Patents

Literature

134results about How to "Avoid mixing unevenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Warm-mixed asphalt mixture and preparation method thereof

ActiveCN102092988ALower the mixing temperatureHigh tensile strengthClimate change adaptationAdhesive cementHigh concentration

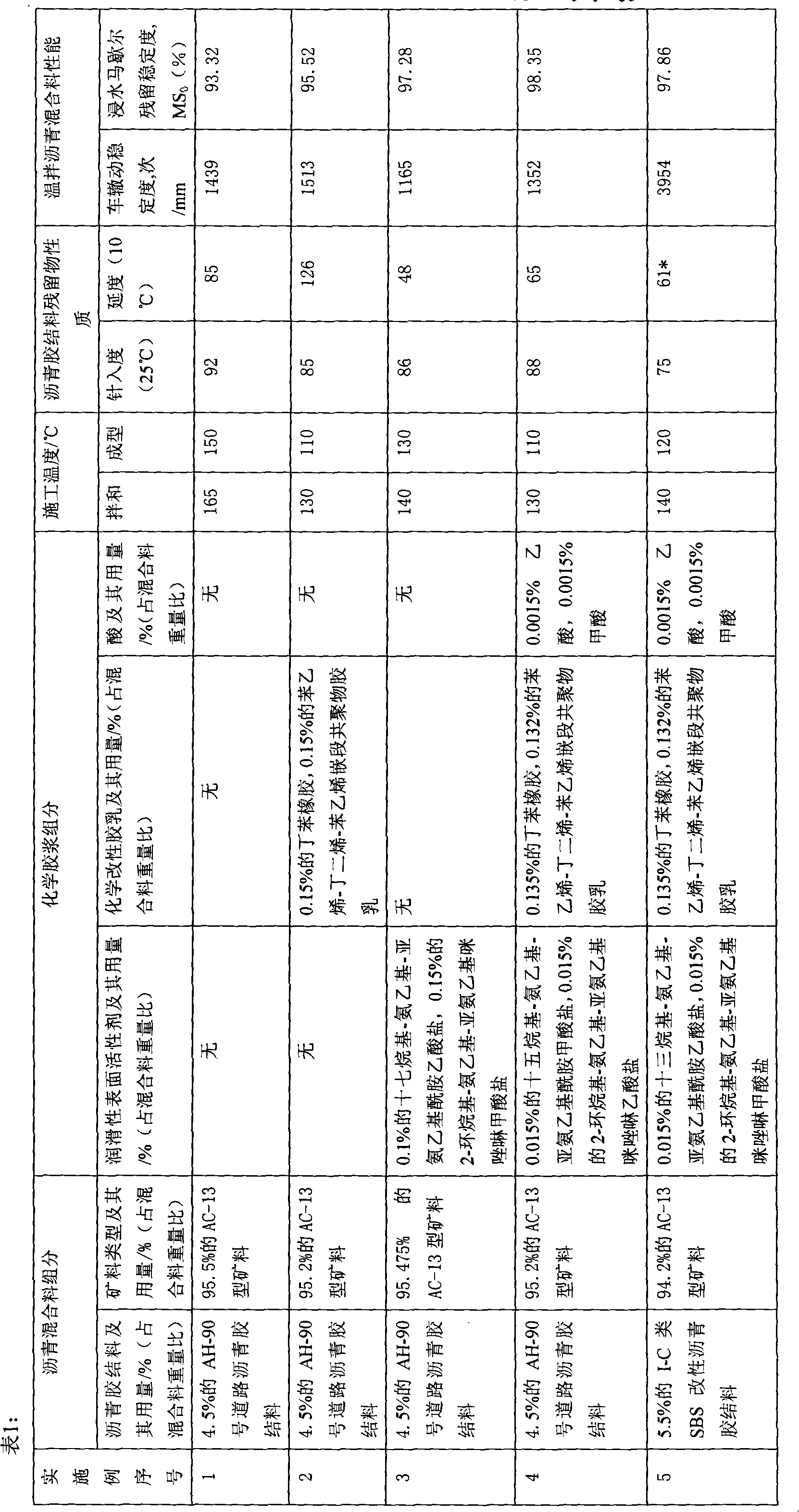

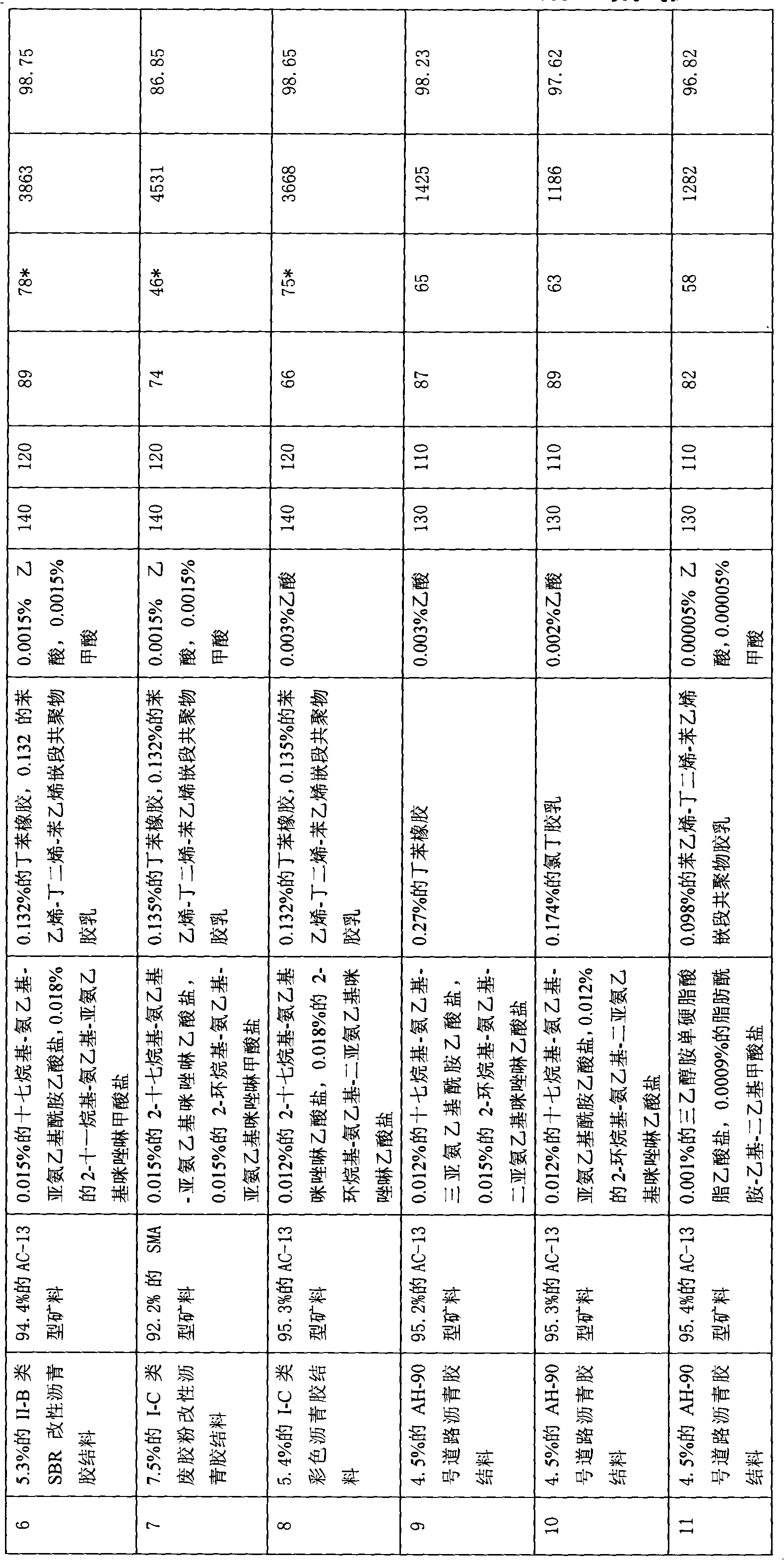

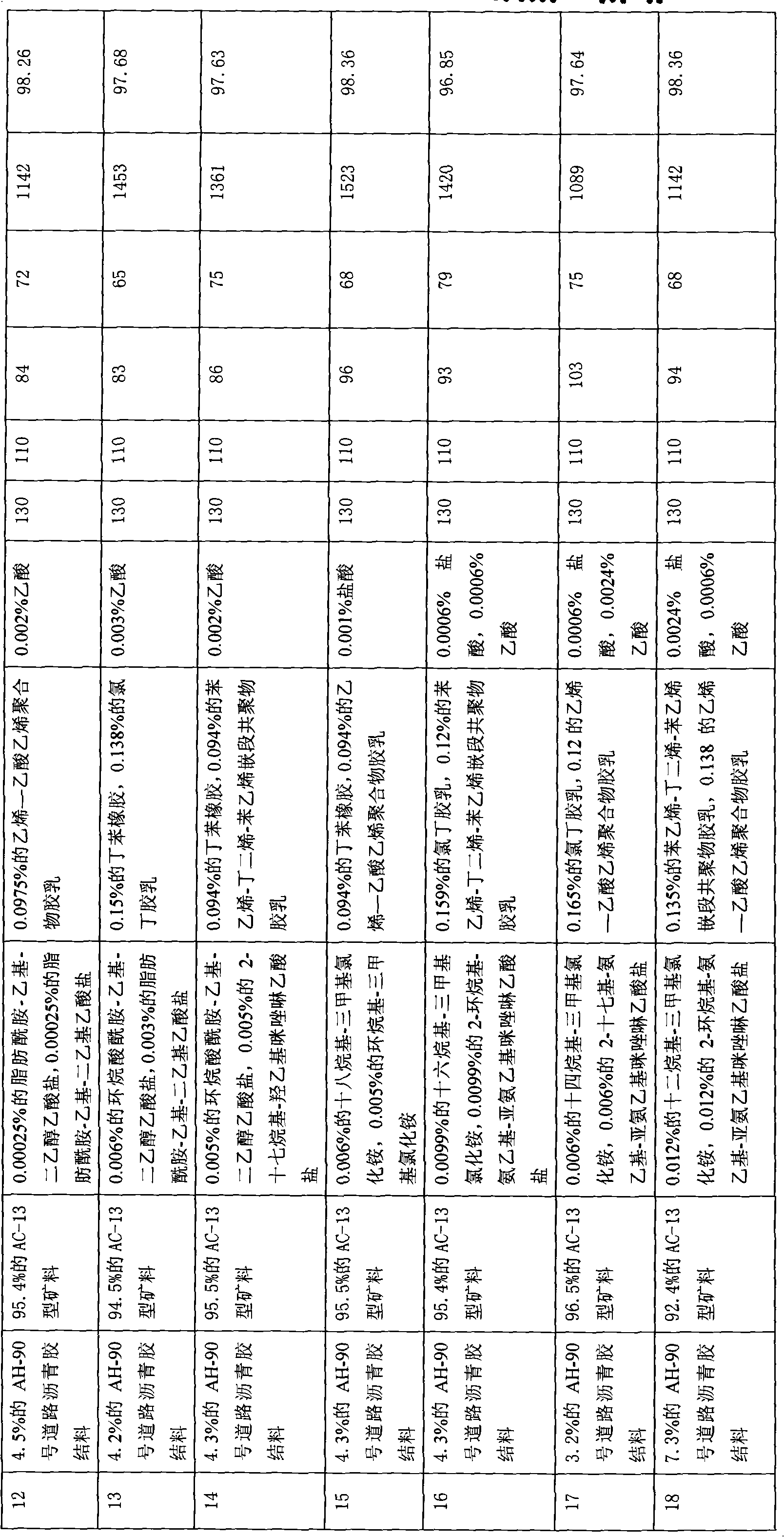

The invention relates to a warm-mixed asphalt mixture and a preparation method thereof. The warm-mixed asphalt mixture is mainly applied to new construction and maintenance of high-grade roads and common roads, and is particularly suitable for cities, parks, tunnels and the like with high environmentally-friendly requirements. The warm-mixed asphalt mixture mainly comprises about 92.4-96.5 percent by weight of mineral, about 3.4-7.5 percent by weight of asphalt cement and 0.05-1.0 percent by weight of chemical modified adhesive cement. The preparation method comprises the following steps of: simultaneously pumping the chemical modified adhesive cement and the hot asphalt cement to the spraying port of a foam generator, fully mixing to generate a foam-containing hot asphalt mixture, spraying the foam-containing hot asphalt mixture into a mixing pan, and further mixing the foam-containing hot asphalt mixture and the hot mineral to form the warm-mixed asphalt mixture. The chemical modified adhesive cement can effectively reduce the mixing, spreading and rolling temperature of the asphalt mixture, and solves the problems of environmental pollution, high energy consumption, asphalt ageing regression and the like. By selecting high-concentration cationic chemical modified latex as a matrix stock of the chemical modified adhesive cement and simultaneously matching a proper proportion of cationic surfactant with lubricating effect and peeling resistance, the influence of the conventional warm-mixed asphalt additive on poor reducing performance and poor adhesive performance of the asphalt cement is solved, and the properties of the warm-mixed asphalt mixture such as water damage resistance, rutting resistance, fatigue resistance, low temperature resistance and the like are improved.

Owner:PETROCHINA CO LTD

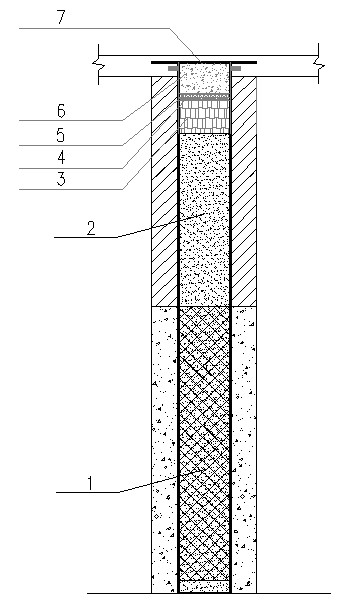

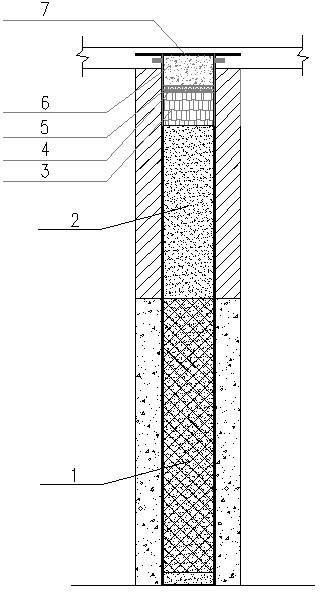

Plugging method for downcomer for well-point dewatering of deep foundation pit

ActiveCN102561372ASolve the leakage problemEasy to operateFoundation engineeringSoluble glassMaterials science

The invention provides a plugging method for a downcomer for the well-point dewatering of a deep foundation pit, and belongs to a falling water plugging method of civil engineering. The plugging method comprises the construction steps as follows: firstly, a filtering layer is disposed; secondly, a sand layer is filled; thirdly, a cotton batting layer is stuffed; fourthly, a soluble glass cement sand bed is poured; fifthly, a leaking stoppage agent layer is smeared; sixthly, a micro-expansive concrete layer is poured; and seventhly, a plugging steel plate is welded, wherein the filtering layer arranged at the lower part of an inner chamber of a conventional downcomer remains the same, and the sand layer is filled until the height of the sand layer reaches 1.5 meters below the top of the downcomer; the height of the cotton batting layer ranges from 0.7 to 1.0 m; the thickness of the soluble glass cement sand bed ranges from 50 to 80 mm, and the soluble glass cement sand bed is curdled when poured; the thickness of the leaking stoppage agent layer ranges from 40 to 60 mm; the micro-expansive concrete layer is poured until the height reaches the upper pipe orifice of the downcomer; and the round steel plate is utilized to plug an upper opening of the downcomer above the micro-expansive concrete layer in a full-length welding manner, wherein the thickness of the round steel plate ranges from 8 to 15 mm. The plugging method effectively solves the difficult problem that leakage is caused when the downcomer is plugged, is simple and convenient to operate, and has the advantages of quick construction progress, high construction quality and low cost.

Owner:CHINA MCC17 GRP

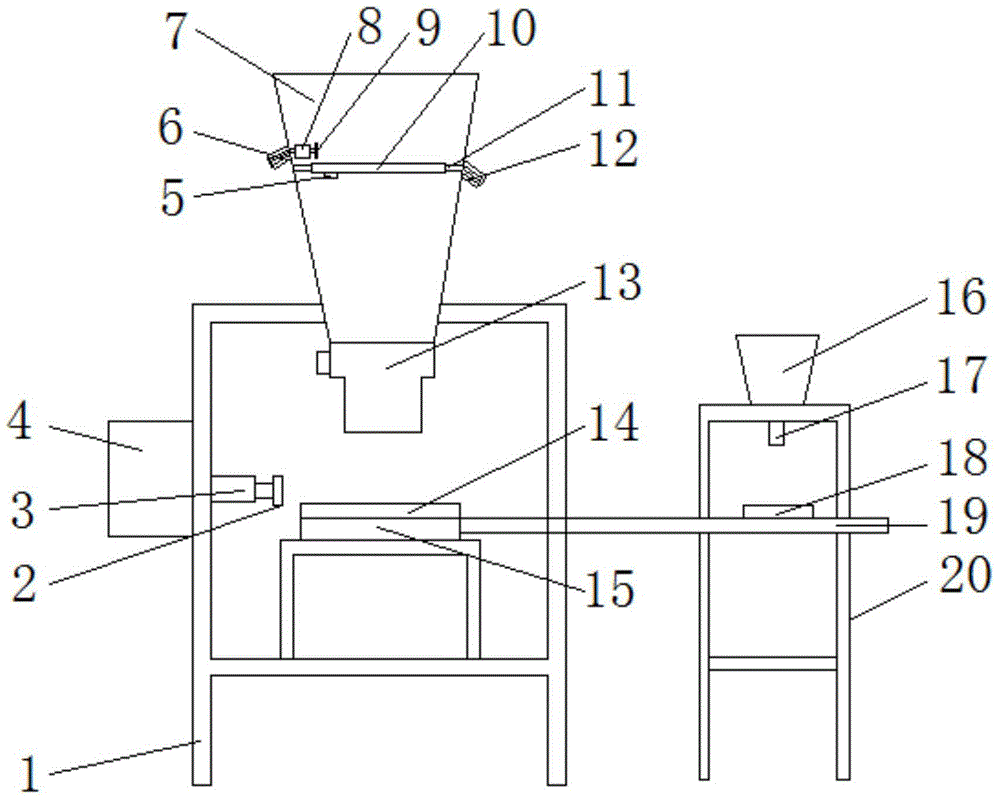

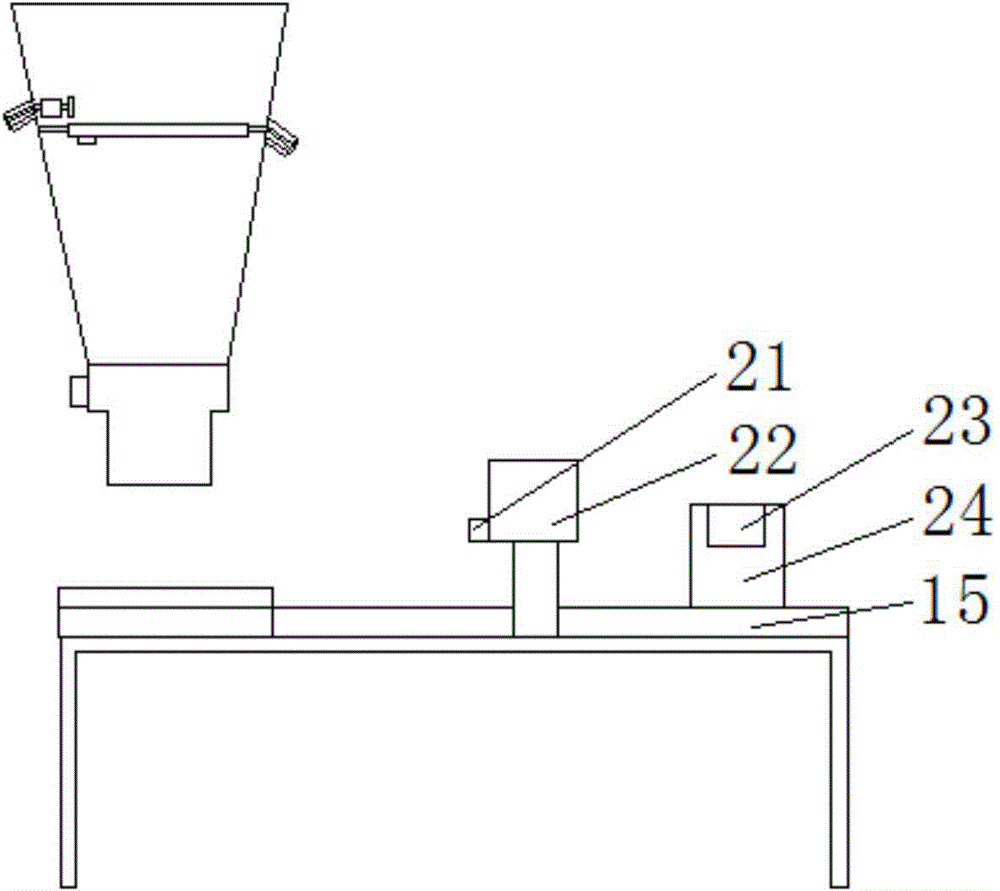

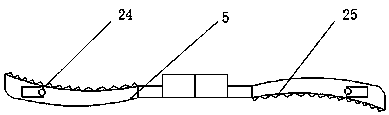

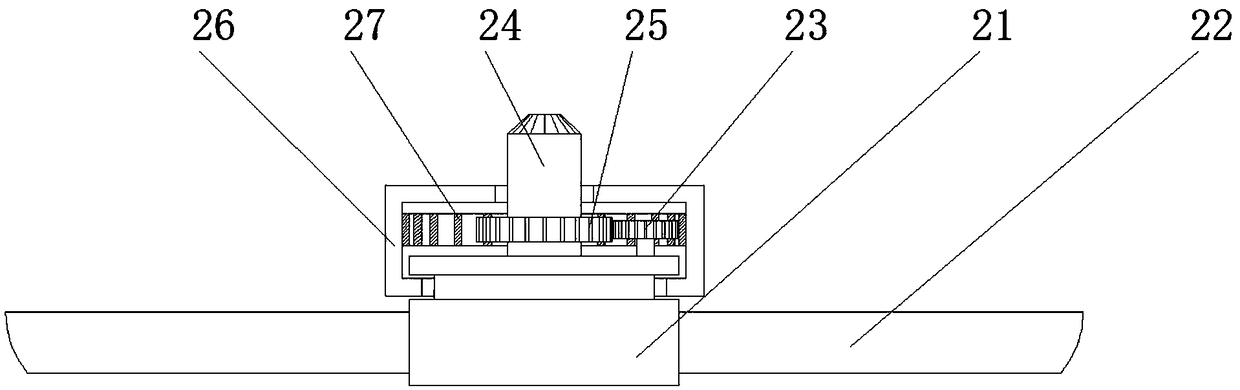

Automatic packer

ActiveCN104691796AAchieve cullingRealize feedingPackaging automatic controlSolid materialPlastic packagingAutomation

The invention discloses an automatic packer. The automatic packer comprises a frame I, a hopper I fixed on the frame I, a qualified product conveying belt, a rejecting device, an unqualified product conveying belt, a frame II and a hopper II fixed on the frame II, wherein an overturning plate is arranged in the hopper I; a weight sensor is arranged on the overturning plate; the lower part of the hopper I is connected with a bagging machine; the rejecting device comprises a cylinder I and a pushing plate connected to a pushing rod; an automatic plastic packaging machine, a labeling machine and a label making machine are arranged on the qualified product conveying belt; an infrared sensor is arranged on the automatic plastic packaging machine; the unqualified product conveying belt penetrates through the frame II. According to the automatic packer, the overturning plate with the weight sensor and the pushing plate are arranged in the hopper I; the materials are fed stably; the uneven stirring and the secondary pollution caused by artistic stirring are avoided; the rejecting device is capable of rejecting unqualified materials and supplementing; the qualified rate of products is ensured; the production efficiency and the automation degree of the equipment are improved.

