Method for acquiring proportion of composite grouting material for reinforcing fractured rock mass

A technology for grouting materials and cracked rock mass, which is applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, and using wave/particle radiation for material analysis, etc. Air bubbles, difficult construction, long construction period, etc., to improve the compressive strength, meet the actual engineering needs, and enhance the stability of the rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in combination with the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the implementation manners in the present invention, all other implementation manners obtained by persons of ordinary skill in the art without making creative efforts belong to the scope of protection of the present invention.

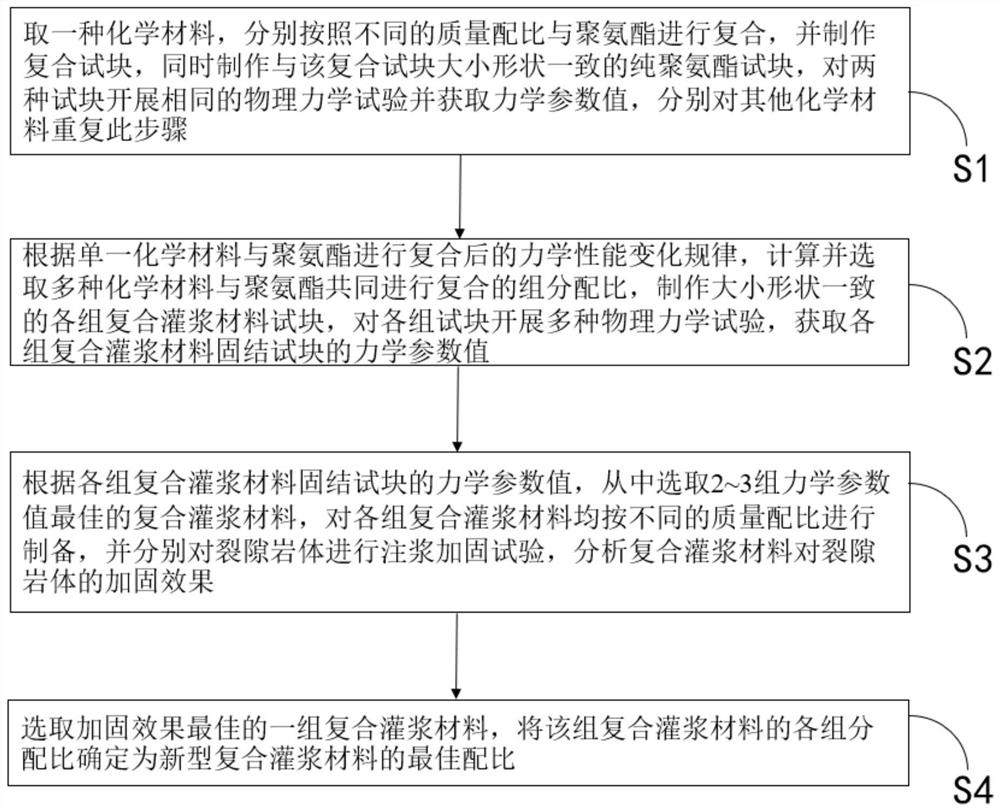

[0033] Such as figure 1 As shown, a method for obtaining the ratio of composite grouting materials for cracked rock mass reinforcement of the present invention comprises the following steps:

[0034] Step S1, compounding a single chemical material with polyurethane: Take a chemical material and compound it with polyurethane according to different mass ratios to make a composite test block of the material and polyurethane, and make a pure polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com