Stirring machine for processing plastic products

A technology of plastic products and mixers, which is applied in the field of plastic processing, can solve the problems of uneven mixing and stirring of plastic products, and achieve the effects of avoiding uneven mixing, increasing the probability of mixing, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

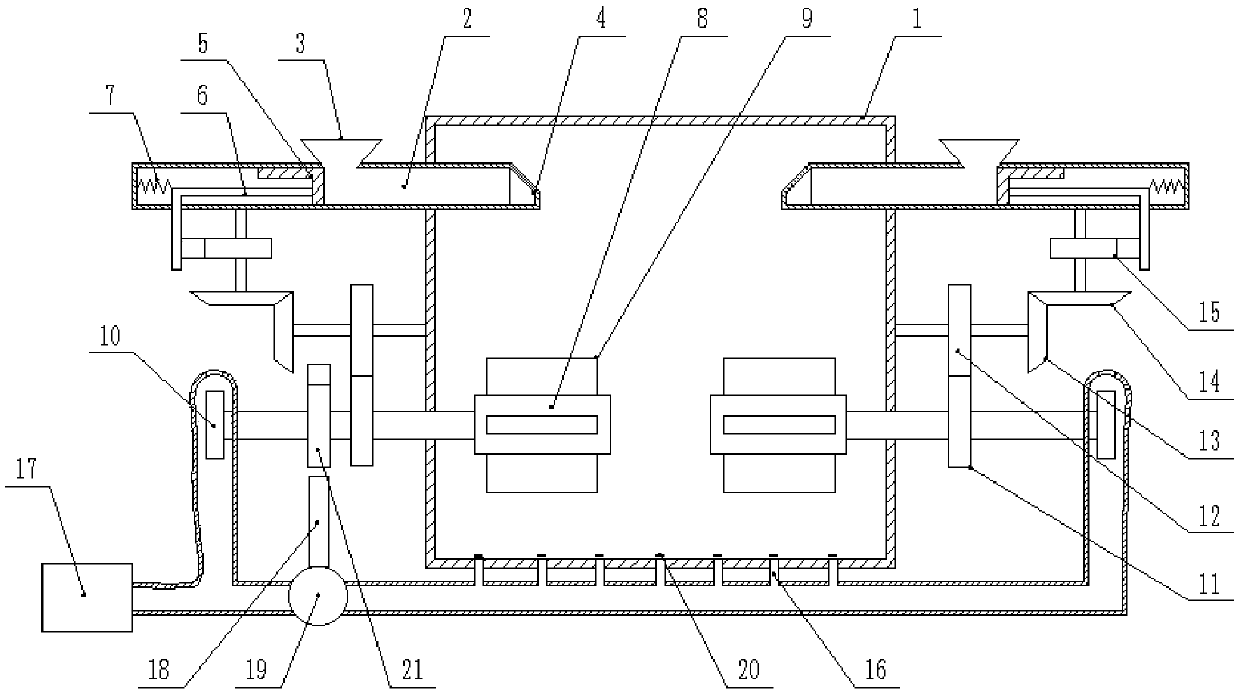

[0014] The reference signs in the drawings of the description include: stirring box 1, feeding channel 2, feeding port 3, elastic contraction port 4, push plate 5, push rod 6, first spring 7, stirring shaft 8, stirring plate 9 , turbine 10, first gear 11, second gear 12, first bevel gear 13, second bevel gear 14, cam 15, through hole 16, air supply box 17, rack 18, air bag 19, filter screen 20, fan gear twenty one.

[0015] The embodiment is basically as attached figure 1 Shown:

[0016] A mixer for processing plastic products, including a frame, on which a stirring box 1 is connected by bolts, and a feeding mechanism and a stirring mechanism are installed on the stirring box 1, and the feeding mechanism is located above the stirring mechanism; the feeding mechanism includes symmetrically arranged In the feed channel 2 on the mixing box 1, there are feed ports 3 and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com