Owner:天津雍和包装股份有限公司

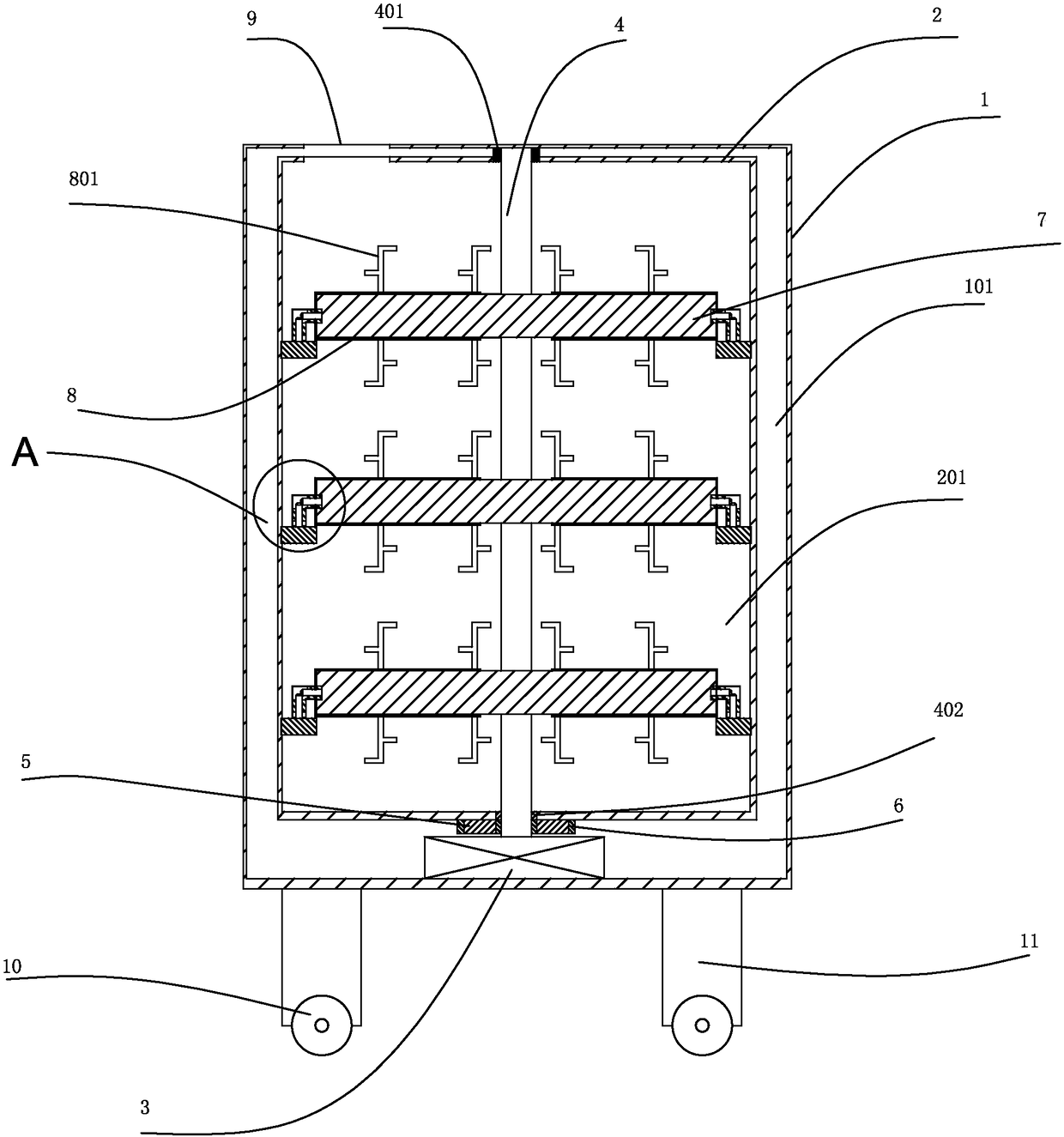

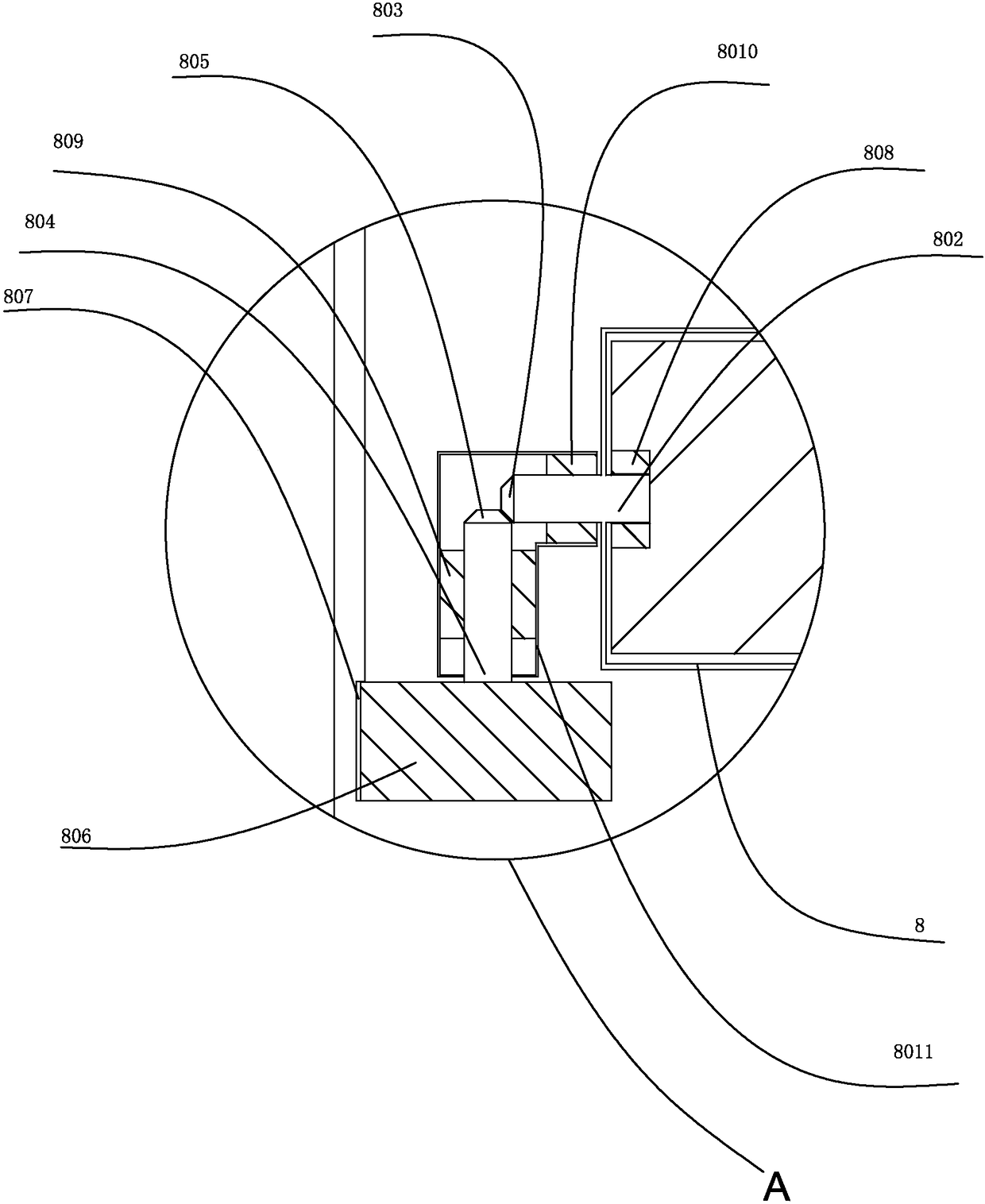

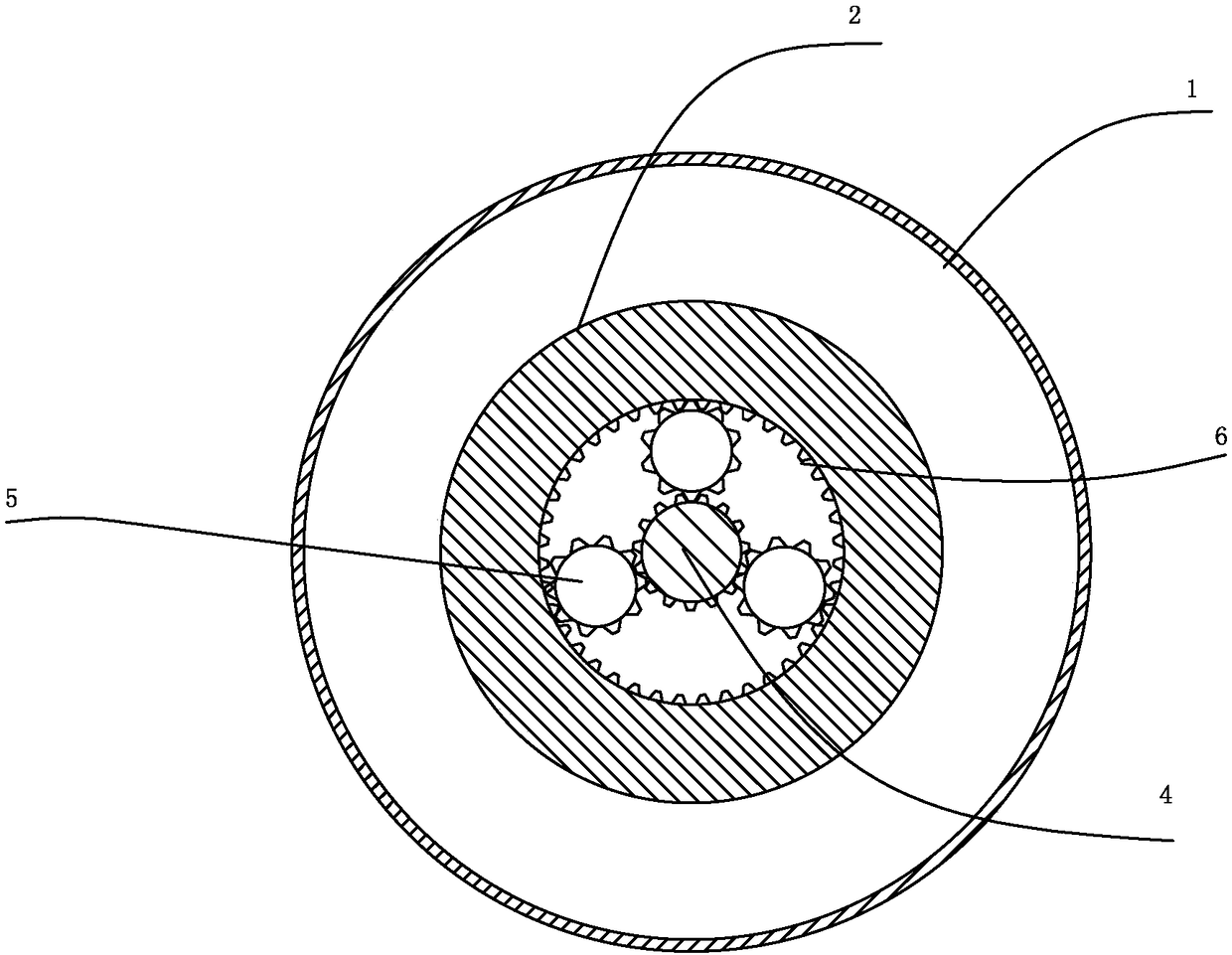

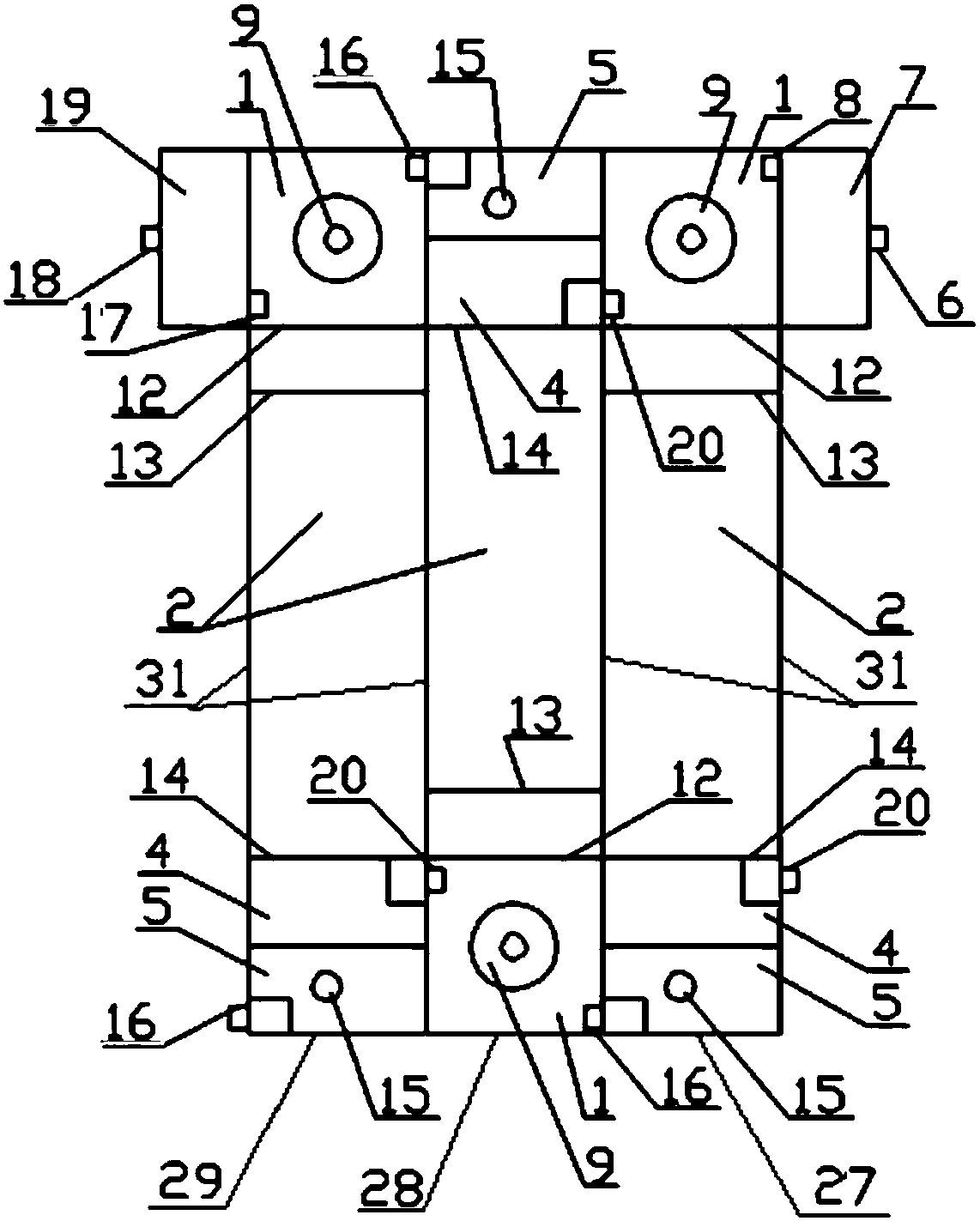

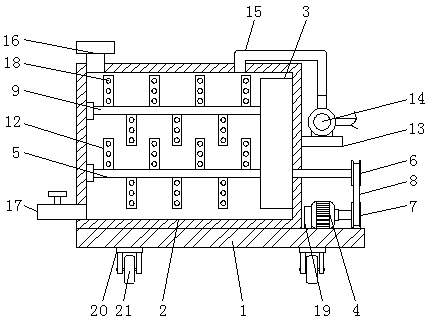

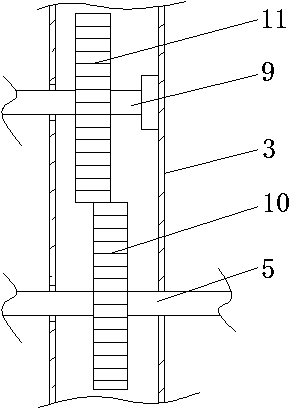

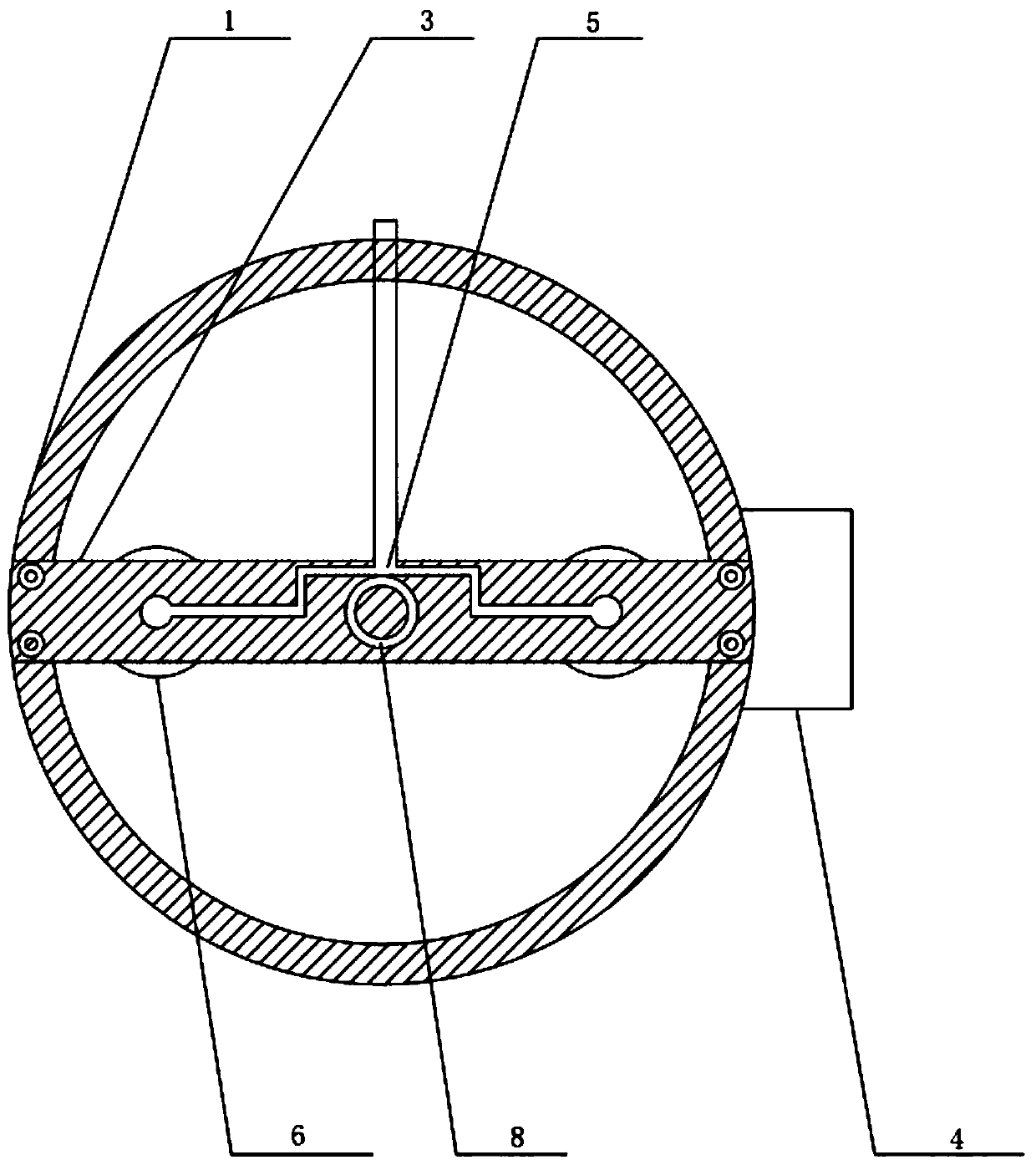

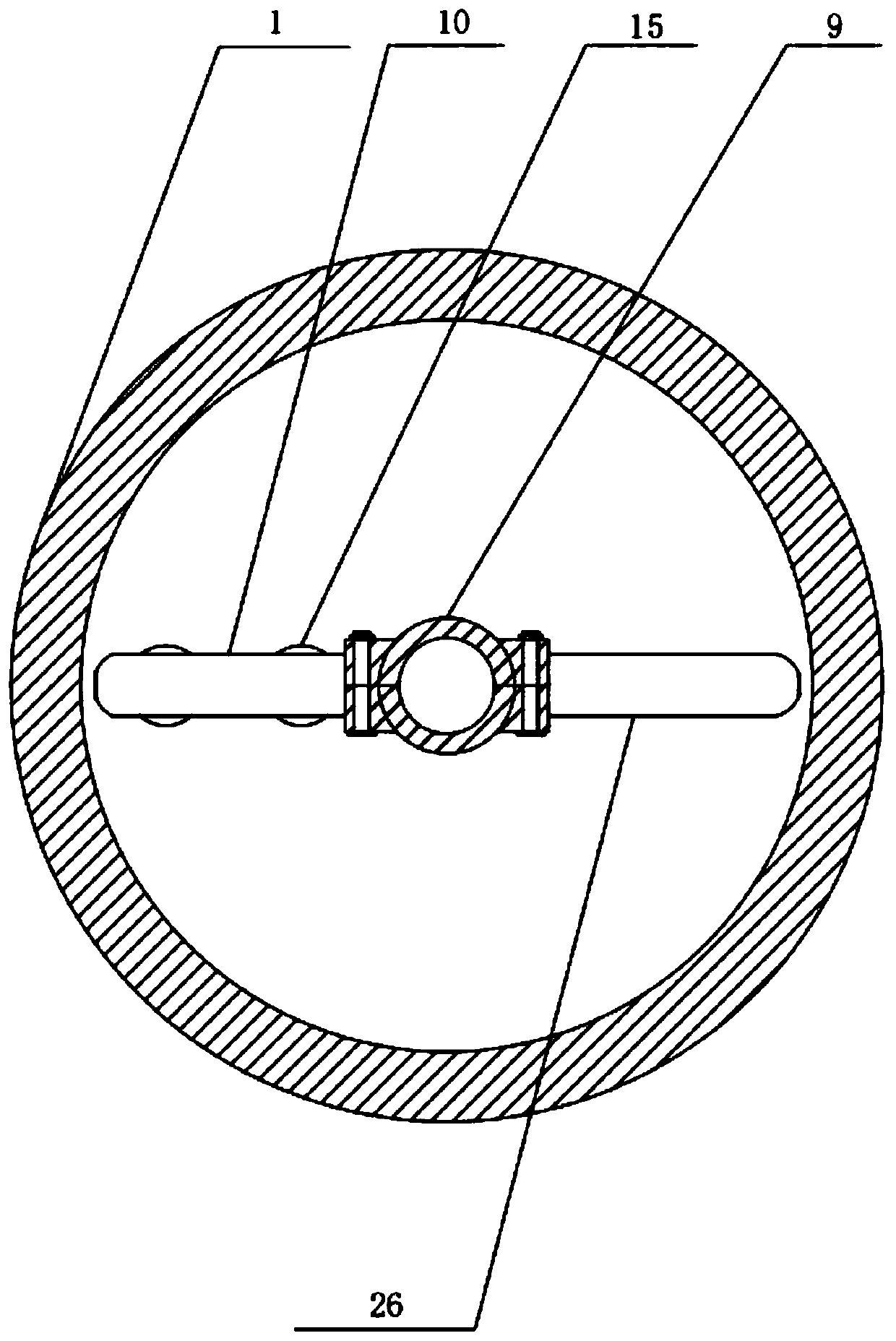

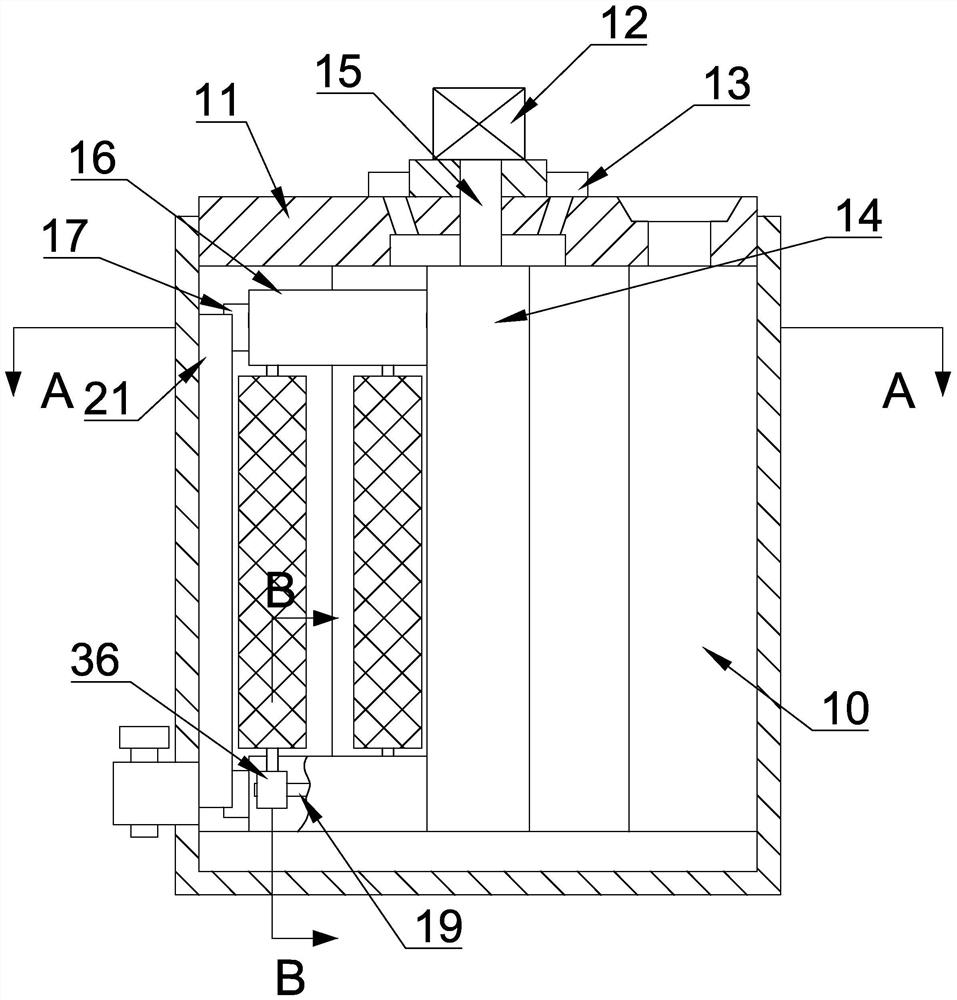

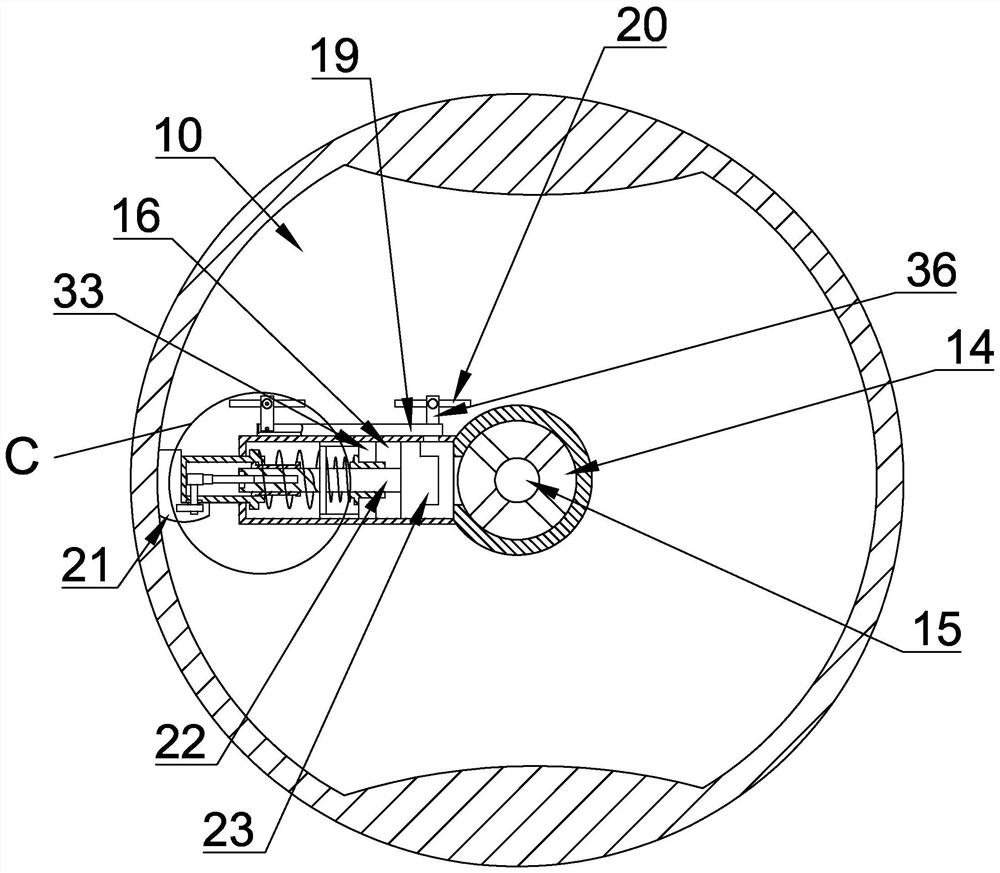

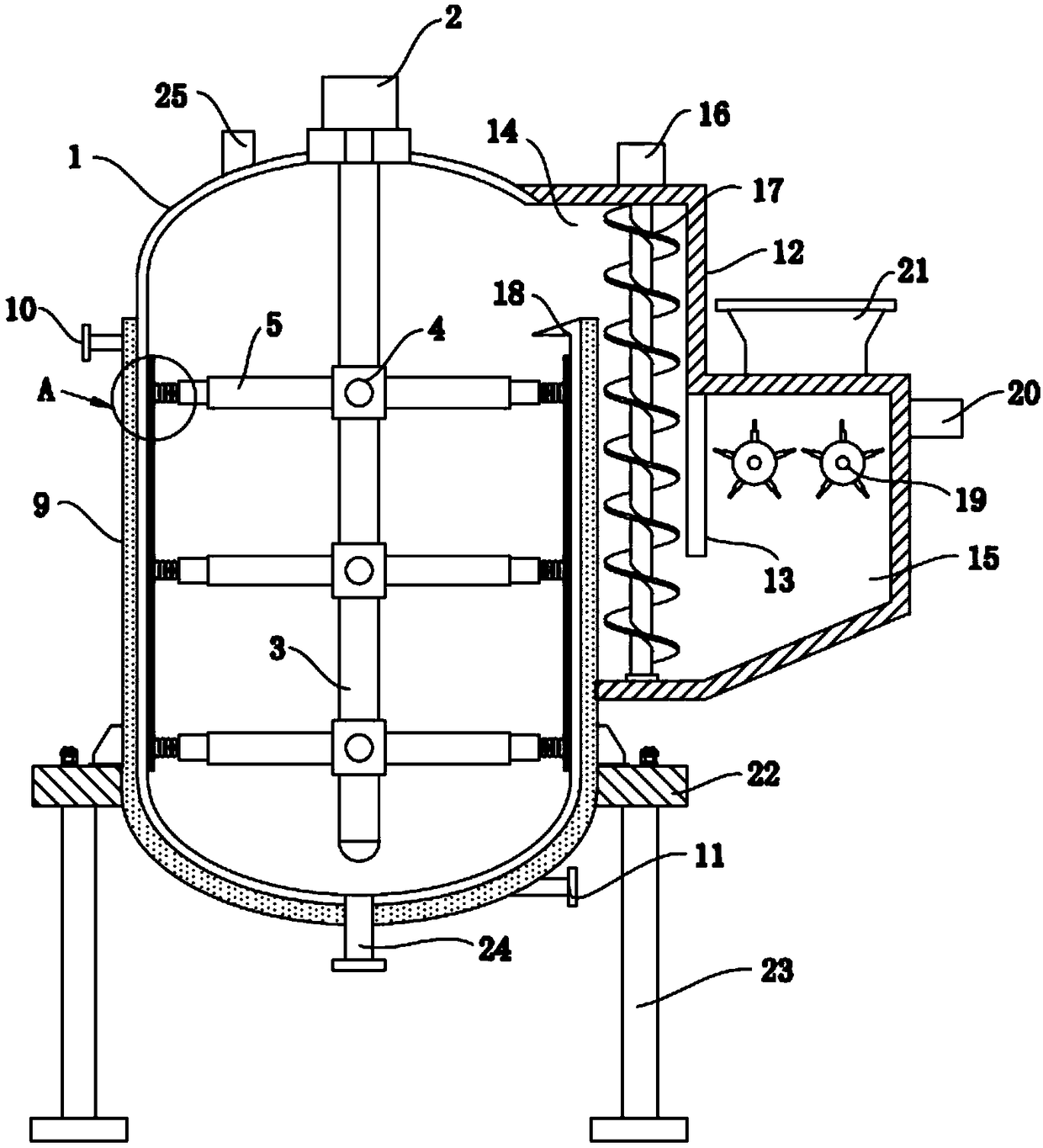

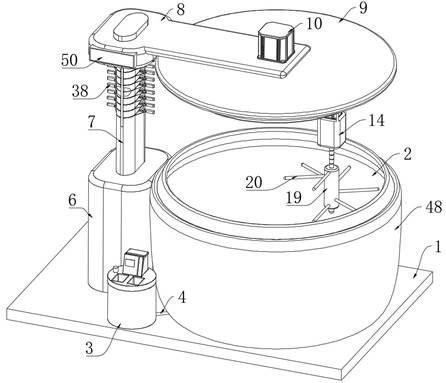

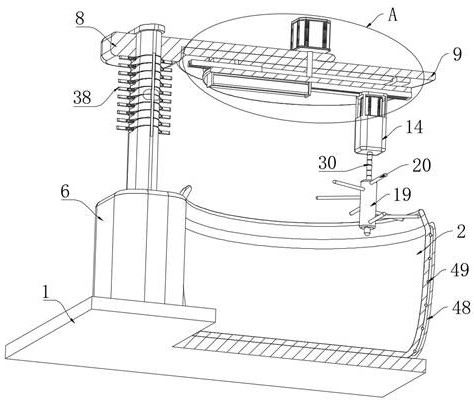

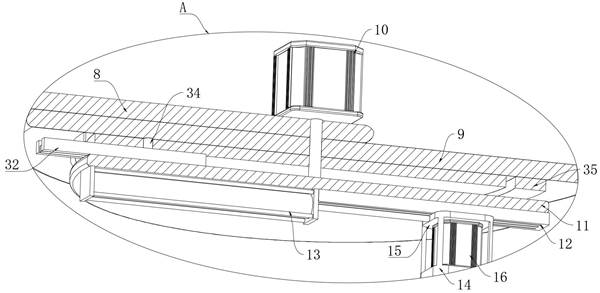

Paper product raw material stirring device

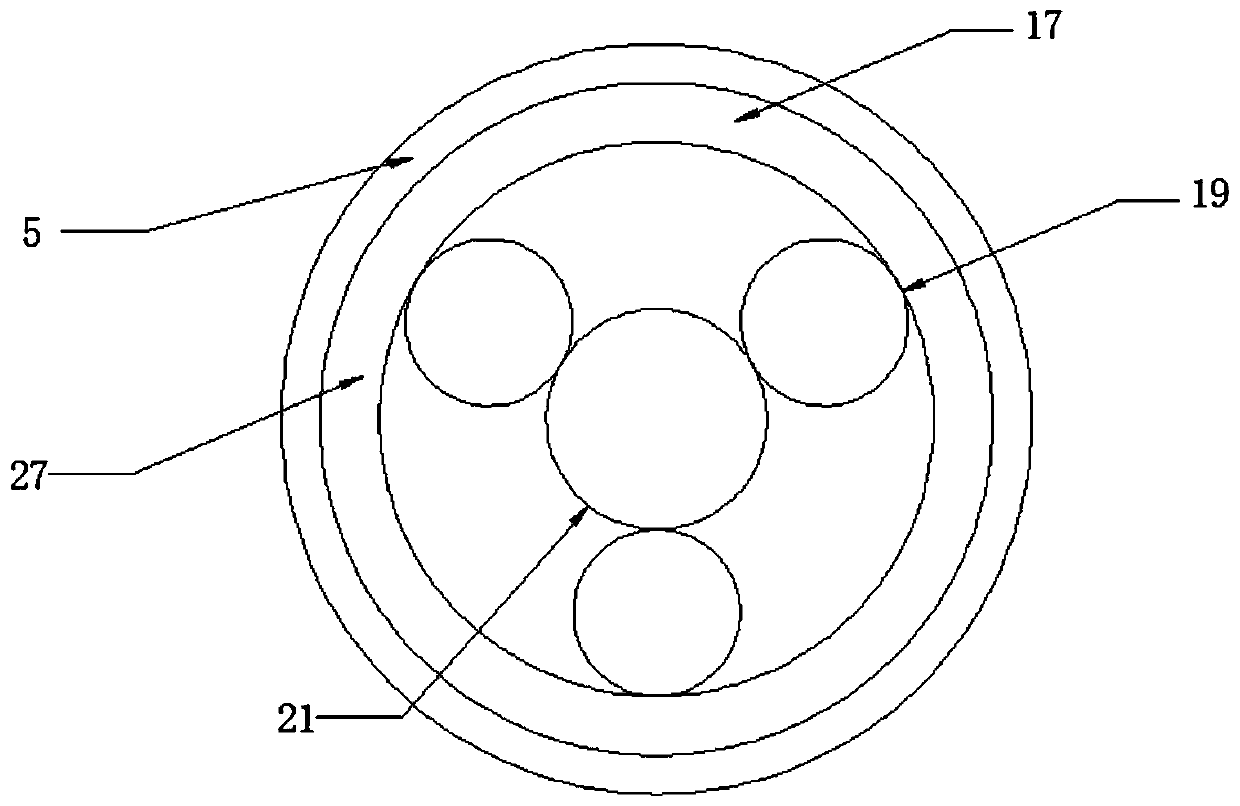

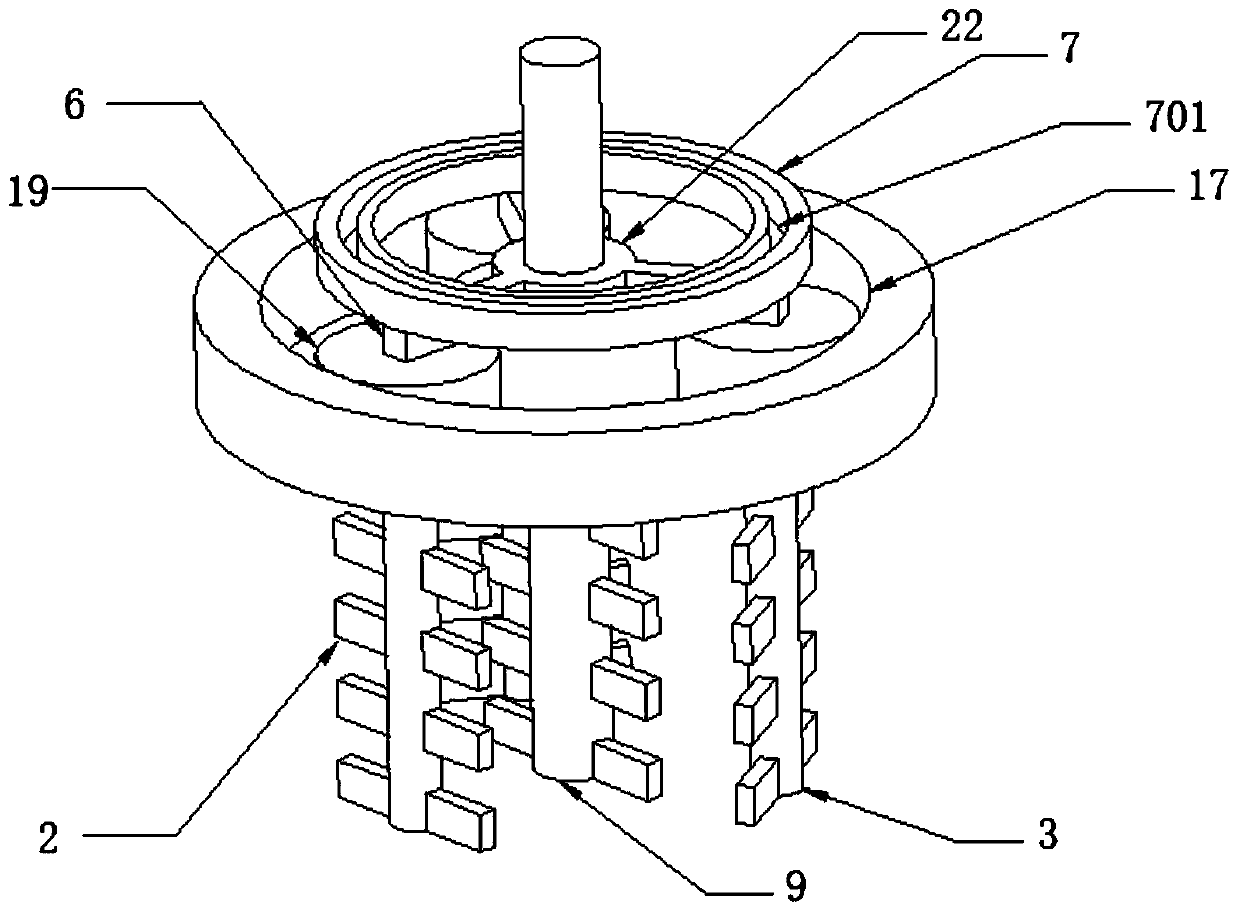

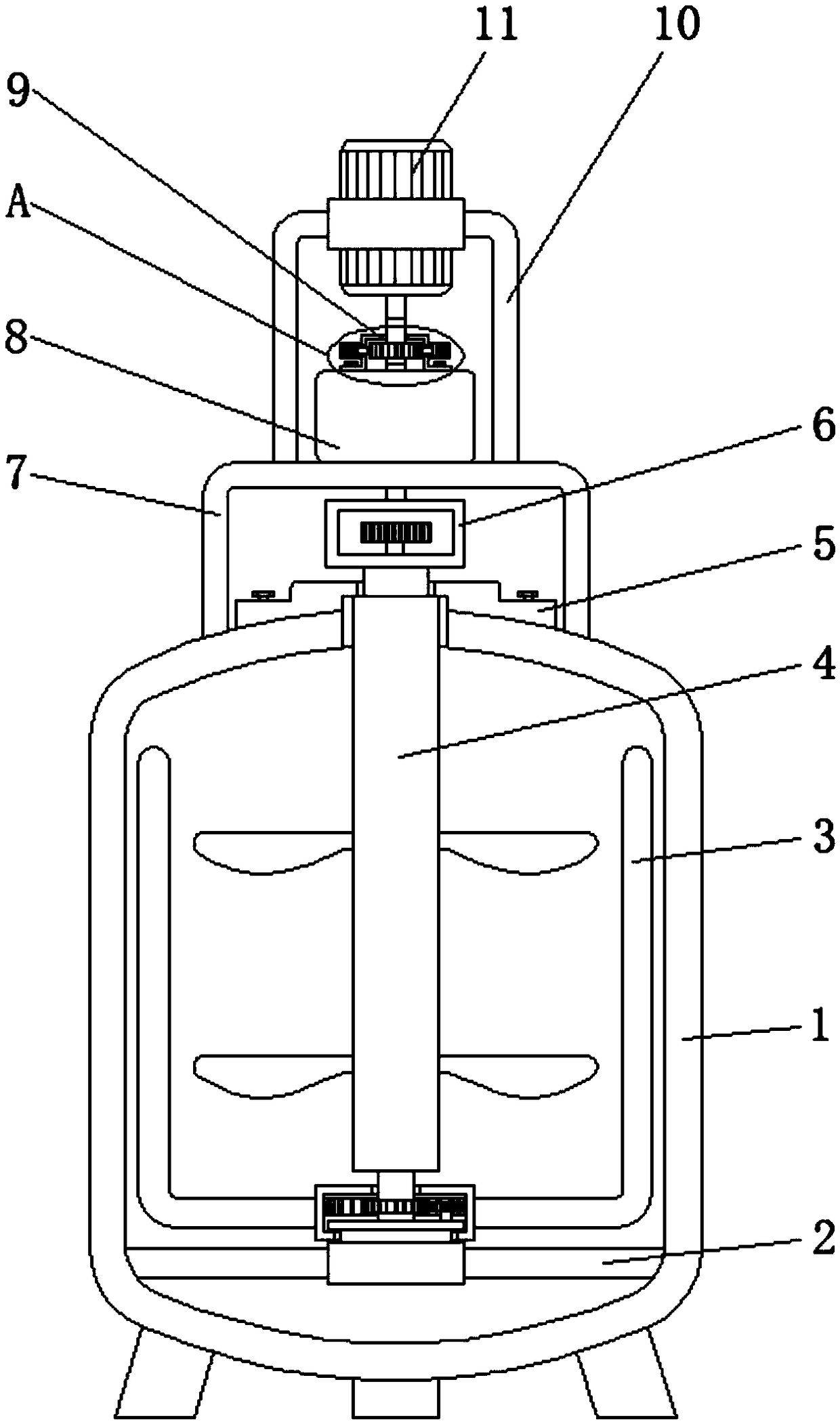

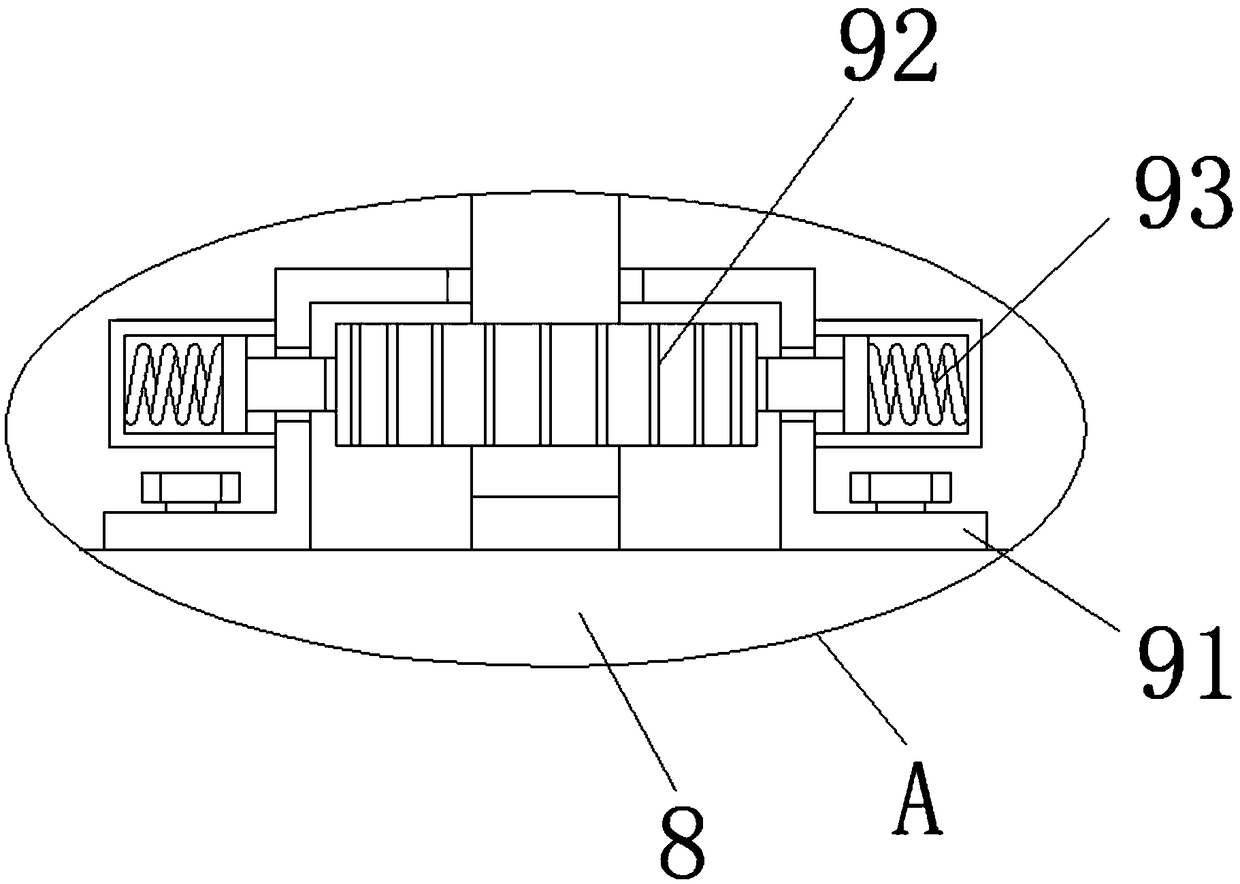

InactiveCN111001349AIncrease stirring speedAvoid mixing unevenlyRotary stirring mixersTransportation and packagingGear wheelElectric machinery

The invention discloses a paper product raw material stirring device which adopts a stirring tank and further comprises a stirrer, a protection disc and a stirring motor. The stirring motor is arranged above the stirring tank; the protection disc is arranged at the top in the stirring tank; the stirrer comprises a gear ring, a stirring shaft, a sun gear and a planetary gear; the gear ring is arranged on the inner wall of the protection disc; a stirring shaft is arranged in the stirring tank; one end of the stirring shaft is connected to the stirring motor, the other end of the stirring shaft is connected with the sun gear in a penetrating manner; the sun gear is arranged in the gear ring in parallel; a planetary ring is arranged on the stirring shaft; three cross rods are uniformly distributed along the circumference of the planetary ring; the number of the planetary gears and the stirring rods is three; one end of each stirring rod is arranged at the tail end of a planet carrier crossrod, the other end is connected to the planetary gear; a plurality of stirring blades are uniformly arranged on the stirring shaft and the stirring rods; a feeding hole is formed in one side of the outer wall of the stirring tank, a liquid inlet is formed in the other side; and a discharge hole is formed in the bottom of the stirring tank. The paper product raw material stirring speed can be effectively increased.

Owner:蚌埠大美印务有限公司

Super-high performance concrete decorative plate and preparation method thereof

