Device for preparing solid acrylic resin and method thereof

A technology of solid acrylic acid and equipment, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., can solve the difficulties of high viscosity transportation, stirring and heat and mass transfer and other problems, to achieve high heat transfer coefficient, large heat transfer area, and improve the effect of monomer conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

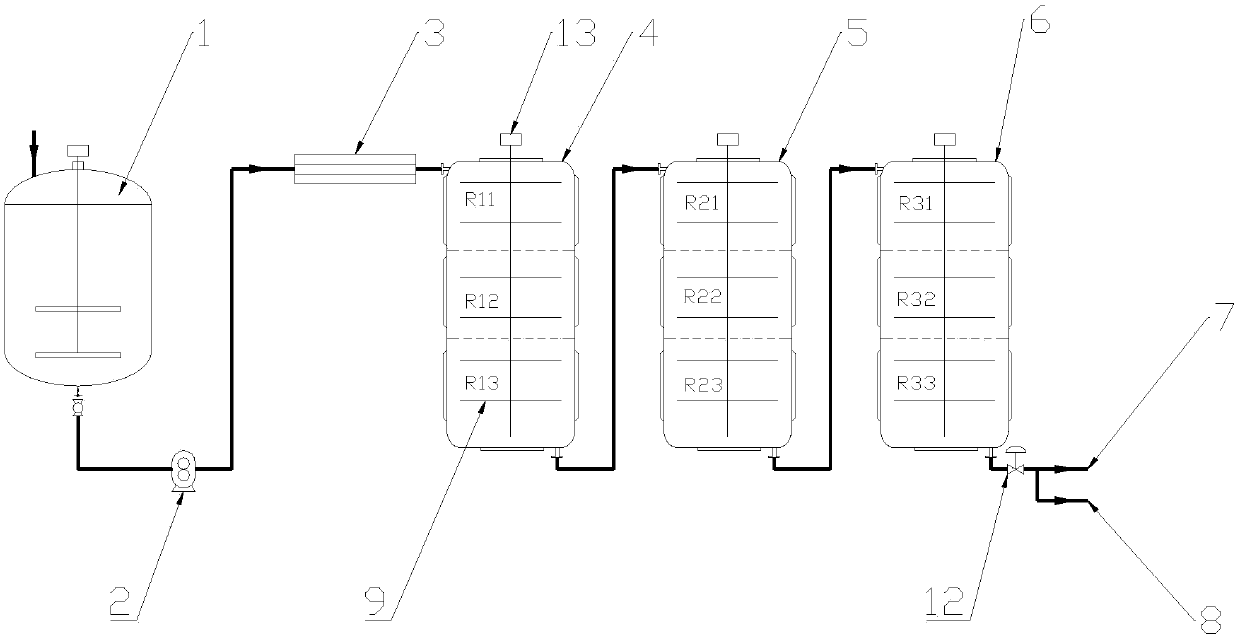

[0046] Add 20kg of methyl methacrylate, 16kg of 2-hydroxyethyl methacrylate, 13.5kg of butyl methacrylate, 0.5kg of methacrylic acid, and 3.5kg of n-dodecyl mercaptan in the batching tank 1 , initiator tert-butyl peroxybenzoate 0.05kg;

