Raw material mixing device for rubber product production

A technology of rubber products and mixing devices, which is applied in the field of rubber products, can solve problems such as difficult to ensure the quality of mixing materials, increase the labor load of manpower, and uneven mixing and mixing, so as to achieve high work efficiency, speed up stirring speed, and reduce labor volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

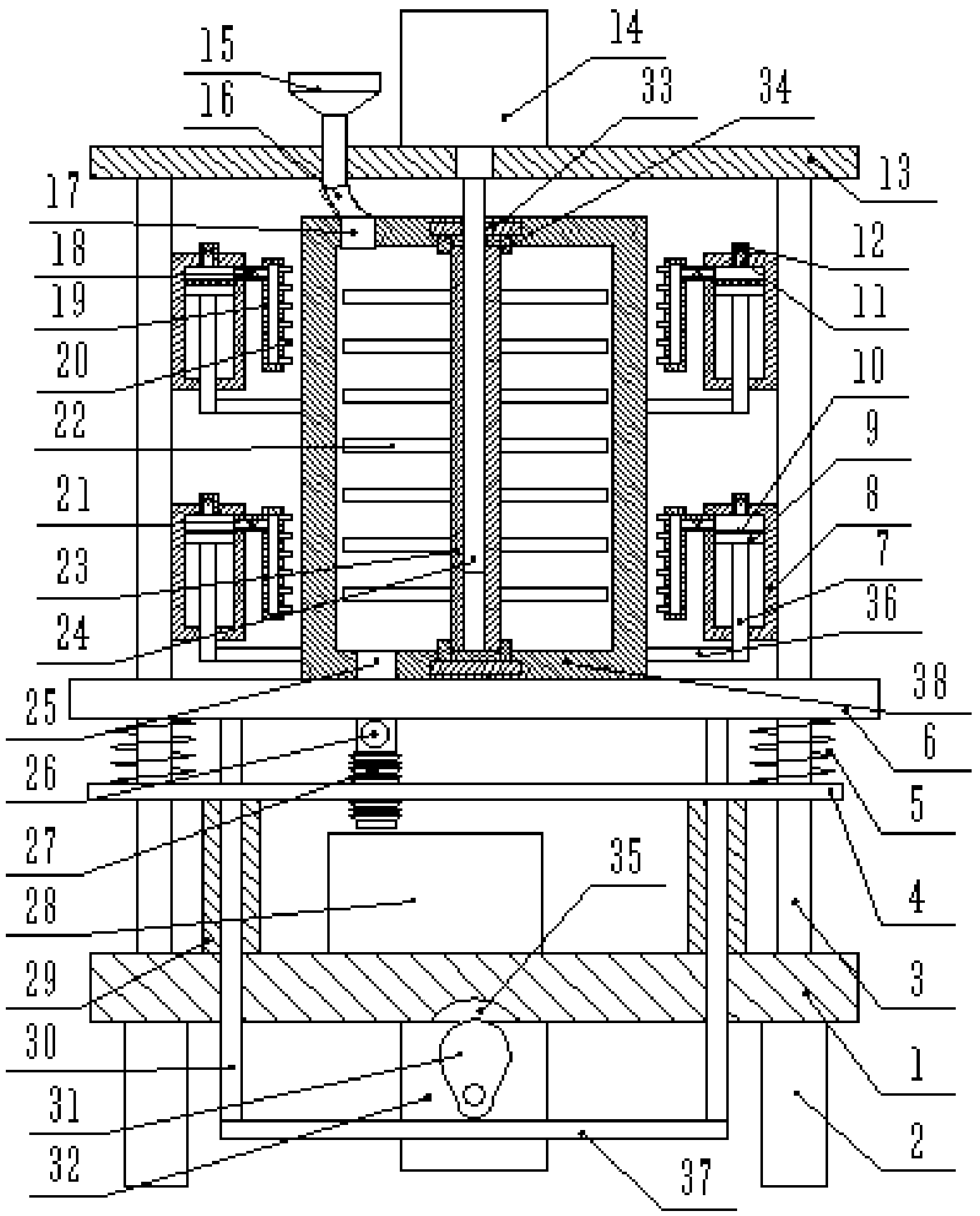

[0014] Such as figure 1 As shown, a raw material mixing device for the production of rubber products includes a support plate 1, the four corners of the bottom surface of the support plate 1 are fixedly connected with outriggers 2, and the top surface of the support plate 1 is symmetrically fixedly connected with two sides. A pole 3, two poles 3 are covered with the same fixed plate 4 and fixedly connected with it, the pole 3 at the top of the fixed plate 4 is covered with a slide plate 6 and is slidably connected with it, the top of the pole 3 is fixed A horizontal plate 13 is connected, and two springs 5 are fixedly connected between the sliding plate 6 and the fixed plate 4. The two springs 5 are respectively set on the poles 3, and the bottom surface of the slide plate 6 between the two poles 3 is fixedly connected. There are two second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com