Lead-free water-soluble environmental-friendly soldering flux for piezoelectric ceramics and preparation method thereof

A piezoelectric ceramic and flux technology, applied in welding medium, manufacturing tools, welding equipment, etc., can solve the problems of high melting point, poor deoxidation layer, difficult to clean, etc. Fast oxide effect

Inactive Publication Date: 2011-05-18

HUNAN JIAYEDA ELECTRONICS

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the flux used in lead-free wave soldering in the piezoelectric ceramic industry is basically based on rosin. In the field of lead-free wave soldering, lead-free solder has poor wettability, high melting point, and is easy to oxidize; The flux itself has poor surface wettability, low melting point, and rosin contains double bonds, so it is easy to oxidize and polymerize at high temperature, and its performance is greatly affected by temperature. Cleaning will bring fatal defects to the appearance of the product; moreover, the rosin flux is poor in removing the oxide layer, and when the product to be welded is oxidized, it is easy to cause false soldering, which will bring fatal defects to the product performance; from the perspective of environmental protection , rosin contains fat, benzene compounds and other substances. Among them, lead is not excreted after eating, and has different degrees of damage to human intelligence. The peroxide produced by rosin after oxidation will seriously damage the liver and kidney of the human body; Ammonolysis reaction will also occur under the circumstance, produce a large amount of ammonia gas, damage the health of operators, and pollute the surrounding environment at the same time; Therefore, it is imminent to invent a kind of lead-free wave soldering suitable for piezoelectric ceramics, rosin-free environment-friendly flux

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

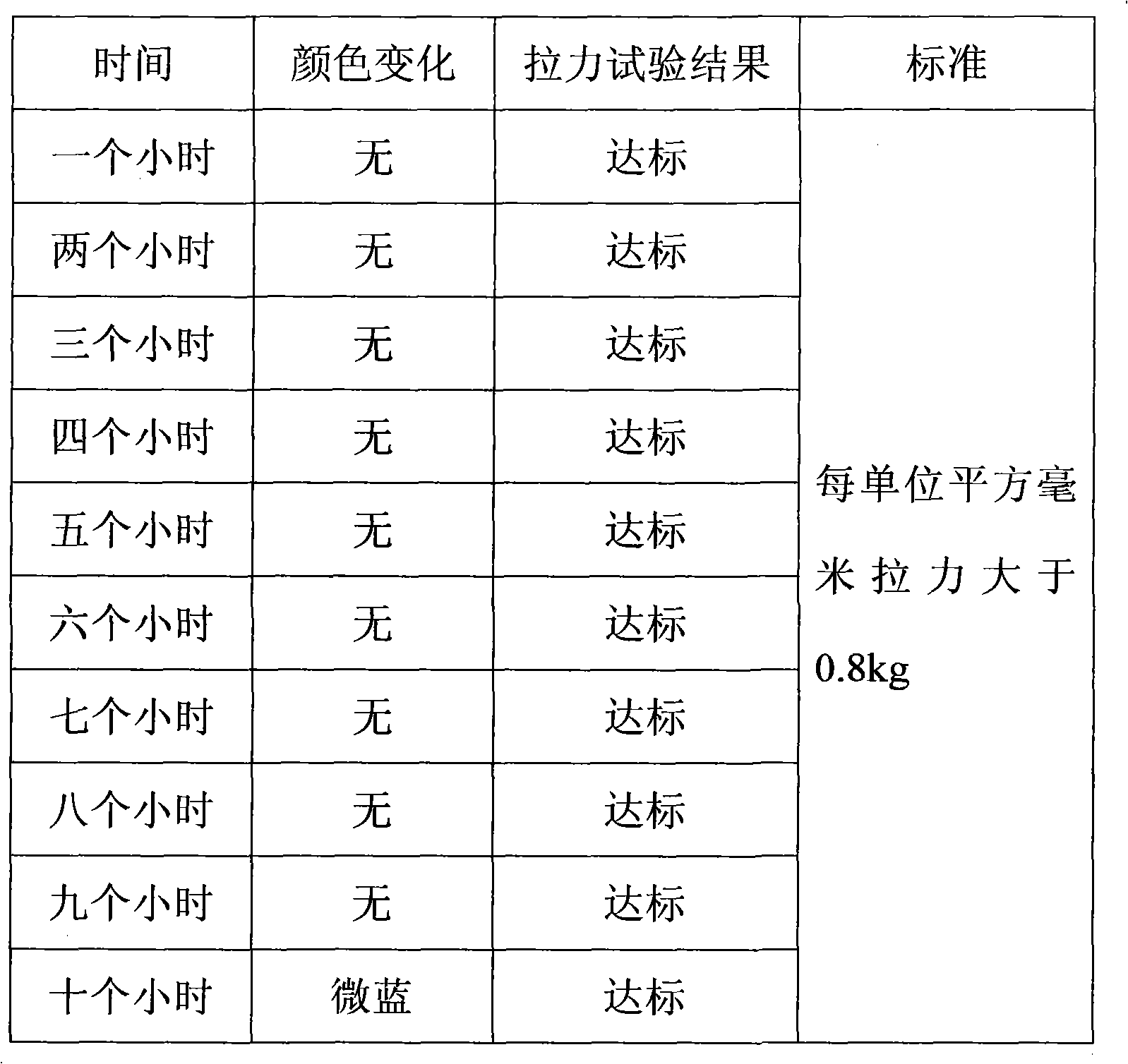

The invention provides a lead-free water-soluble environmental-friendly soldering flux for piezoelectric ceramics and a preparation method thereof. The soldering flux comprises the following components in the terms of total mass: 0.1-4 percent of activating agent, 0.01-1 percent of corrosion inhibitor, 1-10 percent of oxidation inhibitor, 1-30 percent of surface wetting agent and the balance of absolute ethyl alcohol. The preparation method of the soldering flux as a cleaning solution comprises the steps of: heating the surface wetting agent until boiled, stopping heating and then adding the activating agent, uniformly stirring with a glass rod, adding a proper amount of absolute ethyl alcohol, the oxidization inhibitor and benzotriazole (BTA) as the corrosion inhibitor after a mixed solution is cooled, slowly stirring with the glass rod until the solution is not demixed; and washing the product welded by using the soldering flux with flowing water for 5min or cleaning by using an ultrasonic water area method for half a minute, and then drying. By using the soldering flux, the product formed by the wave soldering of the piezoelectric ceramics has the advantages of full and smooth welded point, simplicity of cleaning and cost reduction; and the soldering flux contains no rosin, has small volatilization amount, and is beneficial to the guaranteeing of the health of employees.

Description

technical field [0001] The invention relates to a lead-free water-soluble environment-friendly flux for piezoelectric ceramics and a preparation method thereof, belonging to the field of lead-free welding. Background technique [0002] At present, the flux used in lead-free wave soldering in the piezoelectric ceramic industry is basically based on rosin. In the field of lead-free wave soldering, lead-free solder has poor wettability, high melting point, and is easy to oxidize; The flux itself has poor surface wettability, low melting point, and rosin contains double bonds, so it is easy to oxidize and polymerize at high temperature, and its performance is greatly affected by temperature. Cleaning will bring fatal defects to the appearance of the product; moreover, the rosin flux is poor in removing the oxide layer, and when the product to be welded is oxidized, it is easy to cause false soldering, which will bring fatal defects to the product performance; from the perspectiv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/362

Inventor 刘超慧

Owner HUNAN JIAYEDA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com