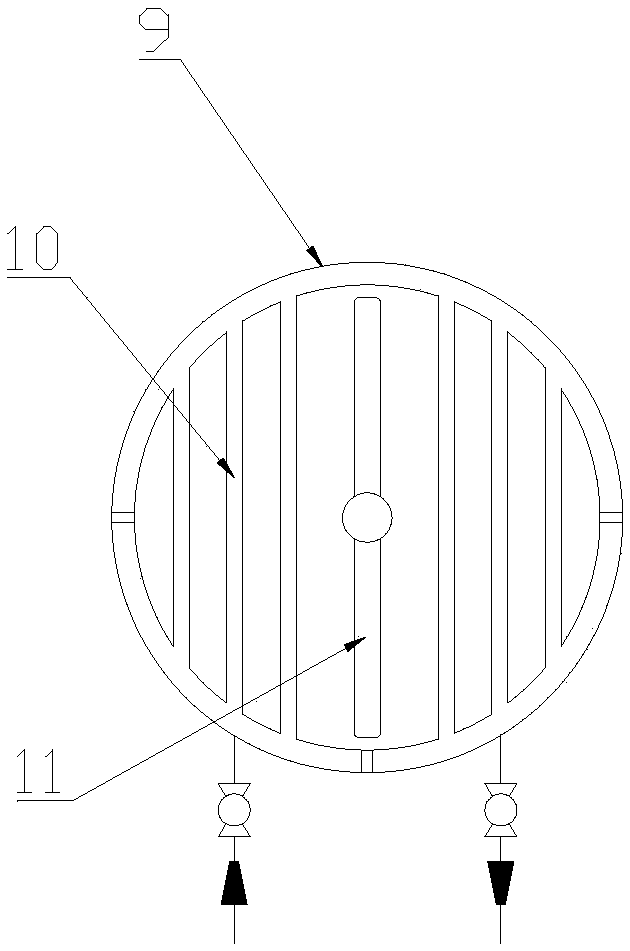

[0047] The mixed material passes through the metering pump 2 and enters the prepolymerization reactor 4 through the preheater 3 . The material is first heated to 60°C through the preheater 3, and the feed rate is 1000ml / hr. The pressure of the reaction system is ~0.45Mpa; the materials are completely filled in the three reactors.

[0048] The temperature of the three temperature control zones R11, R12, and R13 of the prepolymerization reactor 4 is controlled at 92°C, 98°C, and 102°C, respectively; the stirring speed of the reactor is 20rpm; the reaction time is 3.5hr.

[0049] The material passing through the prepolymerization reactor 4 has a conversion rate of 45%, and then enters the second reactor 5, and the three temperature control zone...

Embodiment 2

[0052] In batching tank 1, add methyl methacrylate 24.5kg, isobornyl methacrylate 24.5kg, methacrylic acid 1kg, molecular weight regulator n-dodecyl mercaptan 2.8kg, initiator tert-butyl peroxybenzoate 0.05kg;

[0053] The mixed material passes through the metering pump 2 and enters the prepolymerization reactor 4 through the preheater 3 . The material is first heated to 60°C through the preheater 3, and the feed rate is 1000ml / hr. The pressure of the reaction system is ~0.55Mpa; the materials are completely filled in the three reactors.

[0054] The temperature of the three temperature control zones R11, R12, and R13 of the prepolymerization reactor 4 is controlled at 92°C, 96°C, and 100°C, respectively; the stirring speed of the reactor is 25rpm; the reaction time is 3hr.

[0055] The material passing through the prepolymerization reactor 4 has a conversion rate of 43%, and then enters the second reactor 5, and the three temperature control zones R21, R22, and R23 of the s...

Embodiment 3

[0058] In batching tank 1, add methyl methacrylate 2.5kg, styrene 13kg, α-methylstyrene 16.5, isooctyl acrylate 1kg, molecular weight regulator n-dodecyl mercaptan 6.2kg, initiator benzene peroxide Tert-butyl formate 0.065kg;

[0059] The mixed material passes through the metering pump 2 and enters the prepolymerization reactor 4 through the preheater 3 . The material is first heated to 60°C through the preheater 3, and the feed rate is 800ml / hr. The pressure of the reaction system is ~0.60Mpa; the materials are completely filled in the three reactors.

[0060] The temperature of the three temperature control zones R11, R12, and R13 of the prepolymerization reactor 4 are respectively controlled at 92°C, 95°C, and 98°C; the stirring speed of the reactor is 28rpm; the reaction time is 3.5hr.

[0061] The material passing through the pre-polymerization reactor 4 has a conversion rate of 46%, and then enters the second reactor 5. The three temperature control zones R21, R22, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com