The invention relates to a concrete material, in particular to a super-high performance concrete decorative plate and a preparation method thereof. The super-high performance concrete decorative plateis prepared from the following raw materials in parts by weight: cementitious materials, aggregates, auxiliaries, water, and fibers; the auxiliaries are prepared from at least the following components in parts by weight: 60 to 100 parts of additives, 0.5 to 20 parts of pigments, 0.01 to 0.1 part of wetting and dispersing agent, and 0.3 to 0.8 part of stabilizer; and the cementitious materials areprepared from at least 600 to 900 parts of cement in parts by weight. According to the super-high performance concrete decorative plate, the use of the wetting and dispersing agent effectively improves a dispersion state of the pigments in liquid, ensures stable dispersion of the pigments, and avoids a phenomenon of uneven mixing. Meanwhile, the stabilizer can enable the dispersed inorganic pigments to be uniformly and stably suspended in UHPC slurry, and in particular to be stably suspended in high-flow UHPC slurry, even if bleeding phenomenon occurs accidentally in a forming process of theslurry, the phenomena of floating color and dazzling of the pigments and the like are not generated.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

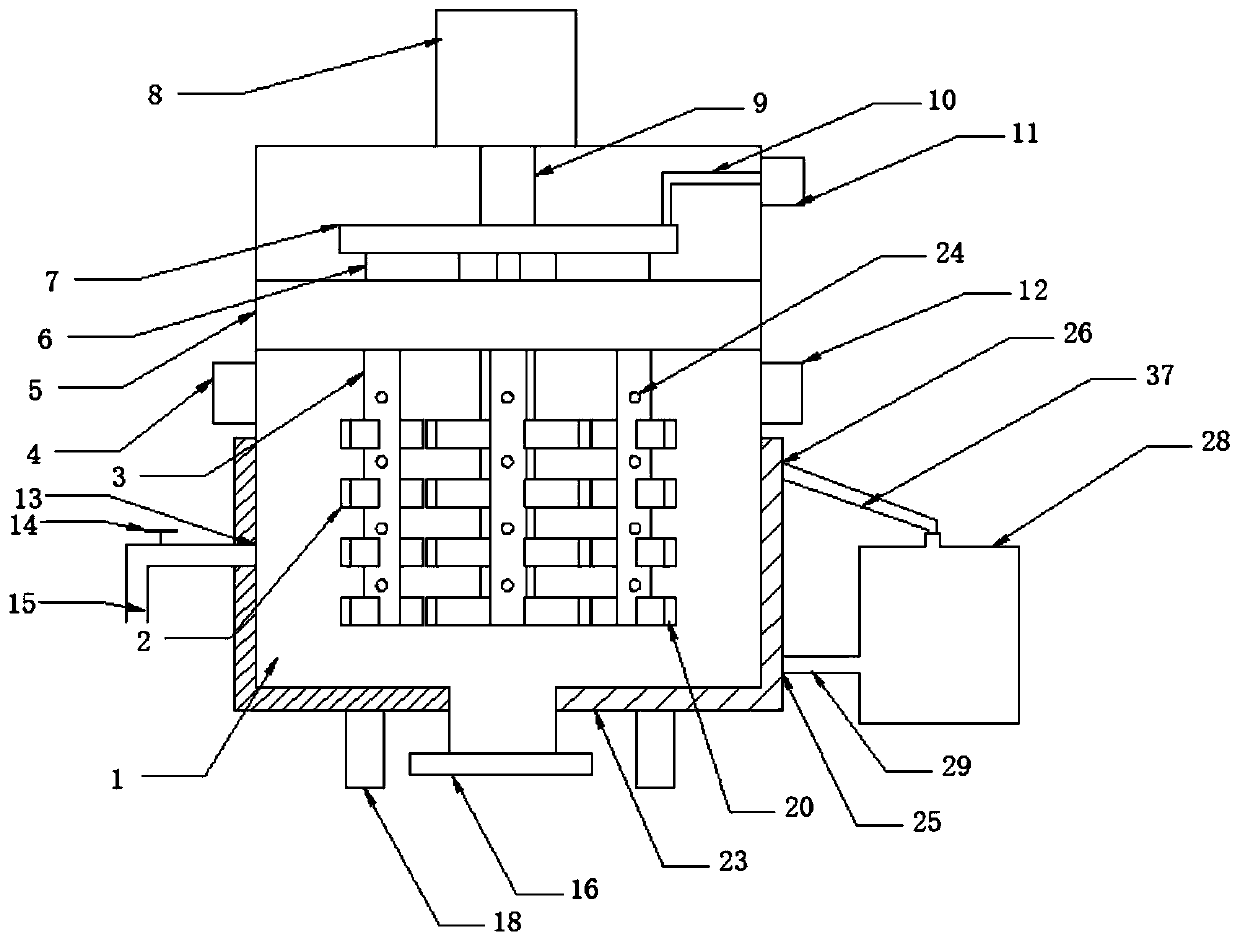

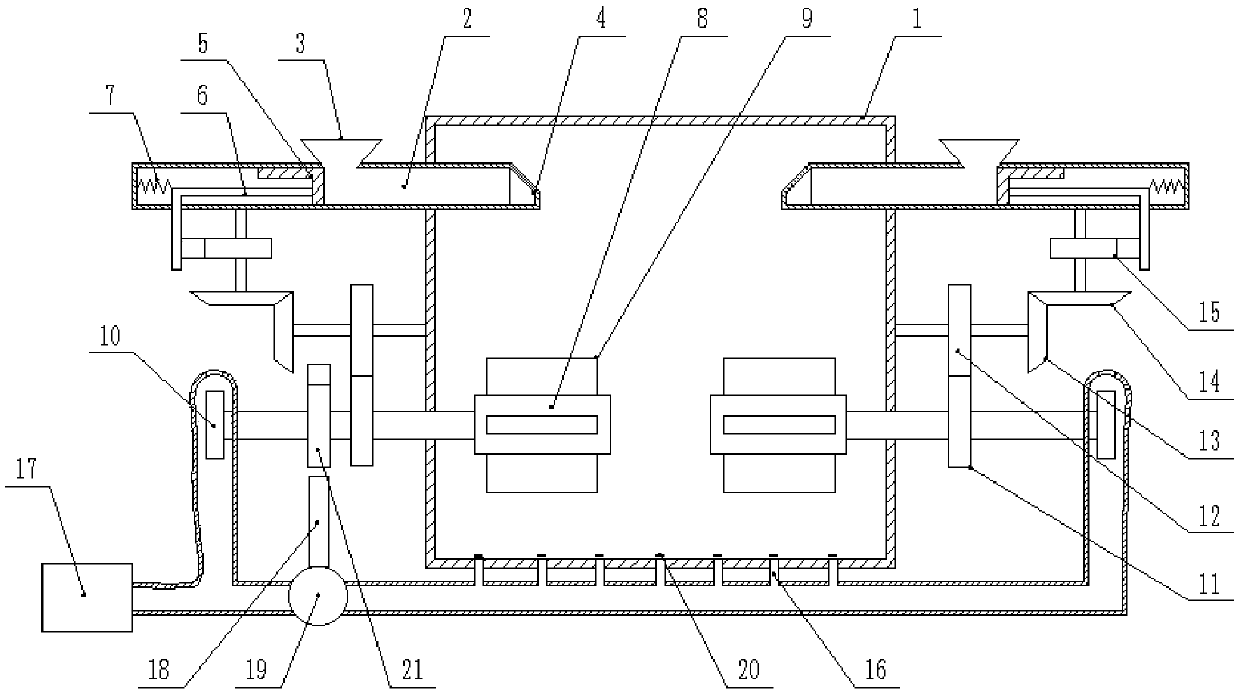

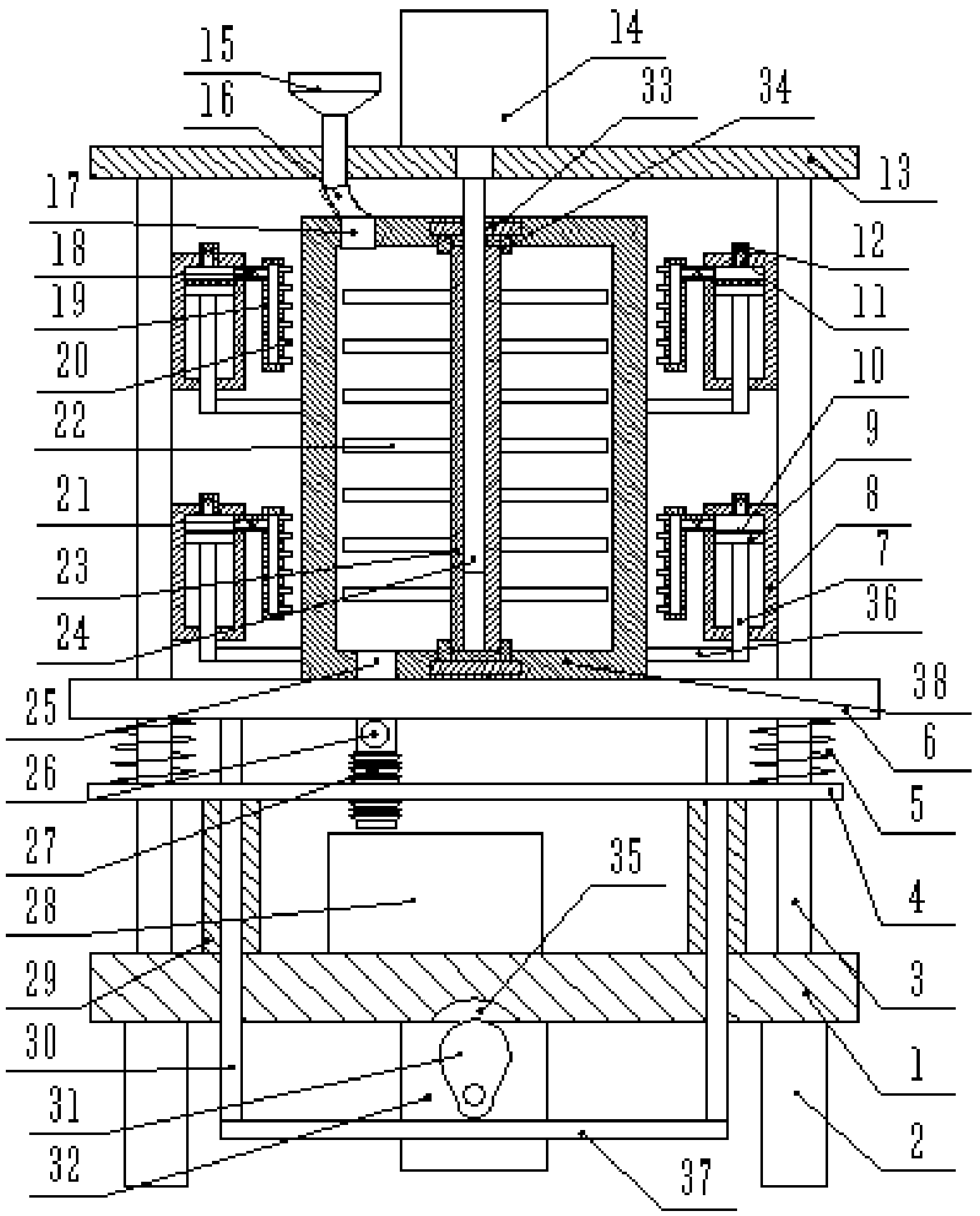

Efficient concrete stirring equipment

InactiveCN107775806ASave human resourcesImprove the effect of the finished productMixing operation control apparatusCement mixing apparatusPressure sensorBiochemical engineering

The invention discloses a high-efficiency concrete mixing device, which comprises a water tank and a bearing frame. A water tank is installed on one side of the inner top of the bearing frame, and a stone quantitative chamber is installed on the other side of the inner top of the bearing frame. The stone quantitative chamber Stone tanks are installed on both sides of the inner top, and a first pressure sensor is installed at the bottom of the stone quantitative chamber. The main body of the mixing tank is installed on the carrier below the stone quantitative chamber. A powder quantitative chamber is arranged on one side of the stone quantitative chamber, and a second pressure sensor is installed at the bottom of the powder quantitative chamber, and a control panel is installed on the side of the carrier near the powder quantitative chamber. The invention can accurately control the amount of each proportion of concrete and improve the overall quality of concrete.

