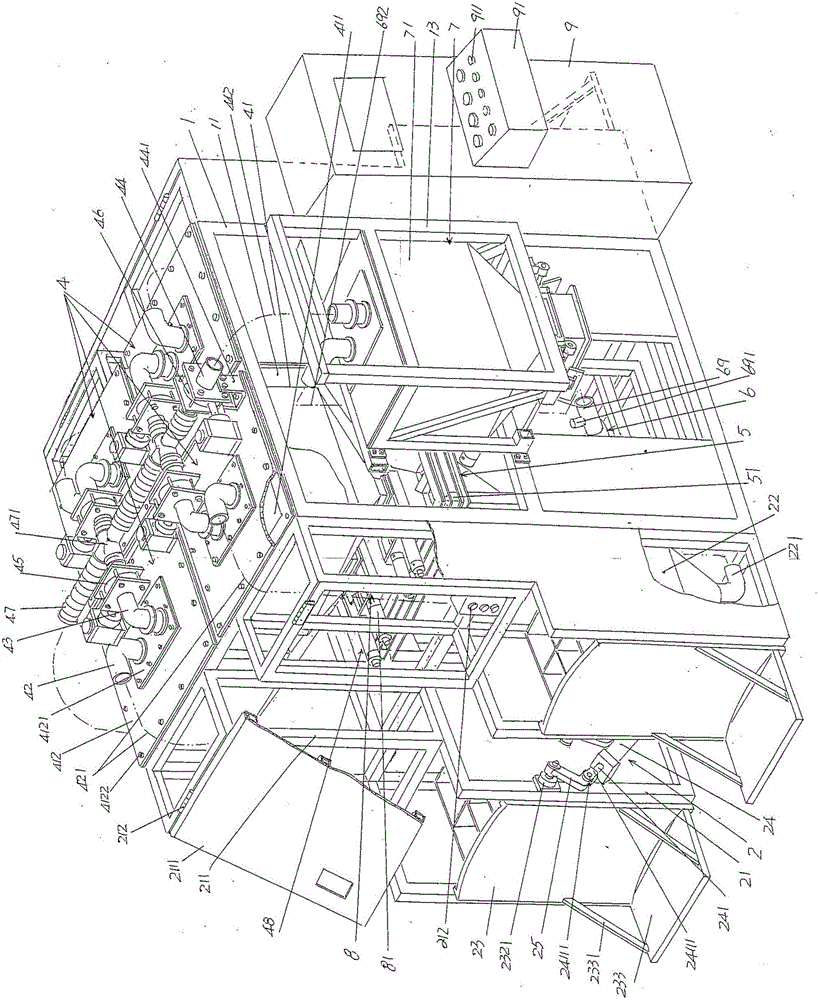

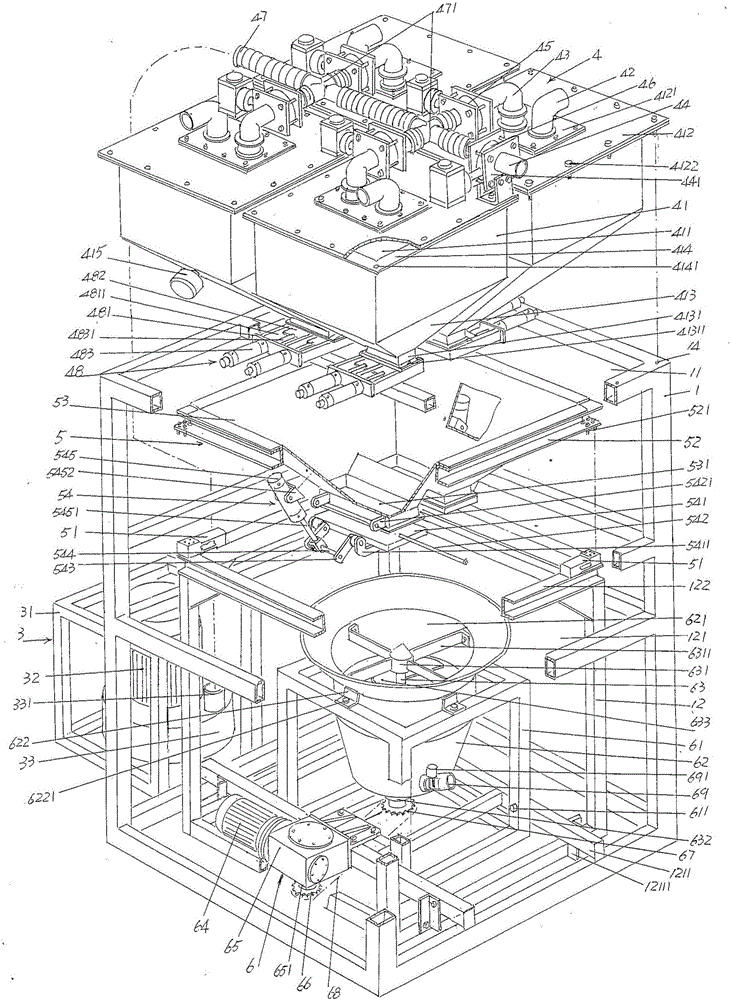

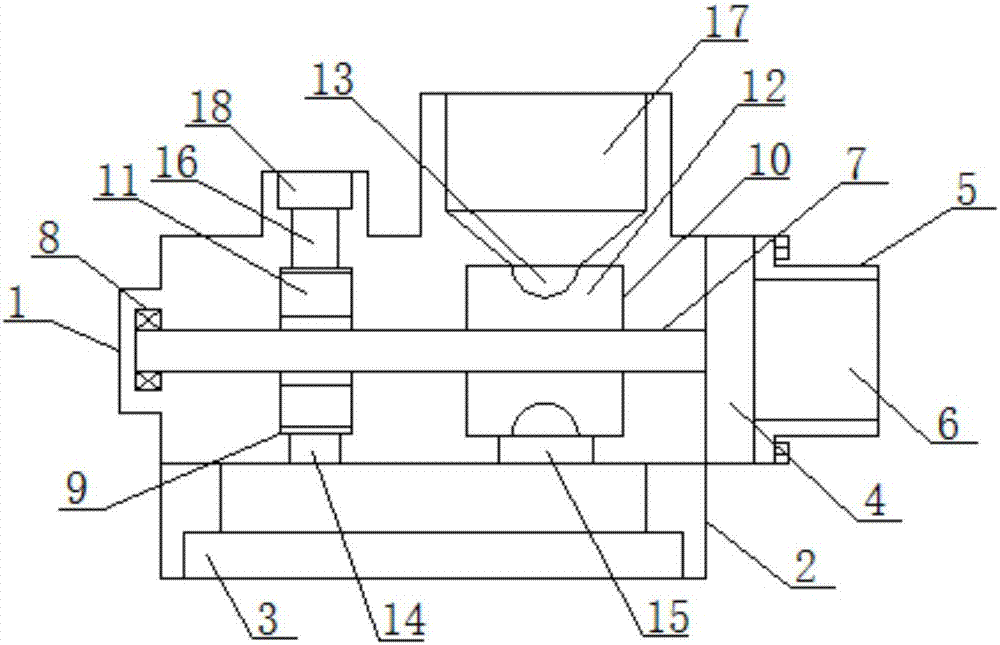

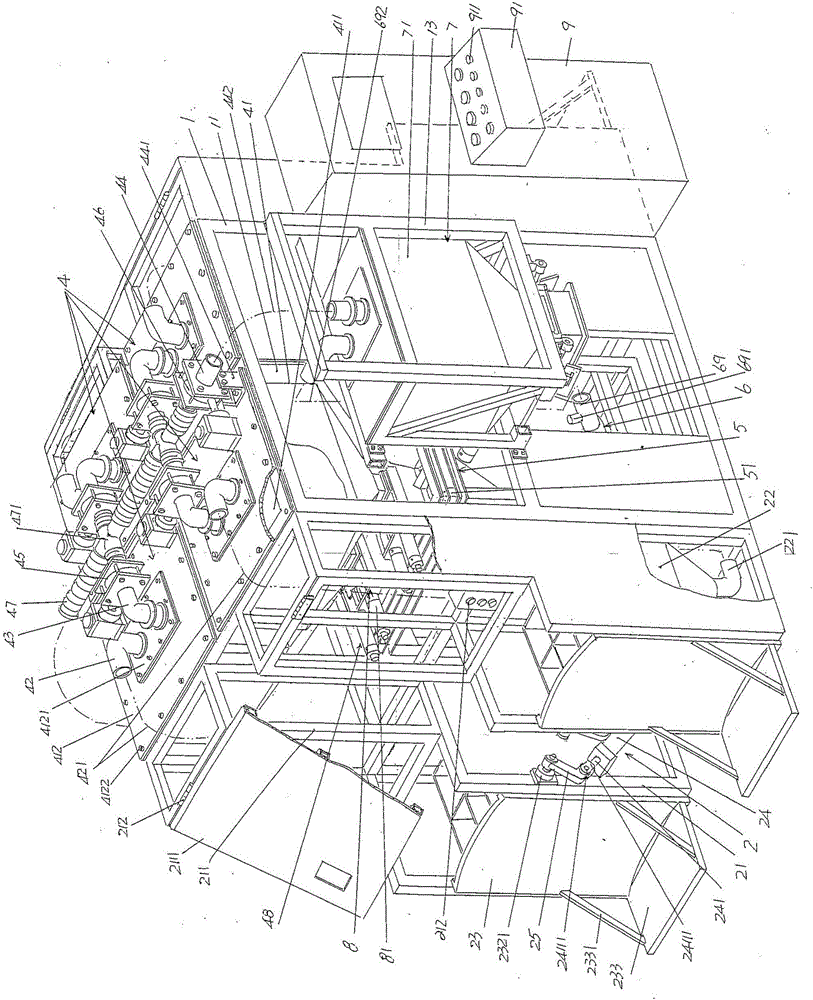

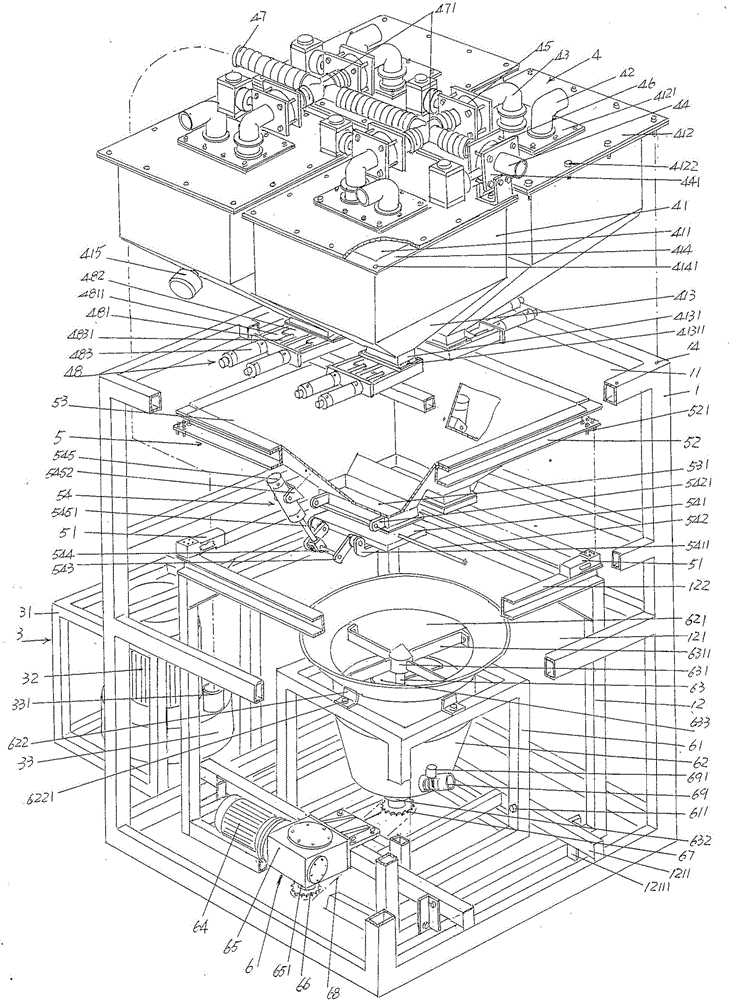

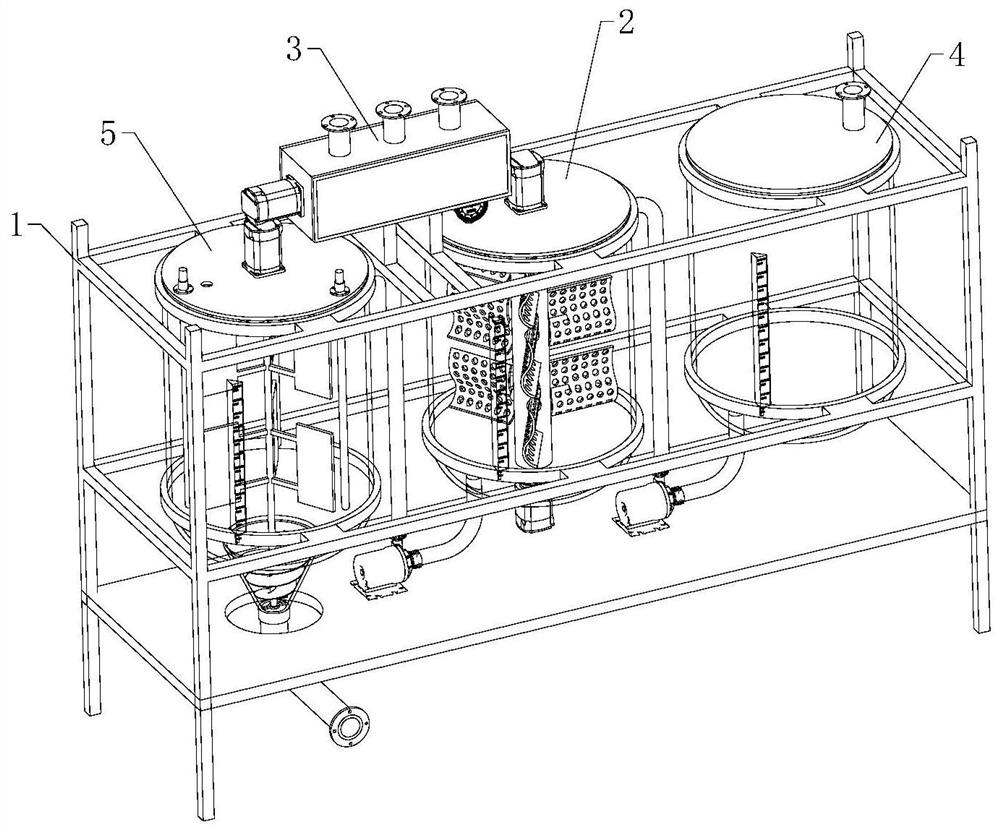

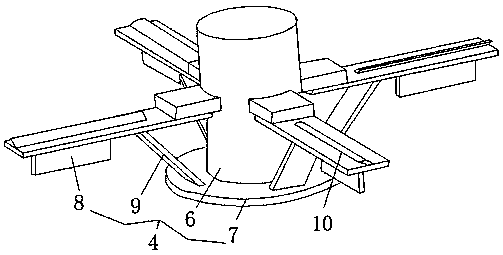

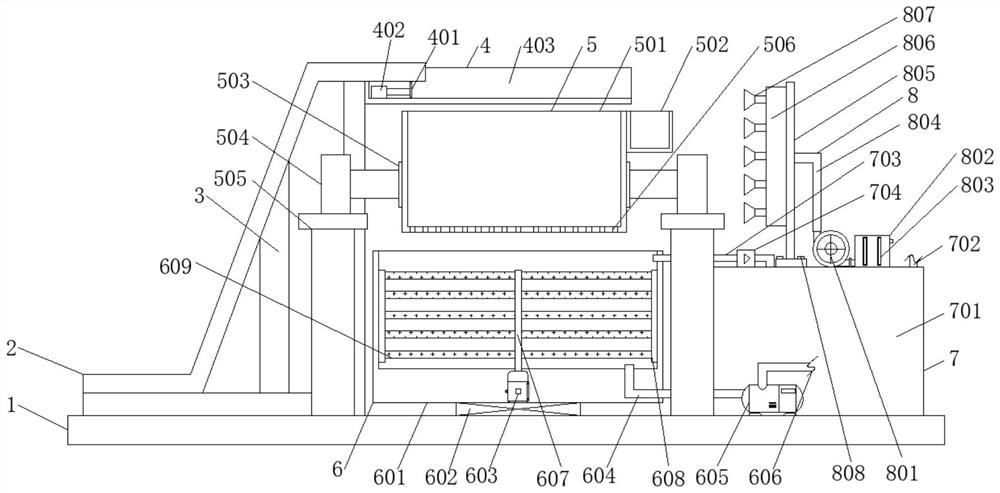

Fertilizer distribution machine

ActiveCN105771751AGood sequenceImprove cleanlinessRotary stirring mixersTransportation and packagingPressure generationAgricultural engineering

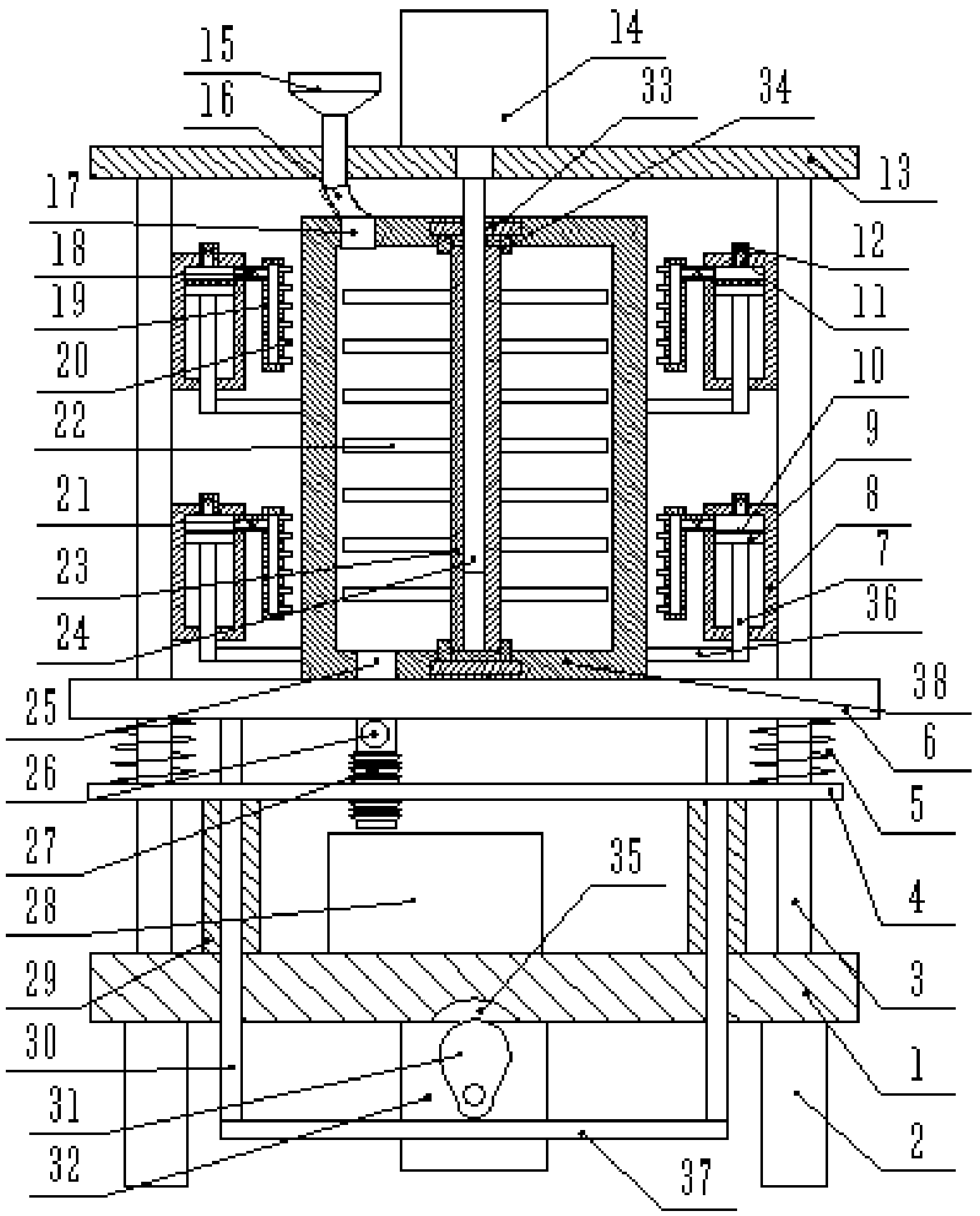

The invention provides a fertilizer distribution machine and belongs to the technical field of agricultural machines. The fertilizer distribution machine comprises a machine frame, feeding mechanisms, a negative-pressure generation mechanism, a storage mechanism, a weighing mechanism, a fertilizer mixing mechanism, a discharging mechanism, a supplement mechanism and an electric control box, wherein the machine frame is rectangular and is provided with a machine frame cavity; at least one feeding mechanism is arranged on the left side of the machine frame, at least one feeding mechanism is arranged on the right side of the machine frame, and the feeding mechanisms are connected with the machine frame; the negative-pressure generation mechanism is arranged on the lower portion of the rear side of the machine frame; the storage mechanism is disposed on the top of the machine frame and connected with the feeding mechanisms and the negative-pressure generation mechanism; the weighing mechanism is arranged in the machine frame cavity and corresponds to the position below the storage mechanism; the fertilizer mixing mechanism corresponds to the position below the weighing mechanism and is arranged in the machine frame cavity; the discharging mechanism is arranged on the front side of the machine frame and connected with the storage mechanism and the fertilizer mixing mechanism; the supplement mechanism is arranged on the lower portion of the storage mechanism and corresponds to the upper portion of the weighing mechanism; the electric control box is connected with the feeding mechanism, the negative-pressure generation mechanism, the storage mechanism, the weighing mechanism, the fertilizer mixing mechanism, the discharging mechanism and the supplement mechanism. The fertilizer distribution machine is small in size and compact in structure, guarantees fertilizer distribution efficiency, guarantees cleanliness of the work environment, guarantees work reliability and stability, is convenient to operate and good in economical efficiency, and guarantees mixing quality.

