Food stirring device

A technology of stirring device and food, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of inconvenience, uneven stirring of agitating bodies, unadjustable height of agitating bodies, etc., to prevent stirring Uneven, ensure full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

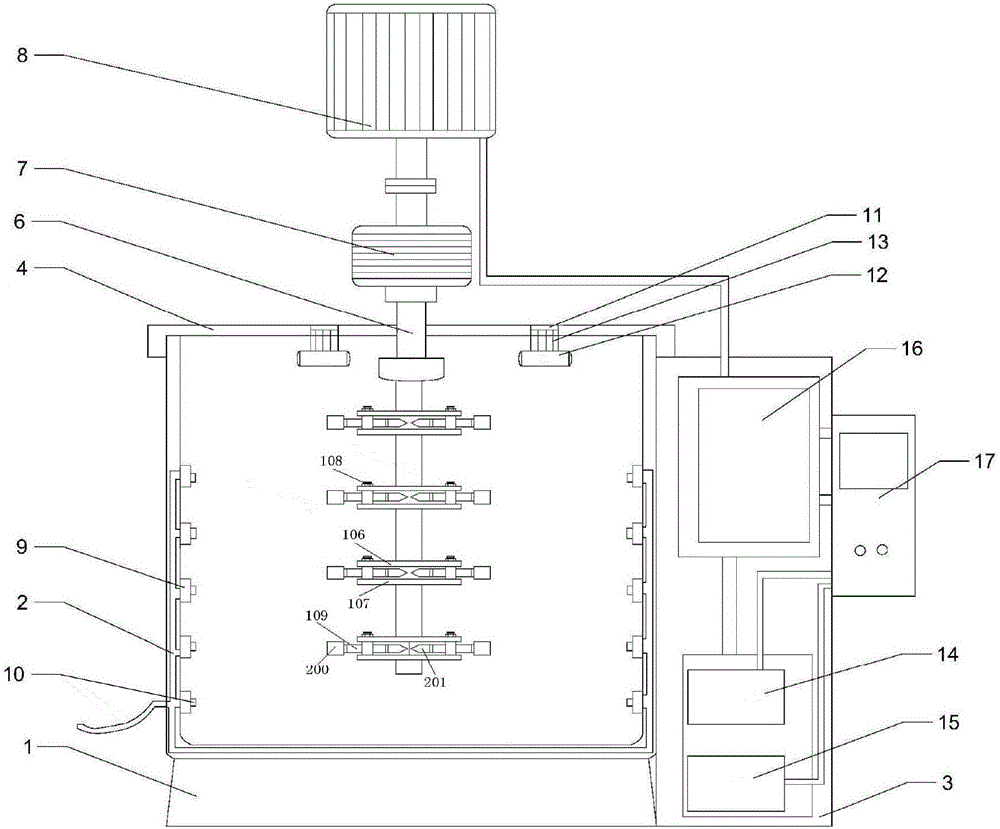

[0029] Such as figure 1 , 3 The present embodiment food mixing device comprises:

[0030] Base 1, mixing tank 2, stirring device and protection body 3, the mixing tank 2 is installed on the base 1, the protection body 3 is installed on the right side of the base 1, and the top of the mixing tank 2 is provided with a sealing cover 4 .