Owner:苏州市瑞川尔自动化设备有限公司

Rotary stirring device for environment-friendly paint

InactiveCN108211939ASimple structureRun smoothlyRotating receptacle mixersTransportation and packagingEngineeringBevel gear

The invention provides a rotary stirring device for environment-friendly paint. The rotary stirring device comprises an outer barrel which is fixedly arranged on a bracket, wherein the bottom wall ofthe outer barrel is provided with a motor; a drive shaft is arranged in the cavity of the outer barrel; the outer side part of the bottom wall of the inner barrel is provided with an inner gear; a driven shaft is arranged on the outer wall of the drive shaft; the outer side part of the driven shaft is rotatably provided with a rotary bearing; the outer side of the rotary bearing is provided with astirring rod; the end part of the driven shaft penetrates through the rotary bearing and is rotatably provided with a first rotary rod; the end part of the first rotary rod is provided with a first bevel gear; a second rotary rod is arranged below the first bevel gear; the end part of the second rotary rod is provided with a second bevel gear engaged with the first bevel gear; the second rotary end part is provided with a rotary wheel; a gear slot is formed in the peripheral direction of the outer wall of the rotary wheel; a rotary slot is peripherally formed in the position, which corresponds to the rotary wheel, of the inner wall of the inner barrel; and a gear slot which is engaged with the gear slot in the outer wall of the rotary wheel is formed in the inner side of the rotary slot.The stirring device is simple in structure, operates stably, and realizes multi-angle multi-direction stirring of paint, low stirring cost and a good stirring effect.

Owner:NINGBO FEICHAI ROBOT TECH CO LTD

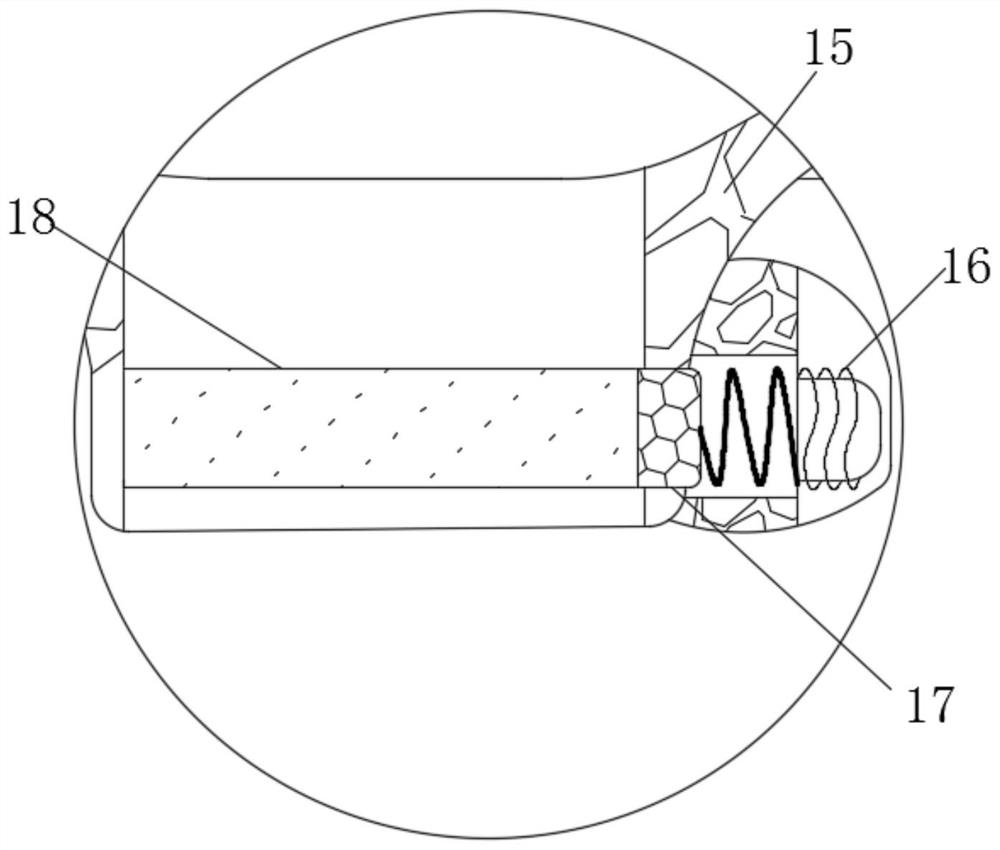

Stirring machine for processing plastic products

The invention relates to a stirring machine for processing plastic products. The stirring machine comprises a rack, a stirring box is arranged on the rack, a feeding mechanism and a stirring mechanismare arranged on the stirring box, the feeding mechanism comprises symmetrical feeding channels, feeding ports and discharging ports are formed in the feeding channels, push plates are arranged in thefeeding channels, and push rods are fixed to the push plates; the stirring mechanism comprises symmetrical stirring shafts, stirring plates are arranged on the stirring shafts, the stirring shafts are coaxially connected with turbines and first gears, the first gears are engaged with second gears, and the second gears are coaxially connected with first bevel gears; the first bevel gears are engaged with second bevel gears, the second bevel gears are coaxially connected with cams abutting against the push rods, through holes are formed in the bottom of the stirring box, the through holes communicate with an air supply box, and the through holes communicate with the air supply box through a guide pipe; and the turbines are located in the guide pipe, an air bag is arranged on the guide pipe,one of the first gears is coaxially connected with a fan gear, and the fan gear is engaged with a rack. According to the stirring machine, the problem that mixing and stirring of the plastic productsare uneven is solved.

Owner:宁波江北文增新材料科技有限公司

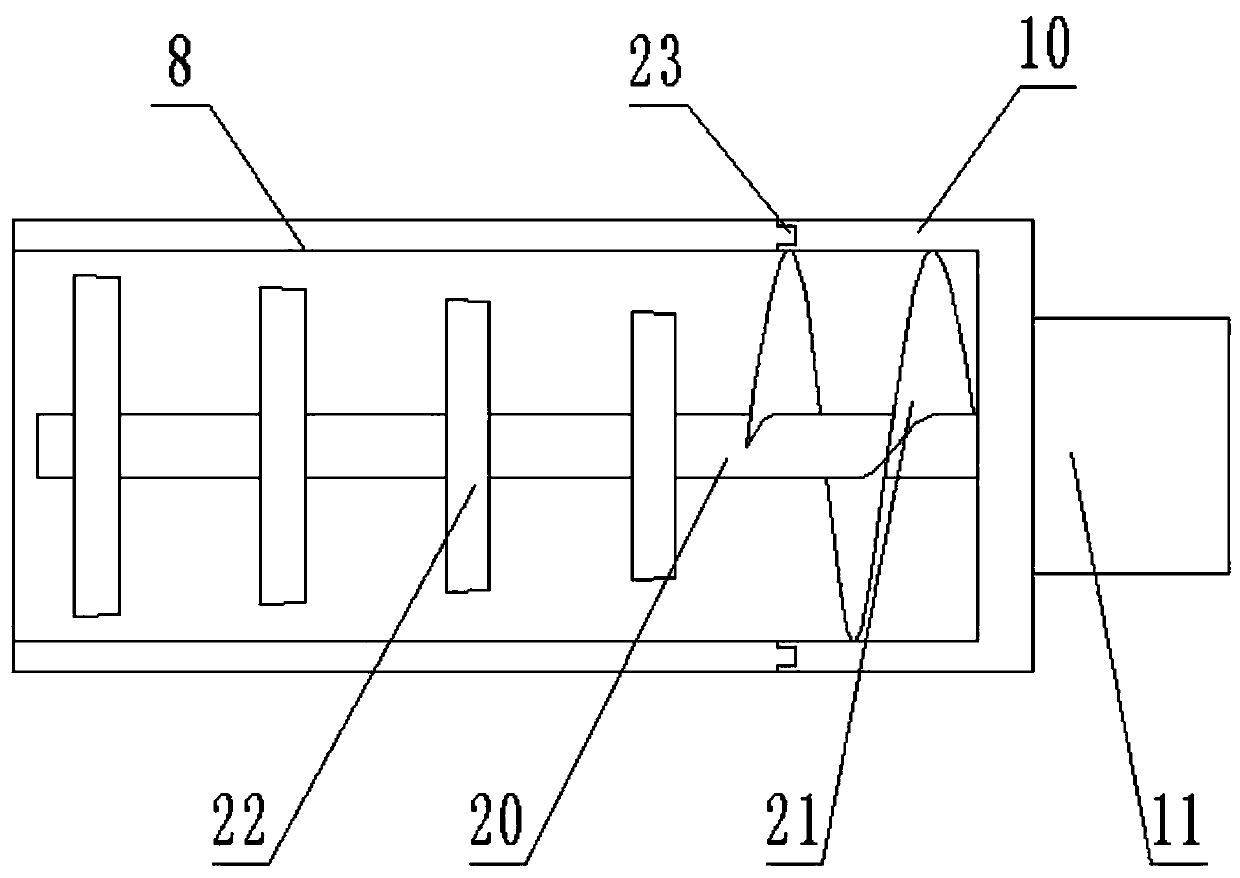

Horizontal shaft type concrete mixer

InactiveCN108943393ANot easy to bendAvoid mixing unevenlyCement mixing apparatusMixing operation plantEngineering

The invention discloses a horizontal shaft type concrete mixer. The horizontal shaft type concrete mixer comprises a device body, a mixing barrel, a mixing rod, a supporting plate and a control electric box, wherein a supporting plate is seamlessly welded to the left side of the top end of the device main body, the right side of the top end of the device body is fixedly connected with a control electric box through a nut, the right side of the supporting plate is fixedly connected with a movable supporting shaft through the nut, and the right side of the movable supporting shaft is fixedly connected with the mixing barrel through the nut. According to the horizontal shaft type concrete mixer, the top end of mixing blades are seamlessly welded with a fixed plate, a large amount of concreteis arranged in the mixing barrel in the mixing process to cause the deformation of the mixing blades, the top end of the mixing blades is seamlessly welded with a fixing plate, so that the mixing blades can be mutually fixed and supported, the mixing blades are not easy to bend, and then the problem that mixing is not uniform an existing horizontal shaft type concrete mixer due to the fact that the mixing blades are easily bent for a long time is solved.

Owner:天津市裕昇建筑工程有限公司

Food stirring device

InactiveCN105749793AAvoid mixing unevenlyFully contactedRotary stirring mixersTransportation and packagingNozzleBarrel Shape

The invention discloses a food stirring device.The food stirring device comprises a base, a stirring bucket, a stirring device body, a protection body, a barrel-shaped inner shell and a barrel-shaped outer shell.The stirring bucket is installed on the base, the protection body is installed on the right side of the base, and a sealing cover is arranged at the top of the stirring bucket; the inner shell and the outer shell are matched and connected to form a cavity of the stirring bucket; a spraying head is arranged in the cavity, a through hole is formed in the inner shell along a spiral line, nozzles of the spraying head and the through hole are adapted, and the spraying head is communicated with compressed air outside the stirring bucket through a pipe; the stirring device body comprises a stirring shaft, a stirring shaft sleeve, stirring shaft supporting rods and cutter fixing discs; the stirring shaft sleeve is rotationally connected to the upper end of the stirring shaft; one ends of the stirring shaft supporting rods are rotationally connected with the edge of the stirring shaft sleeve, and the other ends of the stirring shaft supporting rods are connected into sliding grooves in a sliding mode; the stirring shaft sleeve is rotationally connected with the upper end of the stirring shaft.