Owner:YUNNAN YUNTIANHUA AGRI TECH CO LTD

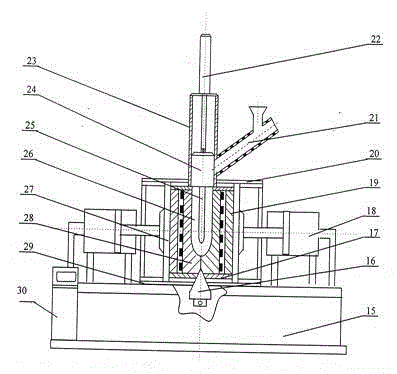

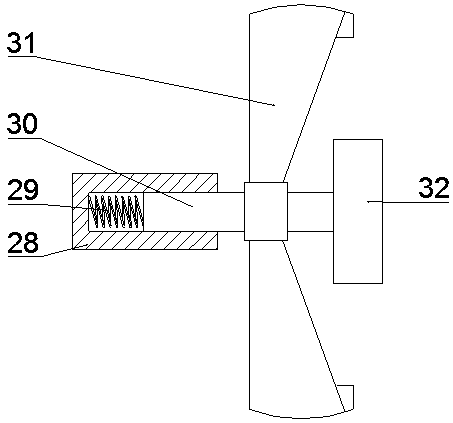

Device for injecting solid and liquid raw materials with special ratio for liquid medicine production

ActiveCN107875967AGuaranteed mix qualityLow costTransportation and packagingMixer accessoriesProtection mechanismEngineering

The invention discloses a device for injecting solid and liquid raw materials with a special ratio for liquid medicine production. The device comprises a main shell; and the bottom of the main shell is provided with a hollow clamping shell, the interior of the bottom end of the hollow clamping shell is provided with a sleeving-joint opening, one side of the main shell is provided with an integrated overload protection mechanism, an electromotor mounting shell is fixed at one side of the overload protection mechanism through bolts, an electromotor is installed in the electromotor mounting shell, a rotating shaft is fixed at the center of the interior of the main shell through a bearing, and the interior of the main shell is provided with a turbine mechanism installing space and a disk valveinstalling space. The device provided by the invention utilizes the rotating electromotor to control the flow quantity, and utilizes the disk valve and a turbine mechanism to perform the equal-proportion mixing action so as to ensure the mixing quality; and the device is a mechanical mechanism, has low costs, lower maintenance costs and high practicality.

Owner:张翼 +1

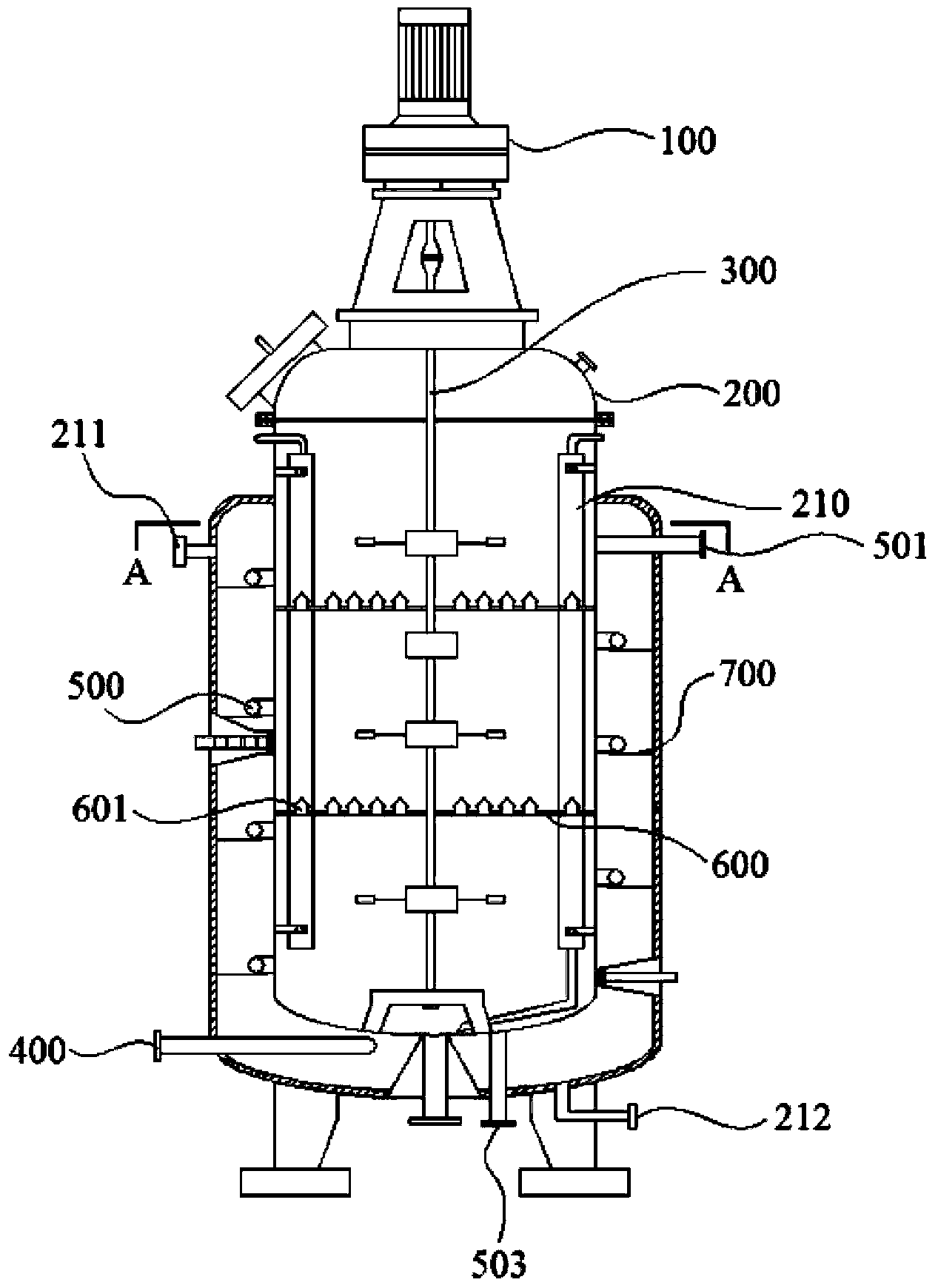

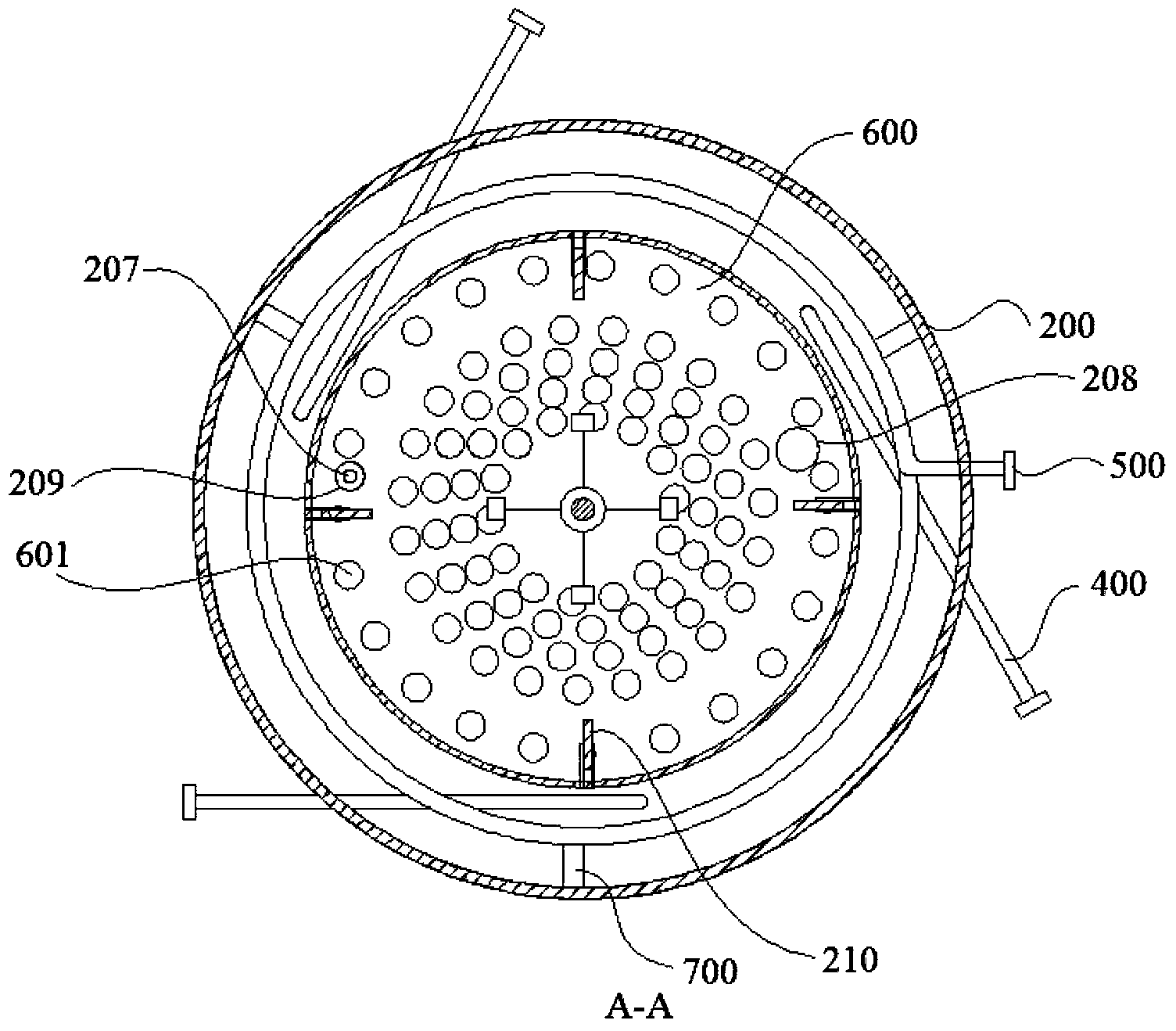

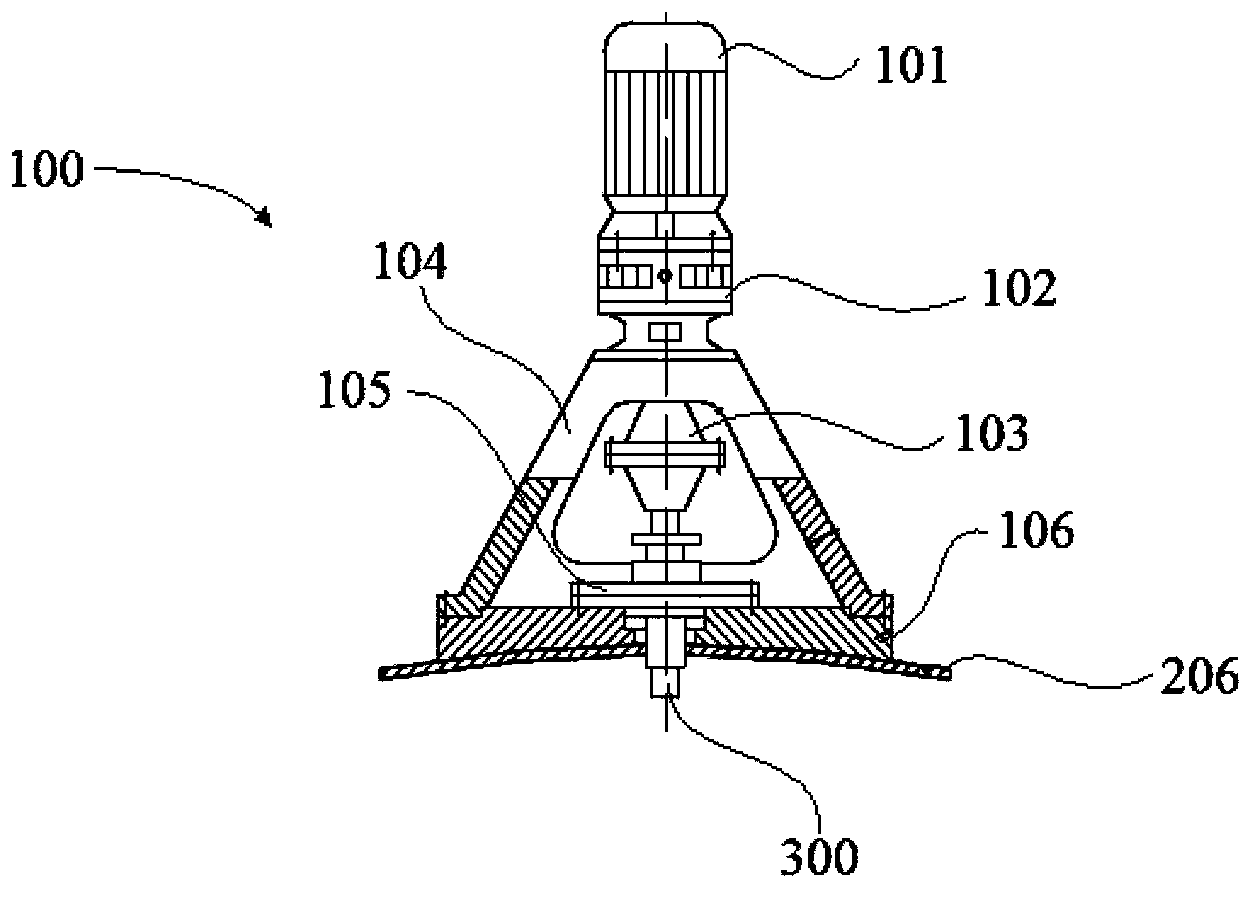

Stirring machine

ActiveCN104107655AWell mixedIncrease the mix rateFlow mixersRotary stirring mixersMixing effectBiochemical engineering

The invention provides a stirring machine which is simple in structure, good in material uniform-mixing effect, adjustable in material mixing temperature and material discharging temperature, and high in efficiency. The stirring machine comprises a transmission apparatus, an accepting apparatus and a stirring apparatus; the transmission apparatus and the stirring apparatus are both arranged on the accepting apparatus and are in connection; the accepting apparatus consists of a body sleeve and a tank body; a heating apparatus and a cooling apparatus are arranged between the body sleeve and the tank body; the body sleeve is provided with a support plate; the tank body is connected with a connection plate; the tank body is provided with a flow baffle plate; and the tank body is provided with a filtering apparatus.

Owner:GUIZHOU CHIEN YEH PLASTIC

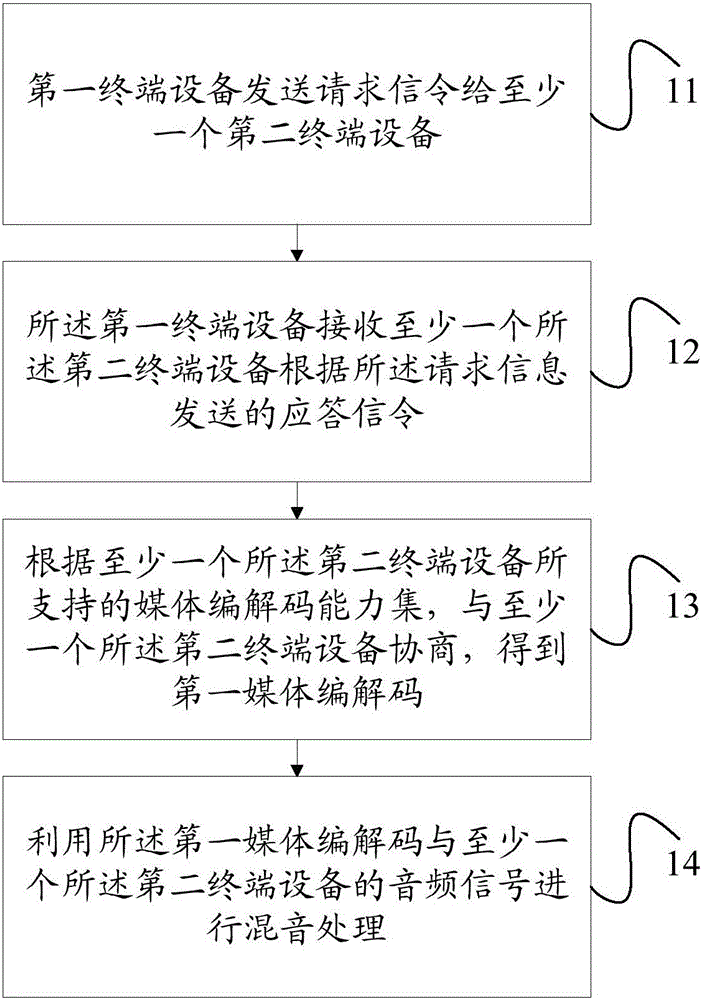

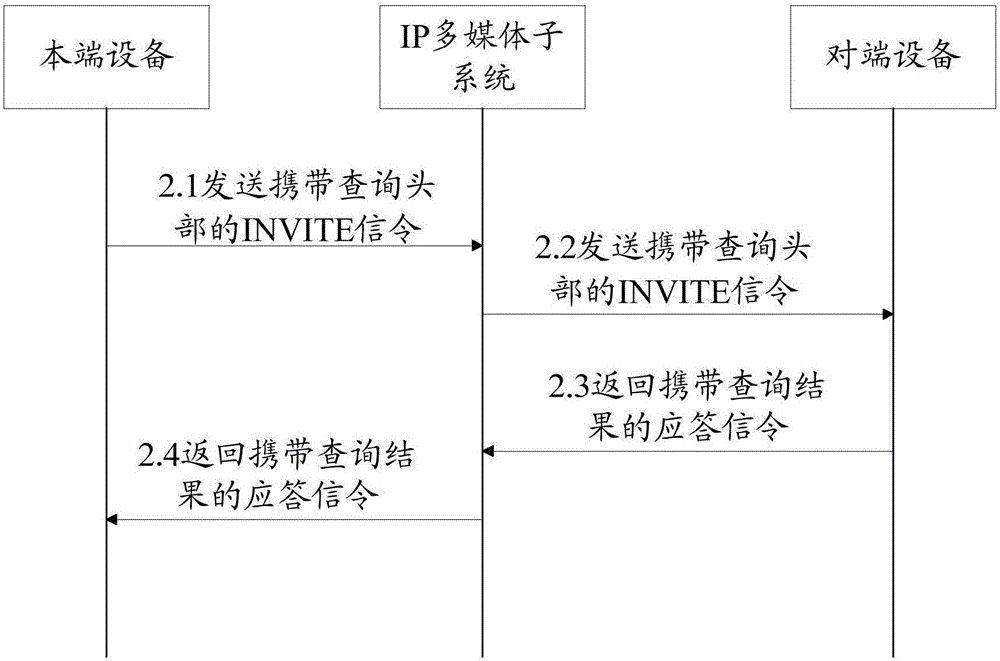

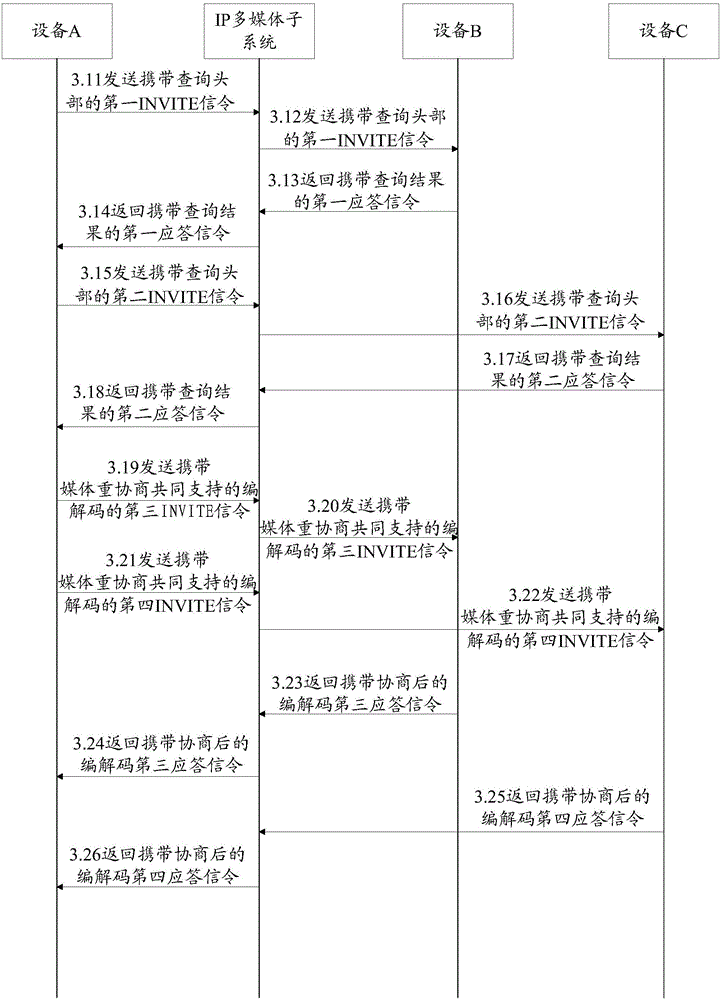

Media coding-decoding negotiation method and terminal device

InactiveCN107181723AIncrease success rateGuaranteed mix qualitySecuring communicationComputer hardwareTerminal equipment

The invention provides a media coding-decoding negotiation method and a terminal device. The media coding-decoding negotiation method applied to a first terminal device comprises: the first terminal device sends a request signaling to at least one second terminal device, wherein the request signaling includes obtaining request information of a media coding-decoding capability set supported by the second terminal device; the first terminal device receives a response signaling sent by the at least one second terminal device based on the request information, wherein the response signaling includes the a media coding-decoding capability set supported by the second terminal device; according to the media coding-decoding capability set supported by the at least one second terminal device, negotiation with the at least one second terminal device is carried out to obtain first media coding-decoding information; and sound mixing is carried out based on the first media coding-decoding information and an audio signal of the at least one second terminal device. Therefore, the success rate of media coding-decoding negotiation is increased; and the sound mixing quality of the terminal device can be guaranteed in terms of multi-side sound mixing.

