Rheological stabilizer for synthetic base drilling fluid and preparation method thereof

A drilling fluid and stabilizer technology, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of easy leakage of lost circulation, difficult control of lost circulation and pressure, and large difference in ECD value, and achieves good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

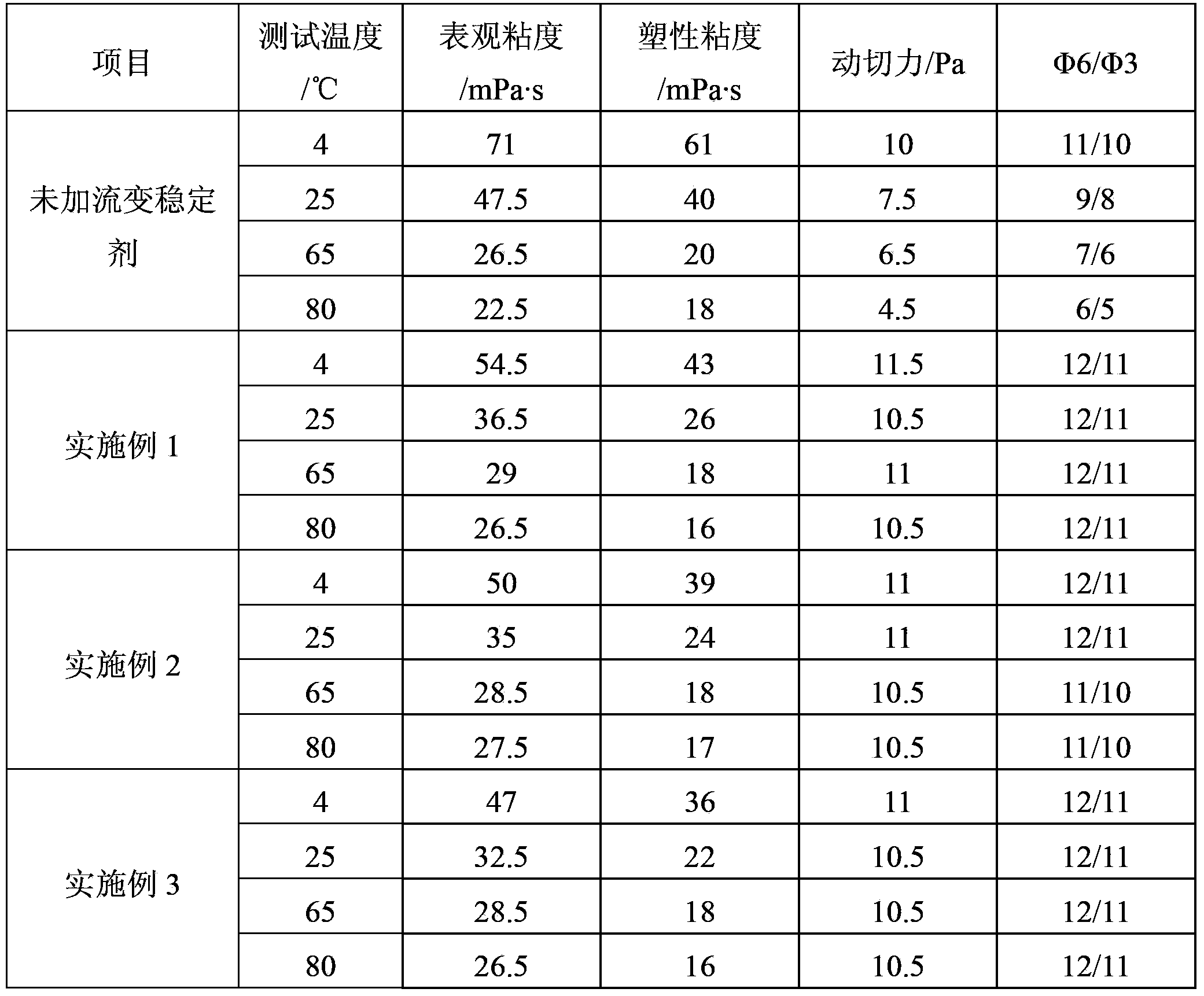

Embodiment 1

[0027] Embodiment 1, preparation rheological stabilizer

[0028] Add 80 grams of methacrylic acid, 50 grams of N-dodecylacrylamide, 50 grams of styrene and 80 grams of toluene into the laboratory autoclave, protect it with nitrogen, start stirring and raise the temperature to 60 ° C, add 3.2 grams of azo Diisobutyronitrile, react at this temperature for 2 hours, then raise the temperature to 110°C, continue to react for 3 hours, vacuumize, remove the solvent under negative pressure of -0.06MPa, cool to 40°C and discharge to obtain the rheological stabilizer.

Embodiment 2

[0029] Embodiment 2, preparation rheological stabilizer

[0030] Add 50 grams of maleic acid, 30 grams of N-octadecyl acrylamide, 50 grams of styrene and 60 grams of toluene into the laboratory autoclave, protect it with nitrogen, start stirring and heat up to 60 ° C, add 2.6 grams of Benzoyl peroxide reacted at this temperature for 2 hours, then raised the temperature to 110°C, continued to react for 4 hours, vacuumed, removed the solvent under negative pressure of -0.06MPa, cooled to 40°C and discharged to obtain the rheological stabilizer.

Embodiment 3

[0031] Embodiment 3, preparation rheological stabilizer

[0032] Add 60 grams of acrylic acid, 50 grams of N-dodecyl acrylamide, 80 grams of styrene and 100 grams of xylene into a laboratory autoclave, protect with nitrogen, start stirring and heat up to 60 ° C, add 4.0 g of azobis Isobutyronitrile, react at this temperature for 2 hours, then raise the temperature to 130°C, continue to react for 3 hours, vacuumize, remove the solvent under negative pressure of -0.07MPa, cool to 40°C and discharge to obtain the rheological stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com