Owner:慈溪市环球电器有限公司

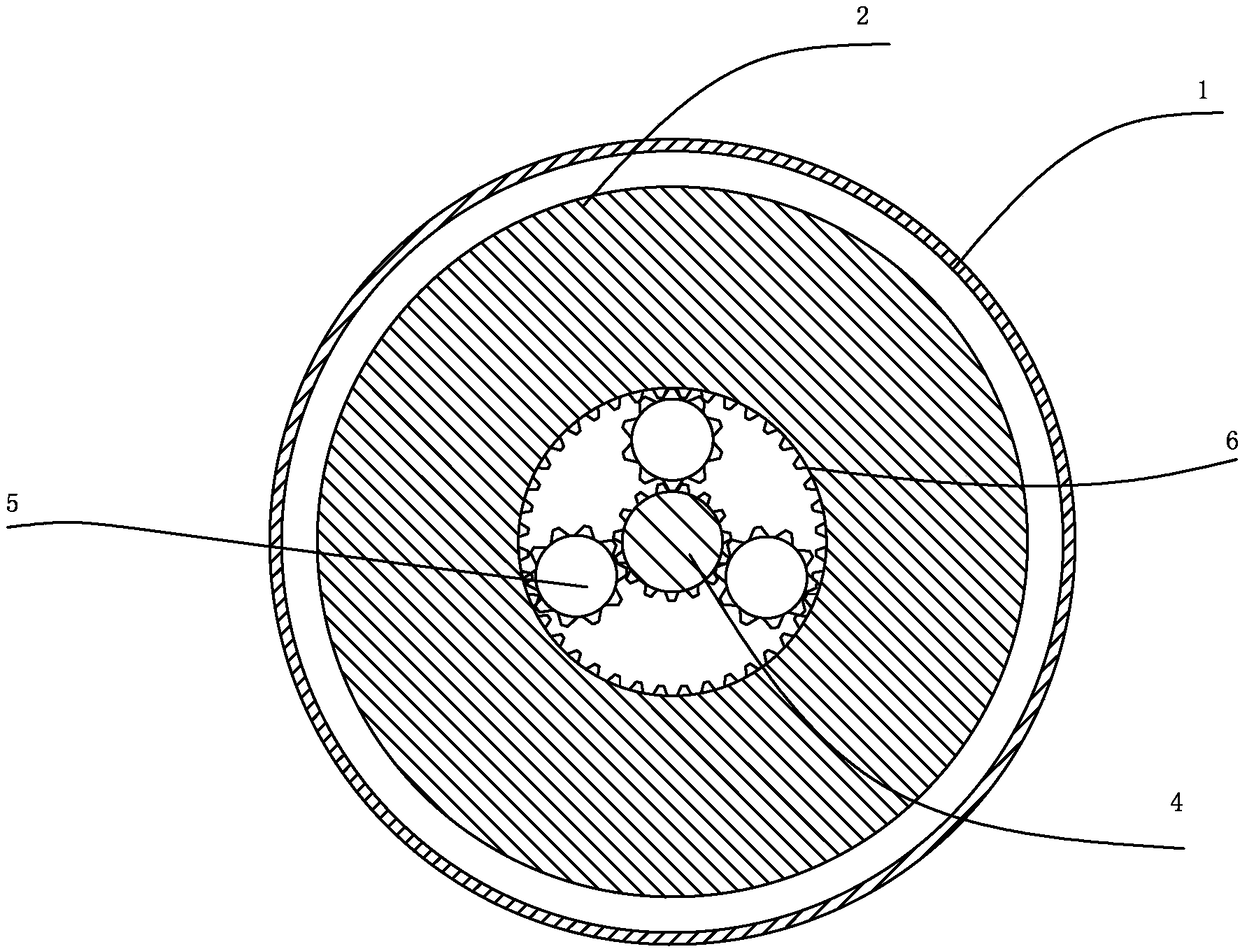

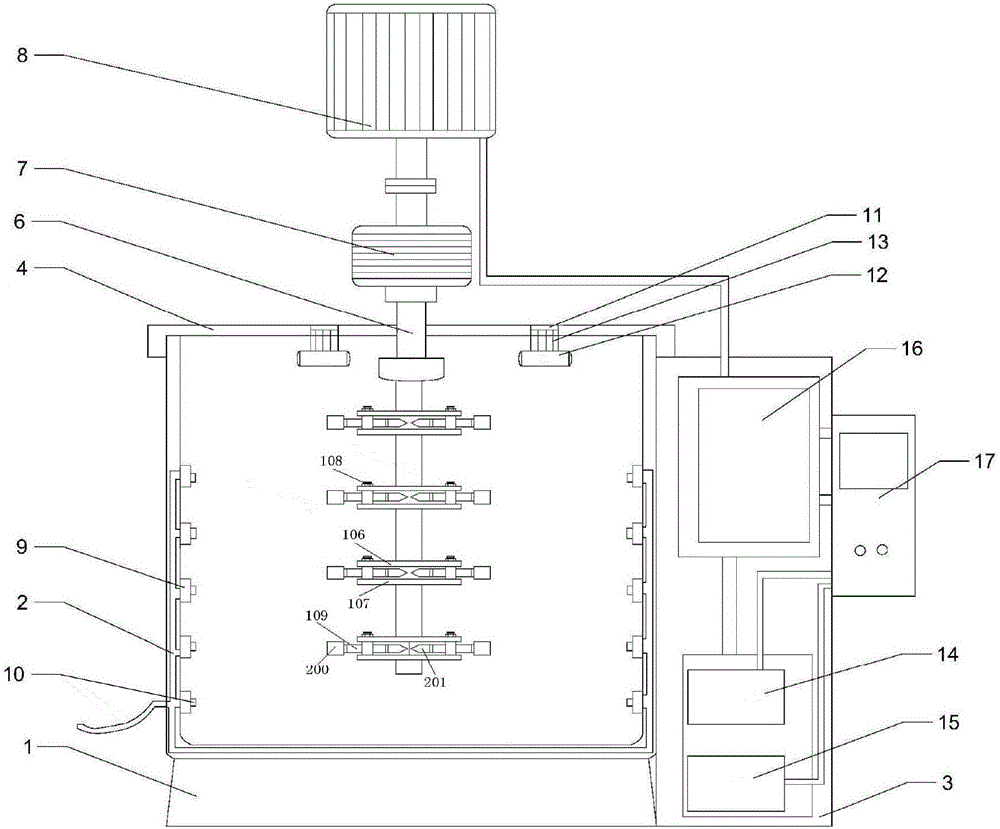

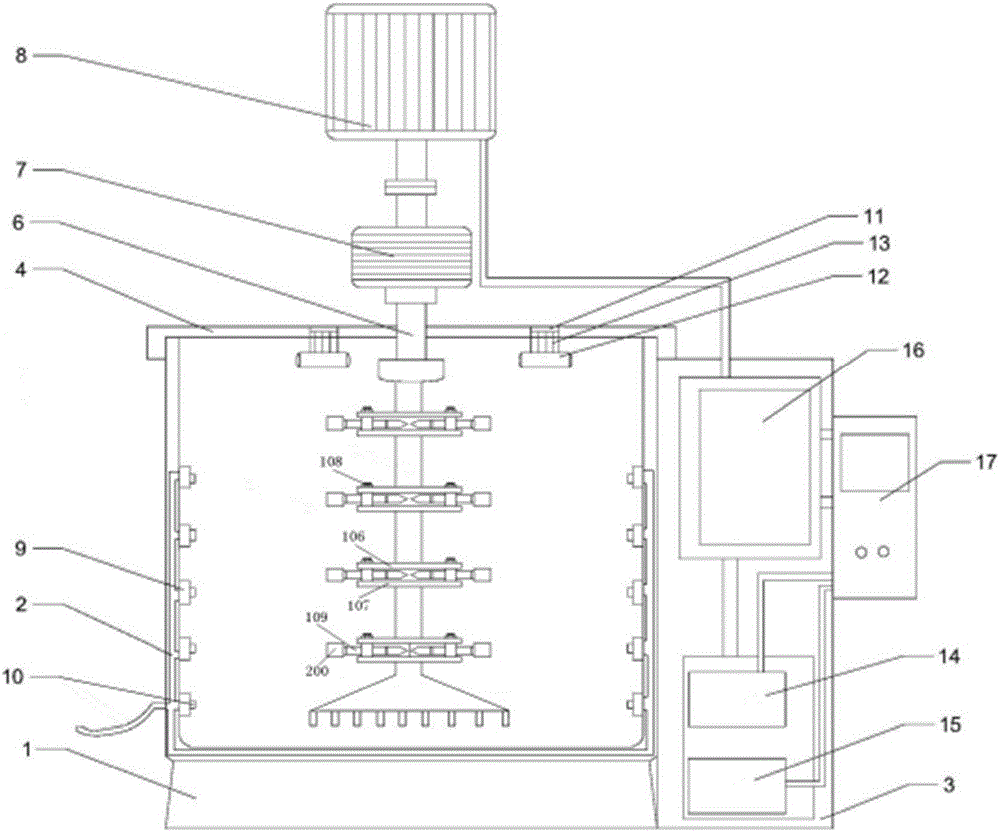

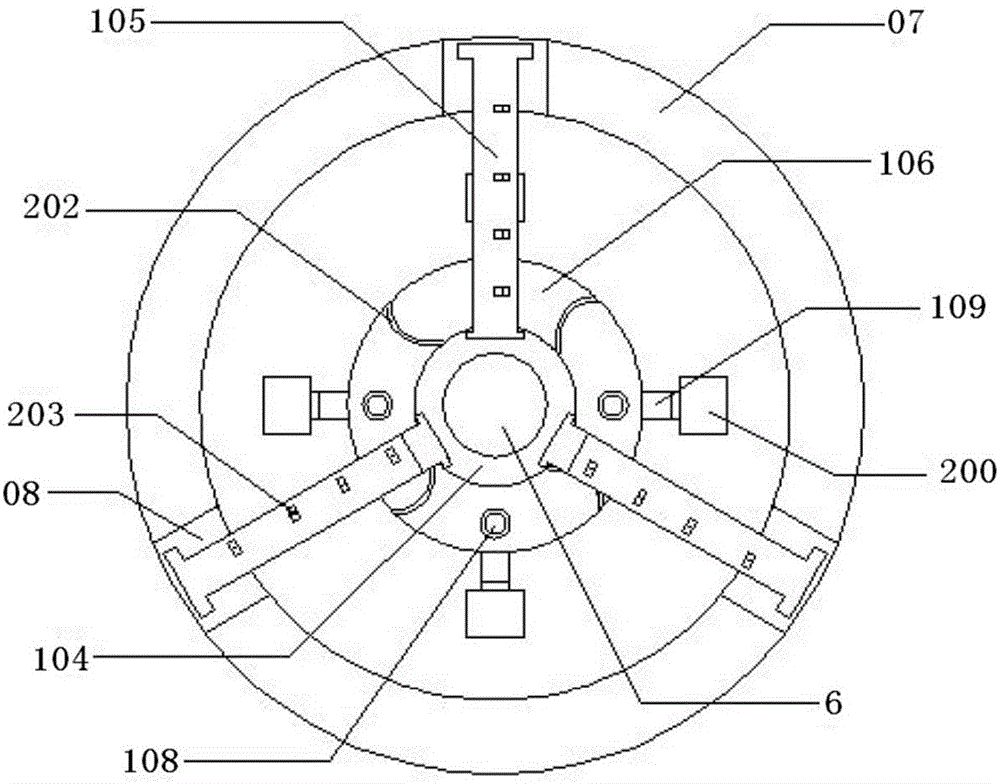

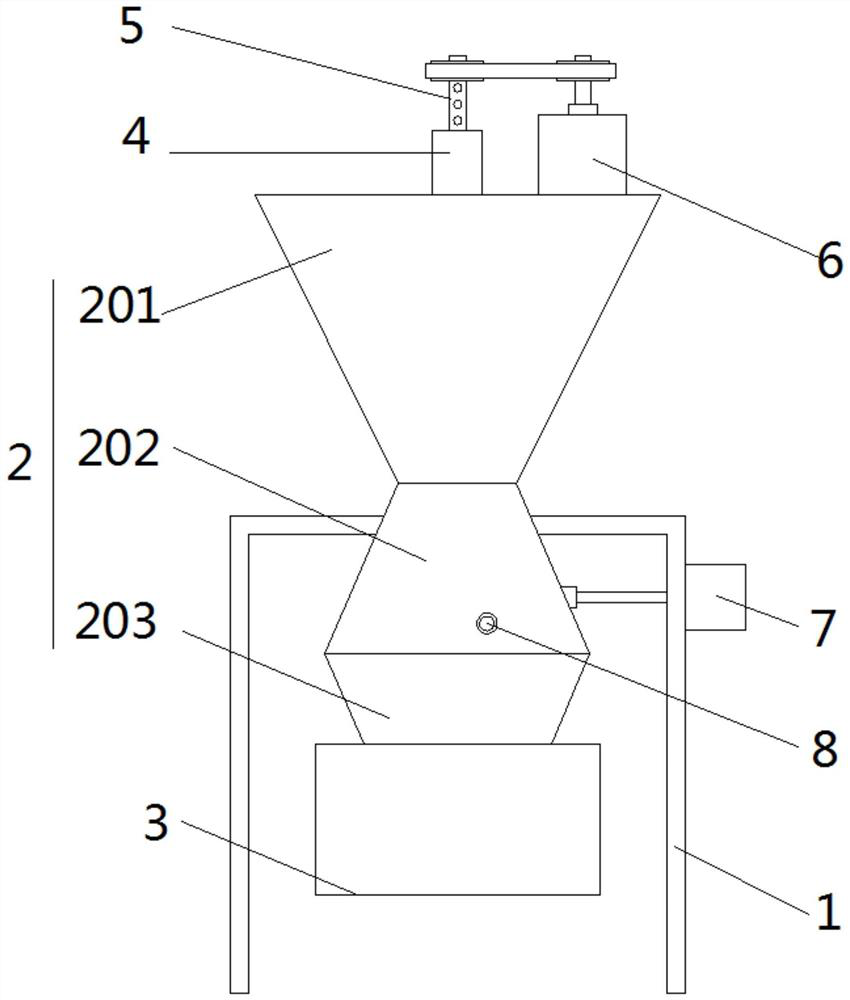

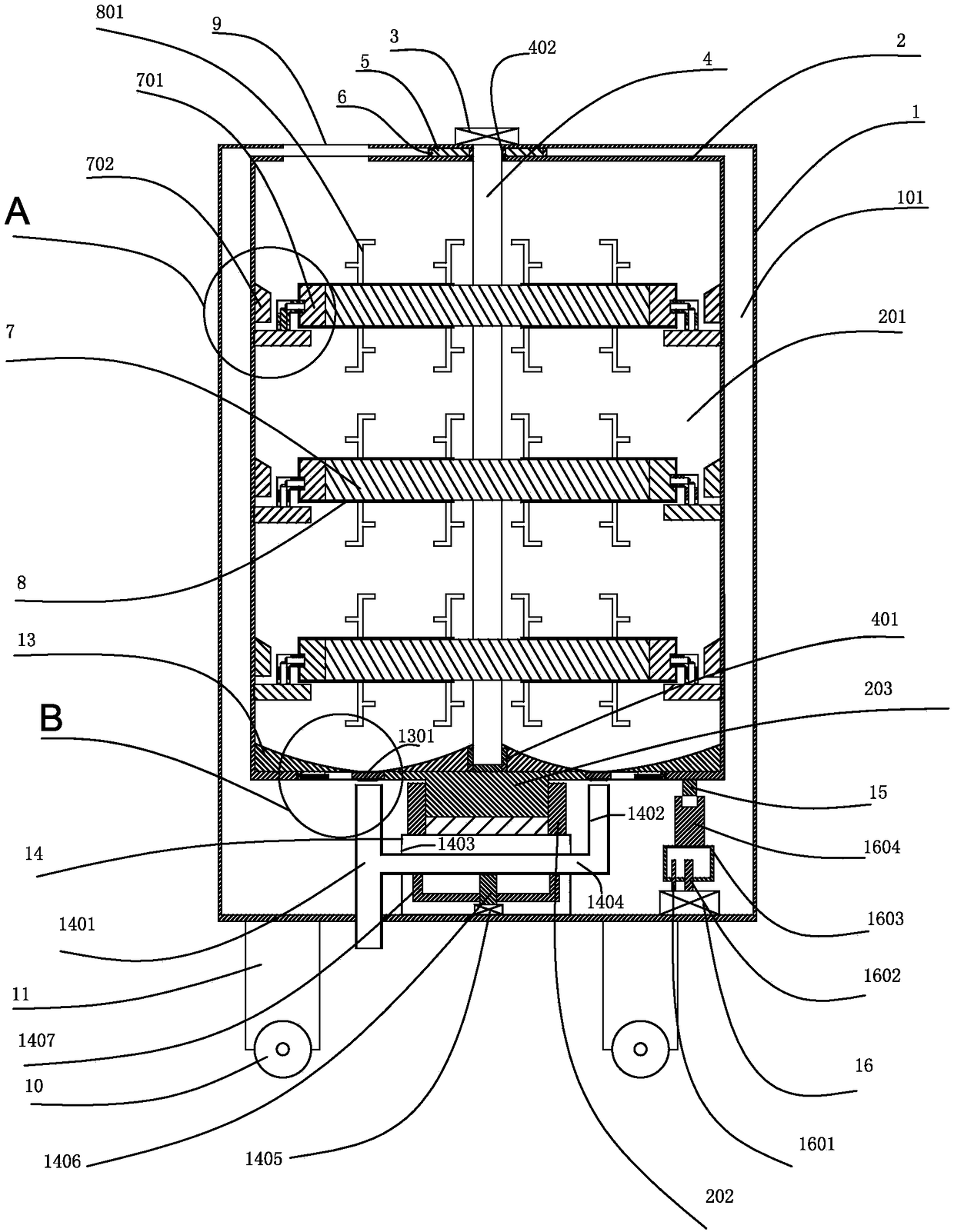

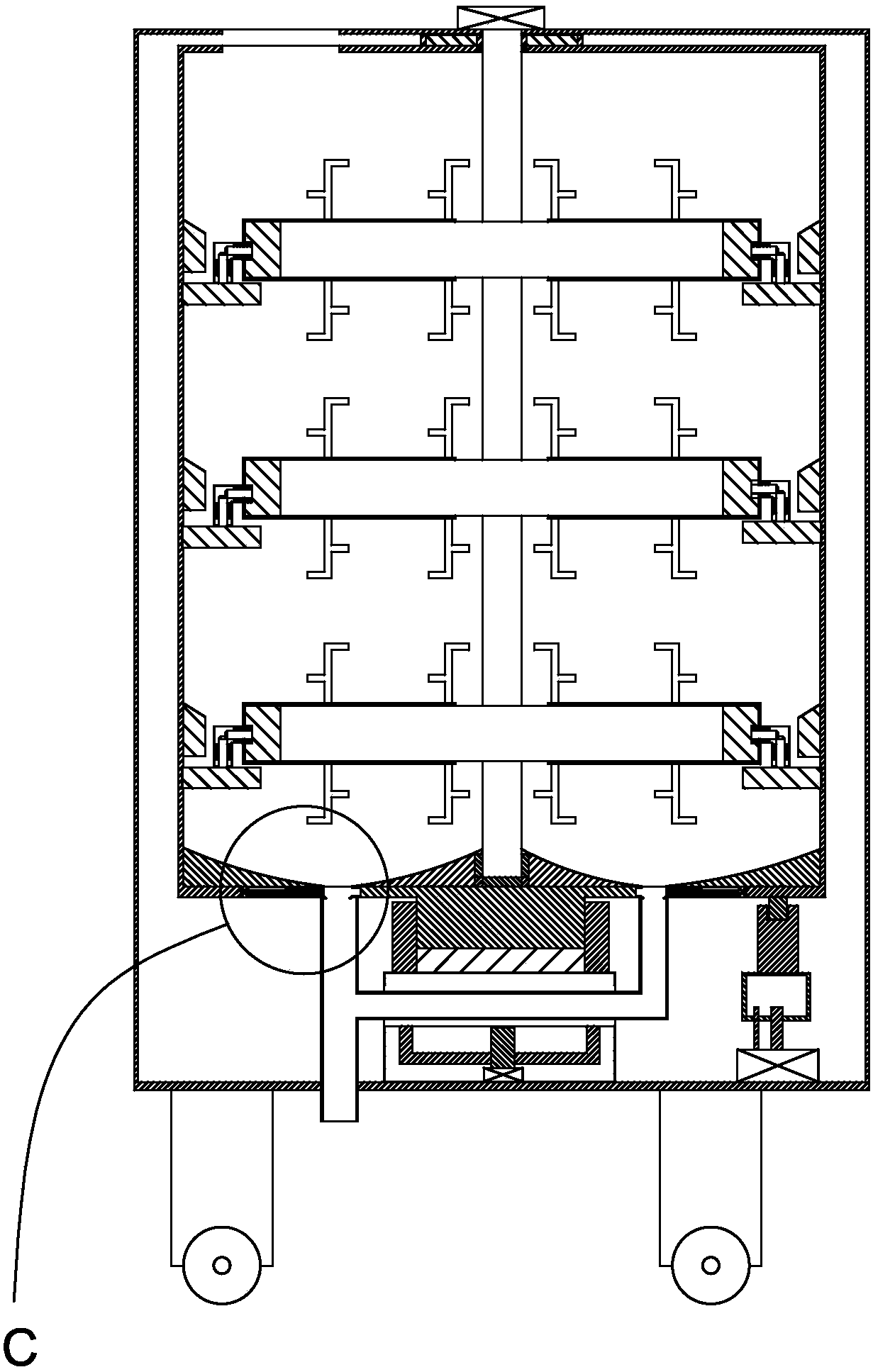

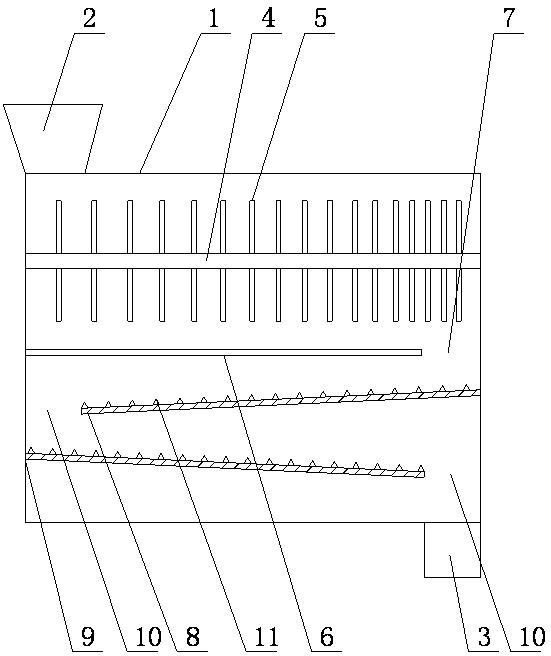

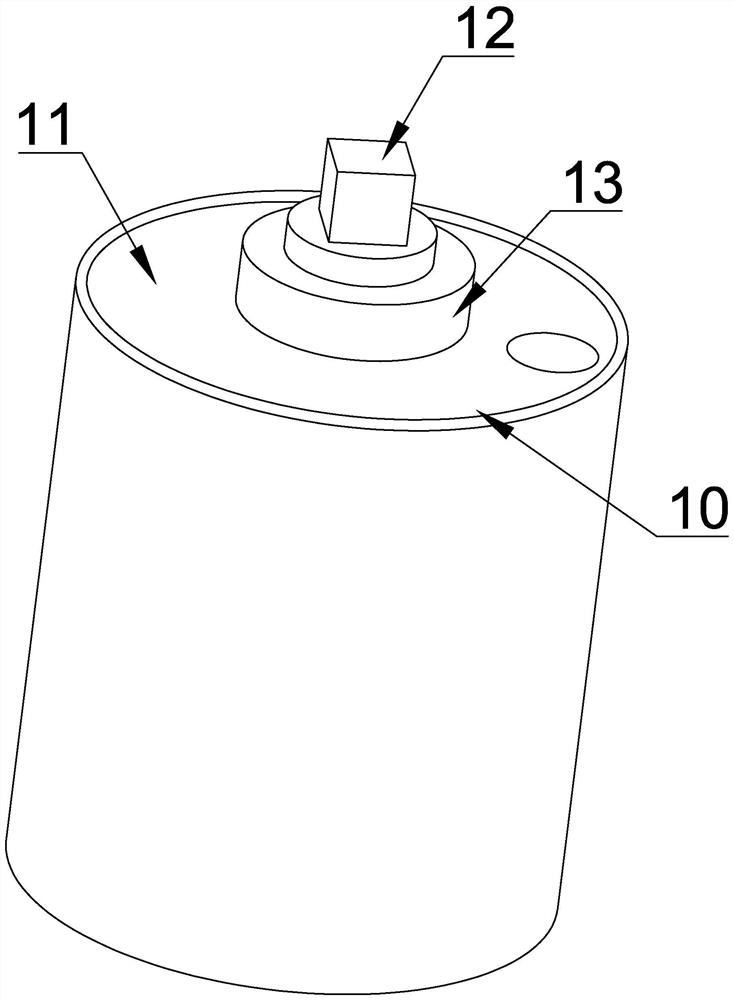

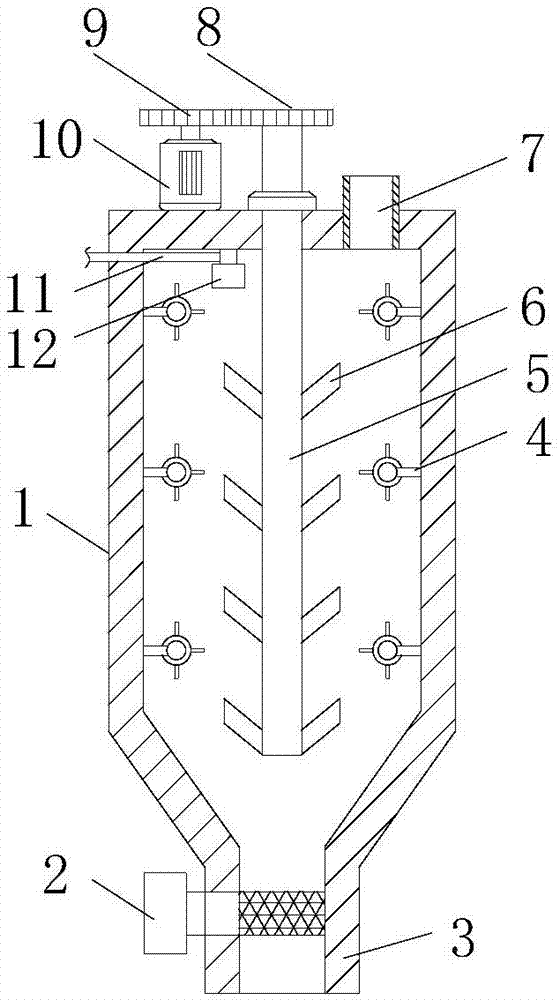

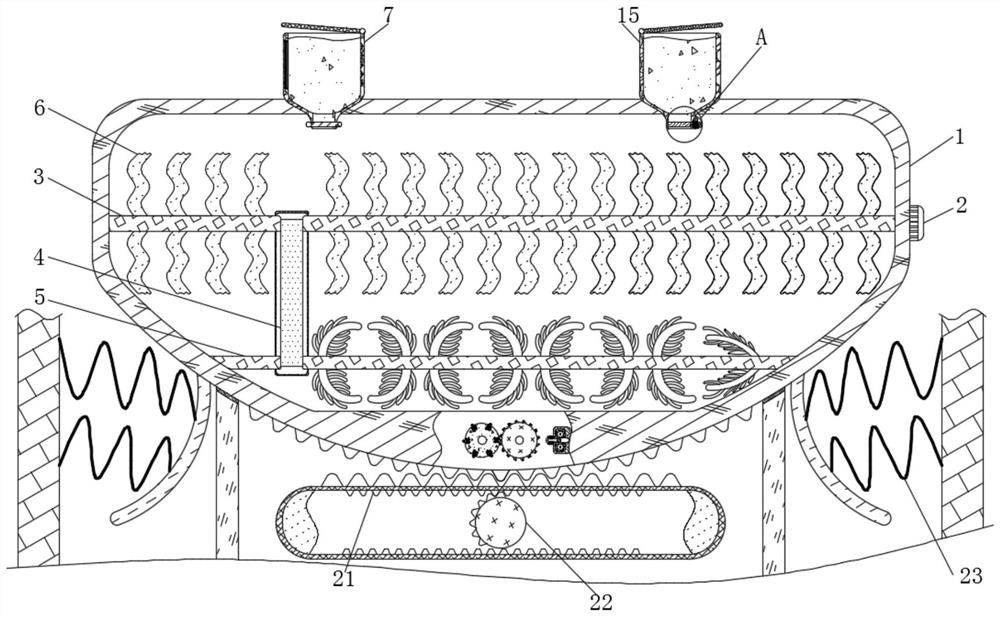

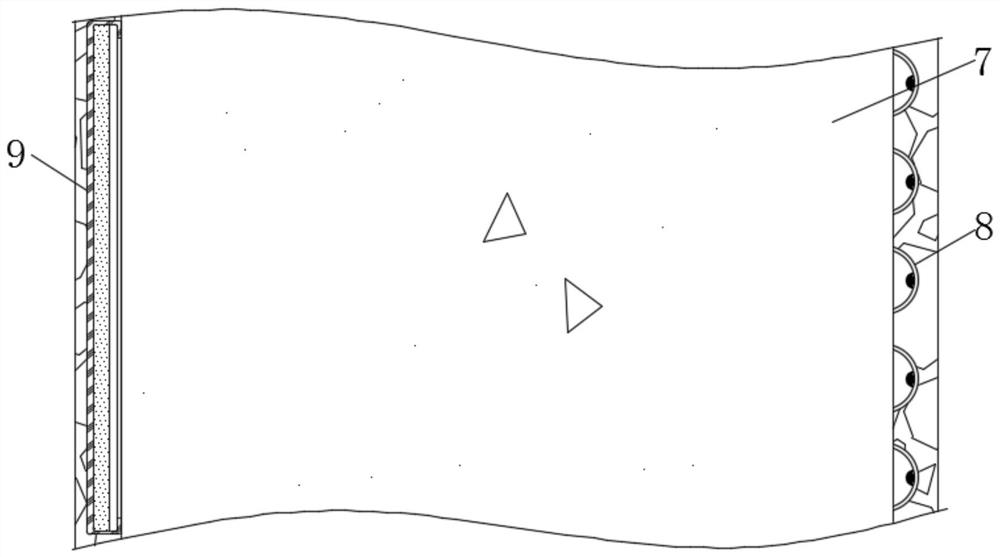

Bio-fertilizer processing and packaging integrated equipment

ActiveCN112159263AAvoid mixing unevenlyStir betterChemical industrySolid materialFertilizerElectric machinery

The invention provides bio-fertilizer processing and packaging integrated equipment which comprises a supporting frame, a processing box and a discharging box; a motor drives a stirring shaft to rotate, the stirring shaft drives a stirring rod assembly to stir a bio-fertilizer in a stirring part, and a push rod moves in an annular waveform sliding groove, so that the push rod is stressed to move forwards and backwards in a stirring rod; when a pressing plate is pushed to extrude an inflation air bag in a reciprocating mode, the inflation air bag inflates back and forth and ejects an anti-blocking ball outwards from a fixing pipe through an air outlet hole, air is blown into the stirring part through a first micro hole and a second micro hole, an electric heating block can heat the stirringshaft, and when the pressing plate is pulled outwards, the inflation air bag sucks in the heated air in the stirring shaft. In the subsequent reciprocating extrusion process, hot air is blown into the stirring part through the first micro hole and the second micro hole, so that the fertilizer in the stirring part is dried, the functions of stirring and drying the biological fertilizer at the sametime are achieved, and the phenomenon that the biological fertilizer is non-uniformly stirred or caked can be avoided.

Owner:北京兴绿生态肥业有限公司

Environment-friendly coating stirring device with magnetic effect

InactiveCN108211937AStir wellAvoid vortexRotating receptacle mixersTransportation and packagingMagnetic effectDrive shaft

The invention provides an environment-friendly coating stirring device with a magnetic effect. The environment-friendly coating stirring device comprises an outer cylinder, an outer cylinder cavity, amotor, a driving shaft driven by the motor, an inner cylinder and an inner cylinder cavity, wherein an internal gear is arranged on the top wall of the inner cylinder cavity; the driving shaft penetrates through the internal gear and is meshed with the internal gear by a first gear; driven shafts are arranged on the outer wall of the driving shaft; a rotating bearing is rotationally arranged at the end part of each driven shaft around the outer side part of the driven shaft; a stirring rod is arranged on the outer side of each rotating bearing; the end part of each driven shaft penetrates through the corresponding rotating bearing and is provided with a first rotating rod; a first bevel gear is arranged at the end part of each first rotating rod; a second rotating rod is arranged below each first bevel gear; a second bevel gear meshed with each first bevel gear is arranged at the end part of the corresponding second rotating rod; a rotating wheel is arranged at the end part of each second rotating rod; a first magnet is arranged at the near end part of each driven shaft; second magnets are arranged on the inner wall of the inner cylinder. The stirring device has the advantages ofsimple structure, stable operation, low stirring cost and good stirring effect; multi-angle and multidirectional stirring of the coating is realized, and a stirring effect is improved by a local magnetic field.

Owner:NINGBO FEICHAI ROBOT TECH CO LTD

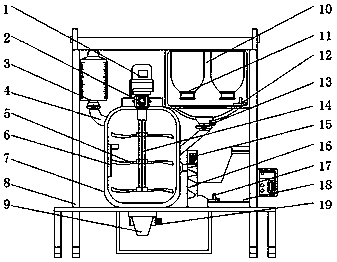

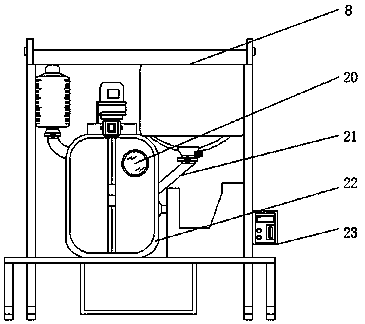

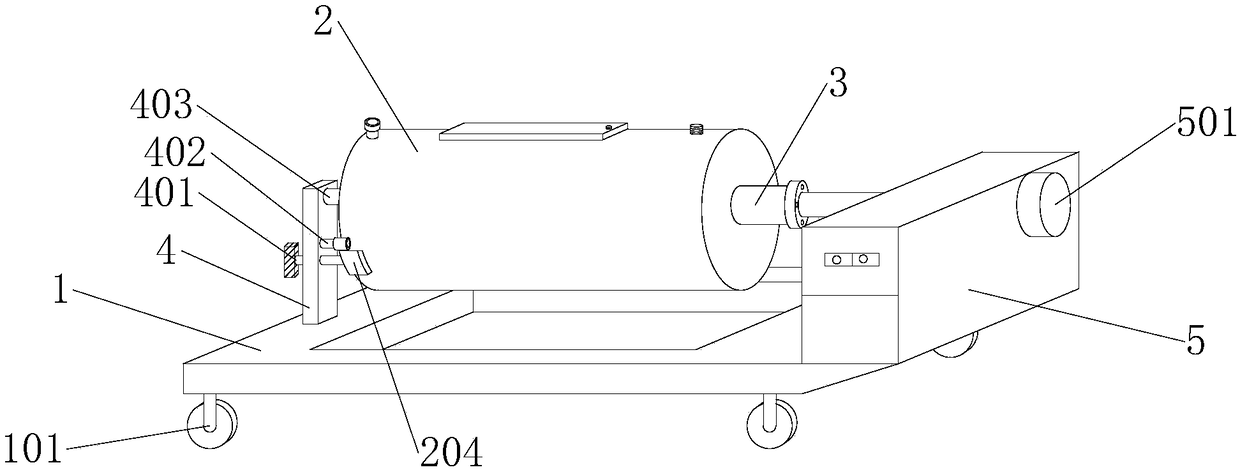

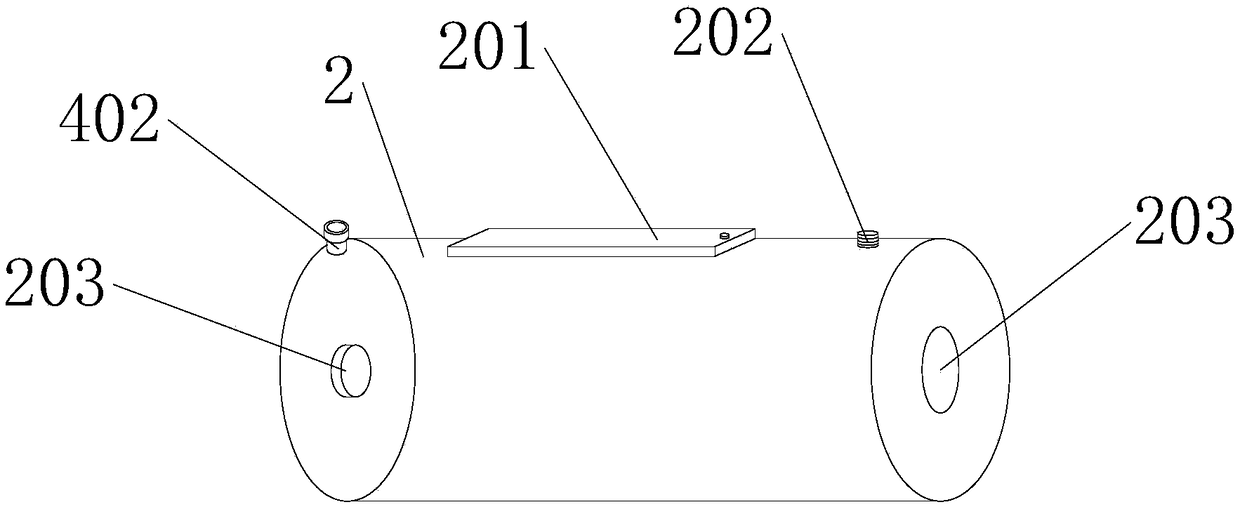

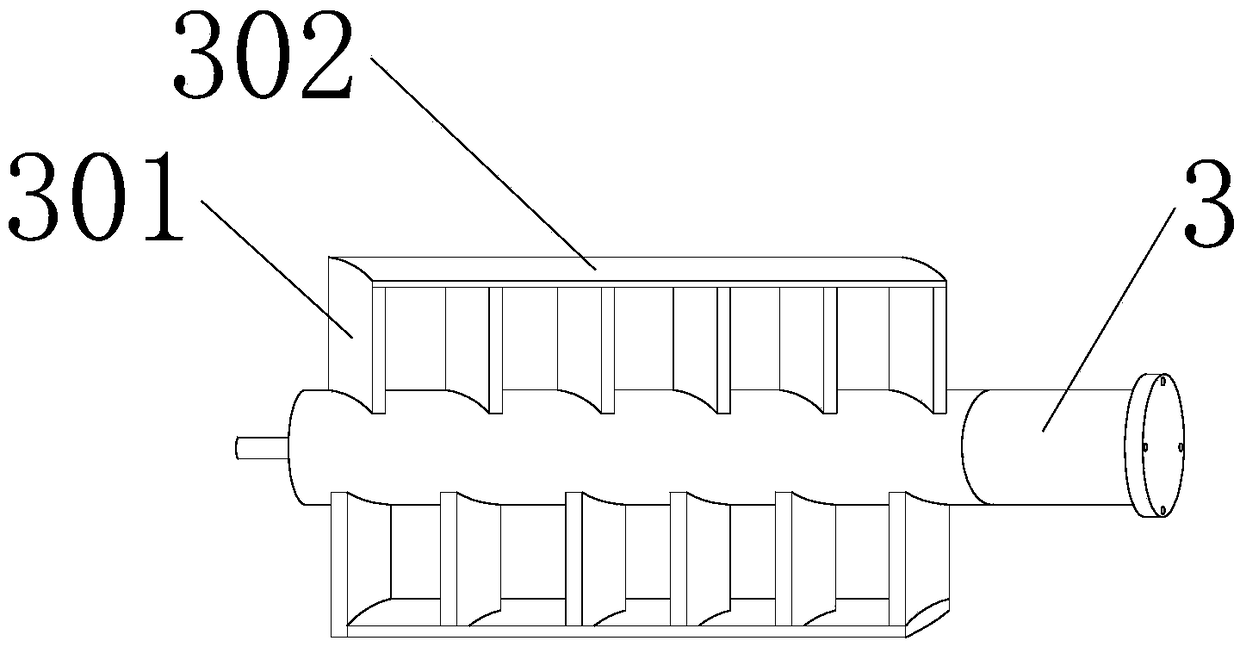

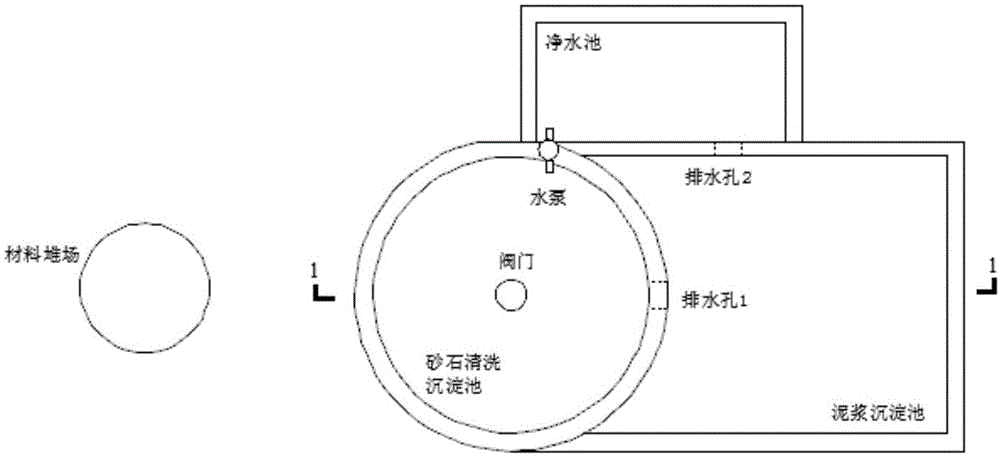

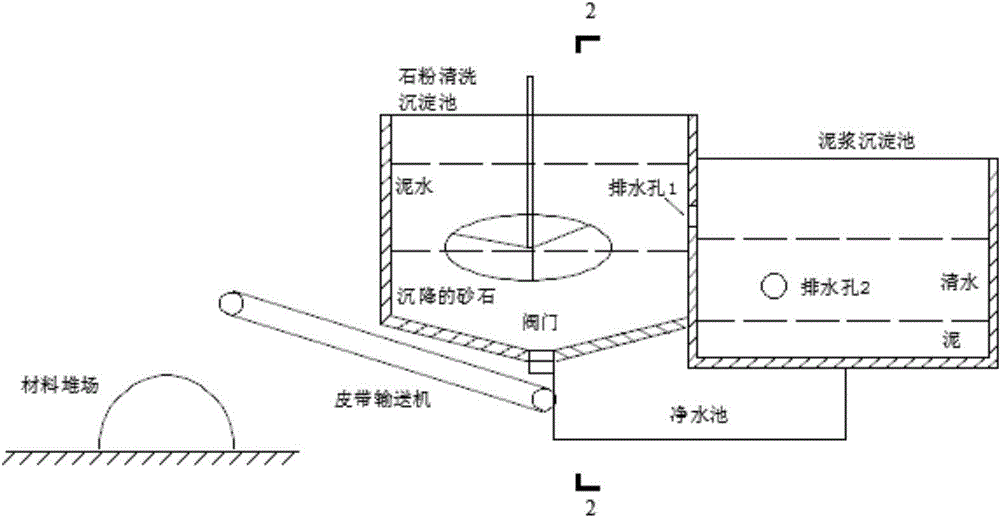

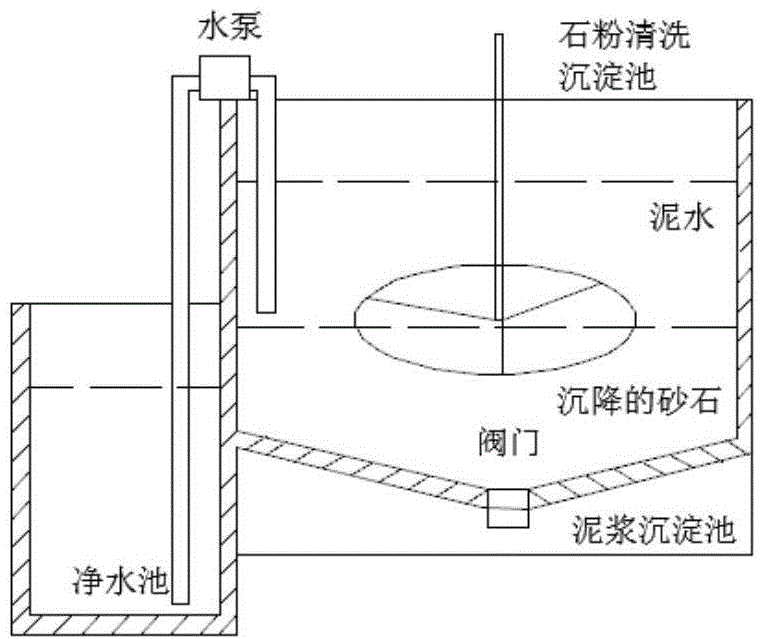

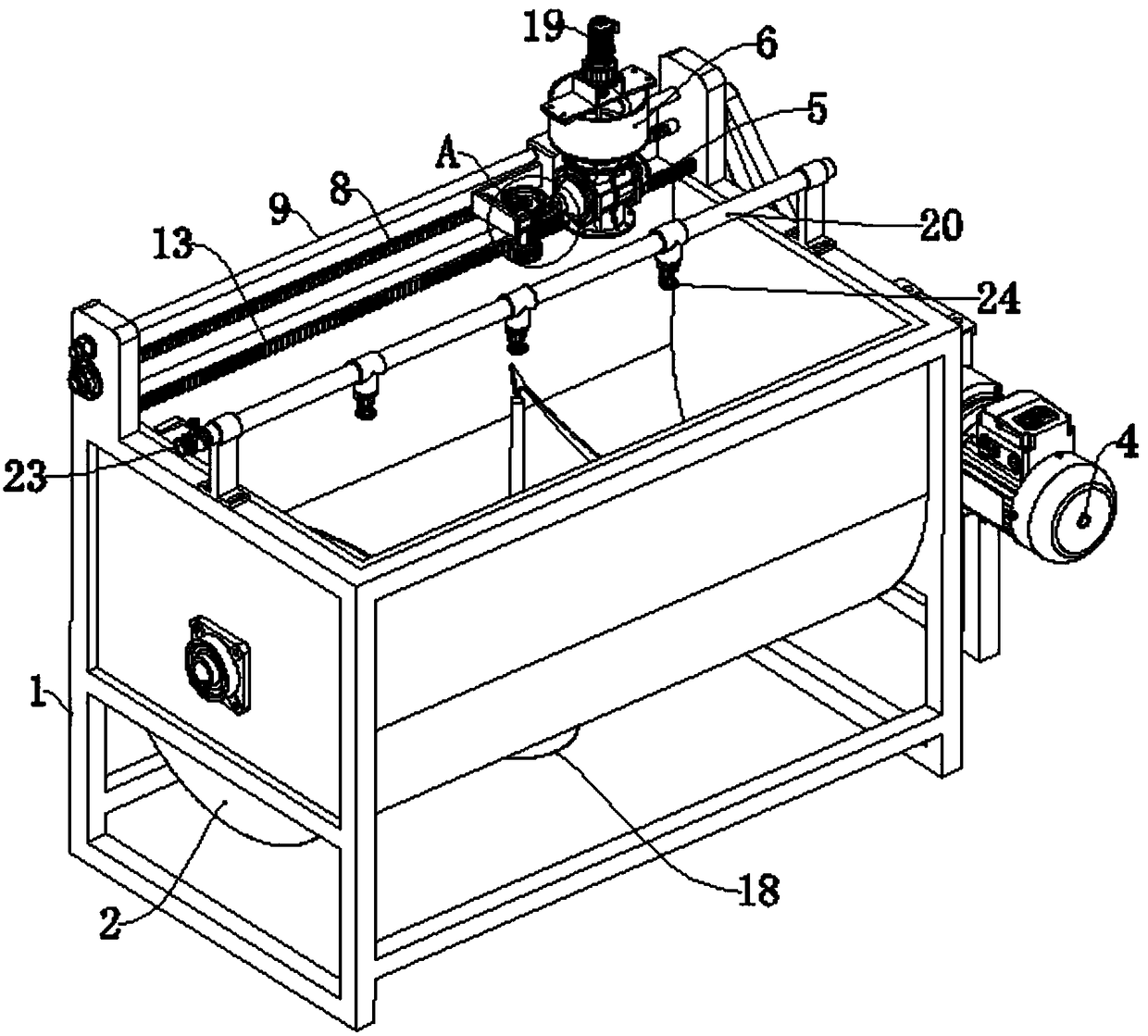

Process and system for cleaning waste residues in quarries and building sand

ActiveCN104858174ASimple cleaning processReduce water consumptionSolid waste managementCleaning using liquidsSiltMaterial recycling