Owner:ZTE CORP

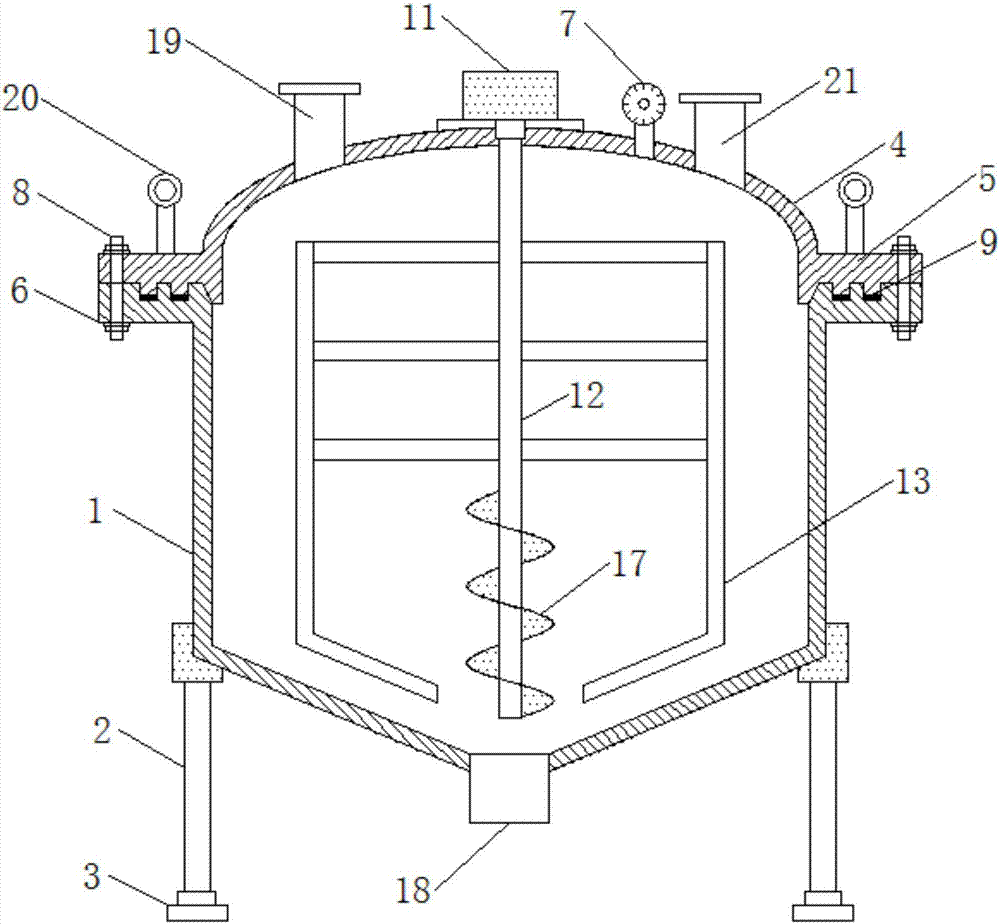

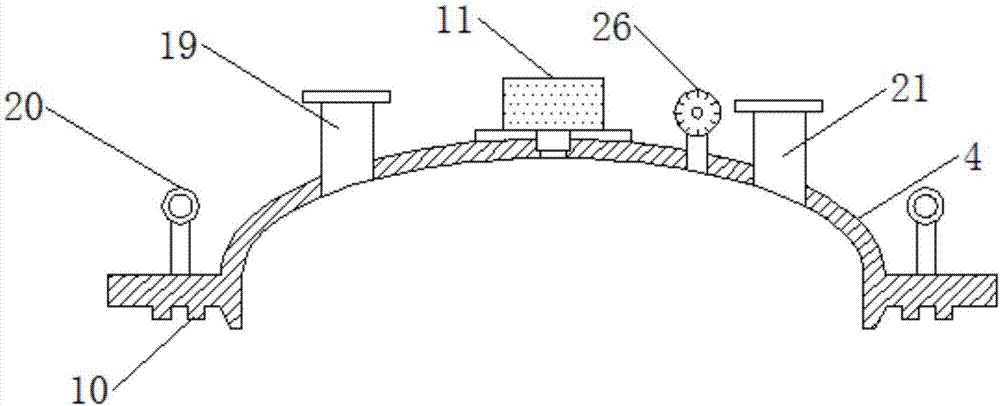

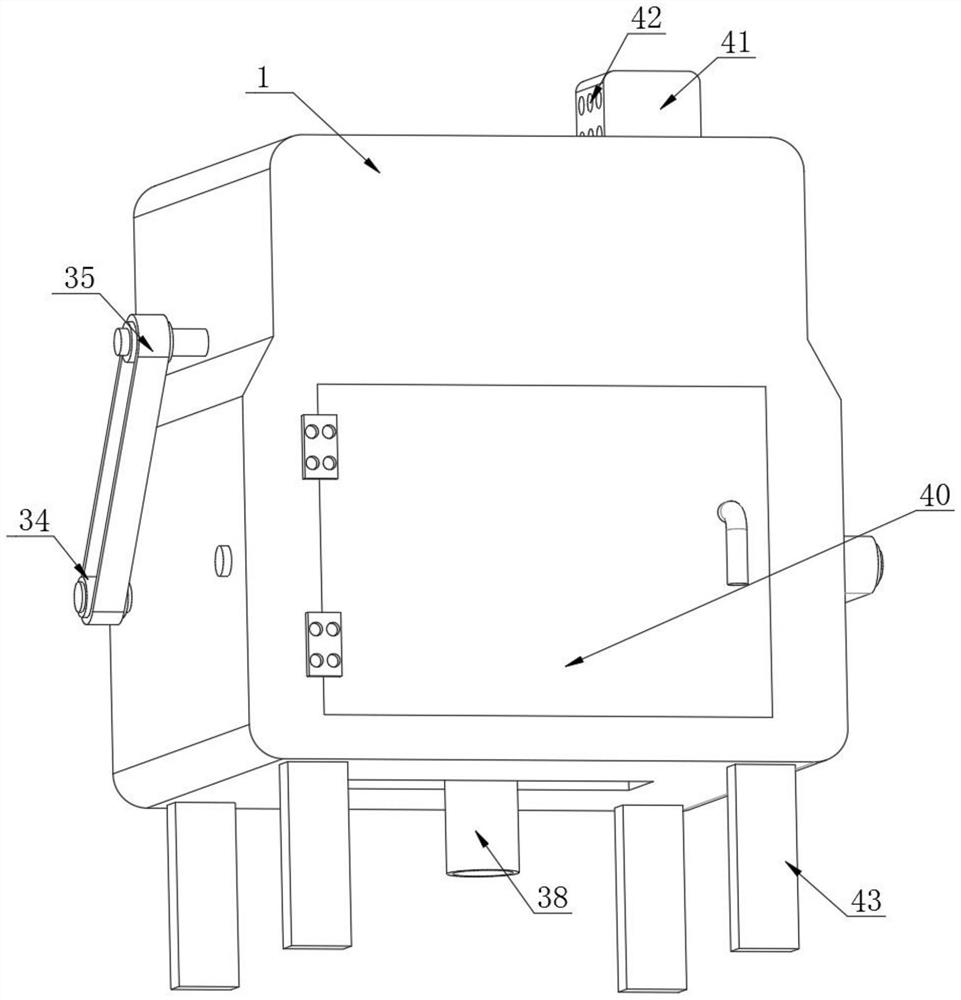

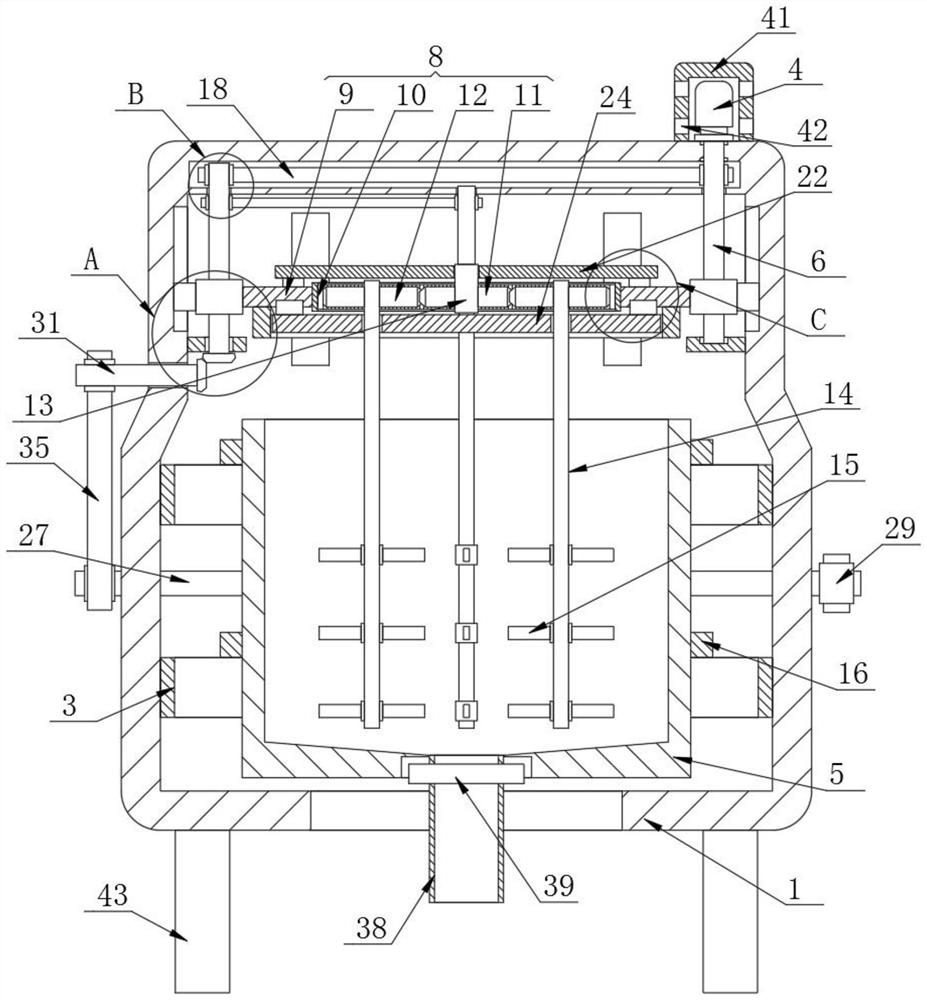

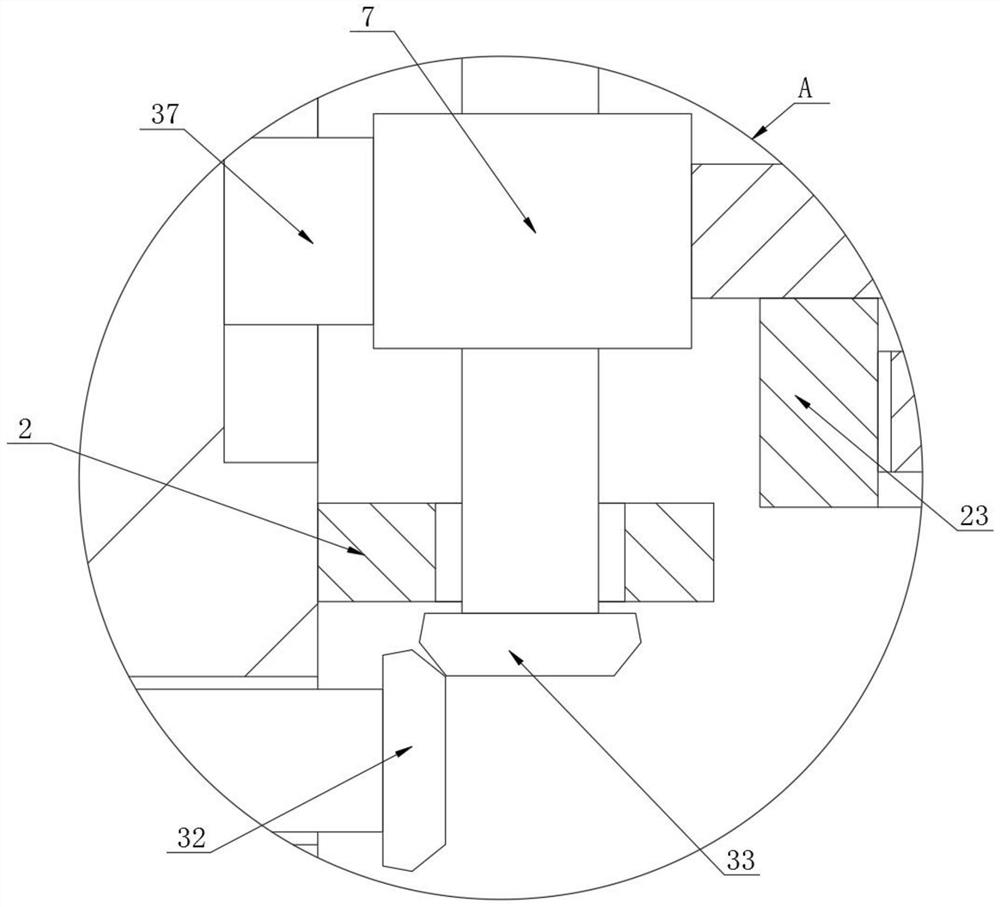

Explosion-proof type chemical raw material premixing equipment

InactiveCN107570049ANovel structureEasy to operateRotary stirring mixersMixer accessoriesInternal pressureCompound (substance)

The invention discloses explosion-proof type chemical raw material premixing equipment. The equipment comprises a shell and a seal cover arranged on the shell, wherein supporting legs are arranged atthe bottom of the shell, and floor pins are arranged at the bottoms of the supporting legs; a lower flange and an upper flange are respectively arranged on the joint of the shell and the seal cover; aseal groove is formed in the top of the lower flange; a seal bar corresponding to the seal groove is arranged at the bottom of the upper flange; the lower flange and the upper flange are fastened through a screw; a motor is arranged in the middle of the top of the seal cover; a filter screen is arranged inside an exhaust pipe; a piston board is arranged at the top of the filter screen, a spring is connected to the top of the piston board, and the piston board can be lifted freely inside the exhaust pipe; the top end of the spring is fixedly connected with the exhaust pipe; and an exhaust holeis formed in the side wall of the exhaust pipe at the top of the filter screen. The equipment ensures the internal pressure in a safe range, effectively prevents explosion, and is suitable for wide popularization.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

Raw material mixing device for rubber product production

The invention discloses a raw material mixing device for rubber product production. A supporting plate is included, and the four corners of the bottom face of the supporting plate are each fixedly connected with a supporting leg; two supporting rods are symmetrically and fixedly connected to the two sides of the top face of the supporting plate, are sleeved with a same fixed plate, and are fixedlyconnected with the fixed plate; and the portions, at the top end of the fixed plate, of the supporting rods are sleeved with a sliding plate, and are in sliding connection with the sliding plate. According to the raw material mixing device for rubber product production, a first motor operates so that a rotating rod drives a stirring rod to rotate, and materials in a stirring bucket are stirred; meanwhile a cam rotates, the stirring bucket is driven to jolt up and down under the effect of a spring, then the inner materials are driven to jolt, it is prevented that bottom stirring is not uniformduring stirring, and the stirring speed of the materials is further increased; meanwhile, a slider slides up and down, the outside gas is sucked into a box body, and then is blown out of a pluralityof air outlets in an arc-shaped box body, cooling work is performed on the materials in the stirring bucket, and it is effectively prevented that due to lasting material mixing, temperature is too high, and consequently the materials are molten and spliced to the inner wall of an inner shell.

