Concrete stirring and mixing device used for construction site of building site

A technology for construction sites and construction sites, which is applied to the field of concrete mixing and mixing devices on construction sites, can solve problems such as unrealistic, inability to meet processing requirements, and inability to guarantee mixing and mixing quality, so as to improve construction quality and avoid uneven mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

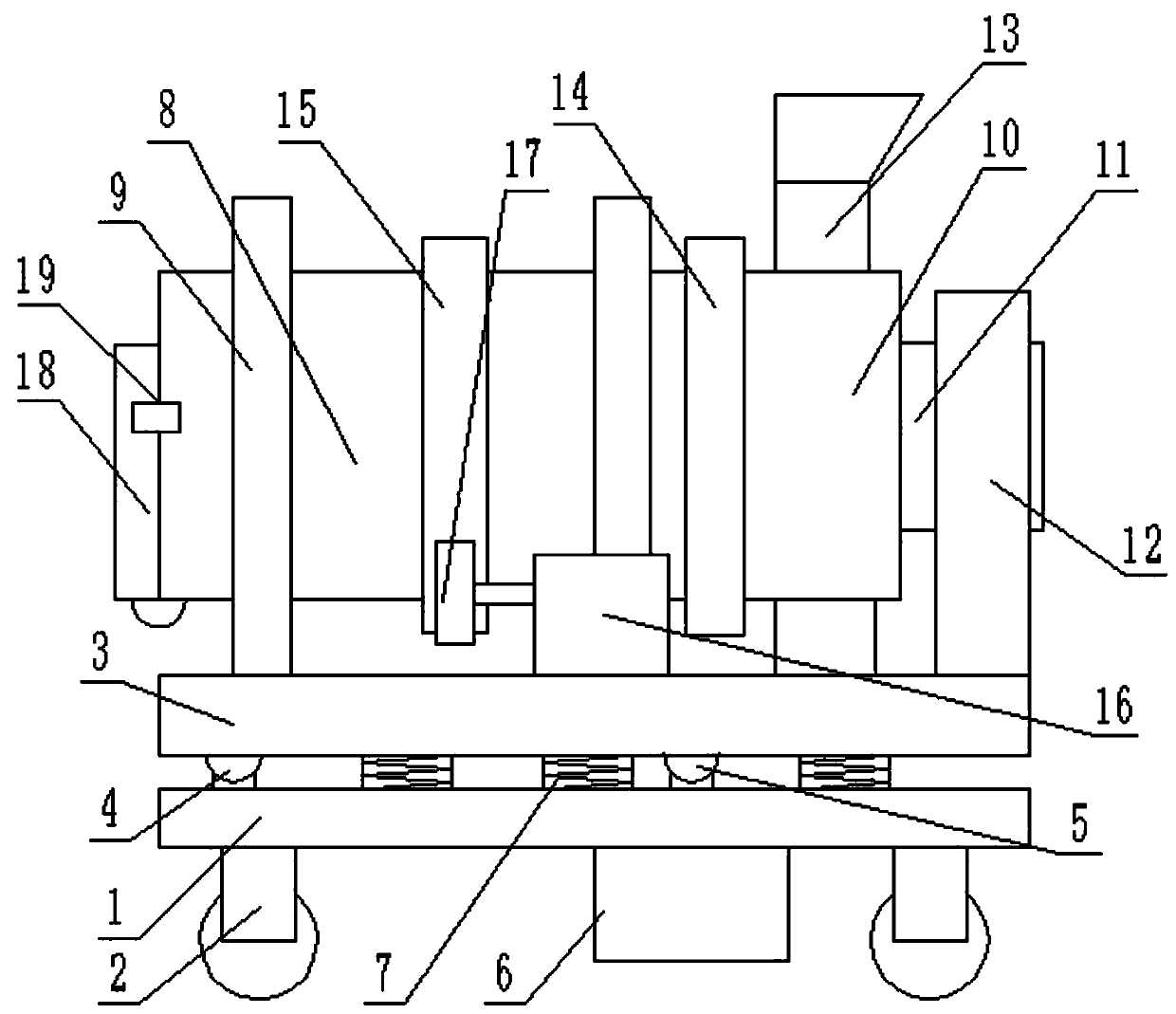

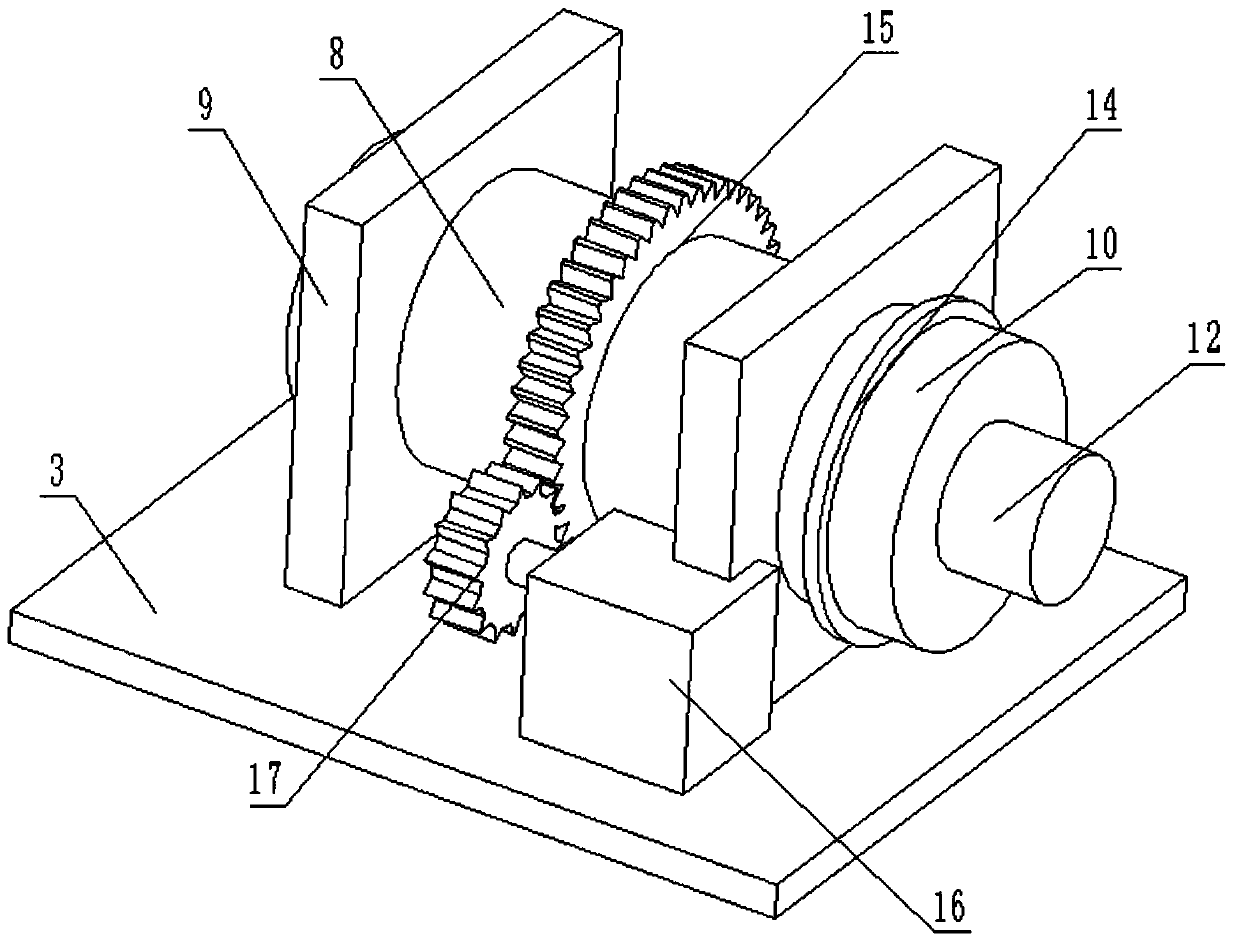

[0019] see Figure 1-3 , a concrete mixing device for a construction site, comprising a frame 1, a turret 3 and a mixing drum, the turret 3 is located above the frame 1, and the bottom of the frame 1 is provided with a plurality of moving wheels 2, and the mixing drum Located above the turret 3, the mixing cylinder includes a fixed cylinder 10 and a rotating cylinder 8, the rotating cylinder 8 is connected to the fixed cylinder 10 in rotation, the fixed cylinder 10 is fixed on the turret 3 through a bracket, and a feeding cylinder is provided on the top of the fixed cylinder 10 13. A number of drum brackets 9 are also provided on the turret 3, and the drum brackets 9 are set on the outside of the rotating drum 8 and connected in rotation with the rotating drum 8. A second drive motor 16 is arranged on the top surface of the turret 3, and the second The output end of drive motor 16 is provided with drive gear 17, is provided with suit gear ring 15 on the outer wall of rotating ...