The invention provides a process and system for cleaning waste residues in quarries and building sand and belongs to building waste residue cleaning processes and systems. The cleaning process comprises the following steps: 1), enabling sand stones to enter a pool; 2), enabling clear water to enter the pool; 3), stirring; 4), discharging mud water; 5), recycling clear water; 6), recycling sand stones; 7), cleaning mud; the cleaning process comprises a sand stone cleaning device (1), a mud sedimentation device (2), a clear water recycling device (3) and a material recycling device (4). The cleaning process has the advantages as follows: only 1-3 pools, one turbine stirrer and one belt conveying device are required, repeated cleaning can be carried out until rinsing, one-time cleaning can be completed by 3-5 minutes only, and water for cleaning can be used repeatedly after being purified; the cleaning process is simple, and low in water consumption, and can efficiently reduce silt content of sand stones with high quality, meanwhile, stone powder in the waste residues in quarries is retained fully, waste residues in the quarries and building sand can be cleaned in batches and industrial production is realized.

Owner:SUQIAN LIYIN IND

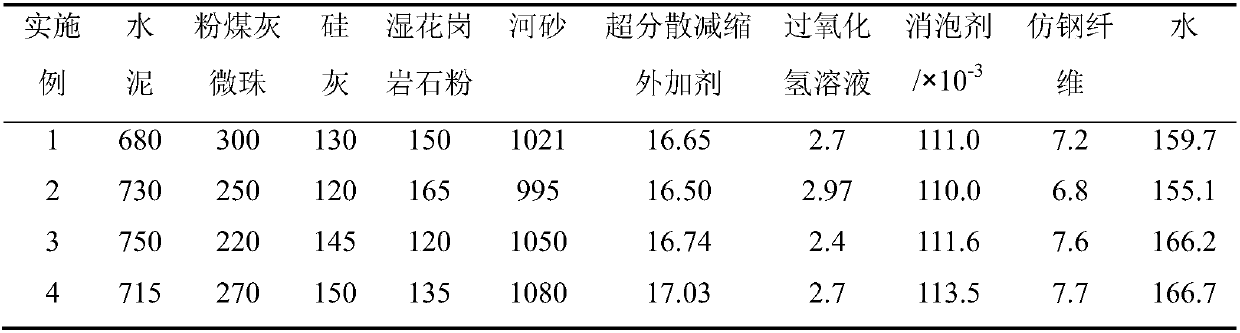

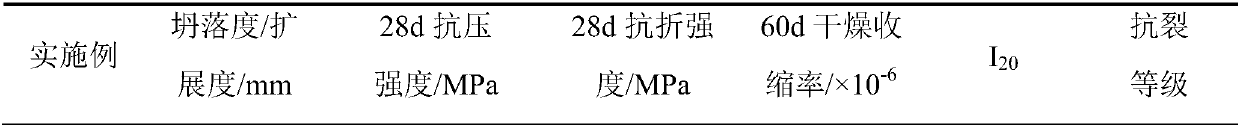

Super high performance concrete prepared by wet granite stone powder and preparation method thereof

ActiveCN107892527ASolve the problem of ball dispersionSolving Recycling ProblemsSolid waste managementFiberCrack resistance

The invention discloses a super high performance concrete prepared by a wet granite stone powder and prepared from cement, fly ash microbeads, silica fume, the wet granite stone powder, a hydrogen peroxide solution, river sand, steel-imitated fibers, a superdispersion shrinkage-reducing admixture, a defoamer and water as main raw materials. The concrete workability and microstructure of concrete are controlled by the fly ash microbeads; the hydrogen peroxide solution is decomposed to release oxygen to disperse the wet granite stone powder, the wet granite stone powder and cementitious materialparticles are dispersed by dispersing groups of the superdispersion shrinkage-reducing admixture, the hydration rate and the utilization ratio of the cementitious material are effectively improved, and shrinkage of the concrete is reduced; bubbles, introduced by oxygen generated from decomposition of hydrogen peroxide and other materials, in concrete are eliminated by the defoamer, so as to ensure the mechanical properties and durability of the concrete. The UHPC prepared by the wet granite stone powder has the advantages of super high strength, toughness, excellent crack resistance and the like, meets the requirements of environmental protection and energy conservation, and has important application value.

Owner:WUHAN UNIV OF TECH

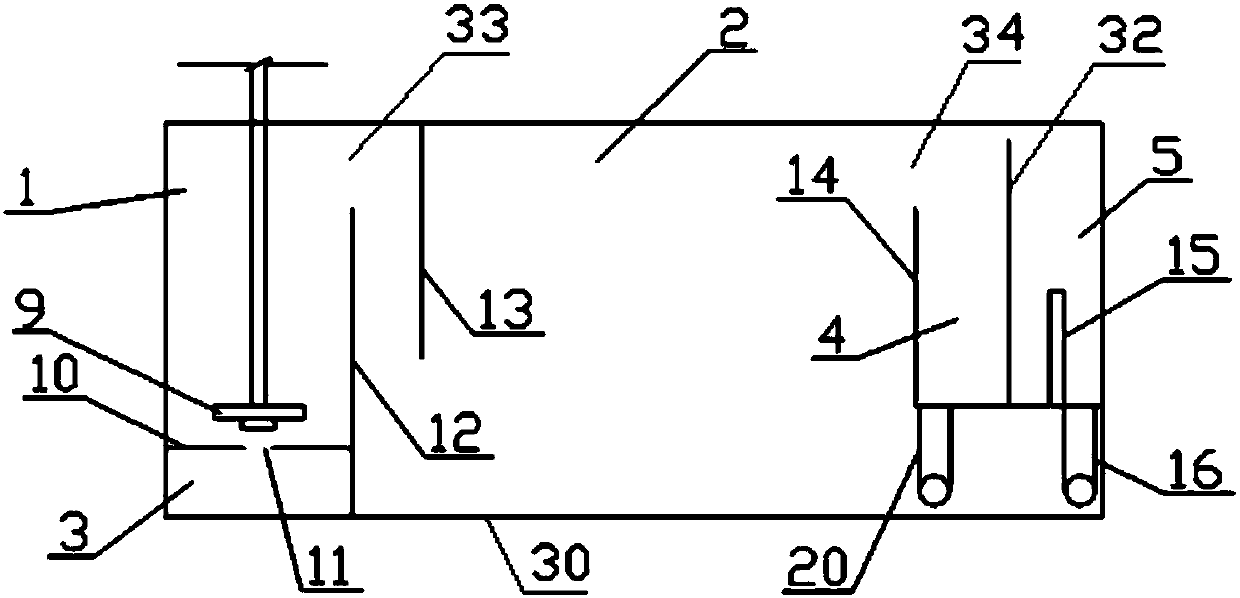

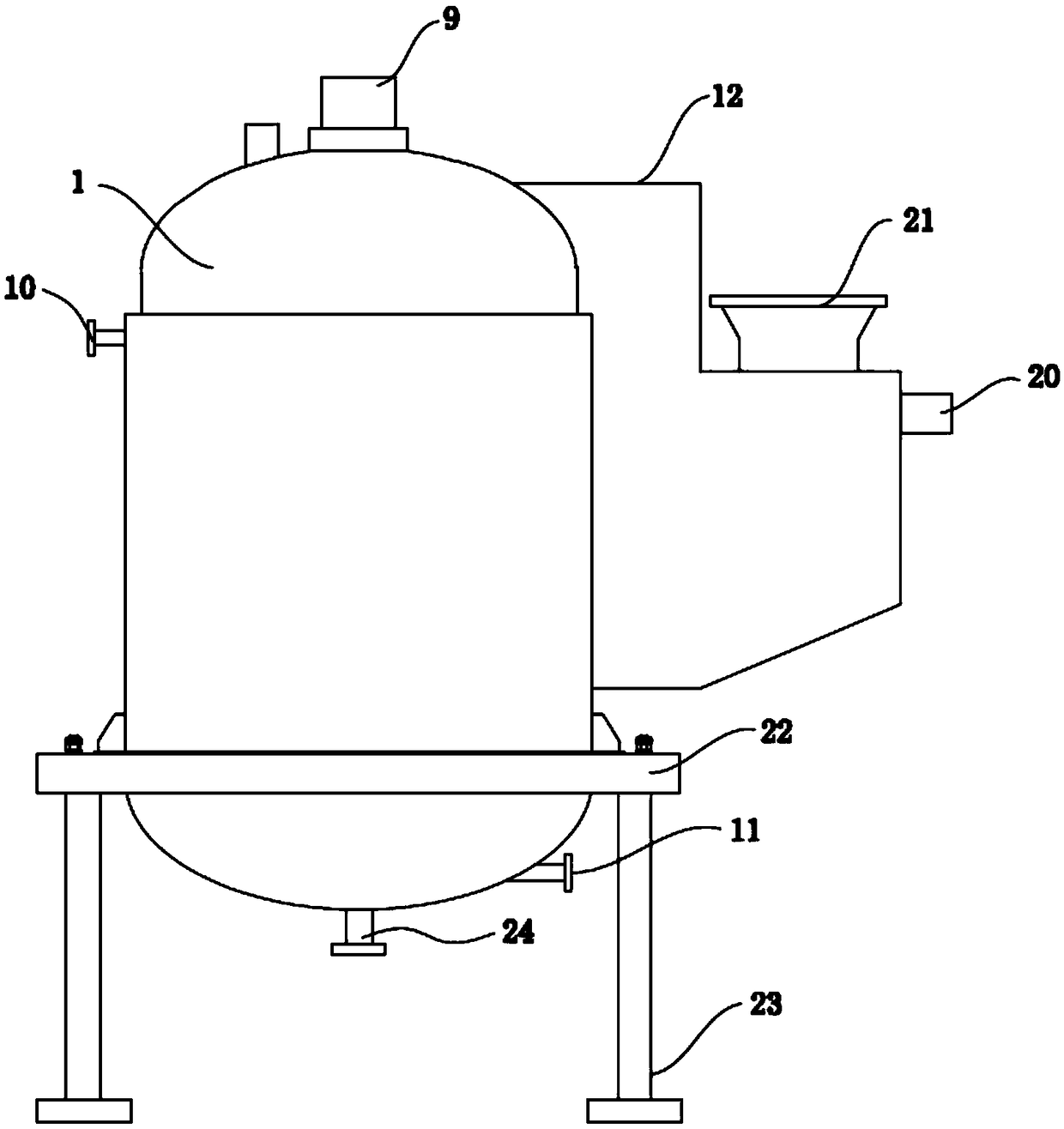

Mixing clarifying tank

PendingCN108014516ALow flow resistanceReduce usageLiquid solutions solvent extractionLiquid–liquid extractionMixing chamber

The invention belongs to the technical field of liquid-liquid extraction, and specifically relates to a mixing clarifying tank. The mixing clarifying tank comprises at least a clarifying tank; the clarifying tank comprises a clarifying chamber with a mixing chamber and a submerging chamber at one end and a light-phase small chamber and a heavy-phase small chamber at the other end; the submerging chamber is positioned at the lower part of the mixing chamber; a light phase and a heavy phase enter the mixing chamber from the submerging chamber, and are stirred into a mixed phase, and the mixed phase is conveyed to the clarifying chamber; the clarifying chamber is used for separating the mixed phase into a light phase and a heavy phase; the light phase and the heavy phase are respectively conveyed into a light-phase small chamber and a heavy-phase small chamber; the light phase and the heavy phase flow out of the clarifying tank from the light-phase small chamber and the heavy-phase smallchamber; the heavy-phase small chamber can adjust the interface height between the light phase and the heavy phase in the clarifying chamber; when the mixing clarifying tank comprises a plurality of clarifying tanks, the submerging chamber of each clarifying tank can also be connected with the heavy-phase small chamber of an upper-stage clarifying tank and the light-phase small chamber of a next-stage clarifying tank, so that the mixing clarifying tank can be expanded into a multi-stage mixing clarifying tank.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Fertilizer mixing unit

InactiveCN103418299AAvoid mixing unevenlyPromote the development of production technologyMixersAgricultural engineeringFertilizer

The invention discloses a fertilizer mixing unit comprising a barrel. The top of the barrel is provided with a feed hole. The bottom of the barrel is provided with a discharge hole. A mixing component is disposed inside the barrel and comprises a mixing shaft and mixing blades. The mixing blades are arranged on the mixing shaft. A partition is disposed at the bottom of the mixing component. The side, far away from the feed hole, of the partition between the inner wall of the barrel and the partition is provided with a gap. A vibrating component is disposed at the bottom of the partition. The bottom of the vibrating component is connected with the discharge hole. The fertilizer mixing unit has the advantages that the whole process flow is continuous, mixing is thorough and effective, uneven mixing of the fertilizer is avoided, production progress is quickened, and the development of fertilizer production process is promoted.

Owner:顾璐璐

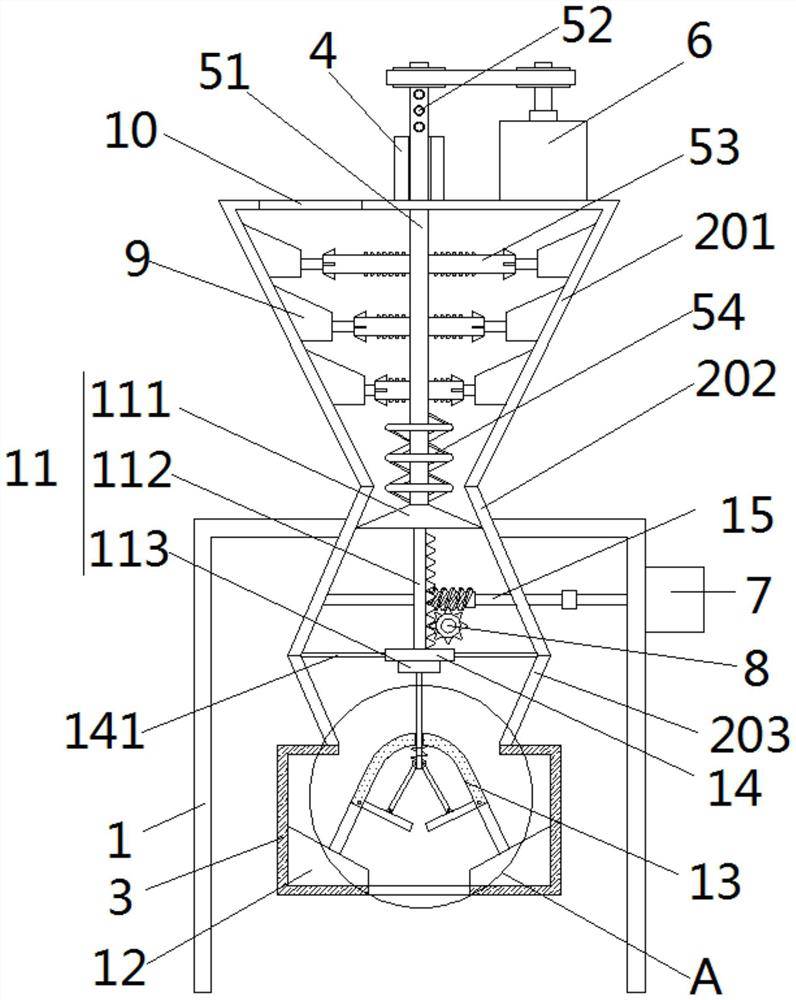

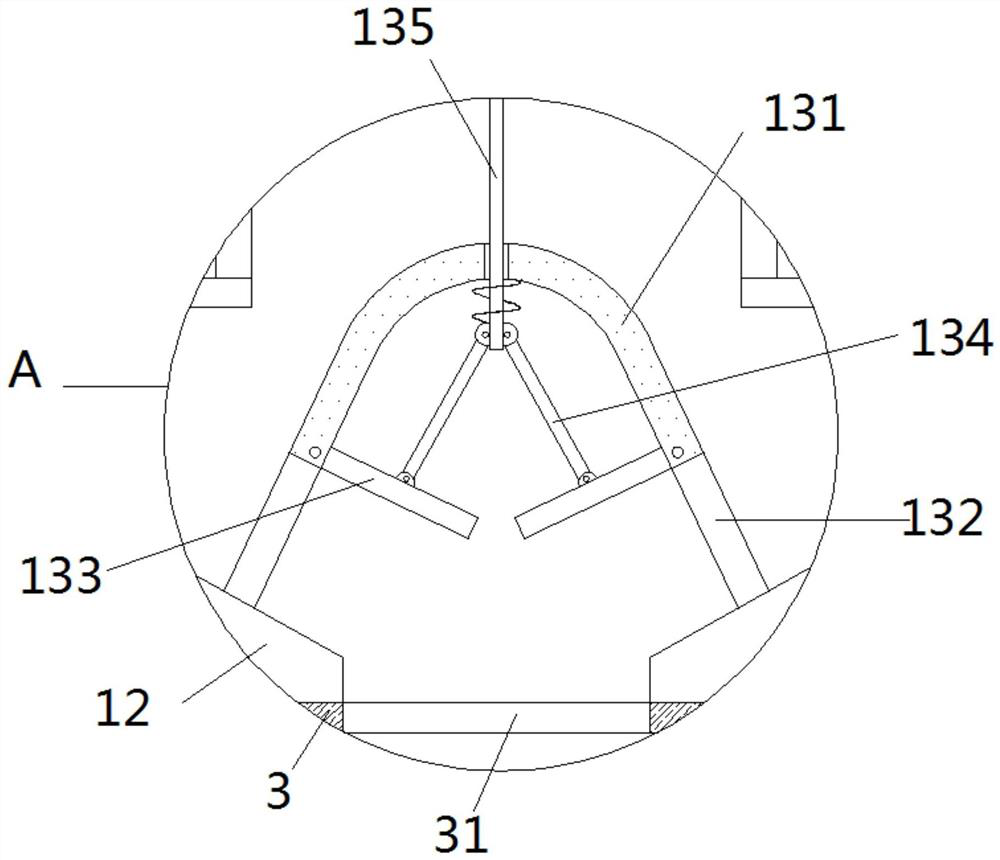

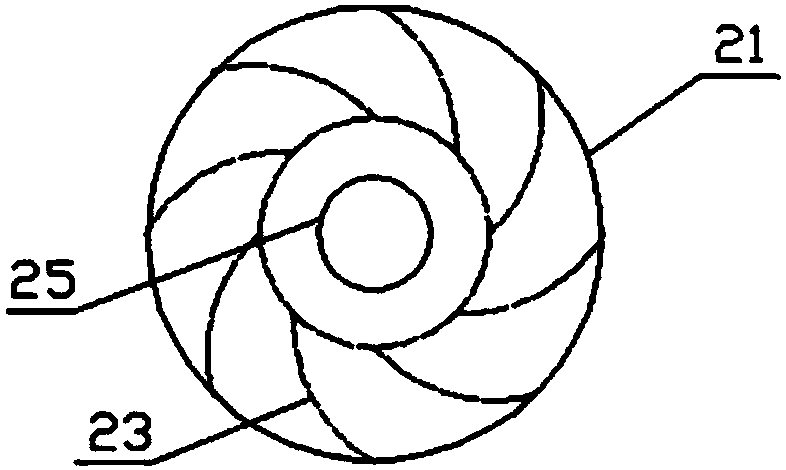

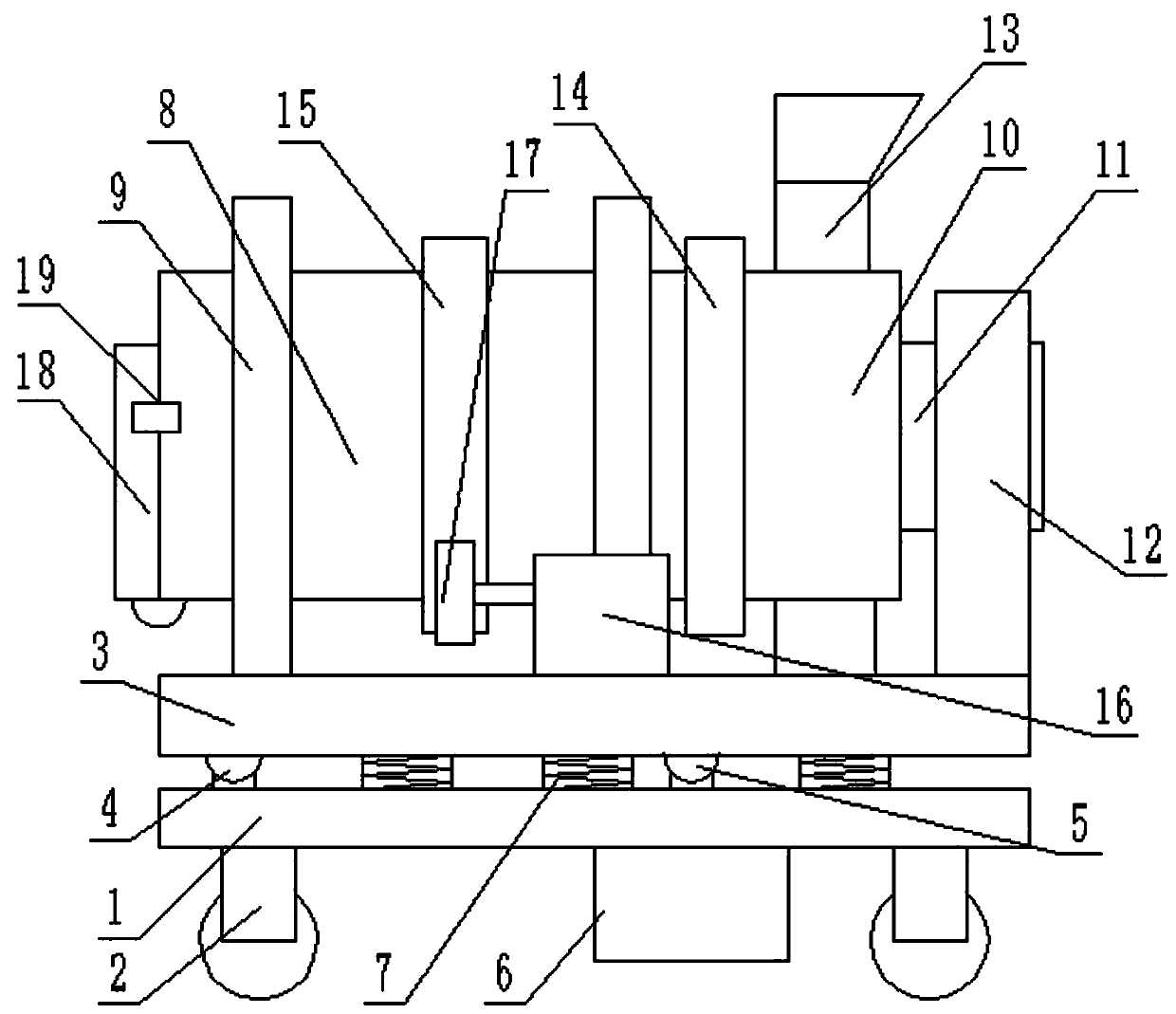

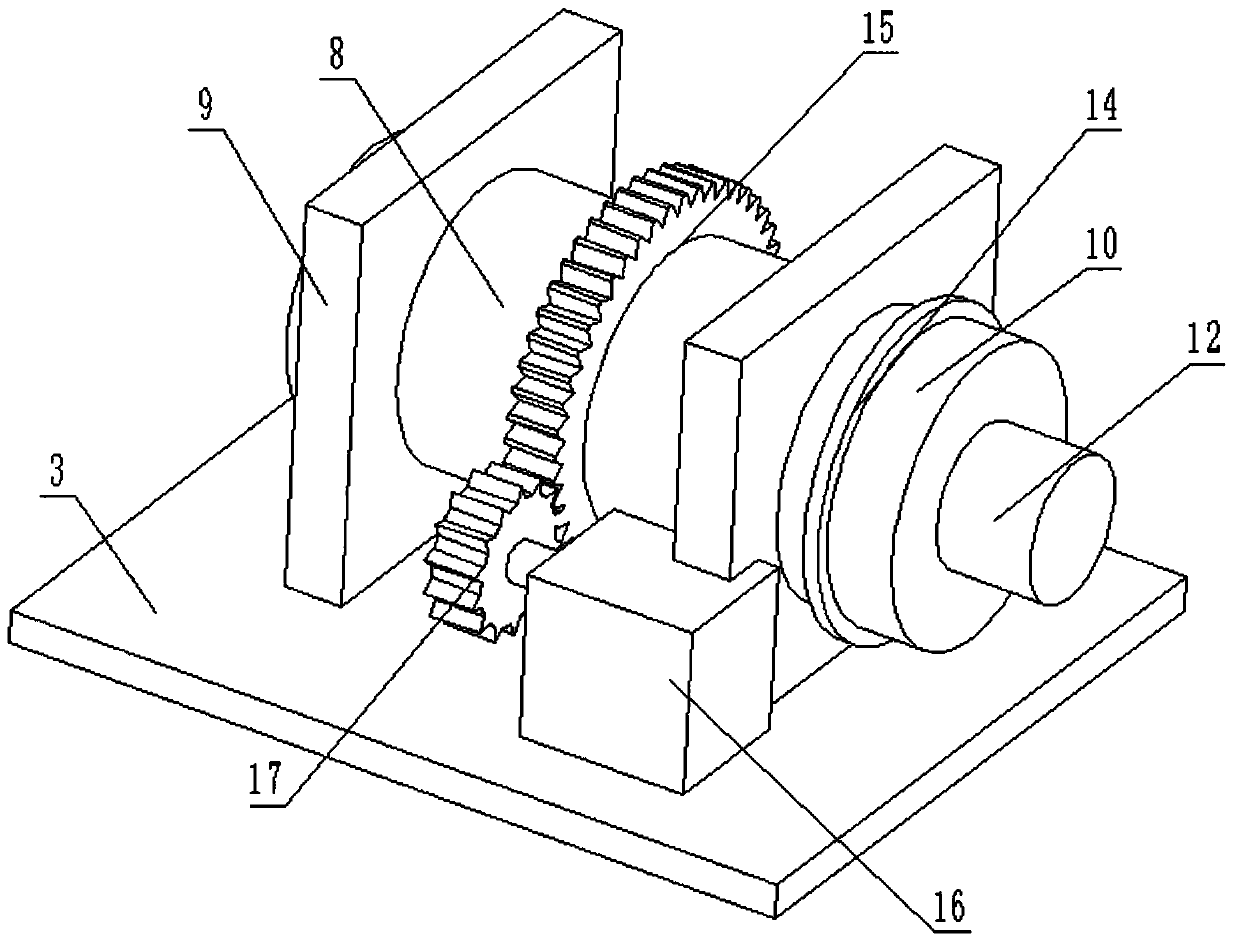

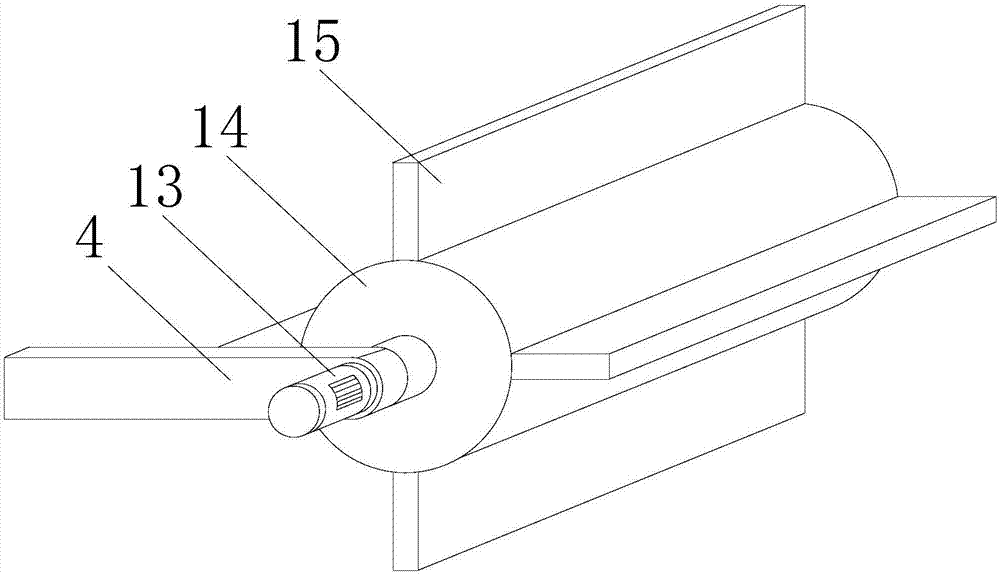

Wet material blender and use method thereof

PendingCN108435022AReduce in quantityUniform materialRotary stirring mixersTransportation and packagingImpellerEngineering