Owner:开平市志杰汽车零部件有限公司

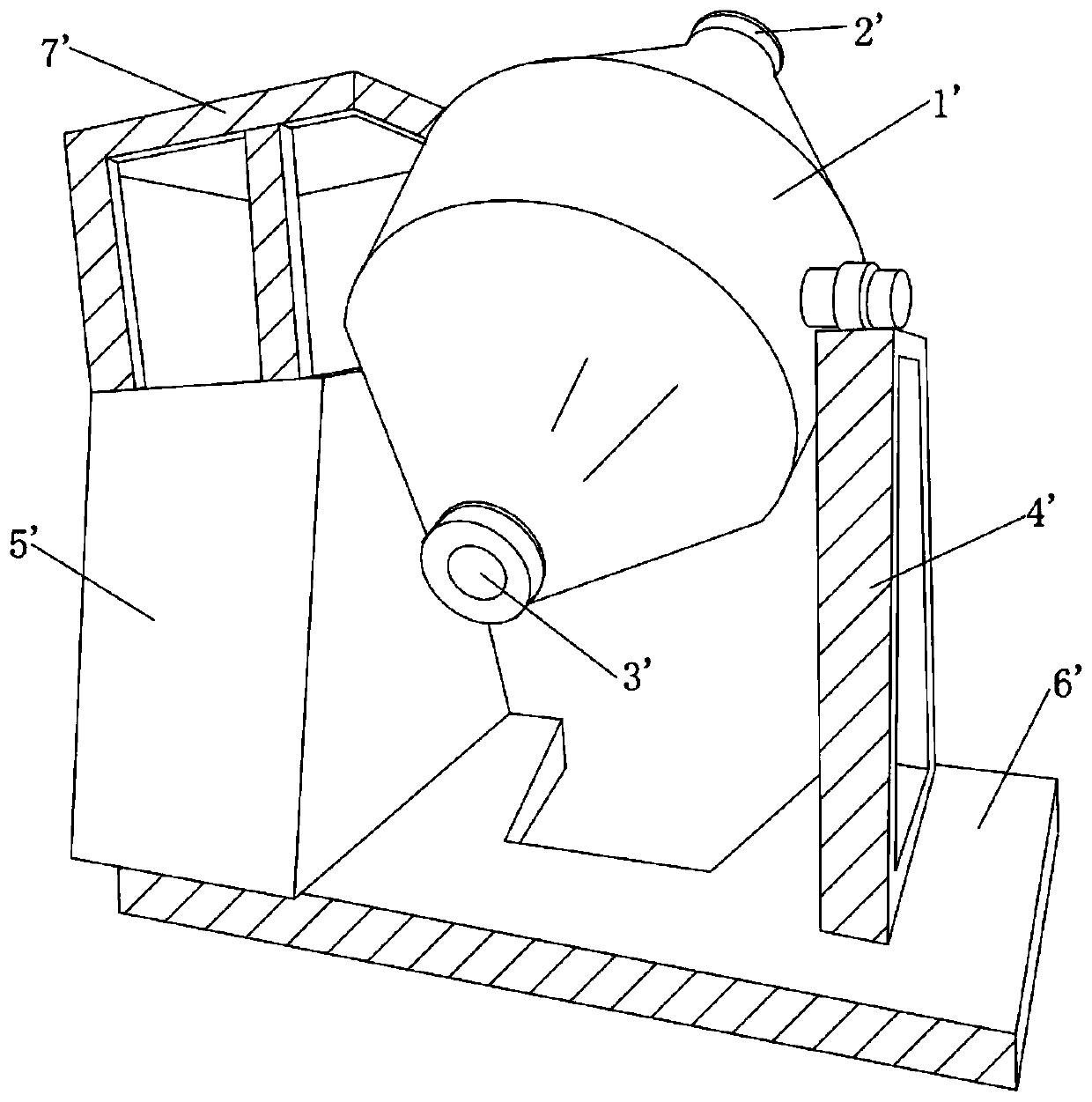

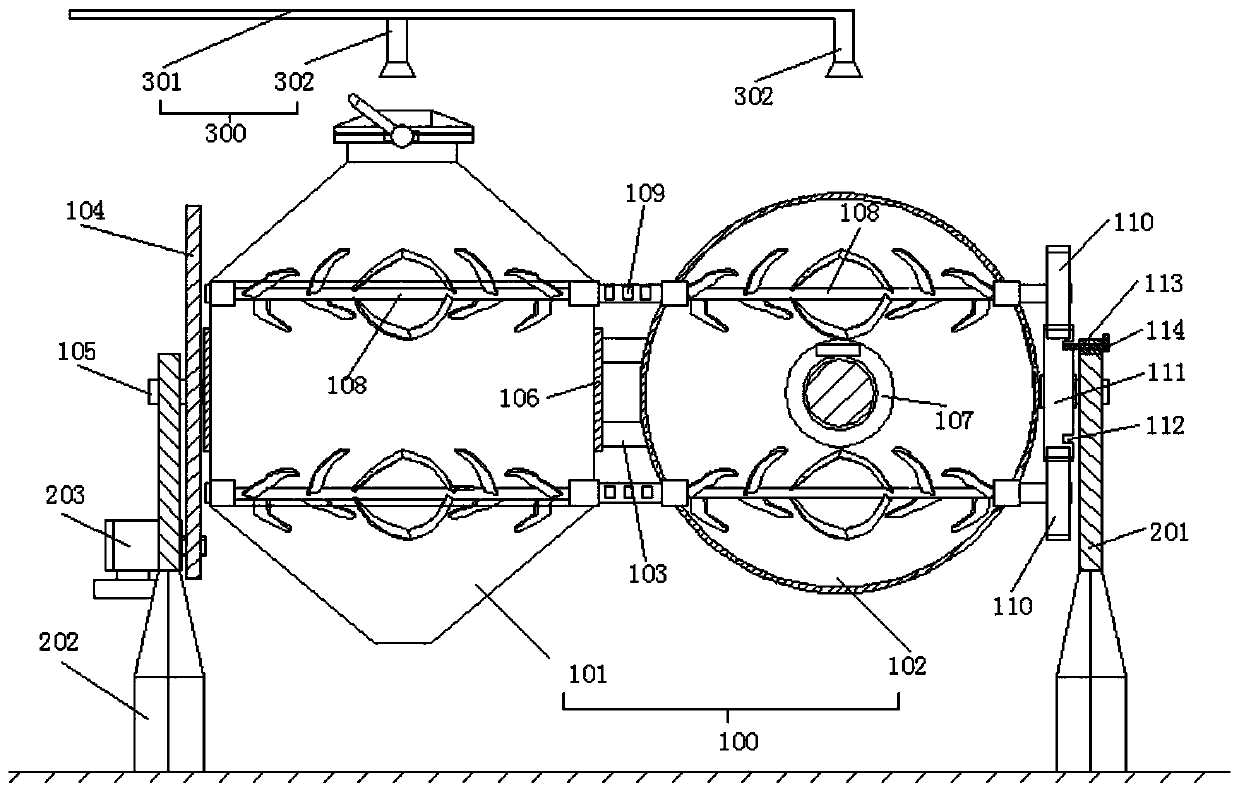

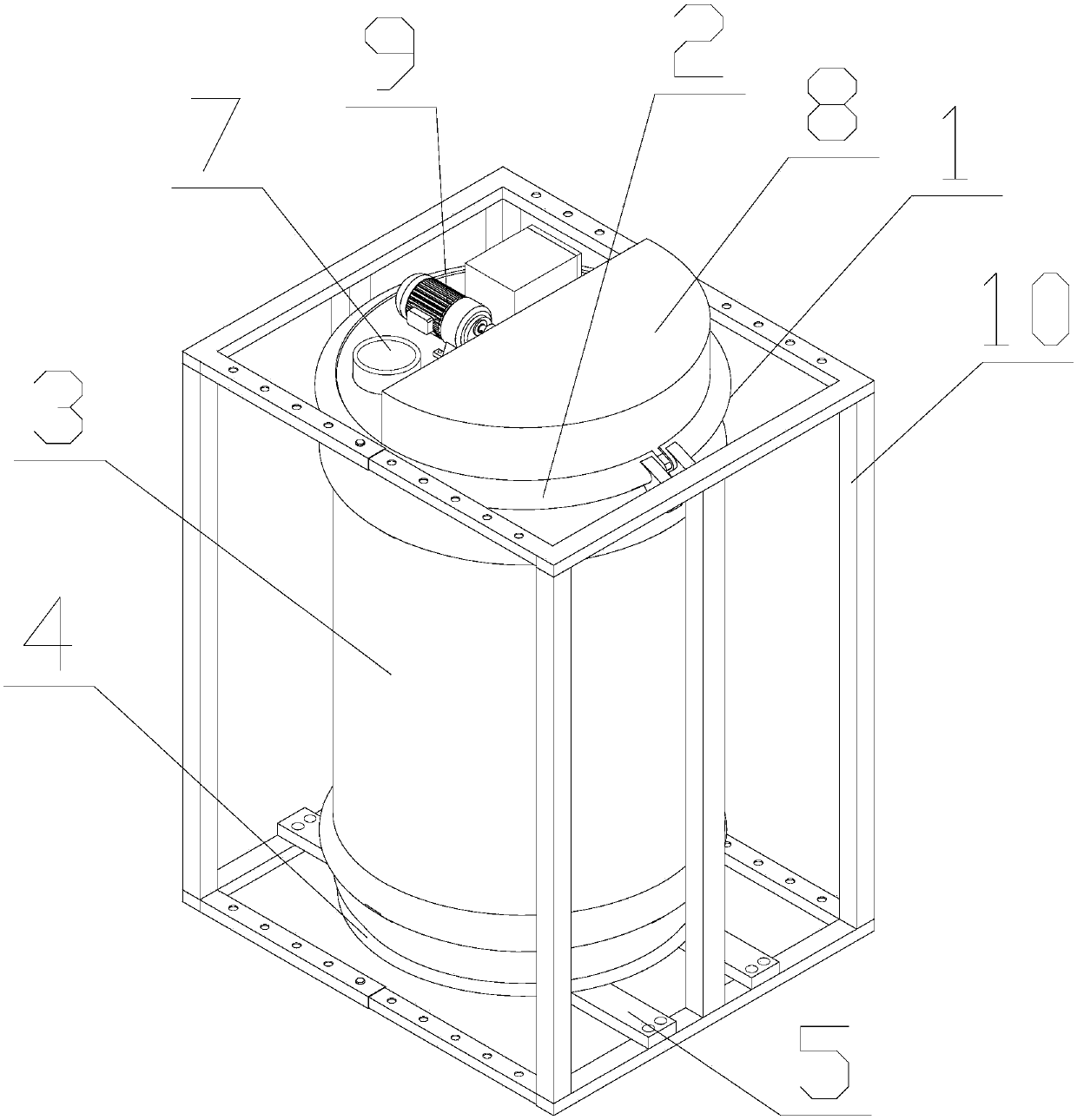

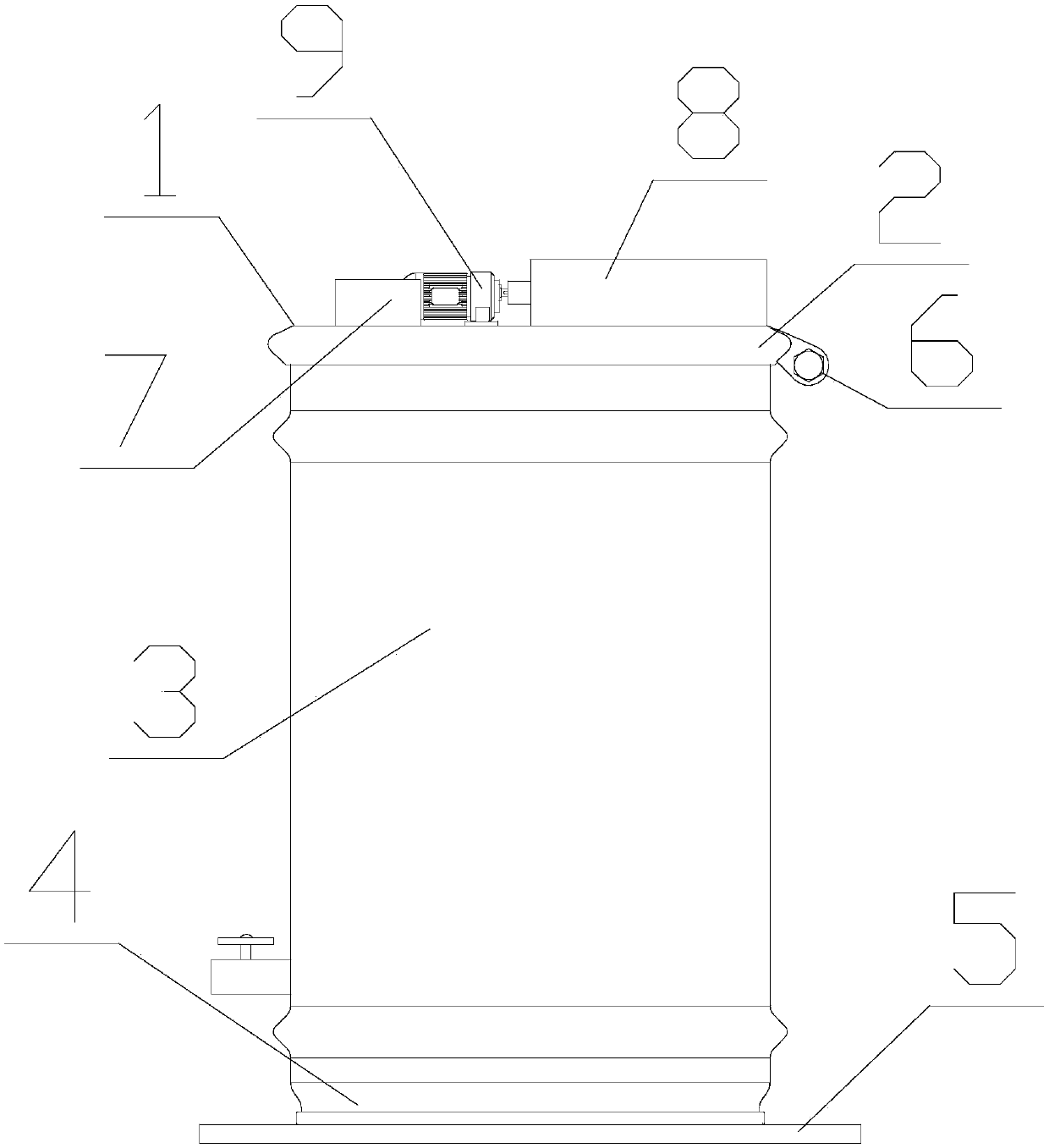

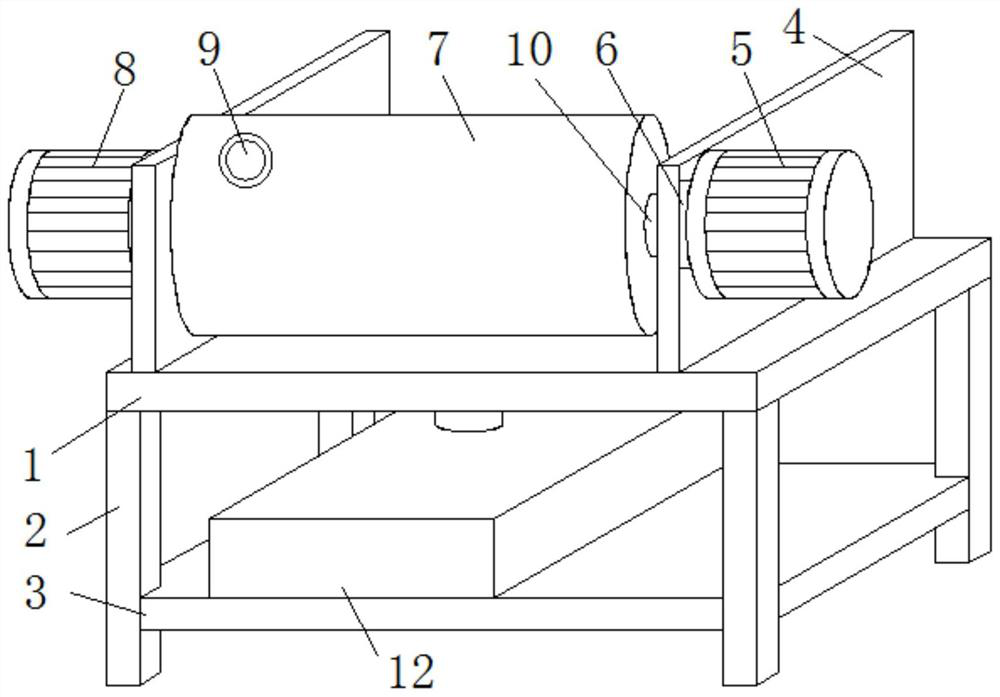

Double-body energy saving material mixer

The invention discloses a double-body energy saving material mixer. The double-body energy saving material mixer comprises a supporting driving assembly and at least one barrel body assembly, whereinthe supporting driving assembly is composed of a supporting frame and a driving motor arranged on the supporting frame; the barrel body assembly comprises a first barrel body and a second barrel bodywhich are connected in a crossed mode; the outer side wall of the first barrel body is fixedly provided with a turnover gear, and the first barrel body and the second barrel body are movably arrangedon the supporting frame through connection shafts arranged on the outer side walls thereof; and the driving motor is in engagement connection with the turnover gear so that the first barrel body and the second barrel body can be driven to synchronously conduct automatic rotary turning on the supporting frame. The double-body energy saving material mixer is novel and reliable in structure, high inproduction efficiency, uniform in quality and free of errors, the material mixing period is shortened trebly or above, or energy consumption is reduced trebly or above, and the double-body energy saving material mixer is suitable for the fields of medicine, metallurgy, food and the like and especially for the field of nano material preparation, and is wide in application range.

Owner:日晶(中国)新材料有限公司

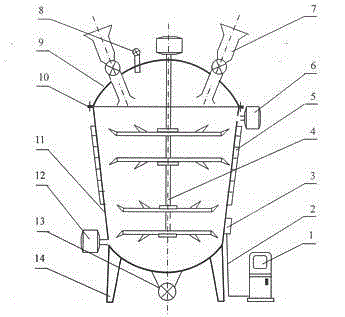

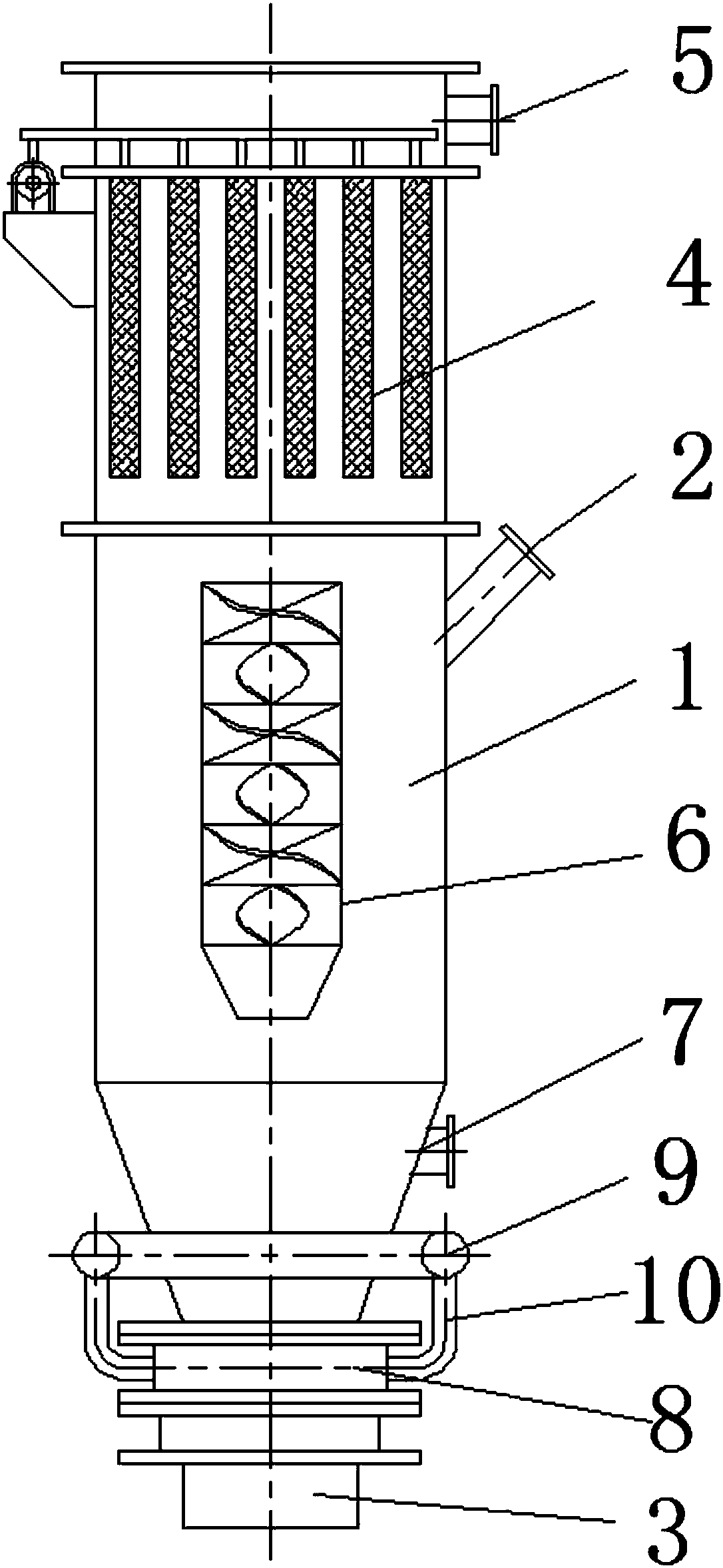

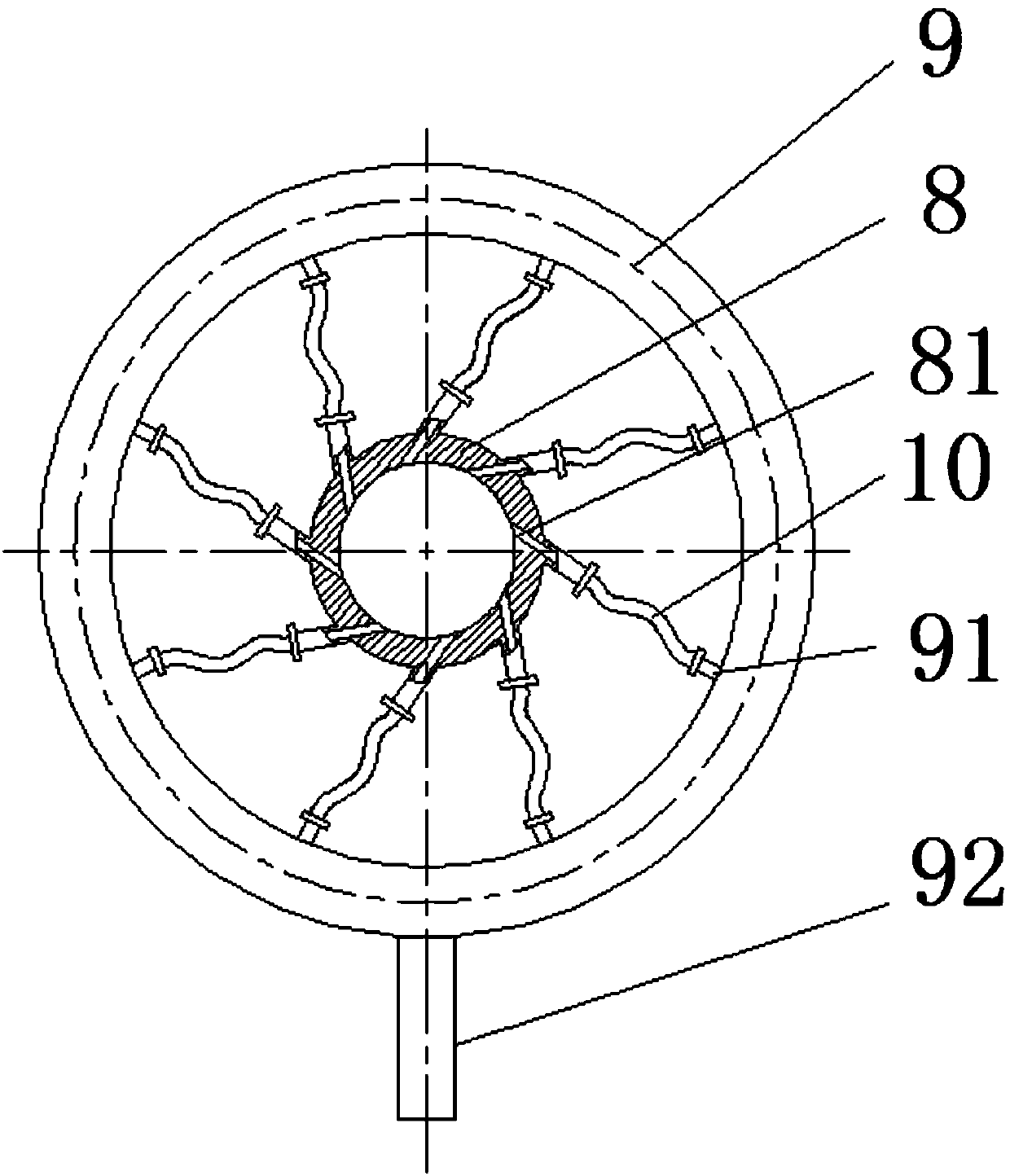

Rotational fluidized bed powder mixing machine

InactiveCN107754627AGuaranteed mix qualitySimple structureTransportation and packagingMixersFluidized bedEngineering

