Polymer battery production ingredient stirring viscosity measuring system

A measuring system and polymer technology, applied in measuring devices, mixers with rotary stirring devices, mixers, etc., can solve the problems of difficult to represent the overall viscosity of ingredients, difficult to confirm that ingredients are fully stirred and evenly mixed, etc., and achieve accurate viscosity measurement values. , uniform viscosity and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

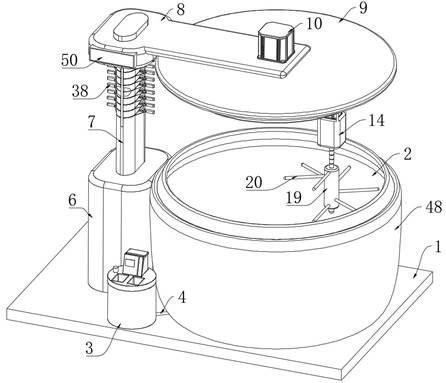

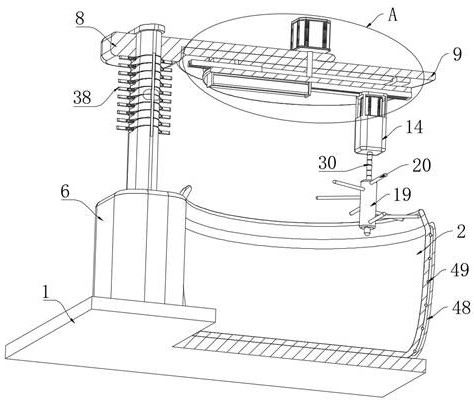

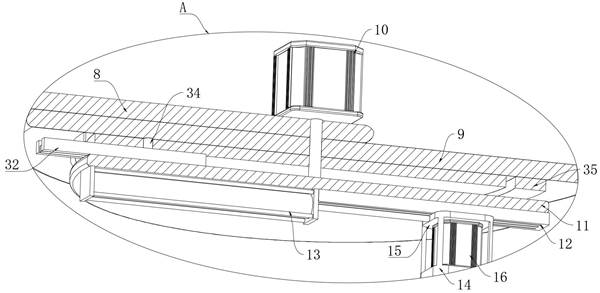

[0052] As an embodiment of the present invention, the stirring detection device includes a first moving table 8 , the first moving table 8 is movably sleeved on the outer ring of the support frame 7 , and the bottom of one end of the first moving table 8 facing away from the support frame 7 is installed with a Track drive mechanism, a stirring drive mechanism is installed between the track drive mechanism and the mixing drum 2 , the track driving mechanism is used to drive the stirring driving mechanism to move cyclically according to a certain track, and the stirring driving mechanism is used to agitate the inside of the mixing drum 2. For real-time viscosity detection, a lowering mechanism is installed between the trajectory driving mechanism and the support frame 7, and the lowering mechanism is used to lower the first moving table 8 by one step after the trajectory driving mechanism rotates every two circles; during operation, The first moving table 8 can be fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com