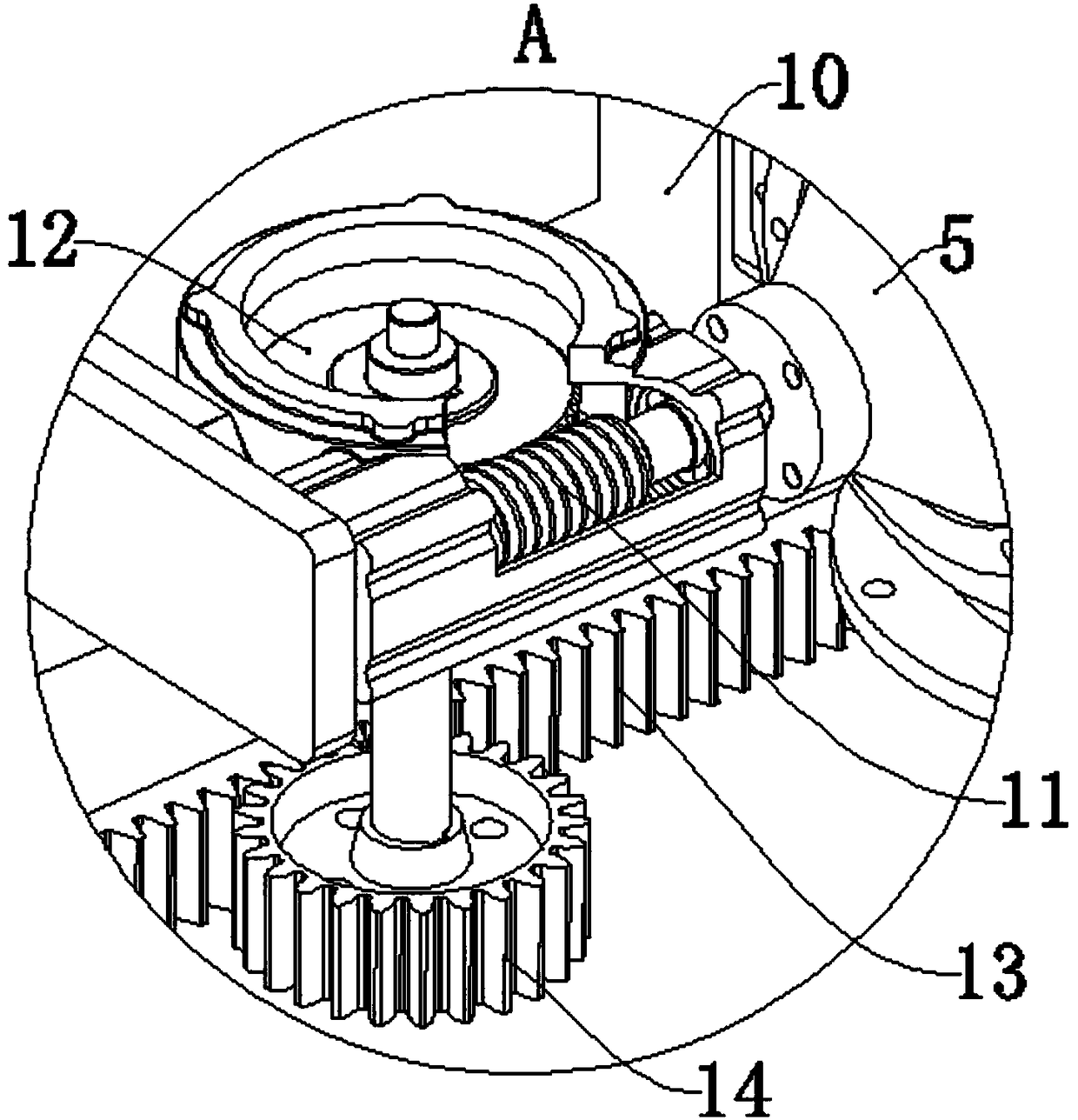

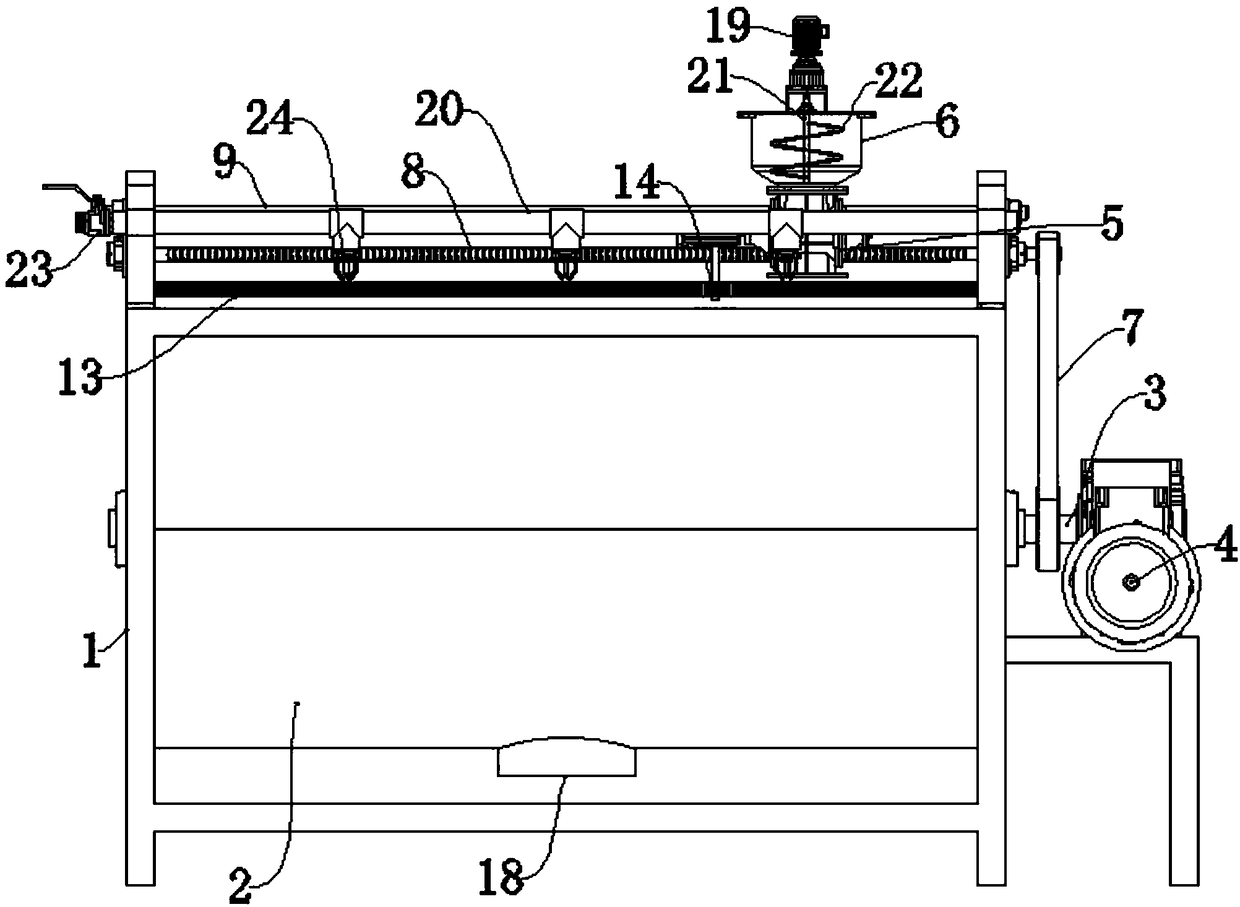

The invention relates to the technical field of agitation equipment, in particular to a wet material blender. The wet material blender comprises a rack, a tank body, a main shaft, a driving motor, a rotating feeding device, an auxiliary material hopper, a belt transmission mechanism, an auxiliary material stirring motor, a spray pipe, a two-way lead screw, a guide column, a sliding block, a worm,a worm gear, a rack and a gear; the rotating feeding device is internally provided with an impeller; the two-way lead screw and the guide column are both arranged on the rack, and the main shaft is connected with the two-way lead screw; the sliding block is slidably connected with the guide column, and in threaded cooperation with the two-way lead screw; the worm is coaxially connected with the impeller, the worm is meshed with the worm gear, and the axis of the worm is vertical; the rack is arranged on the rack, the gear is coaxially connected with the worm gear, and the gear is meshed with the rack. The wet material blender aims to solve the deficiencies in the prior art, and has the advantages that auxiliary materials accounting for smaller proportions can be uniformly added into the main material during the stirring, prevent the accumulation of the auxiliary materials, and improve the product quality.

Owner:HEZE UNIV

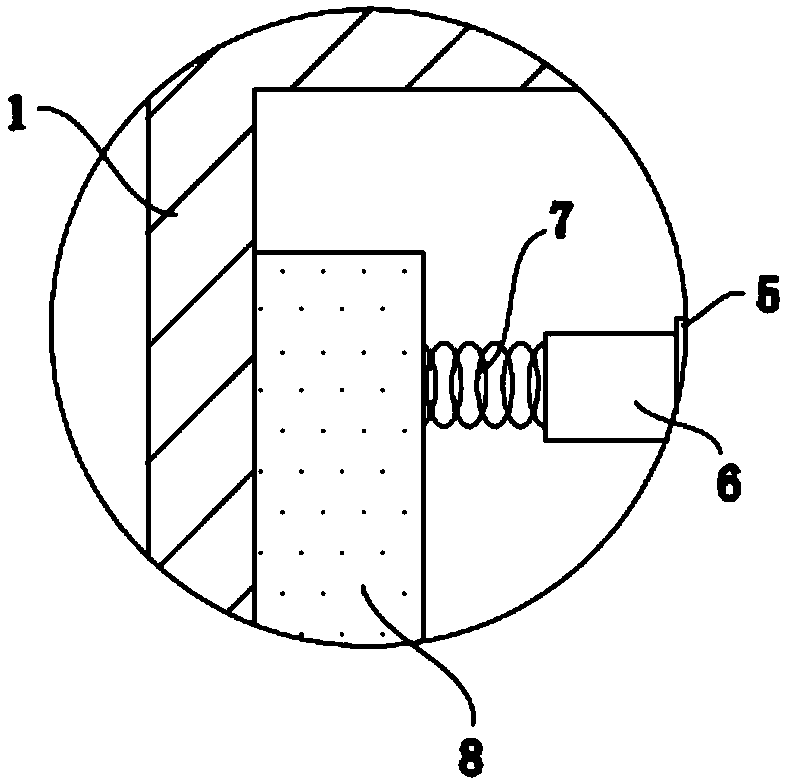

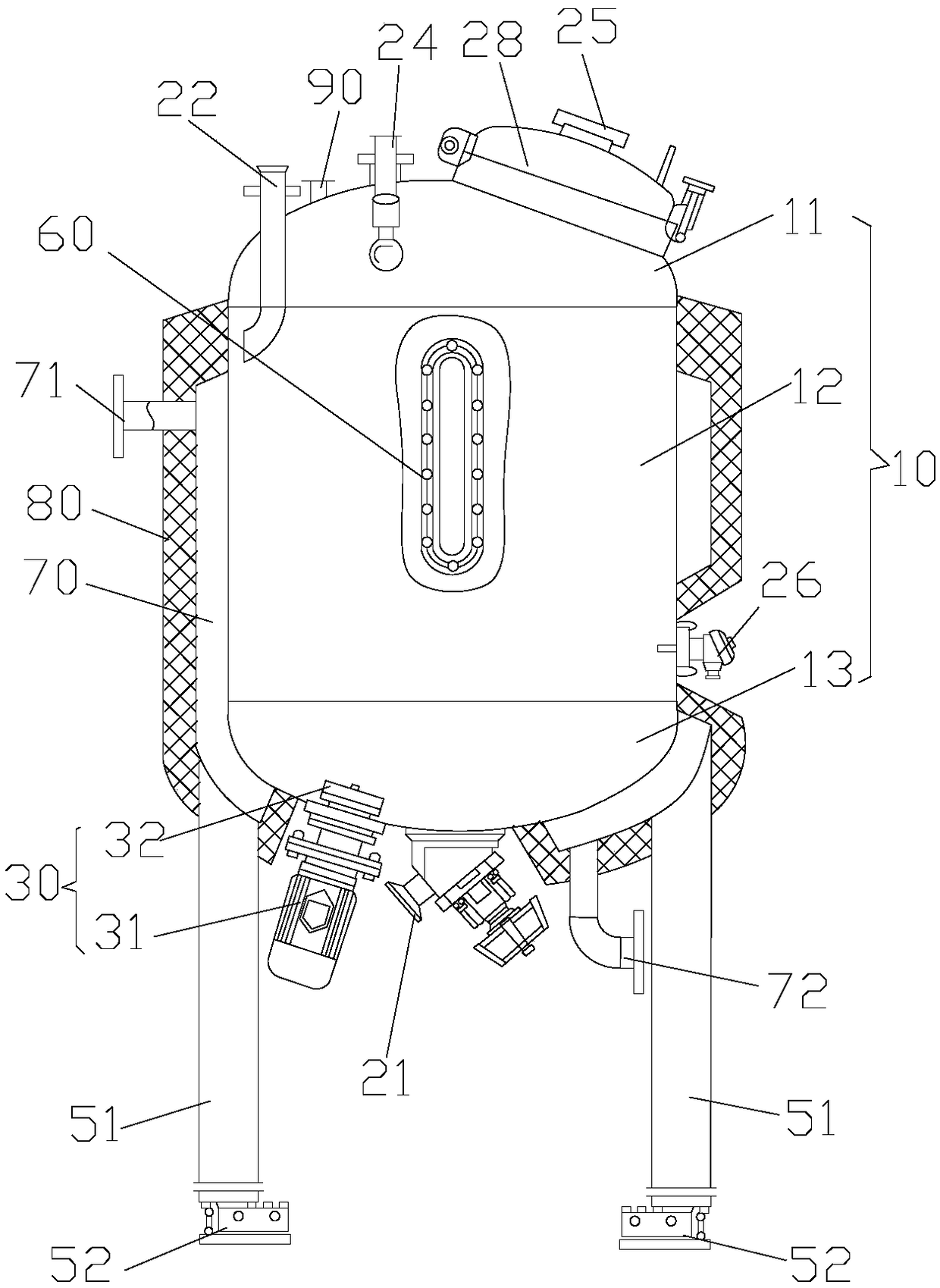

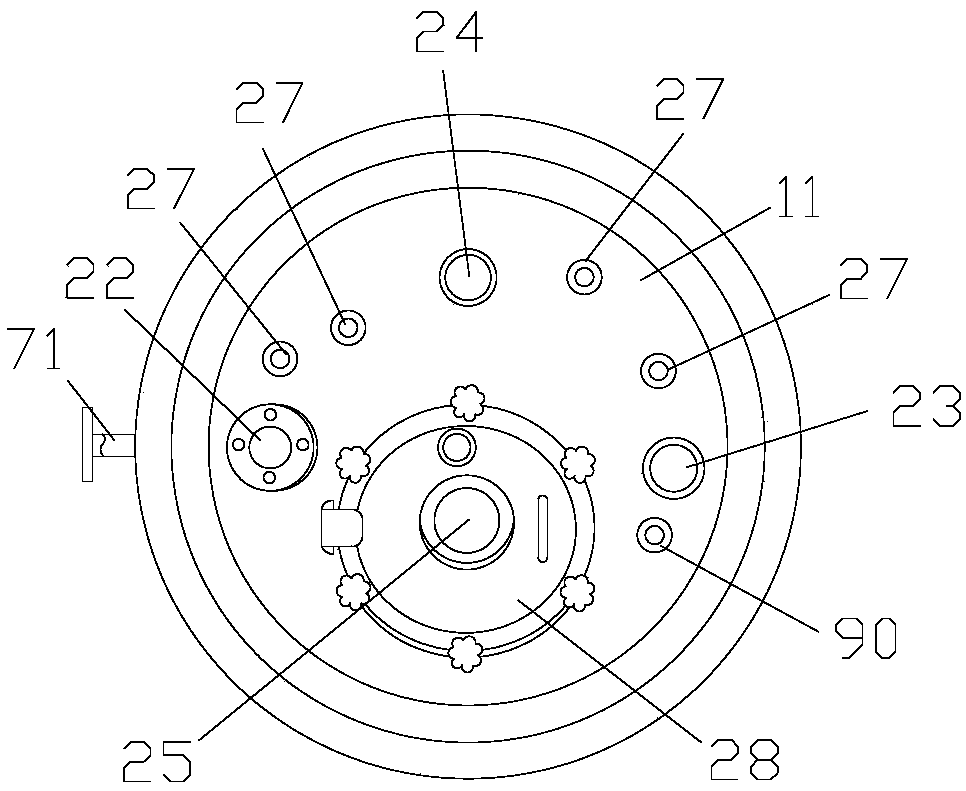

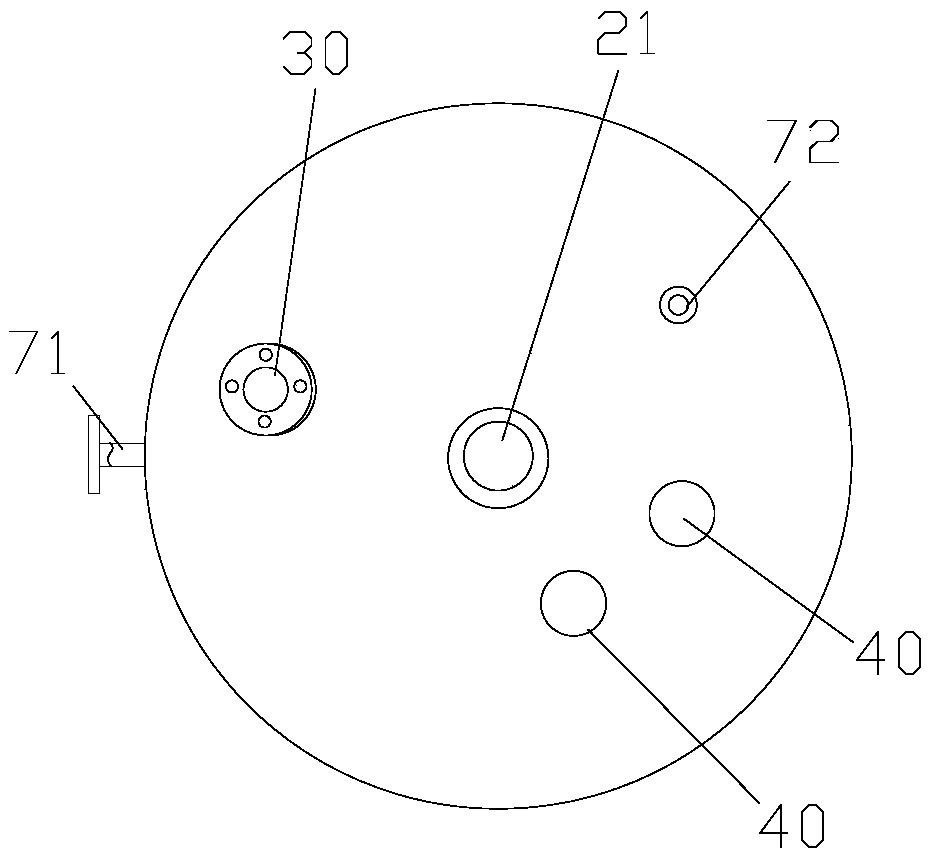

Chemical reaction kettle

InactiveCN109289746AImprove uniformitySolve the situation of uneven mixingChemical/physical/physico-chemical stationary reactorsChemical reactionFixed frame

The invention discloses a chemical reaction kettle, relates to the technical field of chemical equipment, and particularly provides a chemical reaction kettle which comprises a reaction bin, a guide device, stirring rods, a stirring device, a cover plate, a fixing frame, a first fixing bracket, a speed reducer, a reverse locking device, a second fixing bracket and a motor. The chemical reaction kettle has the advantages that the stirring rods can be driven by a driving shell to rotate, and accordingly the problem of uneven reactant stirring due to unidirectional rotation of existing reaction kettles can be effectively solved by the aid of the chemical reaction kettle; the stirring uniformity of the chemical reaction kettle can be effectively enhanced by opposite rotation directions of thestirring rods and the stirring device; the guide device fixedly sleeves the bottom of an inner cavity of the reaction bin, the guide device, the stirring rods and the stirring device are matched withone another, accordingly, driving force of the motor can be effectively utilized, the stirring uniformity of the chemical reaction kettle can be improved, sufficient reaction in the chemical reactionkettle can be guaranteed, and the problem of uneven stirring of the existing reaction kettles can be solved by the aid of the chemical reaction kettle.

Owner:杭州纳尔森精细化工有限公司

Stirring device used for building energy saving materials

InactiveCN108993199AReduce vibrationExtended service lifeRotary stirring mixersTransportation and packagingInternal cavityBuilding energy

The invention discloses a stirring device used for building energy saving materials. The stirring device comprises a pedestal and a belt; the left side of the top of the pedestal is fixedly connectedwith a stirring tank; the right side of an internal cavity of the stirring tank is fixedly connected with a separating box; the right side of the top of the pedestal is fixedly connected with a motor;an output terminal of the motor is fixedly connected with a second belt pulley. The stirring device is provided with the motor, a first stirring rod, a first belt pulley, the second belt pulley, thebelt, a second stirring rod, a first gear, a second gear, and stirring blades, so that building energy saving material stirring is more uniform, nonuniform stirring is avoided, stirring blind angles are avoided, and problems in the prior art that conventional building energy saving material stirring device stirring effect is poor, it is impossible to realize full mixing stirring of internal materials, stirring blind angles are caused, building energy saving material stirring quality is influenced, and it is not convenient for users to use are solved.

Owner:郑州谓凡智能科技有限公司

Raw material mixing device for rubber product production

The invention discloses a raw material mixing device for rubber product production. A supporting plate is included, and the four corners of the bottom face of the supporting plate are each fixedly connected with a supporting leg; two supporting rods are symmetrically and fixedly connected to the two sides of the top face of the supporting plate, are sleeved with a same fixed plate, and are fixedlyconnected with the fixed plate; and the portions, at the top end of the fixed plate, of the supporting rods are sleeved with a sliding plate, and are in sliding connection with the sliding plate. According to the raw material mixing device for rubber product production, a first motor operates so that a rotating rod drives a stirring rod to rotate, and materials in a stirring bucket are stirred; meanwhile a cam rotates, the stirring bucket is driven to jolt up and down under the effect of a spring, then the inner materials are driven to jolt, it is prevented that bottom stirring is not uniformduring stirring, and the stirring speed of the materials is further increased; meanwhile, a slider slides up and down, the outside gas is sucked into a box body, and then is blown out of a pluralityof air outlets in an arc-shaped box body, cooling work is performed on the materials in the stirring bucket, and it is effectively prevented that due to lasting material mixing, temperature is too high, and consequently the materials are molten and spliced to the inner wall of an inner shell.