The invention discloses a rotational fluidized bed powder mixing machine which comprises a material mixing cabin body, a material inlet, a material outlet, a bag type dust collector and a sampling hole, wherein a static mixer is mounted inside the material mixing cabin body; rotational flow nozzles are mounted at the bottom of the material mixing cabin body; and the rotational flow nozzles are connected with an air flow distributor. When the machine is used, continuous air flow is fed into the material mixing cabin body through the rotational flow nozzles, then a rotational fluidized bed layeris formed, granular materials are driven to turn over up and down, powder granular materials can be relatively intensely mixed in the lifting and dropping process through the static mixer inside thematerial mixing cabin body, and a very good mixing effect is achieved within a short time. The rotational fluidized bed powder mixing machine is relatively simple in structural mode and simple and convenient to operate and maintain, and the mixing quality of different batches of powder granular materials can be ensured with relatively low air consumption within a relatively short mixing time.

Owner:CHANGZHOU UNIV

Unique flavor honeydew taro and production method thereof

The invention discloses a honeydew taro having unique taste and a preparation method, comprising the steps of selecting, freezing, alkalizing, cooking, frying, mixing sugar and the like, characterized in that: (1) sizes and freshness of taros are strictly controlled; (2) taros are put into a refrigerating chamber of a freezing chamber processed for 1-2 hours after being cleaned, temperature being controlled at 4 DEG C or so, and the taros are thawed for 30-40 minutes under a natural state after being taken off; (3) the taros are mixed evenly with 0.10-0.20% dietary alkali (sodium carbonate, soda) before being cooked; (4) the taros are cooked to be medium rate; (5) edible oil is blend oil as possible; (6) ratio of brown sugar and taros is 1:2 to 4. The inventive taros are just melt in the mouth and soft and gentle. After eating the inventive taro, immunologic function of human is enhanced.

Owner:SHENGHONG GRP CO LTD

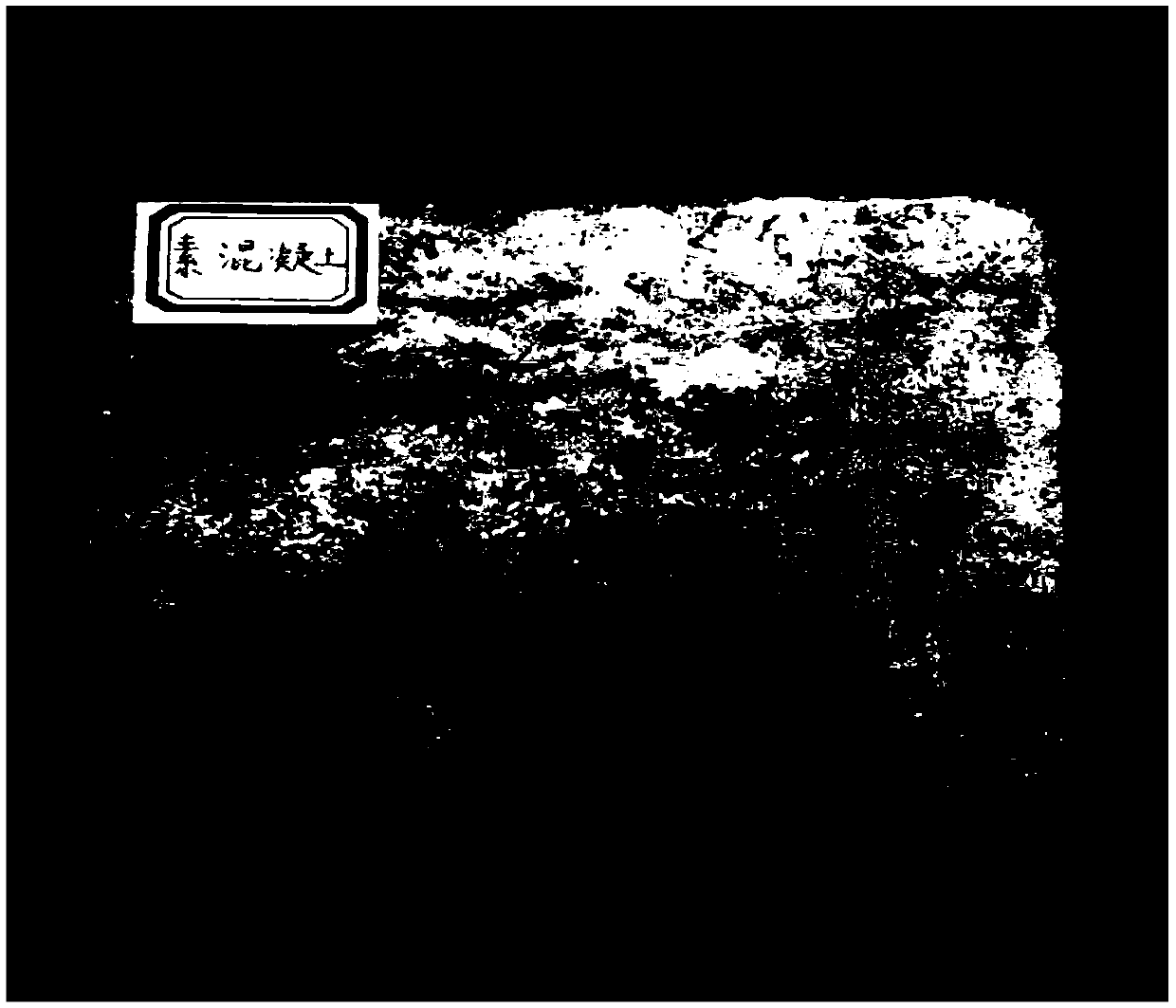

Modified carbon nanotube concrete and preparation method thereof

The invention relates to a modified carbon nanotube concrete and a preparation method thereof. In combination with the international advanced research concept of carbon nanotube concrete materials, the invention proposes that carbon nanotubes are subjected to plasma surface treatment, consequently, the surface hydrophilicity of the carbon nanotubes is improved on the basis of not injuring the surface structure of the carbon nanotubes, and moreover, the dispersivity of the carbon nanotubes in a cement-based material; furthermore, the influence of different amounts of doping plasma-modifed carbon nanotubes (P-CNT) on the mechanical properties of the concrete is studied, and thereby the modified carbon nanotube concrete with excellent properties and the preparation method thereof are achieved.

Owner:SUZHOU UNIV OF SCI & TECH

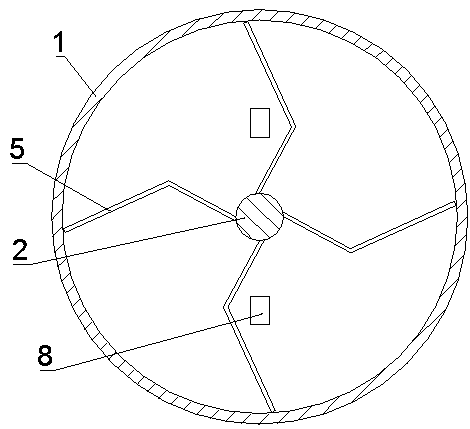

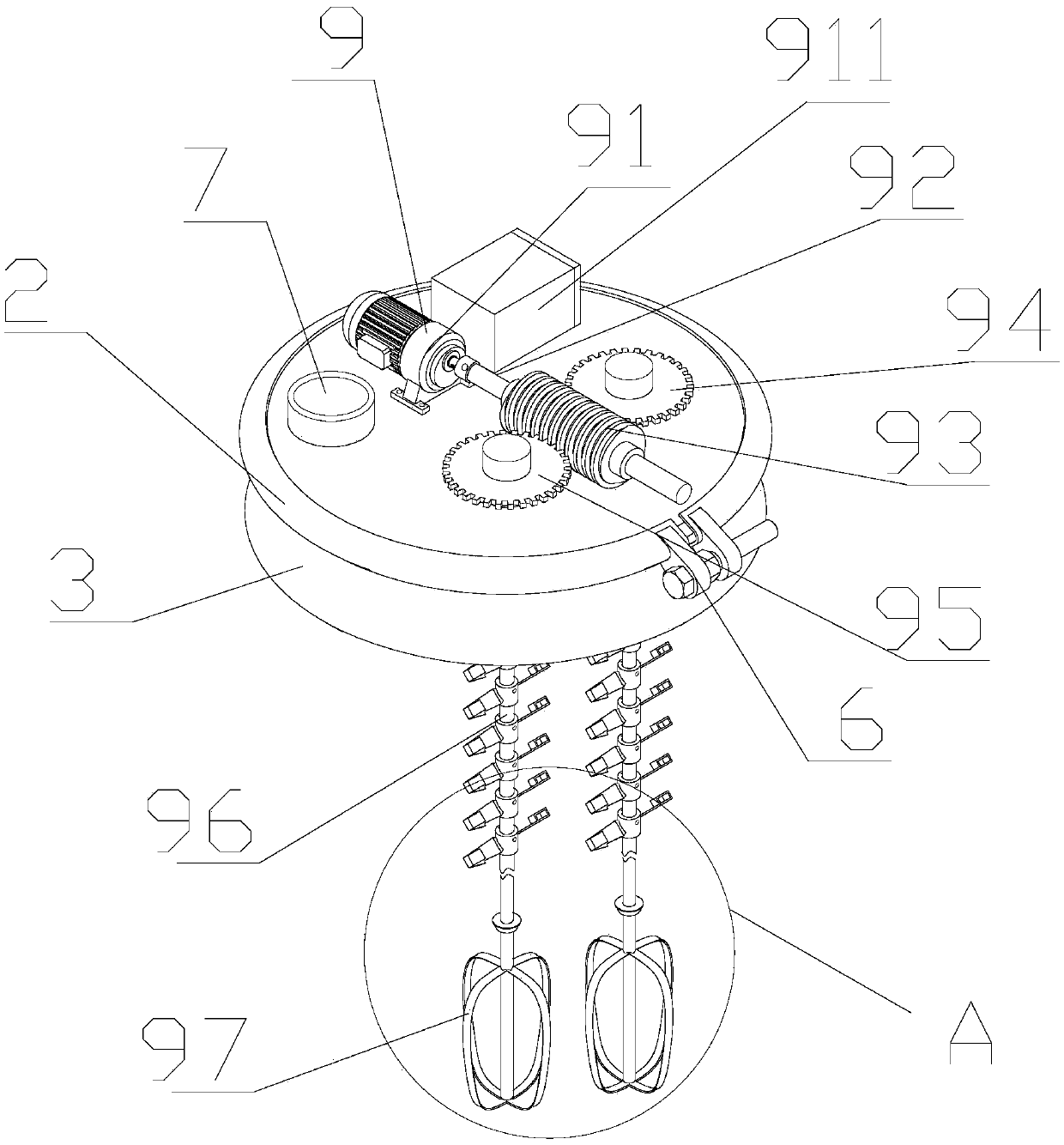

Layered feeding and mixing device for feed production

PendingCN114713125AWell mixedSpread evenlyBatteries circuit arrangementsFeeding-stuffGear wheelElectric machinery

The invention discloses a layered feeding and mixing device for feed production, and relates to the field of feed production.The layered feeding and mixing device comprises a mixing box, a discharging pipe and a discharging pipe arranged on the lower portion of the mixing box and further comprises a layered feeding mechanism and a lifting driving mechanism. Then through cooperation of a driving motor, a first bevel gear and a second bevel gear, a spiral conveying wheel conveys raw materials in feeding barrels from inside to outside, in the conveying process, feed falls into a mixing box through feeding holes, meanwhile, a stirring motor rotates, and through cooperation of a driving gear and a driven gear, a hollow shaft and the multiple feeding barrels rotate at the same time; the raw materials are uniformly spread in the mixing box in the rotating process of the feeding cylinder, the raw materials are poured into the mixing box one by one through the discharging pipe, so that the raw materials are spread layer by layer and are uniformly spread, accumulation of the raw materials is avoided, the raw materials are conveniently mixed, the mixing efficiency of the raw materials is improved, and meanwhile, the mixing effect of the raw materials is ensured.

Owner:河南海大九州生物科技有限公司

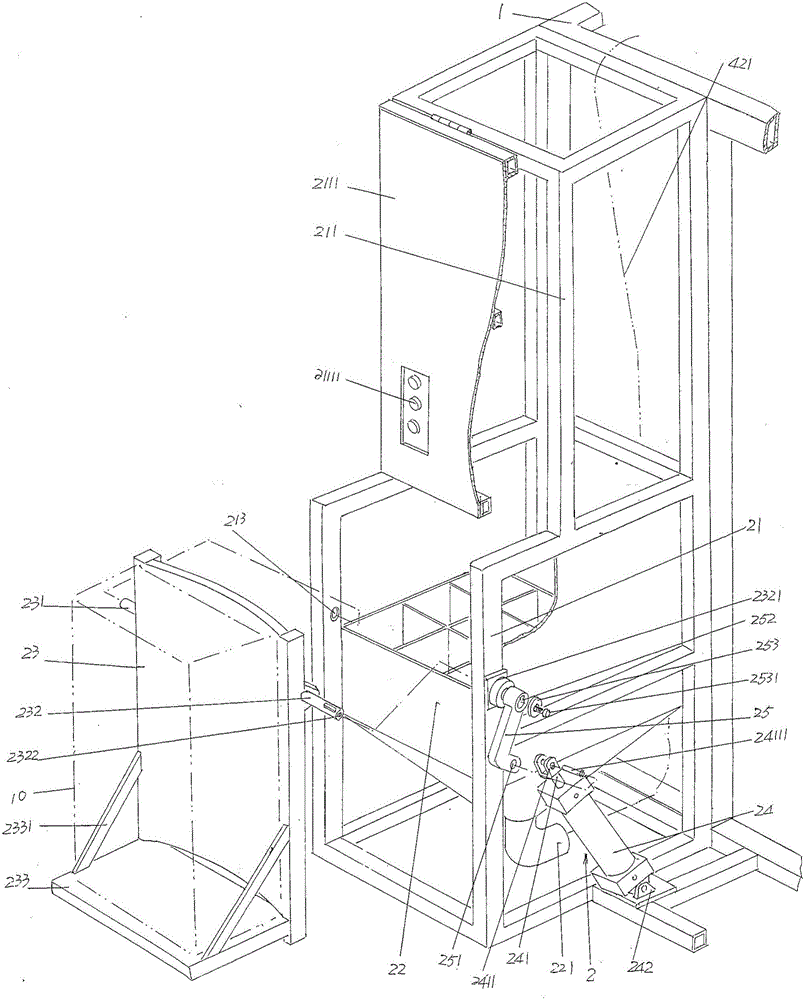

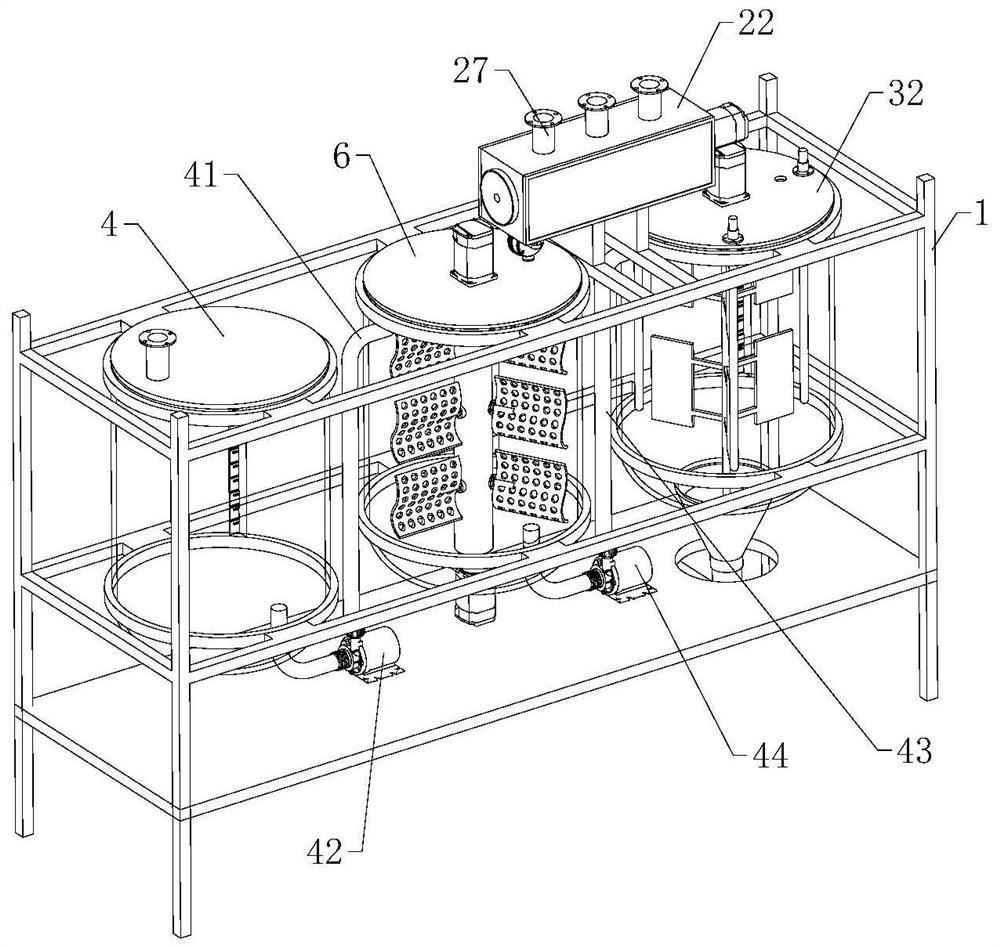

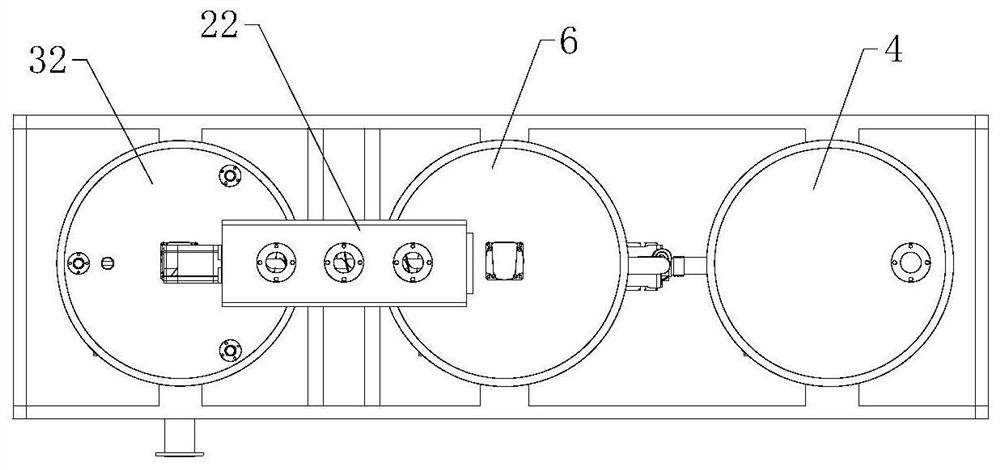

Fertilizer distributor with automatic feeding function

ActiveCN105771734AReduce work intensityGuaranteed reliabilityRotary stirring mixersTransportation and packagingElectrical controlTurning frames

The invention discloses a fertilizer distributor with an automatic feeding function, and belongs to the technical field of agricultural machinery. The fertilizer distributor comprises a machine frame, a negative pressure generating mechanism at the lower portion of the rear side of the machine frame, a material storing mechanism on the top of the machine frame, a weighing mechanism in a cavity of the machine frame, a fertilizer mixing mechanism in the cavity of the machine frame, a discharging mechanism on the front side of the machine frame, a material supplementing mechanism at the lower portion of the material storing mechanism, and an electrical control box. The fertilizer distributor is characterized by further comprising feeding mechanisms, the left side and the right side of the machine frame are each provided with at least one feeding mechanism, the feeding mechanisms are connected with the machine frame, the feeding mechanism on the left side comprises a feeding hopper supporting frame, a feeding hopper, a material bag turning frame, a turning frame driving acting cylinder and a crank arm, a weighing sensor support is fixed in the cavity of the machine frame, a discharging box fixing support is arranged on the front side of the machine frame, the weighing mechanism is fixed to the weighing sensor support, the fertilizer mixing mechanism is arranged in a cavity of the weighing sensor support, and the discharging mechanism is arranged on the discharging box fixing support. The fertilizer distributor is small in size and clean in working environment, and the fertilizer distribution efficiency, the work reliability and mixing quality are guaranteed.

