Process and system for cleaning waste residues in quarries and building sand

A construction sand and cleaning system technology, which is applied to cleaning methods and appliances, cleaning methods using liquids, solid waste management, etc., can solve the problems of low-cost and efficient cleaning of quarry waste and construction sand, and achieve effective It is beneficial to industrial production and popularization and application, reduces mud content, and reduces water demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

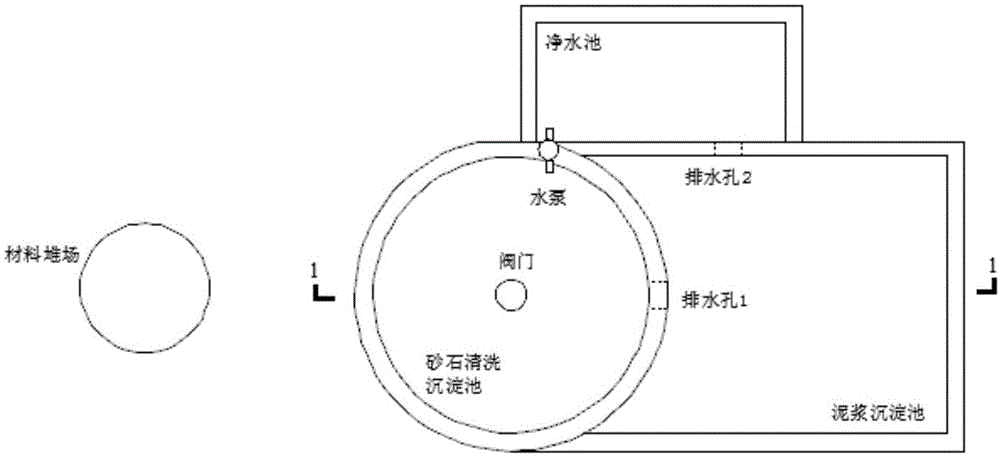

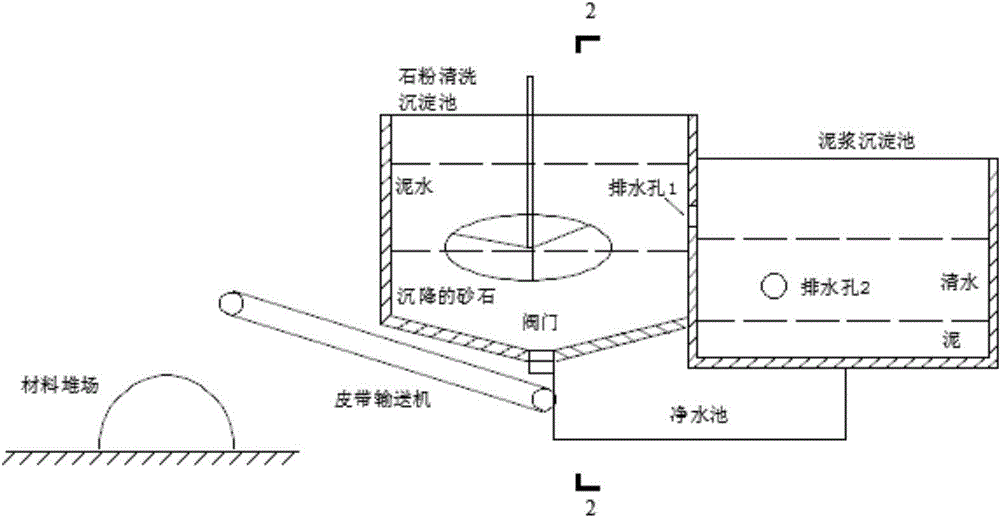

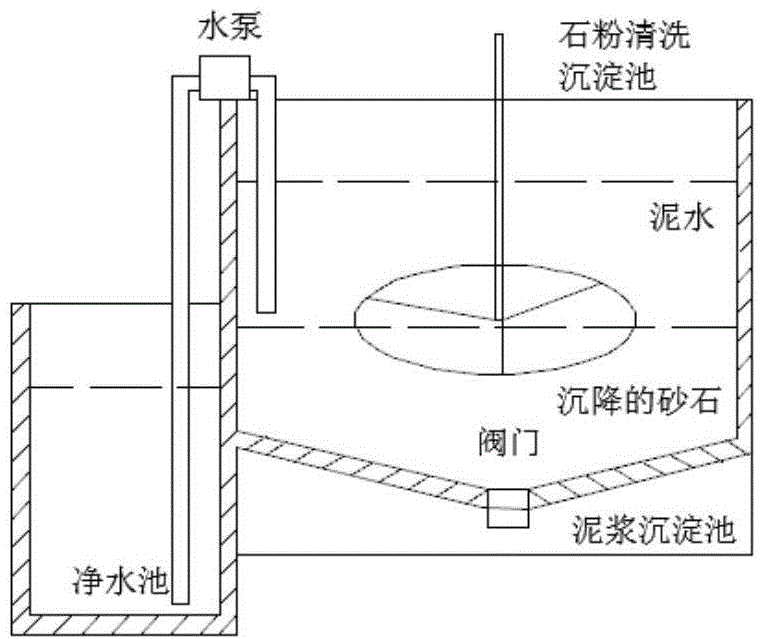

[0028] Embodiment 1: the present invention comprises cleaning process and cleaning system; Cleaning process comprises: 1) gravel enters pond, 2) clean water enters pond, 3) stirs, 4) muddy water discharges, 5) clear water recycles, 6) sandstone reclaims and 7) Mud cleaning; the specific process is as follows:

[0029] 1) Sand and gravel into the pond: introduce quarry waste residue or construction sand into the sand and gravel cleaning sedimentation tank;

[0030] 2) Clean water into the pool: use the water pump to introduce the clean water in the clean water tank into the sand and gravel to clean the sedimentation tank;

[0031] 3) Stirring: Use a turbine mixer to fully stir the quarry waste or construction sand in step 1 in the sand cleaning sedimentation tank, and then let it stand for 20-30 seconds to ensure that the stone powder and sand particles are fully settled while the mud remains. Suspension;

[0032] 4) Muddy water discharge: Open the drain outlet with appropria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com