Plugging method for downcomer for well-point dewatering of deep foundation pit

A technology of well point dewatering and dewatering pipe, applied in infrastructure engineering, construction and other directions, can solve problems such as difficult construction, difficulty in plugging, and many hidden dangers, and achieve the effects of reducing construction costs, improving construction quality, and fast construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

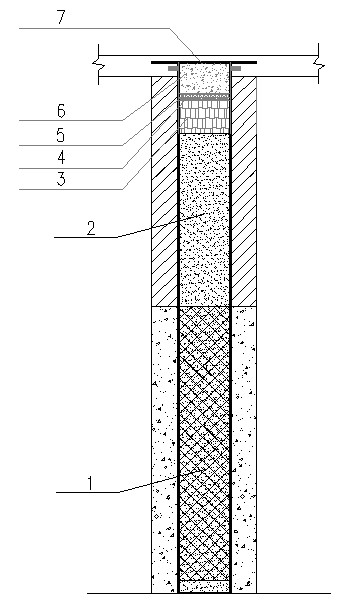

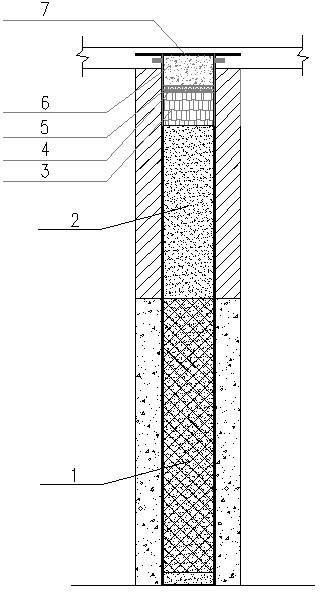

[0026] In the 8# building of the Lianhua Village Group B project in Nanjing, the downwater pipe plugging method of the deep foundation pit well point precipitation is adopted. The construction steps are: retain the filter layer 1 buried during the drainage and precipitation construction, fill the sand layer 2, medium and fine Fill it with sand to a depth of 1.5m downward from the top of the downcomer, and then seal it with a 0.8m thick cotton wool layer 3, followed by a 50mm thick water glass cement slurry layer 4 (sealed and set) and a 50mm thick The plugging king layer 5, the upper part of the plugging king layer 5 is poured to the upper end of the downcomer with a C35 micro-expansion concrete layer 6, and finally the downcomer is fully welded on the micro-expansion cement layer 6 with a 10mm thick round steel plate 7 Concrete was poured on the top of the round steel plate 7, and the concrete floor was poured flush with 40mm thick fine stone concrete. After repeated inspectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com