Owner:YUNNAN YUNTIANHUA AGRI TECH CO LTD

Vertical planetary mixer for pharmaceutical apparatus

InactiveCN114797614AImprove mixing efficiencyGuaranteed mix qualityShaking/oscillating/vibrating mixersTransportation and packagingBLENDER/MIXEREfficacy

According to the technical scheme, the vertical planetary mixer comprises a shell, a first cavity is formed in the top of the shell, supporting blocks are fixedly connected to the inner walls of the two sides of the shell, two shells are fixedly connected to the interior of the shell, and the two shells are linearly distributed up and down and located at the bottoms of the supporting blocks; an auxiliary mechanism is arranged in the shell and comprises a motor, the motor is fixedly connected to the top of the shell, a mixing box is arranged at the bottoms of the two supporting blocks, and the mixing box penetrates through the two shells. Therefore, secondary stirring and mixing are not needed, the stirring and mixing time can be shortened, the phenomenon that medicine loses the efficacy due to long-time stirring can be avoided, the phenomenon of medicine waste is avoided, and unnecessary economic losses are avoided.

Owner:JIUJIANG JIEBAO MACHINERY CO LTD

Chemical equipment for producing chemical raw materials

InactiveCN108393026AImprove the mixing effectImprove mix qualityTransportation and packagingMixersMagnetThree stage

The invention discloses chemical equipment for producing chemical raw materials. The chemical equipment comprises a first mixing box, wherein a rotating shaft is arranged inside the first mixing box;the top end of the rotating shaft passes through the upper side wall body of the first mixing box and is rotationally connected with the upper side wall body of the first mixing box; the upper side ofthe first mixing box is fixedly provided with a first motor; through the effect of a stirring paddle, by matching with the mixing effect in the first mixing box and a second mixing box, the three-stage mixing effect is performed; the mixing quality is ensured; when the rotating rod drives an iron block to rotate, when the iron block and a magnet are in corresponding positions, the iron block andthe magnet attract each other, so that the movable rod drives a material pushing plate to move; chemical engineering raw materials are leftwards and rightwards pushed; the mixing effect is further improved; the mixing quality is improved; the bending plate is used for stirring the chemical raw materials at the lower part of the first mixing box, so that a discharging opening 8 cannot be easily blocked by the chemical raw materials; through the collision by transverse steel wires, the chemical raw materials form a uniform and scattered state.

Owner:JIANGSU XINHUA CHEM +1

Mixing device for producing fruit mousse and using method

ActiveCN112657413AImprove solubilityImprove finenessMixer accessoriesMixing materials pretreatmentGelatinBiology

The invention relates to a mixing device for producing fruit mousse and a using method, and belongs to the field of mixing equipment, the mixing device comprises a dissolving barrel, a feeding port is formed in the top end of the dissolving barrel, a crushing device is arranged at the position, close to the feeding port, of the dissolving barrel, a stirring and hammering device is arranged in the dissolving barrel, and a temperature control jacket is arranged outside the dissolving barrel; a first discharging pipe is arranged at the bottom end of the dissolving barrel in a penetrating mode, a first discharging valve is arranged on the first discharging pipe, the end, away from the dissolving barrel, of the first discharging pipe is fixedly connected and communicated with a mixing tank, a feeding port is formed in the top end of the mixing tank, and a discharging port is formed in the bottom end of the mixing tank. Fruit and gelatin are crushed through the crushing device and stirred and beaten through the stirring and hammering device, on one hand, the fineness of puree is improved, the taste of a finished product is improved, on the other hand, the gelatin is crushed into small pieces and can be quickly dissolved into fruit pulp, and effective mixing of the gelatin and the fruit pulp is achieved at a low temperature; and the mouth feel and the flavor of the mousse are improved.

Owner:莱阳永安食品有限公司

Efficient stirring and storing device for textile dyeing raw materials

PendingCN112452197APrevent precipitationAvoid stickingRotary stirring mixersLarge containersProcess engineeringTextile dyeing

The invention relates to the technical field of textile processing, in particular to an efficient stirring and storing device for textile dyeing raw materials. The device comprises a rack; a mixing mechanism, which is arranged on the rack; a metering leading-in mechanism, which is arranged on the rack; a water delivery tank, which is arranged on the rack; and a storage mechanism, which is arrangedon the rack; wherein the mixing mechanism comprises a mixing tank vertically arranged on a rack, a rotary sleeve that is vertically and rotatably arranged in a storage box, a threaded inner rod thatis vertical and can be rotatably arranged in the rotary sleeve; and multiple sets of mixing adjusting assemblies that are distributed on the threaded inner rod at equal intervals in the vertical direction of the threaded inner rod. The device can meter and input different raw materials, the mixing and stirring power can be automatically adjusted, excessive mixing is prevented, the mixing quality is guaranteed, and the mixed raw materials can be automatically stored.

Owner:张浩彬

Bidirectional stirring and uniform mixing device for medicine preparation

PendingCN114247356AImprove mixing efficiencyTo achieve the purpose of two-way mixingShaking/oscillating/vibrating mixersTransportation and packagingPharmacy medicineEfficacy

According to the technical scheme, the bidirectional stirring and uniform mixing device comprises a shell, a first cavity is formed in the top of the shell, an auxiliary mechanism is arranged in the shell and comprises a first mixing box and a second mixing box, and the second mixing box is connected to the bottom of the first mixing box and connected with the first mixing box through a sealing bearing; supporting plates are fixedly connected to the inner walls of the two sides of the shell, the two supporting plates are located at the top of the first mixing box, and a through groove is formed in the top of the first mixing box. The medicine mixing device has the beneficial effects that the first mixing box and the second mixing box rotate, the rotating directions are opposite, and medicine can be mixed at a time through cooperation with the first stirring rod and the second stirring rod; therefore, secondary mixing is not needed, the mixing time can be shortened, the phenomenon that the medicine loses the efficacy due to long-time mixing can be avoided, the phenomenon of medicine waste is avoided, and unnecessary economic loss is avoided.

Owner:YICHUN WANSHEN PHARMA MACHINERY

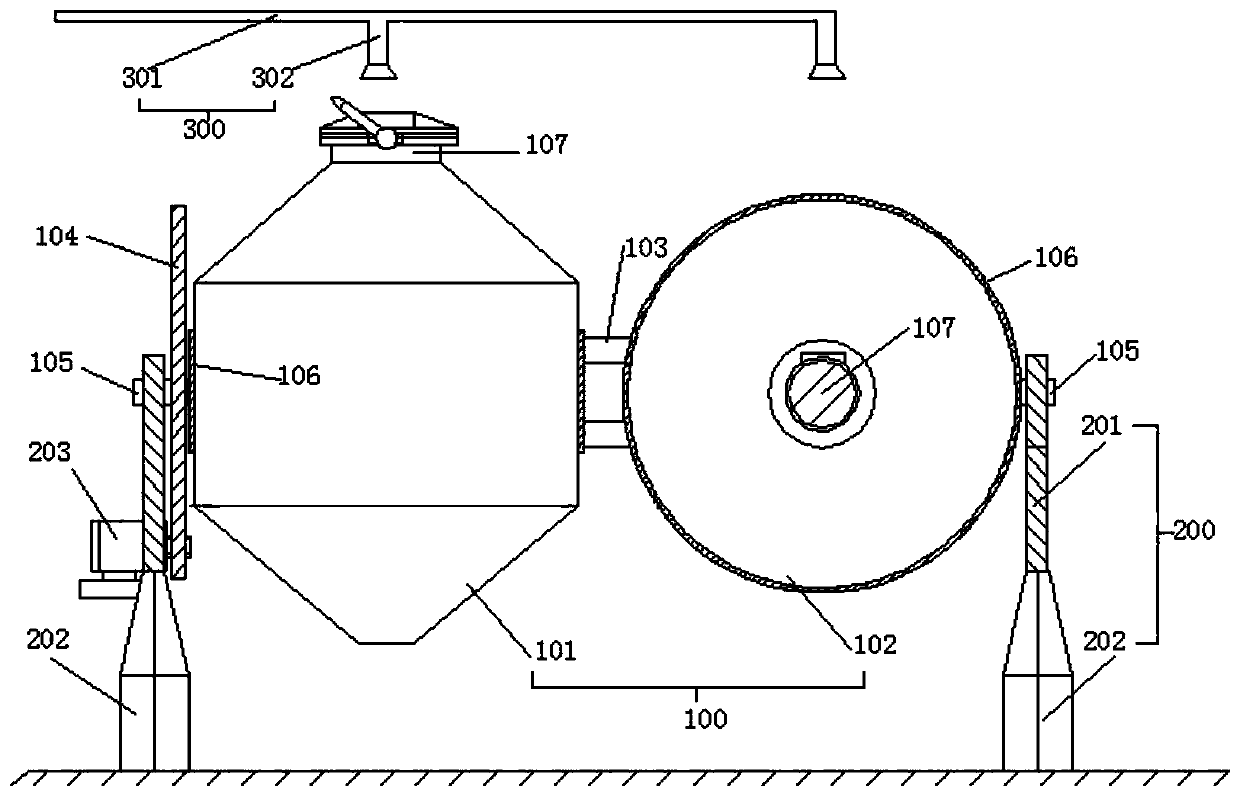

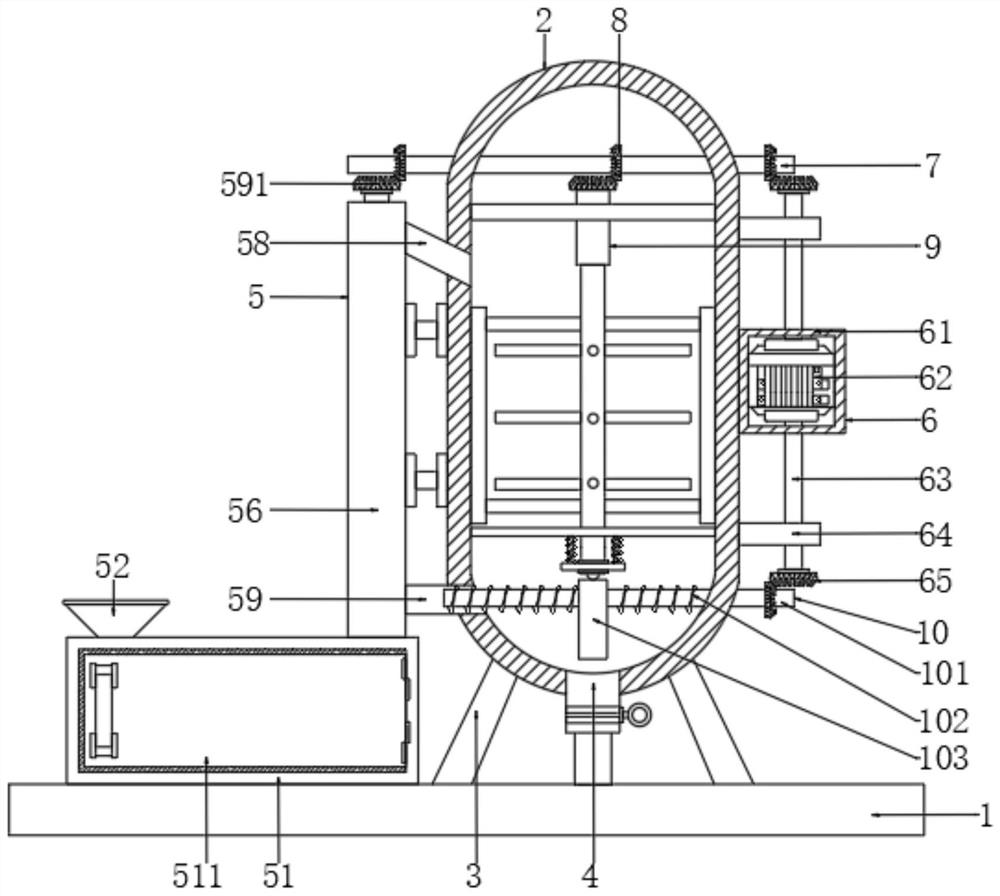

Fish feed self-circulation efficient mixing machine facilitating feeding and using method

InactiveCN111686598AGuaranteed mix qualityEasy loadingFlow mixersFeeding-stuffElectric machineryAnimal science

The invention discloses a fish feed self-circulation efficient mixing machine facilitating feeding, and belongs to the technical field of efficient mixing machines. The machine comprises a base, a feeding mechanism matched with the shell is arranged on the left side of the top of the base. A driving mechanism matched with a right transmission bevel gear is arranged on the right side of the shell;an anti-residue mixing mechanism matched with the middle transmission bevel gear is arranged in an inner cavity of the shell; a self-circulation linkage mechanism matched with the anti-residue mixingmechanism, the feeding mechanism and the driving mechanism is arranged at the bottom of an inner cavity of the shell; the feeding mechanism is arranged; the vibration motor enables the filter screen to vibrate, dust or impurities and the like in the fish feed are enabled to flow downwards through the filter screen and the subsequent mixing quality of the fish feed can be greatly guaranteed; and with cooperation of the driving mechanism, the auxiliary rotating rod and the transmission bevel gear, the fish feed in the treatment box is transmitted upwards to the discharging pipe and enters the shell from the discharging pipe, feeding is facilitated, the working efficiency is greatly improved, and the burden of manual feeding is also reduced.

Owner:潘杰宁

Novel chemical material barrel

ActiveCN109533639ASolve the problem of separation and precipitation, which affects the storage qualityAvoid squeezingRotary stirring mixersClosure with auxillary devicesCompound (substance)Engineering

The invention discloses a novel chemical material barrel. The novel chemical material barrel comprises a material barrel body, a barrel cover, a can, a base plate, a connecting frame, a connecting piece, a connecting pipe, a protective cover, a stirring device and a protective support, the barrel cover is arranged on the top end surface of the material barrel body, moreover, the top end surface ofthe material barrel body is parallel to the top end surface of the barrel cover, and the inner diameter of the barrel cover is the same as the outer diameter of the top end surface of the can in size. The material barrel body is lifted up and moved to the top end surface of a second fixing block, due to the fact that the connecting frame is arranged on the bottom end surface of the base plate, through holes in the bottom end surface of the connecting frame are moved to inner threaded holes in the top end of a second fixing block, the left side and the right side of the bottom end surface of the connecting frame are fixed to the inner threaded holes in the left inner side and the right inner side of the top end of the second fixing block through bolts, then the material barrel body is fixed to the inner diameter of the protective support, the structure of the material barrel body is protected, the chemical material barrel is prevented from being extruded by external objects, and the problem that when logistics transportation is performed, the chemical material barrel is prone to be impacted and extruded by other objects, so that the chemical material barrel is deformed because of bearing extrusion, and a solution inside the chemical material barrel is prone to leaking is solved.

Owner:江苏广域化学有限公司

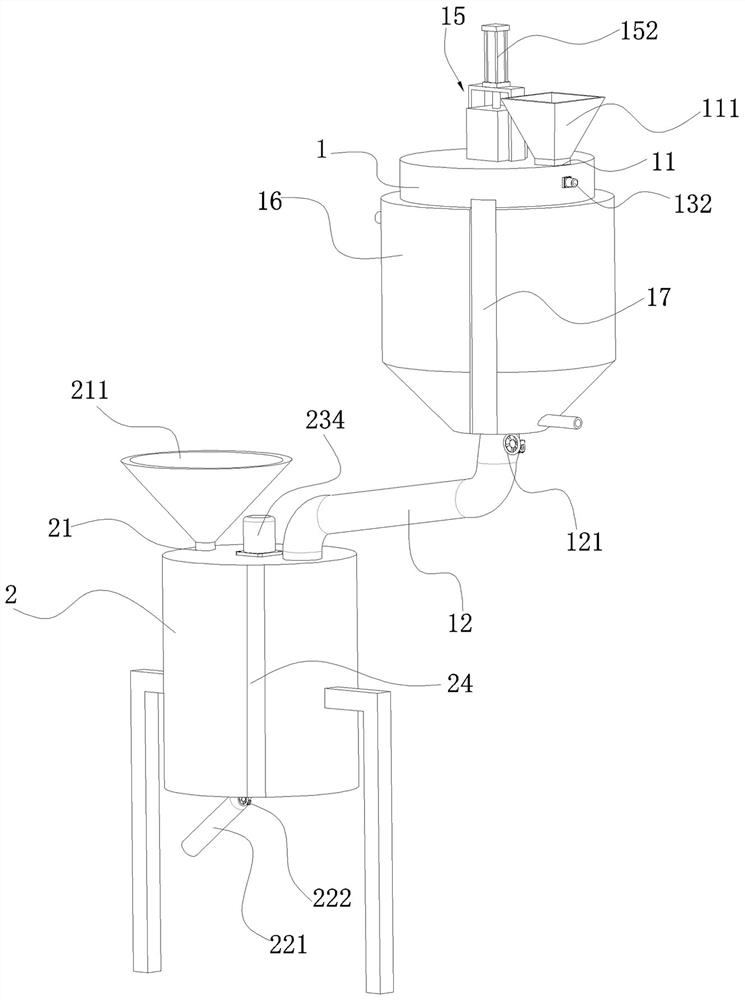

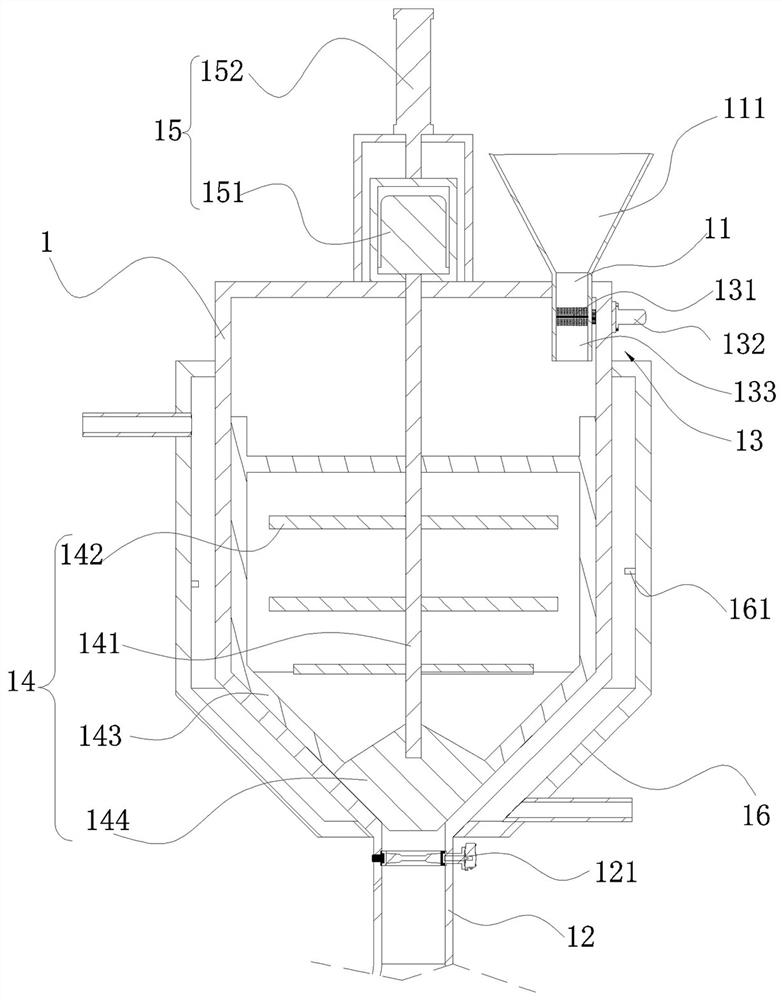

Soybean phospholipid oil meal production device based on micro-capsule technology