Owner:开平市志杰汽车零部件有限公司

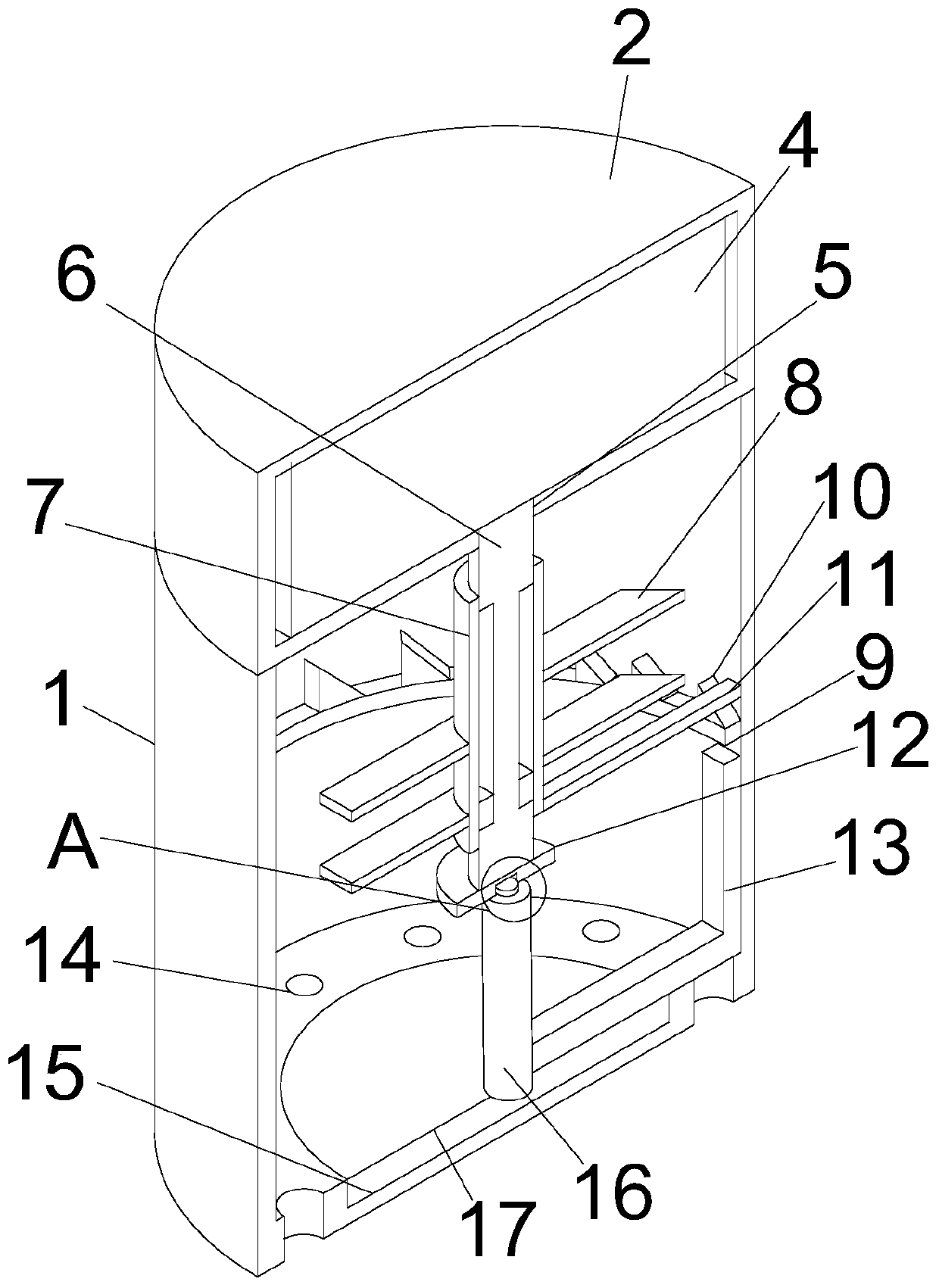

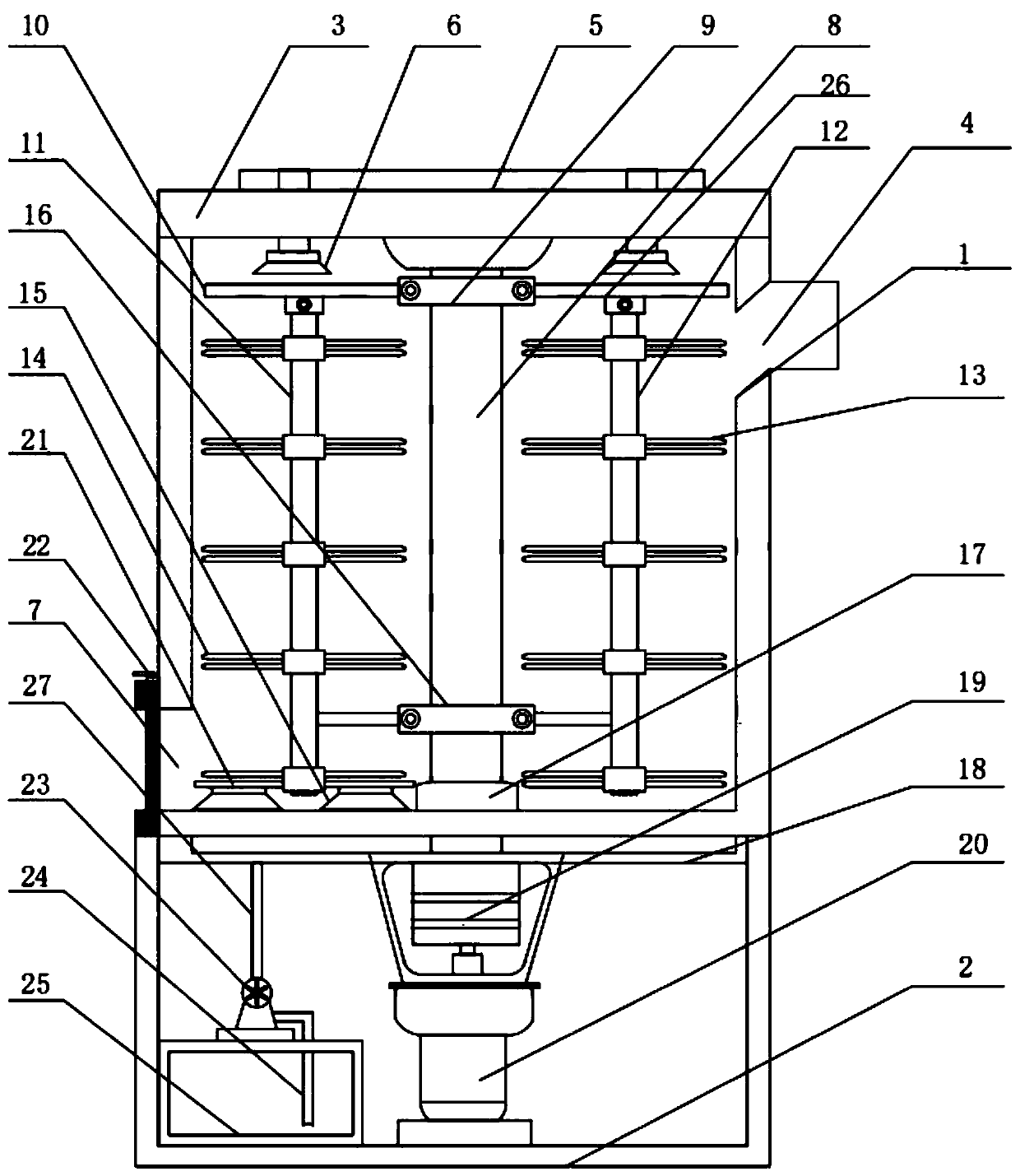

Circulating separation system based on ceramic membrane process

InactiveCN111111592AStir wellAvoid mixing unevenlySemi-permeable membranesChemical/physical/physico-chemical stationary reactorsElectric machineryProcess engineering

The invention relates to the technical field of acidification tanks. The invention further discloses a circulating separation system based on a ceramic membrane process. The system comprises an acidification tank and a ceramic membrane, an output port of the acidification tank is communicated with the ceramic membrane through a pipeline, an output port of the ceramic membrane is communicated withthe acidification tank through a pipeline, after ceramic membrane separation, thick slurry containing mushroom dregs is obtained, enters into the acidification tank again, then enters the ceramic membrane again through circulation and realizes repeated circulation, when the motor is started to work, the motor drives a connecting column to rotate, the connecting column drives a movable sleeve to rotate, the movable sleeve rotates to drive stirring blades to stir, then, a stock solution in the tank body is stirred, in the stirring process, the connecting rod can gradually move upwards along theinclined surface of a triangular block, when the stock solution passes through the triangular block, the connecting rod can move downwards, the connecting rod moves up and down to drive the movable sleeve to move up and down, and the movable sleeve moves up and down to drive the stirring blades to vibrate and stir up and down, so that the raw liquid can be fully stirred.

Owner:SHANDONG RUNDE BIOTECH CO LTD

Steel fiber concrete mixer

InactiveCN110744716AAvoid mixing unevenlyGuaranteed reliabilityHollow article cleaningCement mixing apparatusEngineeringStructural engineering

The invention discloses a steel fiber concrete mixer. The steel fiber concrete mixer includes a mixer body. The upper end of the mixer body is provided with a supporting plate. The bottom part of themixer body is provided with a supporting steel frame. The middle end of the interior of the supporting steel frame is provided with a motor. The left and right ends of a first rotating shaft sleeve are provided with a first fixed rod and a second fixed rod correspondingly. The first fixed rod and the second fixed rod are provided with a first mixer shaft and a second mixer shaft correspondingly. The first mixer shaft and the second mixer shaft are provided with a plurality of first mixing rods and a plurality of second mixing rods correspondingly. When the steel fiber concrete mixer is in use,steel fibers are added into the concrete inside the mixer body separately and evenly through a feed inlet, and the first mixing rod, the second mixing rod, a brushing and scraping rod and a cleaningsteel sheet are driven by a rotating shaft on the motor to evenly mix the steel fibers and the concrete, the steel fibers are made to be evenly distributed in the concrete, agglomeration and uneven mixing of the steel fibers in the concrete are avoided, and the reliability of the steel fiber concrete is guaranteed.

Owner:FOSHAN UNIVERSITY

Concrete stirring and mixing device used for construction site of building site

InactiveCN110978281AAvoid mixing unevenlyImprove construction qualityCement mixing apparatusCounter rotationDrive shaft

Owner:李付民

Activated carbon raw material stirring preparation device

InactiveCN114471264APrevent sprayingAvoid uneven mixingRotary stirring mixersTransportation and packagingActivated carbonMaterials science

The invention belongs to the field of activated carbon preparation, and relates to an activated carbon raw material stirring preparation device which comprises a shell and is characterized in that a top cover is arranged on the shell in a sliding mode, a rotating sleeve is fixedly arranged on the lower side wall of the top cover, and a solvent mixing device is arranged in the rotating sleeve; and the solvent mixing device is used for injecting a solvent needed for producing the activated carbon into the cavity, a stirring frame is fixedly arranged on the outer side wall of the rotating sleeve, a sliding frame is fixedly arranged on the outer side wall of the stirring frame, and a stirring device is arranged in the sliding frame and used for stirring the activated carbon and spraying the solvent in the stirring process. The equipment is provided with the sliding frame capable of automatically stretching out and drawing back, stirring blades on the rotating frame are matched to stir and prepare activated carbon raw materials, a solvent is sprayed outwards in the stirring process, more sufficient, deep and uniform stirring is carried out, and a better stirring effect is achieved.

Owner:唐建军

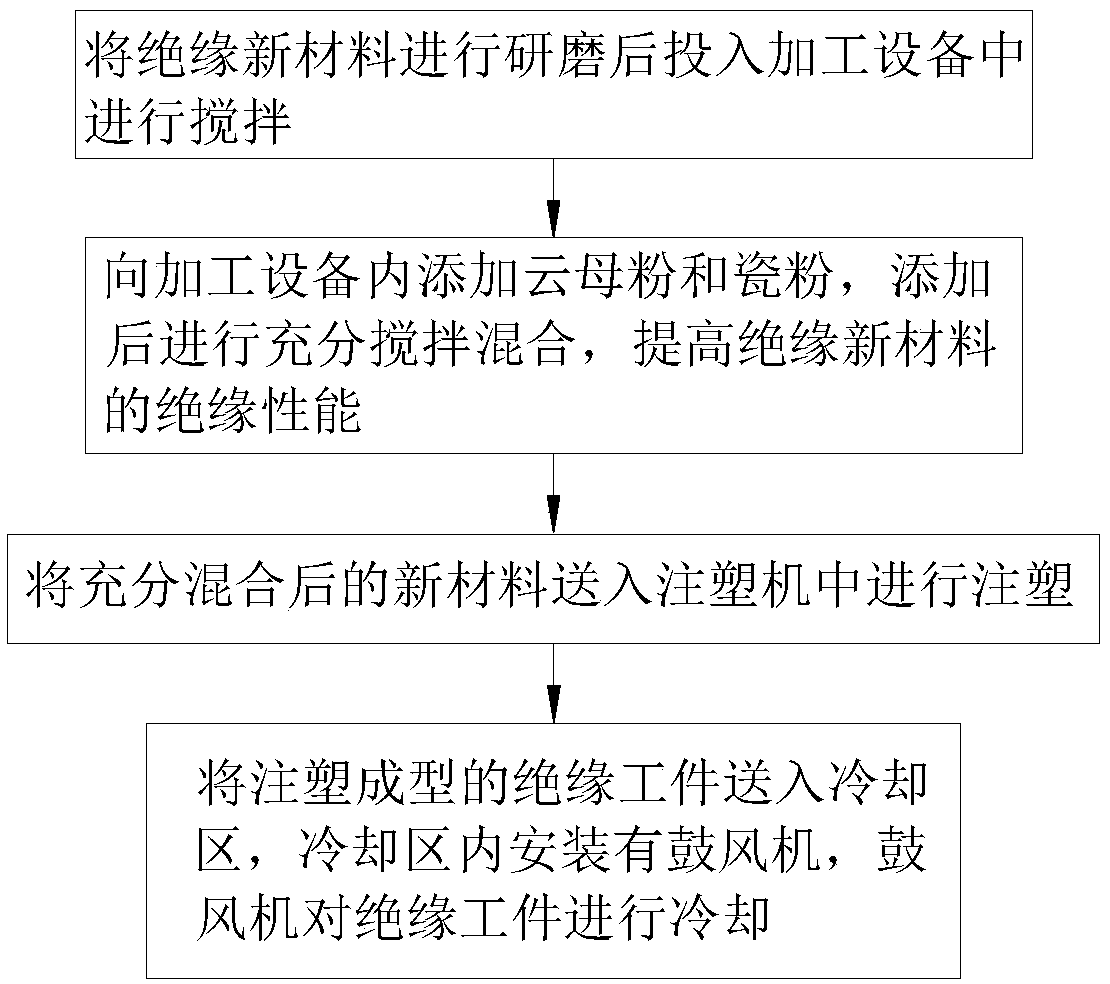

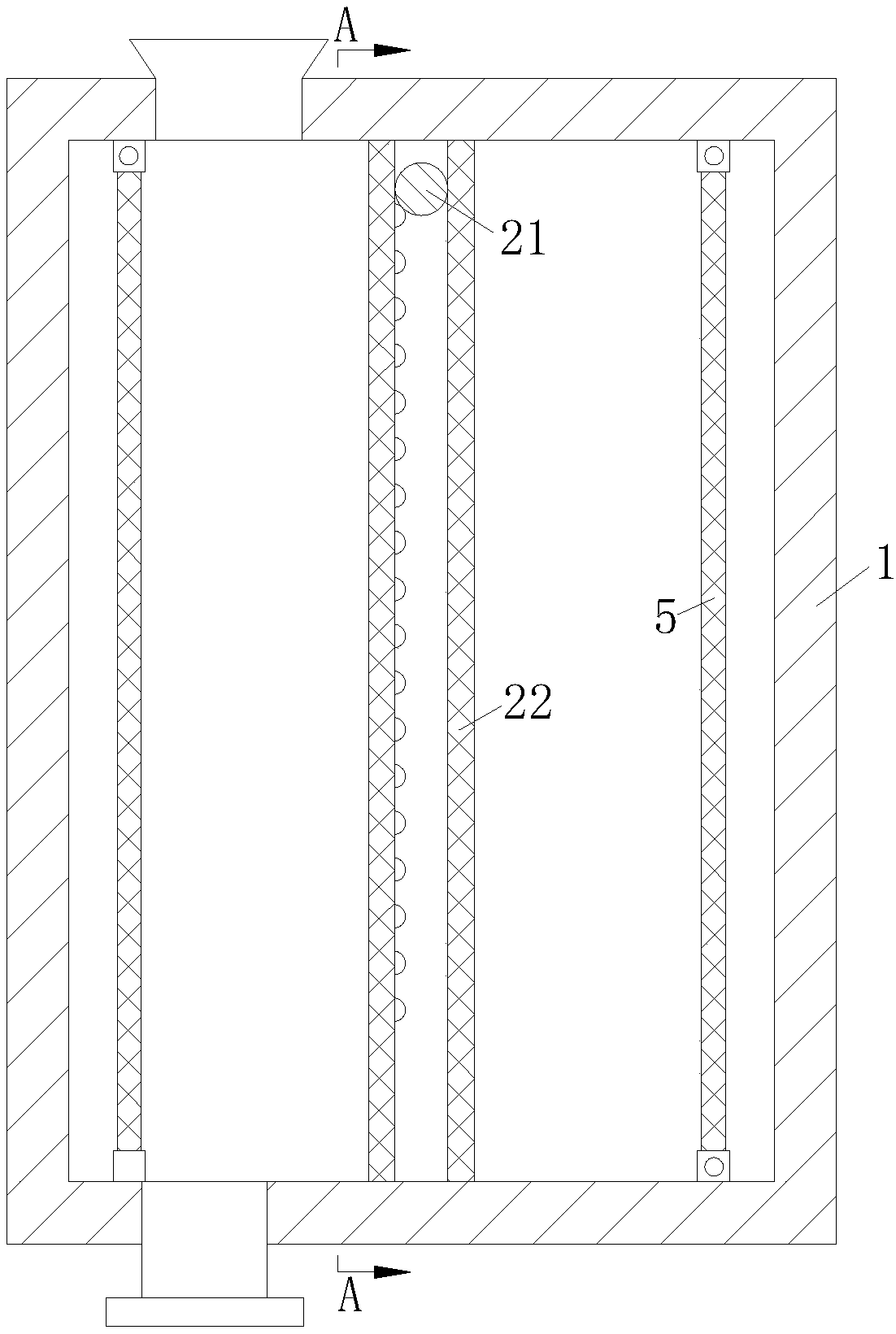

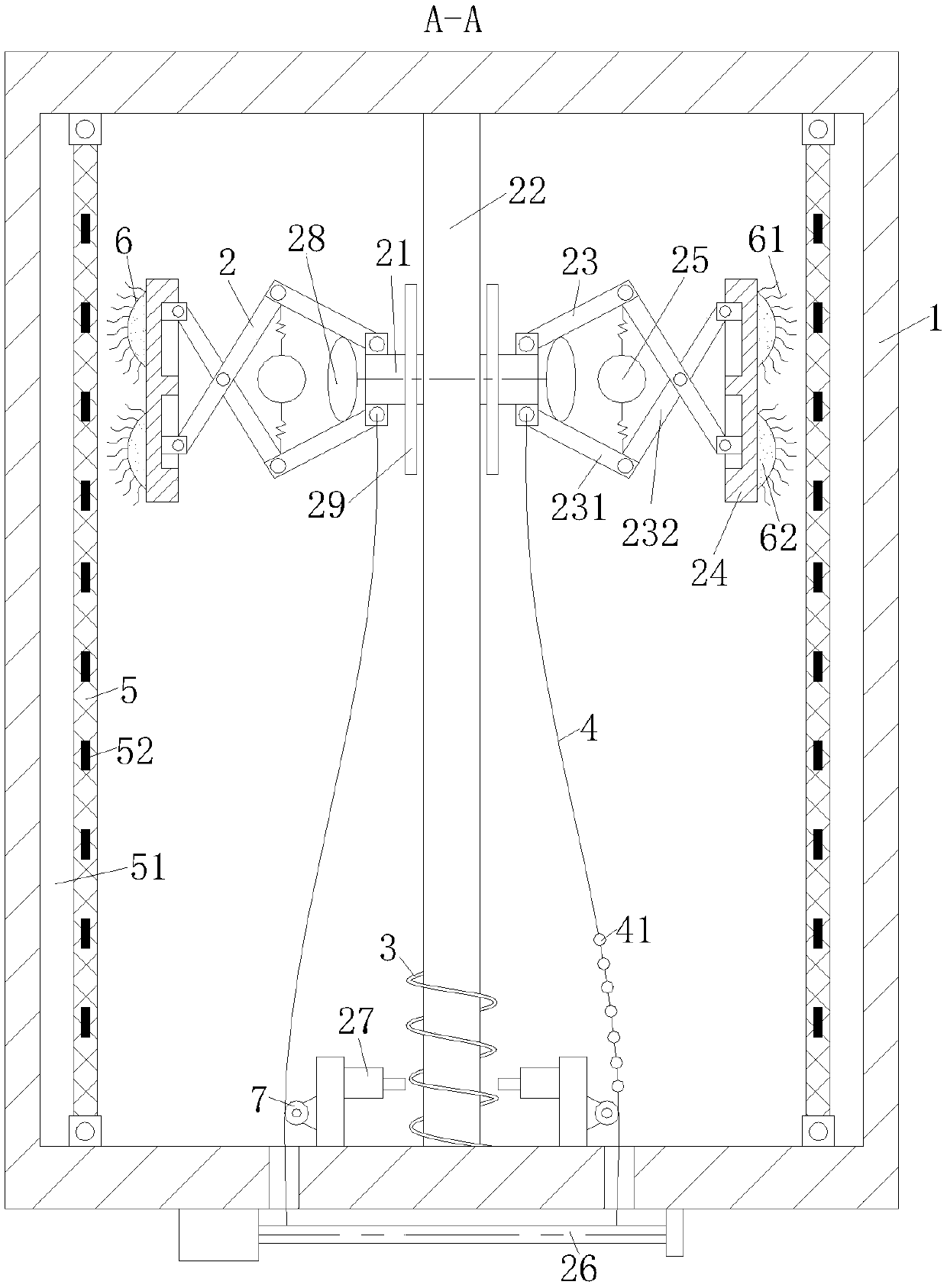

Production process for insulating workpieces

The invention belongs to the technical field of processing of insulating materials and particularly relates to a production process for insulating workpieces. A processing device for the process comprises a shell, a stirring module, a controller and a motor. The stirring module is located inside the shell. The stirring module comprises a sliding shaft, elastic plates, shear fork mechanisms, push plates, centrifugal balls, a rotary shaft, a supporting plate, telescoping cylinders, extrusion air bags, rotary plates and a pressure spring, wherein the two elastic plates are vertically and fixedlyconnected in the shell; two through holes are symmetrically formed in the bottom of the shell; the space between the two elastic plates is a slide, and one of the elastic plates is provided with a setof elastic protrusions; the sliding shaft is slidably installed in the slide; the shear fork mechanisms are symmetrically hinged to both ends of the sliding shaft; the sliding shaft is sleeved with the two rotary plates symmetrically; and both ends of the sliding shaft are each connected with a steel wire rope. According to the production process for the insulating workpieces, by adding mica powder and porcelain powder to novel insulating materials, the novel materials obtain a higher insulating property, and thus the insulating property of the insulating workpieces is improved.

Owner:苏州壬和控股有限公司

Small concrete stirring device

InactiveCN109397536AImprove usabilityEasy to useMixing operation control apparatusPretreatment controlMotor driveCold winter

The invention discloses a small concrete stirring device, which comprises a first shell. A first motor is mounted at the top of the first shell, the output end of the first motor is connected with a rotating rod through a coupling, and the rotating rod stretches into the first shell; stirring paddles are evenly arranged on the rotating rod, and guiding columns are mounted at the ends of the stirring paddles on the left and right sides correspondingly; and the other sides of the guiding columns are connected with scraping plates through springs correspondingly, and the scraping plates are in clearance fit with the inner wall of the corresponding shell. The first motor drives the rotating rod to rotate, and thus materials are stirred and mixed through the stirring paddles; the other sides ofthe guiding columns are connected with the scraping plates through the springs correspondingly, and under the effect of the springs, the scraping plates are pushed to be tightly attached to the innerwall of the first shell to clean the inner wall of the first shell along with rotating of the rotating rod; and through the mode that hot water is circularly injected into a second shell, the stirring device works in the cold winter, and the temperature in the first shell is increased, so that the situation that the materials in the first shell are frozen and consequently stirred unevenly is avoided.

Owner:开平市建城混凝土有限公司

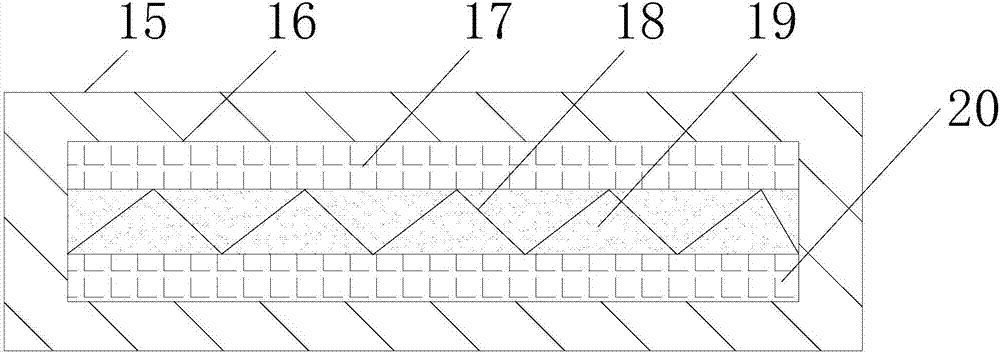

Building material processing powder mixing machine

InactiveCN107398213AStir wellAvoid mixing unevenlyRotary stirring mixersTransportation and packagingBiochemical engineeringFan blade

The invention discloses a building material processing powder mixing machine, which comprises a machine body, wherein the bottom of the machine body is provided with a discharging pipe; a valve is arranged inside the discharging pipe; a stirring shaft is arranged in the center position of the top of the machine body; the bottom end of the stirring shaft is arranged inside the machine body; a stirring fan blade is arranged on the stirring shaft; a first gear is arranged on the top end of the stirring shaft; a feeding pipe is arranged at one side of the stirring shaft; a first motor is arranged at the other side of the stirring shaft; a second gear is arranged at the bottom end of the first motor; a high-pressure spray head is arranged on the inner wall of the top of the machine body; a water pipe is arranged at one side of the high-pressure spray head; a plurality of stands are arranged on the inner walls of the two sides of the machine body; a second motor is arranged at one side of the stand; a rotating shaft is arranged on each stand; a plurality of fixing plates are arranged on each rotating shaft; a heating sheet is arranged inside each fixing plate; each heating sheet consists of an upper aluminum plate, an electric heating wire, heat conduction silicon gel and a lower aluminum plate. The powder material mixing machine has the advantage of high powder material stirring efficiency.

Owner:麻大伟

Water phase tank device

PendingCN108993190AAvoid mixing unevenlyStir wellRotary stirring mixersMixing methodsMiddle segmentBiochemical engineering

The invention provides a water phase tank device. The water phase tank device comprises a tank body and a stirring assembly; the tank body is provided with a stirring cavity, and is provided with a feed inlet and a feed outlet; the feed inlet and the feed outlet are communicated with the stirring cavity respectively; the tank body comprises an upper cover, a middle segment, and a lower cover whichare connected successively; the lower cover is provided with a first end and a second end facing each other; the first end of the lower cover is connected with the middle segment; the diameter of thesecond end of the lower cover is smaller than the diameter of the first end of the lower cover; the feed inlet is arranged on the upper cover; the feed outlet is arranged on the lower cover; the stirring assembly is arranged on the lower cover, and is used for stirring materials in the tank body. The water phase tank device is capable of solving problems in the prior art that the adaptability ofconventional water phase tanks is poor.

Owner:本溪恒康制药有限公司 +1

Polymer battery production ingredient stirring viscosity measuring system

ActiveCN114527038AStir wellAccurate dataFlow propertiesRotary stirring mixersThermodynamicsProcess engineering

The invention relates to the technical field of battery production, in particular to a polymer battery production ingredient stirring viscosity measuring system, which comprises a stirring barrel fixed at the top of a base; the viscosity detector is fixed at the top of the base; the connecting pipe is fixedly communicated with the input end of the viscosity detector, and one end, opposite to the viscosity detector, of the connecting pipe is fixedly communicated with the interior of the stirring barrel; the electromagnetic valve is fixed in the connecting pipe; and the stirring detection device is mounted at the top of the supporting frame. According to the device, through the arrangement of the stirring detection device, ingredients in the stirring barrel are uniformly stirred, and through relative pressure detection during stirring, an operator can accurately identify whether the ingredients are uniformly stirred or not, so that data accuracy during viscosity measurement of the ingredients is facilitated.

Owner:佛山市天劲新能源科技有限公司

Intelligent quantitative mixing device capable of avoiding uneven stirring of novel coating material

InactiveCN112604530AAvoid mixing unevenlyQuality improvementRotary stirring mixersTransportation and packagingElectric machineGear wheel

The invention relates to the technical field of manufacturing of novel functional coating materials, and discloses an intelligent quantitative mixing device capable of avoiding uneven stirring of a novel coating material. The intelligent quantitative mixing device comprises a shell I, the exterior of the shell I is fixedly connected with a motor, and the exterior of the motor is fixedly connected with a rotating rod I; under the interaction of a feeding shell I, lamp beads, a photosensitive assembly, an annular turntable, a movable plate, an annular gear, a movable rack, a turntable I, a feeding shell II, an electromagnet I, an iron block I, a baffle plate, a control assembly and an electromagnetic assembly, the device can be used for quantitatively mixing corresponding coating materials according to the requirements of people, thus errors caused by manual mixing can be avoided, the mixing quality of coating materials can be good, the production cost of enterprises can be saved, traditional coating material manufacturing can be converted into modern intelligent manufacturing, and the device better conforms to the modern intelligent manufacturing concept.

Owner:沛县蓝徒科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com