Embodiment 2

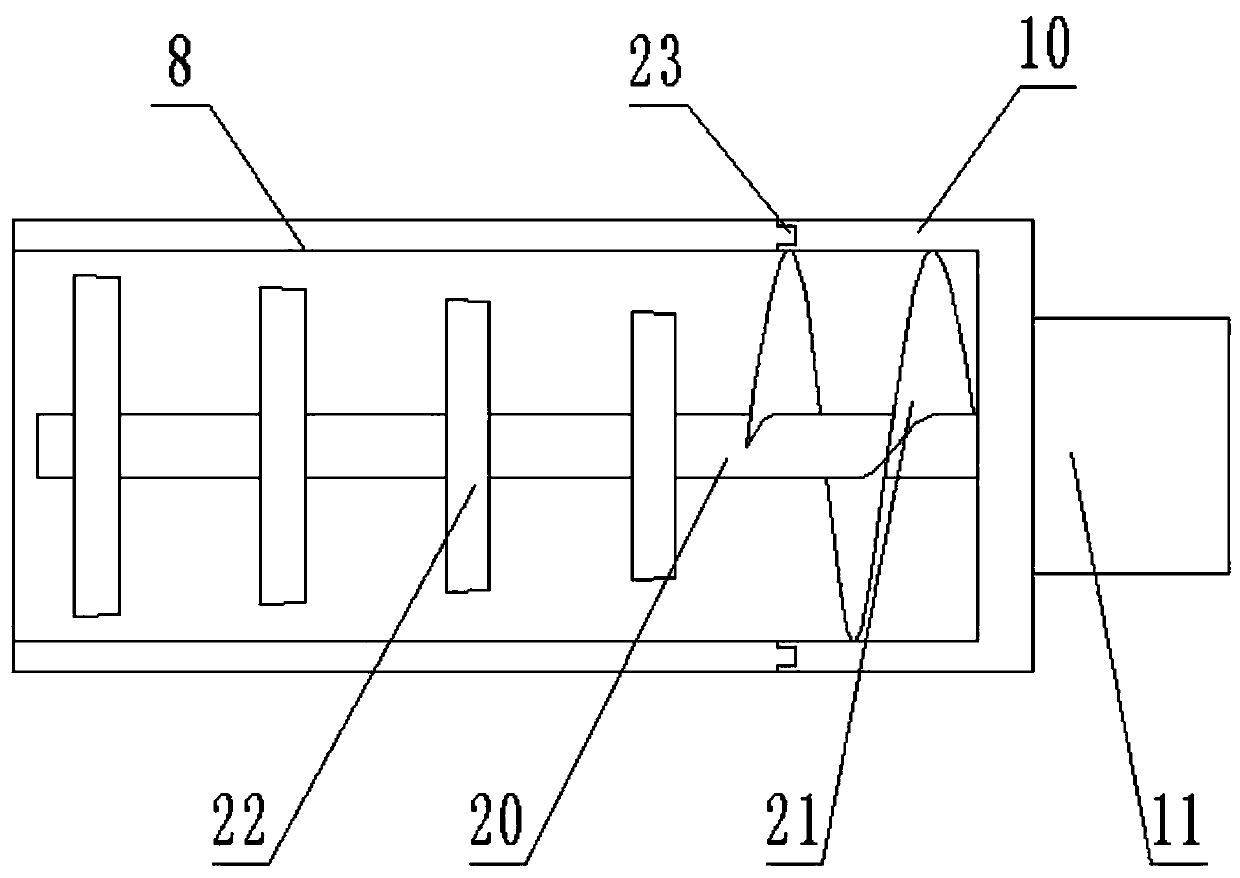

[0024] On the basis of Embodiment 1, in order to further facilitate the output of raw materials and ensure the sufficient mixing of concrete, a push auger 21 is provided on the drive shaft 20, and the push auger 21 is located in the fixed cylinder 10, and the push auger The outer side of 21 fits and is slidably connected to the inner wall of the fixed cylinder 10. During the stirring process, the raw material first enters the fixed cylinder 10 through the feeding cylinder 13. At this time, the first driving motor 11 drives the drive shaft 20 to work, and the driving shaft 20 is driven by the pushing auger 21. The raw materials can be transported into the rotating cylinder 8, so that the raw materials can obtain a two-way stirring effect, and in the process of conveying the raw materials to the rotating cylinder 8 through the pushing auger 21, the raw materials are carried out by the pushing auger 21 and the inner wall of the fixed cylinder 10. Extrusion avoids agglomeration cau...

Embodiment 3

[0026] On the basis of Embodiment 1, in order to ensure the stable operation of the equipment, a plurality of buffer spring columns 7 are provided between the frame 1 and the turret 3, and the buffer spring columns 7 are fixed on the frame 1, and the buffer The top of the spring column 7 is provided with a rubber pad. When stirring, the shock can be absorbed and buffered by the buffer spring column 7 to avoid equipment damage, and when the turret 3 is rotated and retracted, the impact force can also be absorbed by the buffer spring column 7 , to ensure the safety of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com