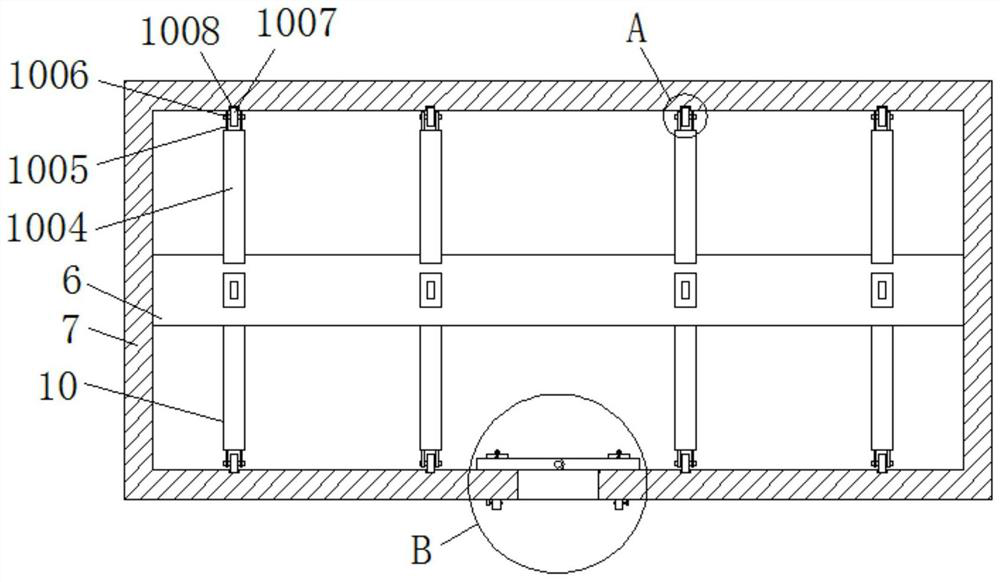

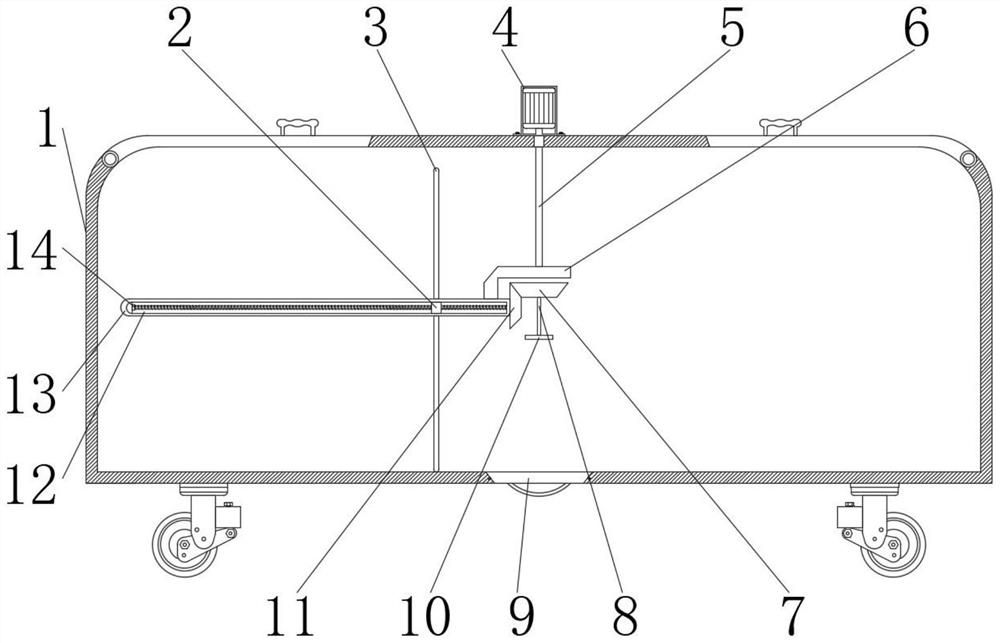

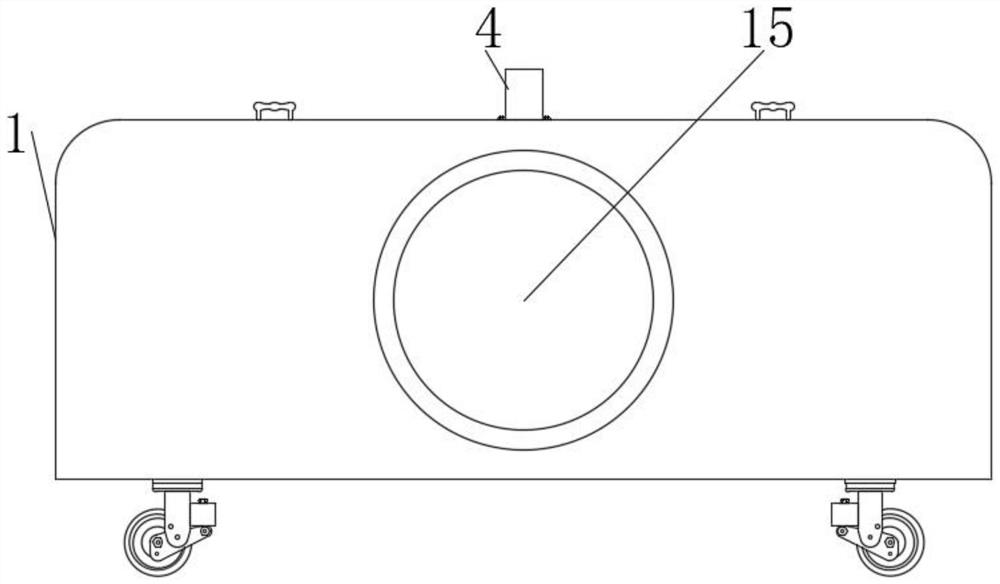

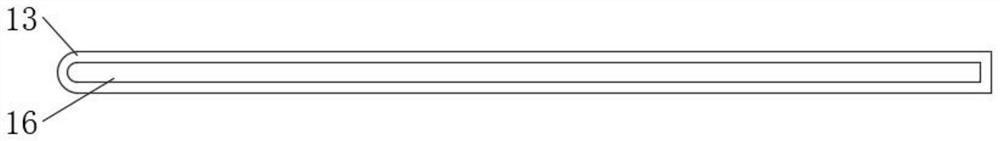

PendingCN110860251AQuality assuranceProblems affecting uneven compositionNon-rotating vibration suppressionTransportation and packagingEngineeringSoybean Phospholipids

The invention discloses a soybean phospholipid oil meal production device based on a micro-capsule technology. The soybean phospholipid oil meal production device comprises a treatment box, wherein anupper cavity and a lower cavity are formed in the inner wall of the treatment box body; a feeding groove is formed in the upper side wall of the upper cavity; a primary mixing device is arranged on the lower side wall of the upper cavity; the lower side of the upper cavity is V-shaped; an arc-shaped cavity is formed in the lower side wall of the upper cavity; a second motor is embedded into the side wall of the arc-shaped cavity; and a rotating ball is fixedly mounted at the output end of the second motor. According to the invention, dual oil meal mixing structures are arranged, so the quality of an oil meal raw material added into a micro-capsule is ensured, and the problems that micro-capsule manufacturing is affected and finished product components are uneven due to uneven mixing are solved; and a crushing structure for caked oil meal is arranged between the dual mixing structures and carries out crushing on preliminarily mixed and caked oil meal, so mixing quality during subsequent mixing is guaranteed, and therefore, subsequent micro-capsule production is facilitated.

Owner:临沂正能量生物有限公司

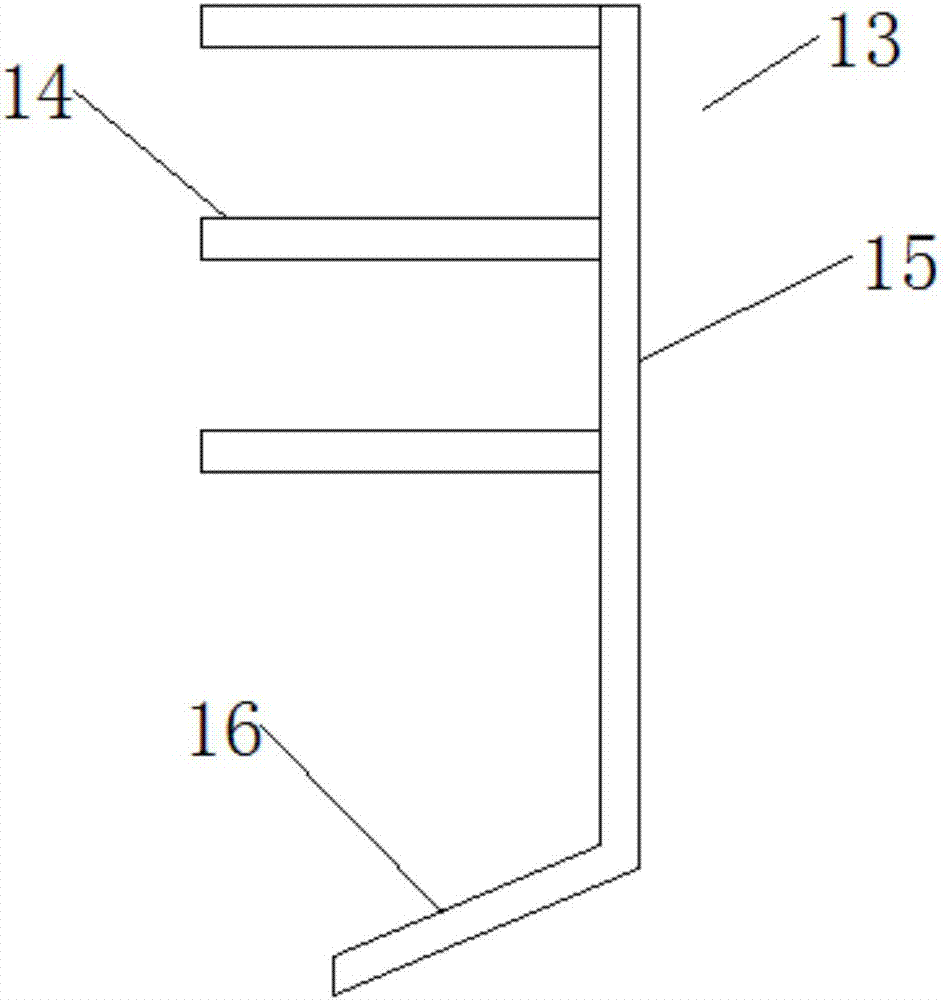

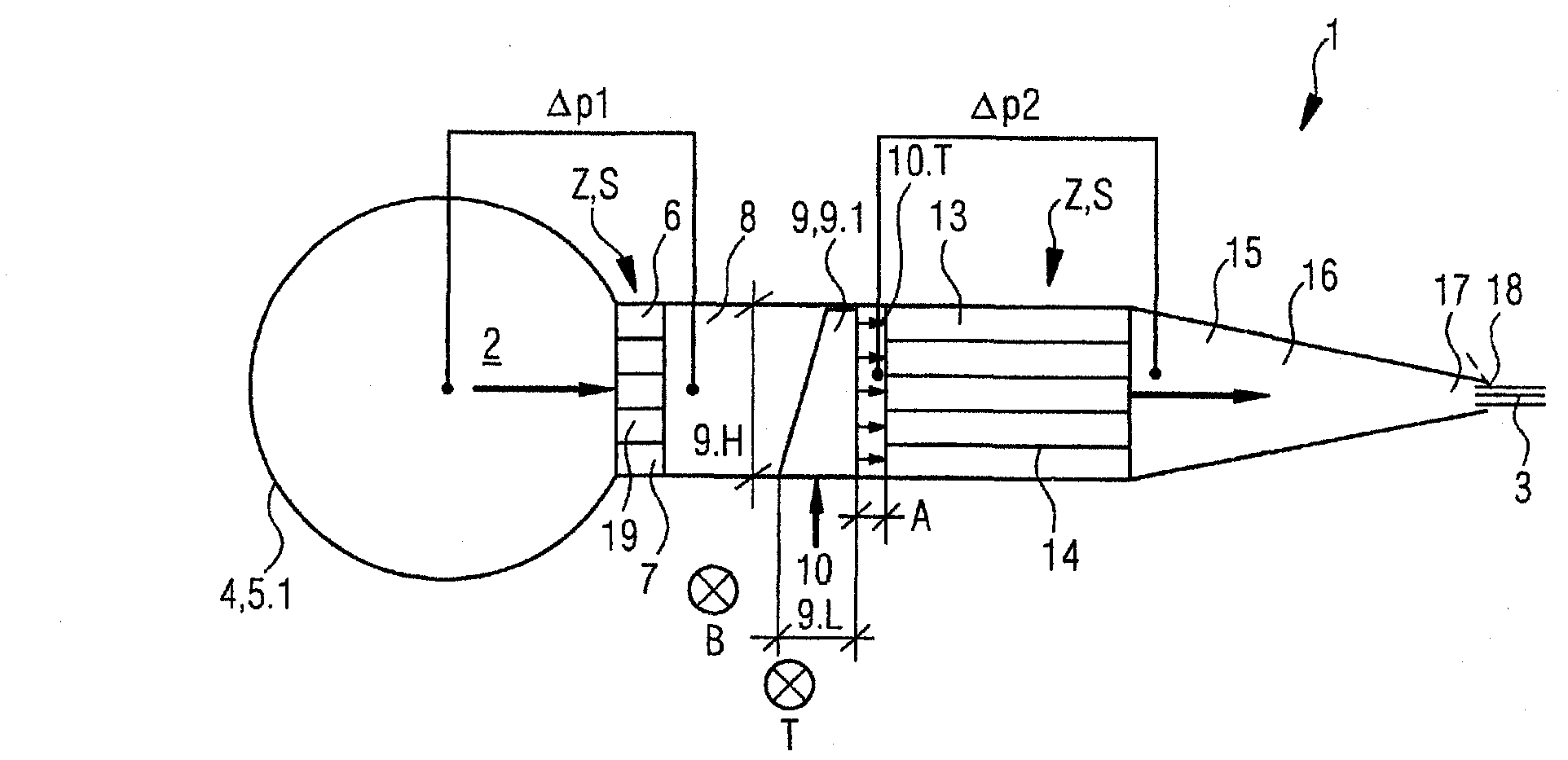

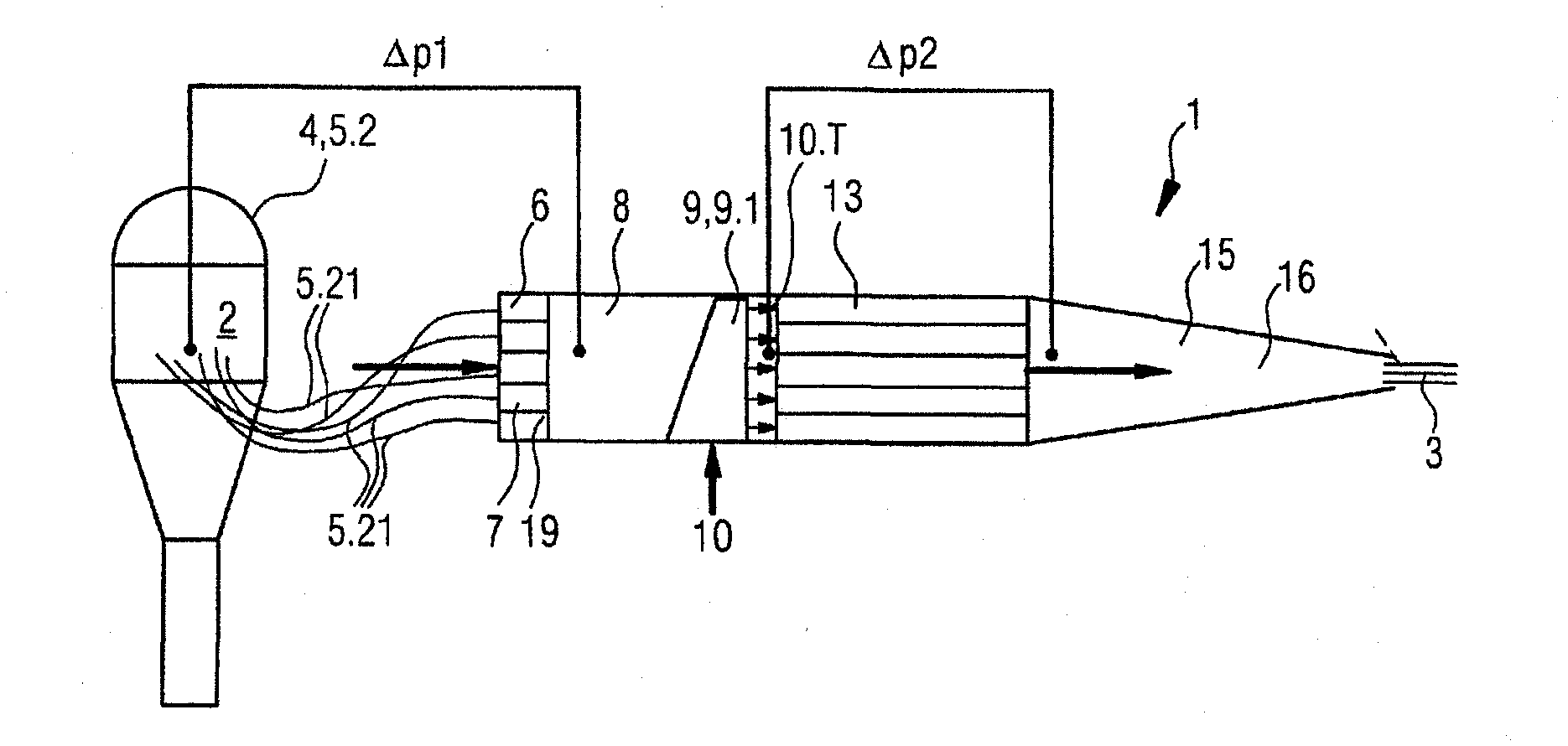

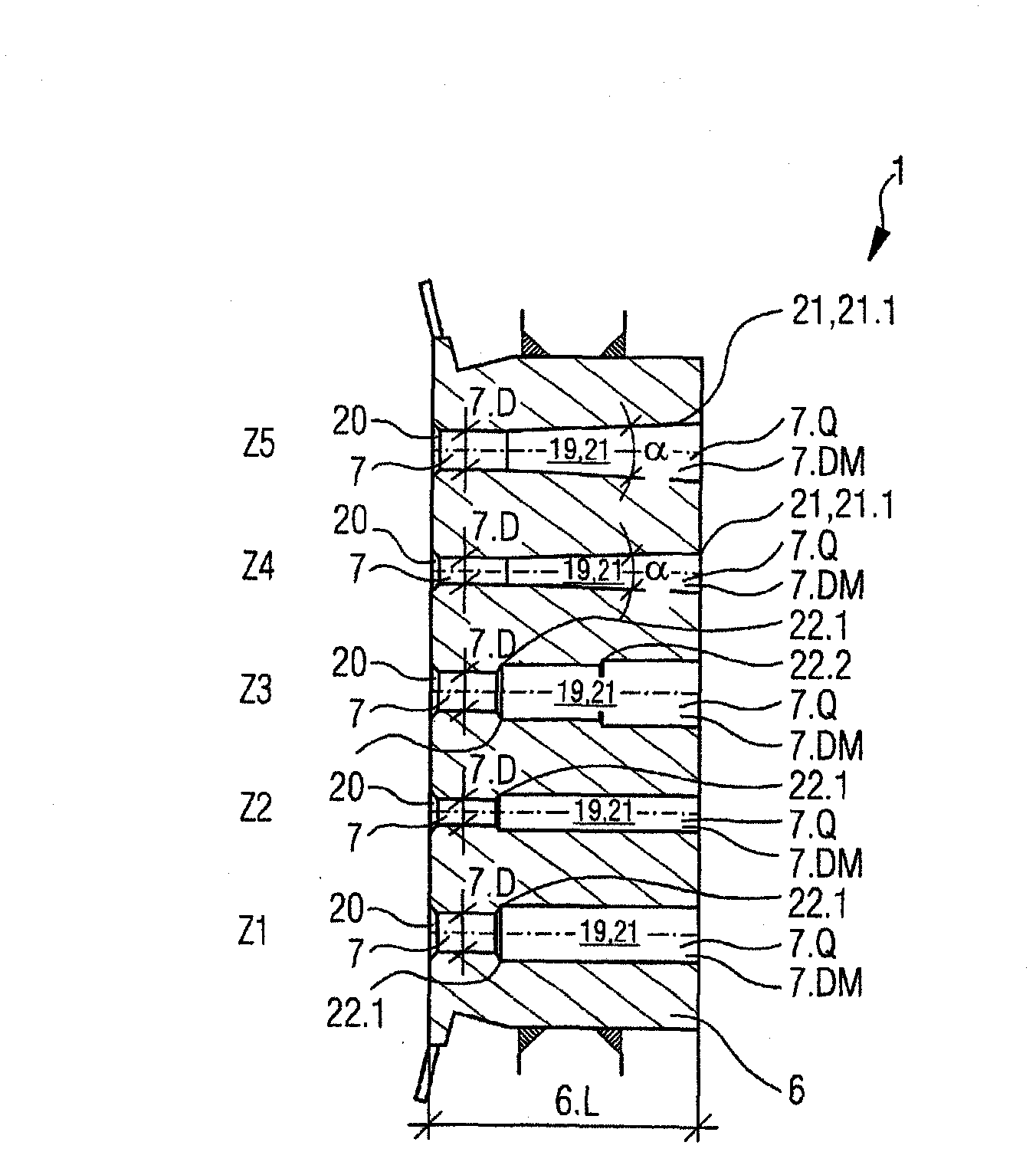

Headbox for a machine for producing a fibrous web

ActiveCN102216523AReduce energy consumptionReduce lossMachine wet endSystem pressureFiber suspension