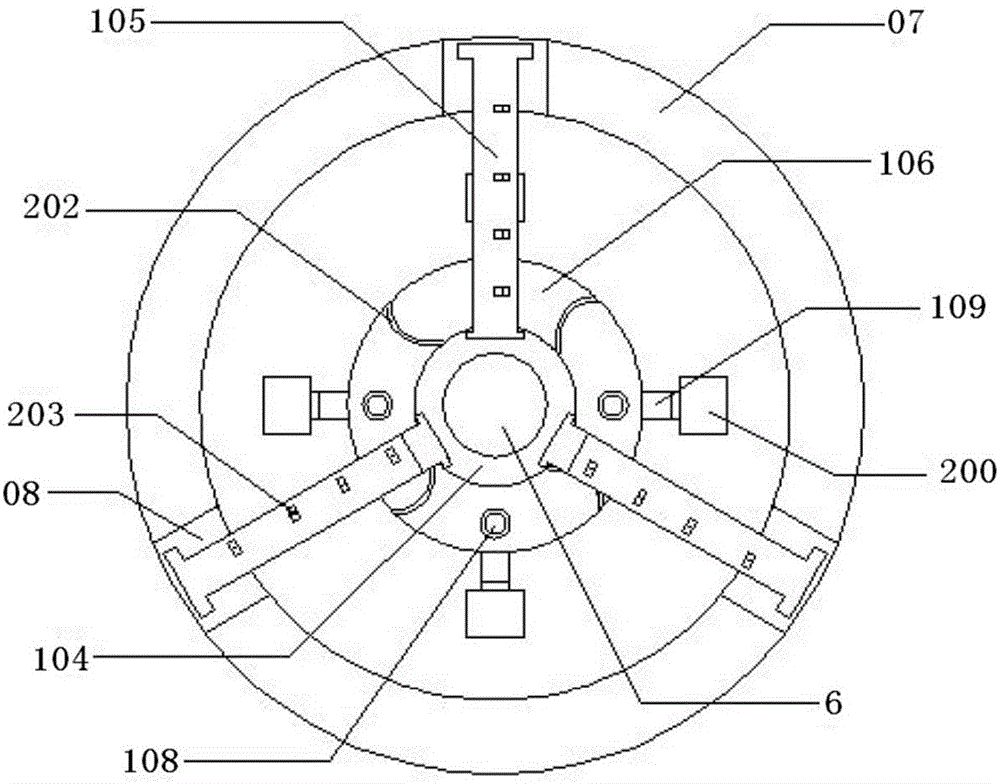

[0031] Described stirring device comprises stirring shaft 103, stirring shaft sleeve 104, stirring shaft support bar 105 and cutter fixed plate; The quantity is the same, and the number of the sliding groove 08 and the stirring shaft support rod 105 is three; one end of the stirring shaft support rod 105 is rotationally connected with the edge of the stirring shaft sleeve 14, and the other end is slidably connected in the sliding groove 08; the stirring shaft The sleeve 104 is rotatably connected with the upper end of the stirring shaft 103 .

[0032] The cutter fixed disk is evenly fixed on the stirring shaft 103, including an upper cutter ...

Embodiment 2

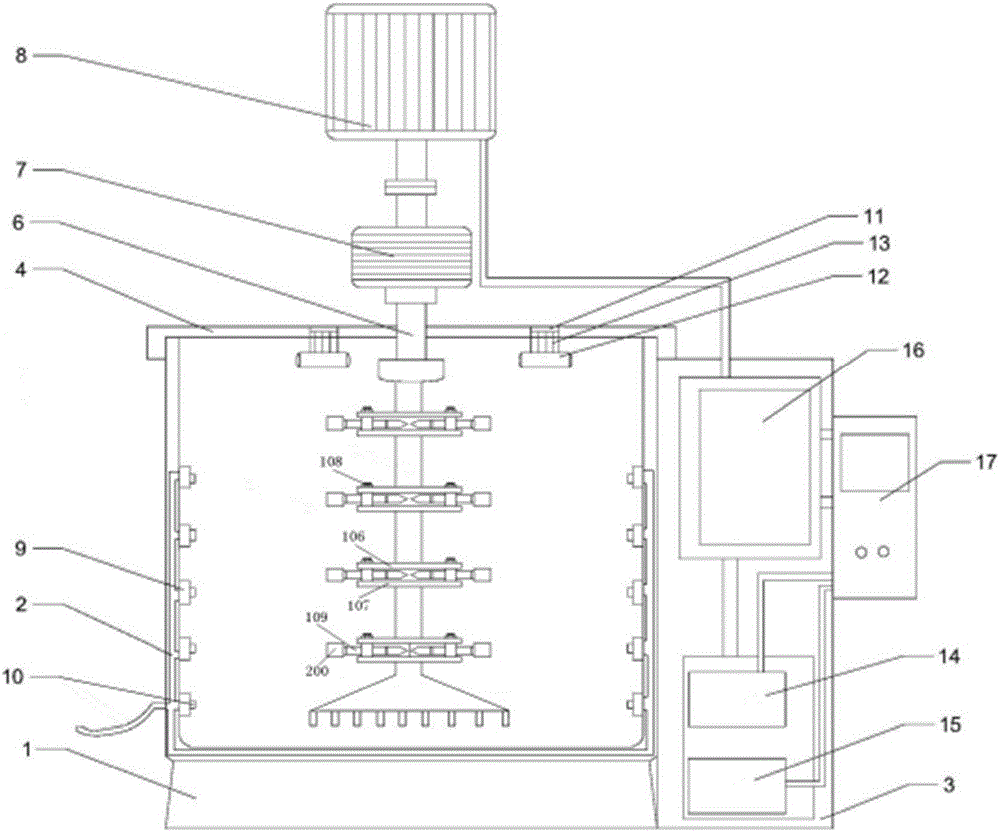

[0042] Such as figure 2 , 3 As shown, in the food stirring device of this embodiment, on the basis of Embodiment 1, in order to further enhance the stirring effect at the bottom of the stirring barrel, the bottom end of the stirring shaft is connected with a brush body.

Embodiment 3

[0044] Such as Figure 4 As shown, the food mixing device of this embodiment, on the basis of Embodiments 1 and 2, the rotating electrical machine is connected to a solar power generation device 22, and the solar power generation device 22 includes a butterfly condenser 23, a Stirling engine, and an automatic sunlight tracking device 24 and a generator 25, wherein the butterfly condenser 23 reflects, concentrates and directly heats the thermal chamber of the Stirling engine, and then utilizes the rotational motion generated by the Stirling engine to drive the generator 25 to rotate to realize power generation, and Utilize the automatic sunlight tracking device 24 to improve the solar energy receiving rate; the solar power generation device 22 is connected to the storage battery 29 through wires, and the storage battery 29 realizes the electric energy storage of the solar power generation part, and at the same time, starts the Stirling engine and the automatic sunlight tracking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com