The invention relates to a headbox (1) which comprises a feed device (4, 5.1; 4, 5.2) feeding the at least one fiber suspension (2), a perforated distribution pipe plate (6) arranged immediately downstream thereof and having a plurality of channels (7) arranged in lines (Z) and columns (S), an intermediate channel (8) arranged downstream thereof, extending over the width (B) of the headbox (1) and having a plurality of means (9, 9.1) for dosing a fluid (10) in partial fluid streams (10.T) to the at least one fiber suspension (2) in a preferably adjustable / controlled manner, the means being spaced apart from each other in the width direction of the headbox (1) and the individual means (9; 9.1) comprising a plurality of dosing channels (11) having respective dosing channel openings (11.O) and an opening center line (11.M), arriving at different levels and being connected to a common supply channel (12). The headbox further comprises a downstream turbulence generator (13) having a plurality of flow channels (14) arranged in lines (Z) and columns (S) and a headbox nozzle (16) which is directly contiguous to the turbulence generator (13) and which has a nozzle gap (17). The headbox (1) according to the invention has a system pressure loss which is substantially composed of a first pressure loss (Delta p1) between the feed device (4, 5.1; 4, 5.2) and the intermediate channel (8) and a second pressure loss (Delta p2) in the turbulence generator (13), the second pressure loss (Delta p2) and the first pressure loss (Delta p1) being in a ratio ranging from 8:1 to 1:1, preferably from 4:1 to 1:1, particularly from 2:1 to 1:1.

Owner:VOITH PATENT GMBH

Mixing device of gypsum production line

InactiveCN112497497APrevent moistureAvoid unevennessDischarging apparatusMixing operation control apparatusMixing effectGypsum

The invention discloses a mixing device of a gypsum production line. The mixing device of the gypsum production line comprises a workbench; a supporting column is fixedly mounted at the bottom end ofthe workbench; a supporting plate is fixedly connected to the inner side of the bottom of the supporting column; a vertical plate is fixedly mounted at the top end of the workbench; a first servo motor is connected to the outer side of the vertical plate; a rotating rod is mounted on the other side of the first servo motor; a mixing barrel is arranged outside the rotating rod in a sleeving mode; and a second servo motor is mounted on the other side of the mixing barrel. According to the mixing device of the gypsum production line, under the action of a damp-proof mechanism, the first servo motor is powered on to drive the rotating rod to rotate; and under the action that the rotating rod is fixedly connected with a heating rod, the heating rod heats gypsum while the gypsum is mixed in themixing barrel, so that the gypsum is prevented from being affected with damp in the mixing barrel; and therefore, uneven mixing is effectively prevented, the mixing effect of the device is improved, and meanwhile, the gypsum is prevented from being affected with damp and adhering to the inner wall of the mixing barrel, and the service life of the device can be prolonged.

Owner:贵溪市法拉第石膏板有限公司

Aluminum alloy mixing device for filter shell production

PendingCN112387172AImprove mixing efficiencyGuaranteed mix qualityShaking/oscillating/vibrating mixersTransportation and packagingGear wheelBevel gear

The invention provides an aluminum alloy mixing device for filter shell production, and belongs to the technical field of machining equipment for filter accessory production. The aluminum alloy mixingdevice for filter shell production comprises a mixing box body and a servo motor, a fixed bevel gear is arranged in the mixing box body, and the driving end of the servo motor penetrates through thetop of the mixing box body, extends into the mixing box body and is fixedly connected with a transmission rod; and a connecting frame is fixedly connected to the end, away from the output end of the servo motor, of the transmission rod, a mounting plate is fixedly connected to the end, away from the transmission rod, of the connecting frame, and a mounting groove is formed in the mounting plate. When the threaded rod rotates, the adjusting nut can move in the horizontal direction, then the two stirring plates are driven to rotate around the transmission rod and move back and forth in the horizontal direction at the same time, and compared with traditional equipment, the equipment can greatly improve the mixing efficiency and ensure the mixing quality.

Owner:金寨春兴精工有限公司

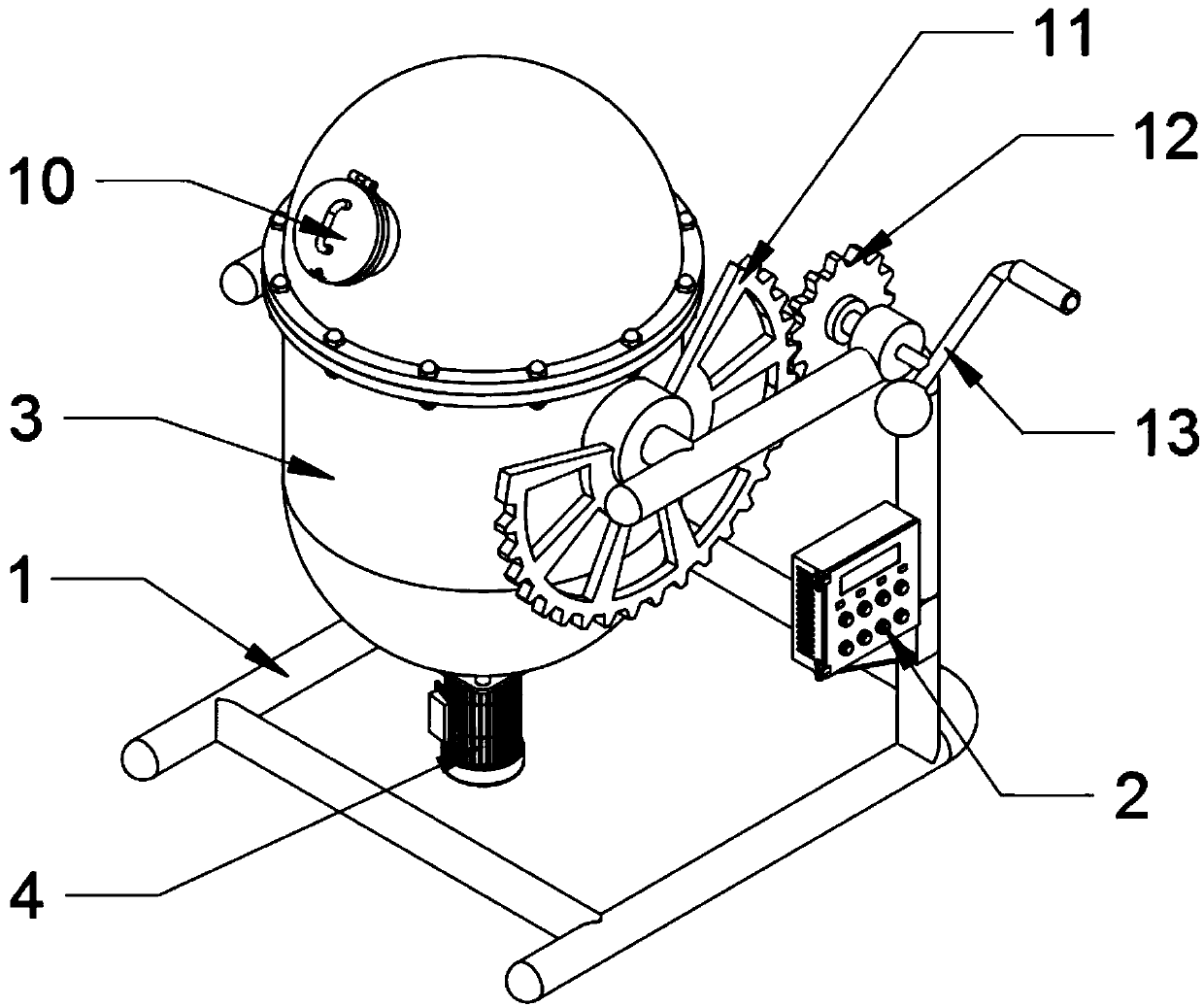

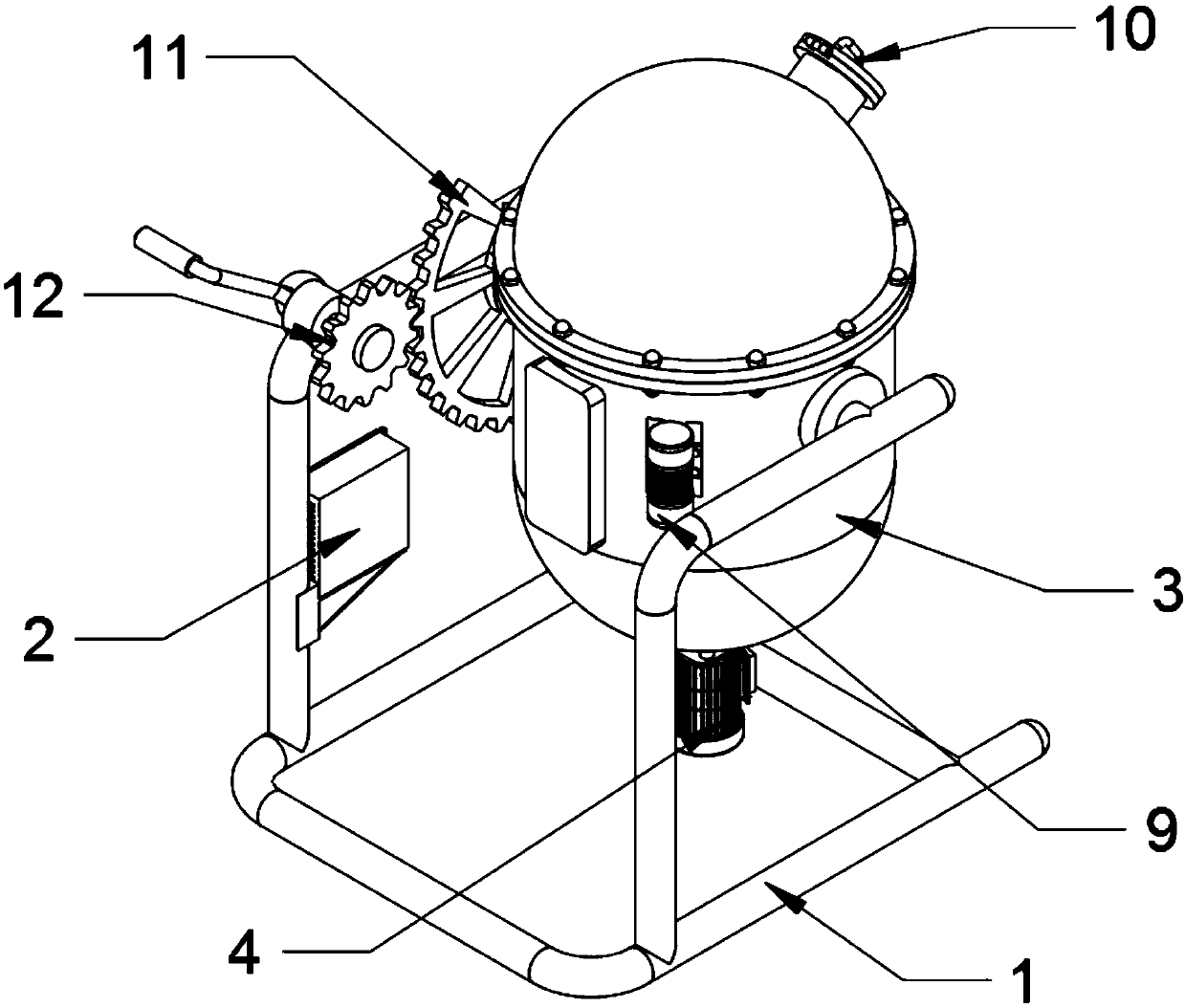

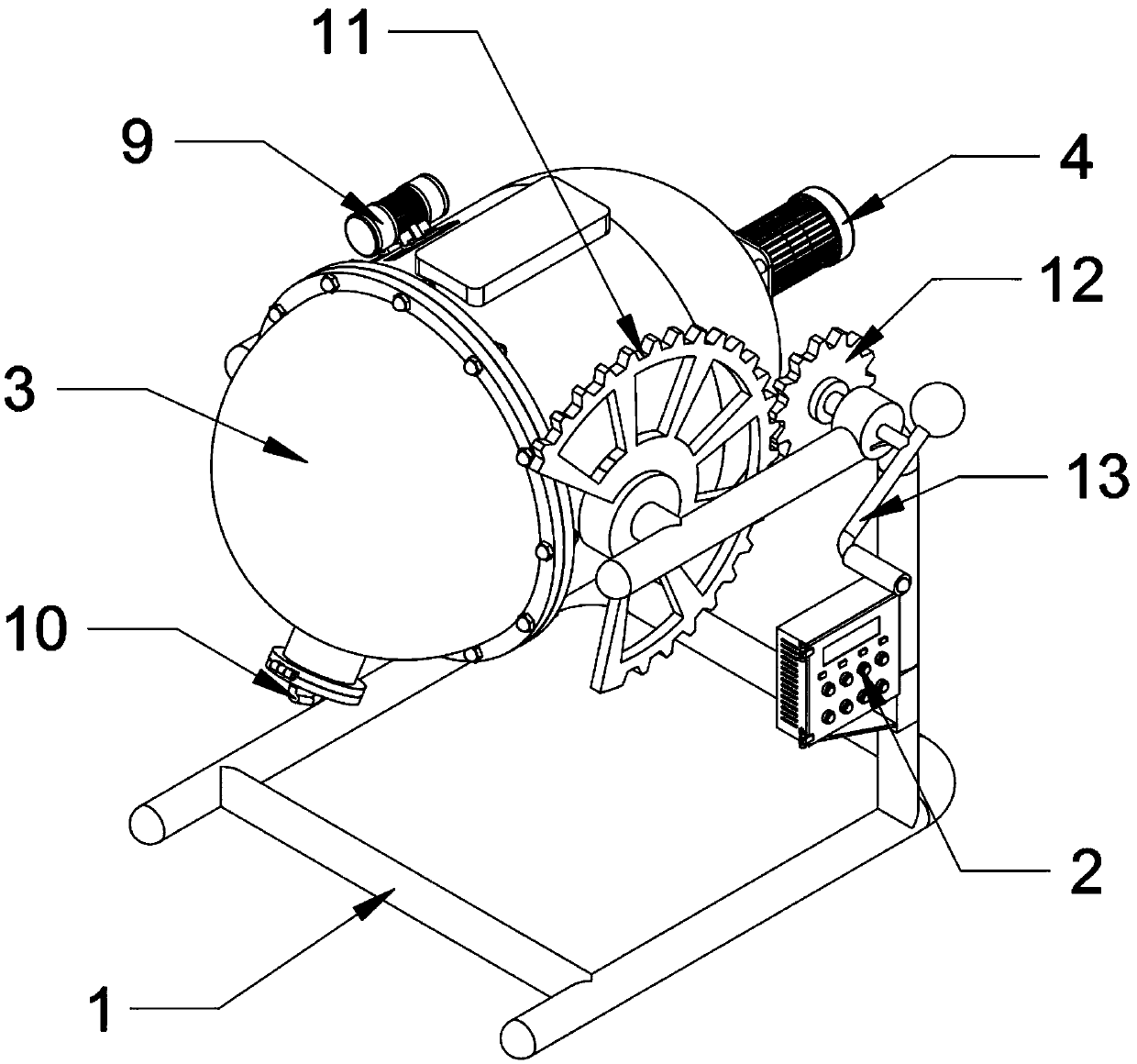

Mixing and stirring integrated facility for producing and processing semi-conductive materials

InactiveCN109603636AGood for surround heating workEasy to mix and mixRotary stirring mixersTransportation and packagingDrive wheelConductive materials

The invention provides a mixing and stirring integrated facility for producing and processing semi-conductive materials. The facility comprises a driving wheel and a manual rocking handle; a power supply control box is mounted on the right side of a support base, the support base is of a frame structure, and a mixing barrel is mounted in the top of the support base; the interior of the mixing barrel is of a hollow structure, and the top of the mixing barrel is provided with a feed inlet; a stirring motor is mounted on the end face of the bottom of the mixing barrel and electrically connected with the power control box through a power supply circuit; the bottom of a mixing shaft is connected with the top of the stirring motor, and the mixing shaft rotates in the mixing barrel; the stirringframe is mounted on the mixing shaft, and stirring blades are mounted on the stirring frame; a heating ring is mounted in the mixing barrel, and a vibration motor is mounted outside the mixing barrel.The facility is beneficial to mixing and stirring of the semi-conductive raw materials contained in a device, so that the semi-conductive raw materials are mixed more uniformly, and the mixing quality of the semi-conductive materials is ensured.

Owner:宁波华越高分子科技有限公司

Pre-proportioning stirring device for slurry

InactiveCN112265143AGuaranteed accuracyQuality assuranceSievingGas current separationHydraulic cylinderControl engineering

The invention discloses a pre-proportioning stirring device for slurry. The pre-proportioning stirring device comprises a bottom plate, a filtering mechanism, a screening mechanism, a stirring device,a water supply mechanism, a dust suction mechanism and a controller, and an electric telescopic rod is arranged on a filtering plate; the screening mechanism is arranged below the filtering mechanism; the screening mechanism comprises a screening box, a waste box, a fixing frame, hydraulic cylinders, support columns and screening holes, and the outer side of the screening box is fixedly connectedwith the fixing frame; and the right and left sides of the fixing frame are symmetrically connected with the hydraulic cylinders. The pre-proportioning stirring device for the slurry is provided witha weighing sensor, and the weighing sensor can be used for weighing materials entering the stirring box; when the weighing sensor detects that the weight of the materials in the stirring box reachesa set value, the information can be transmitted through the weighing sensor to the controller; a buzzer is controlled by the controller to make a sound to remind a worker to stop feeding to a materialconveyer, thereby facilitaing guarantee of the proportioning accuracy; and thus, the quality of the slurry is easy to guarantee.

Owner:徐州格雷安环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com