Paper product raw material stirring device

A stirring device and paper product technology, which is applied in the field of paper product processing, can solve problems such as low stirring efficiency and uneven stirring, and achieve the effect of avoiding uneven stirring and increasing the stirring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

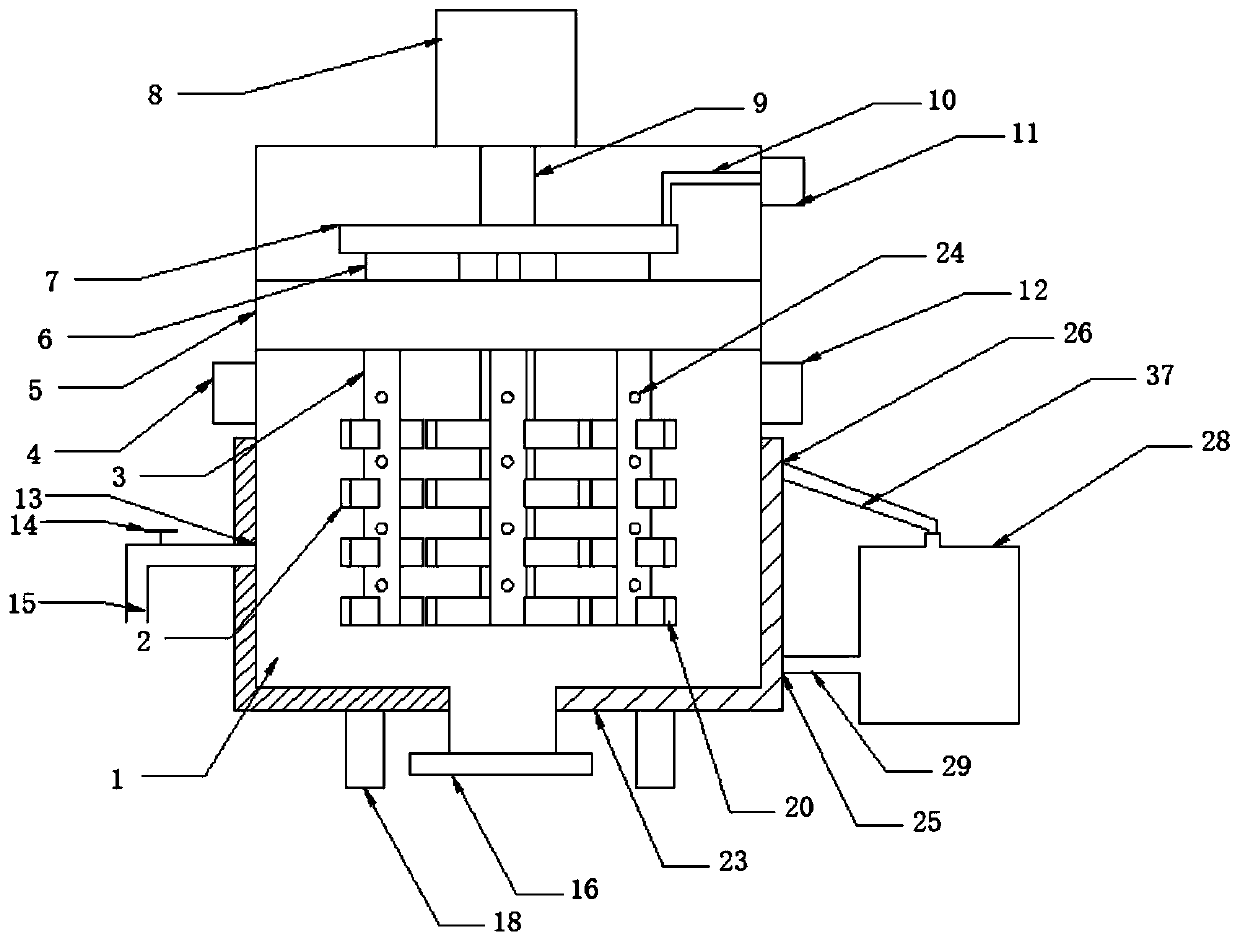

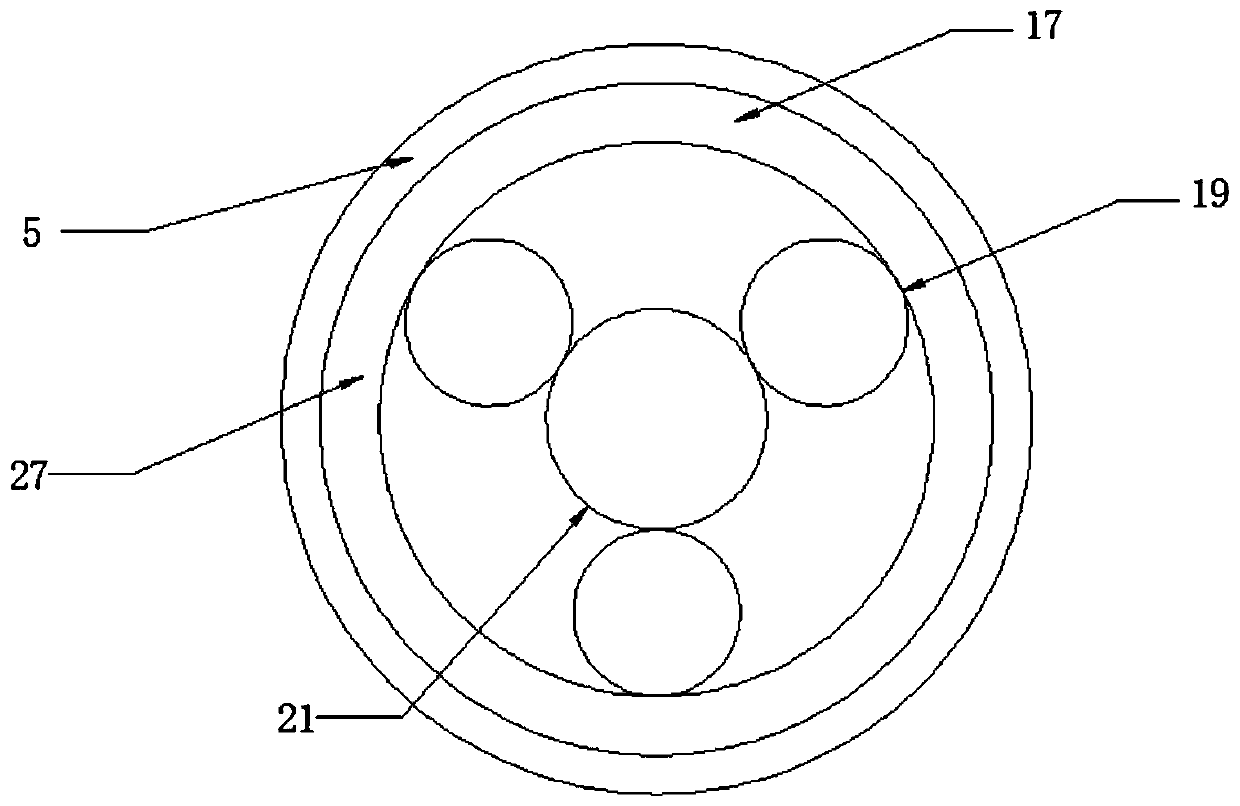

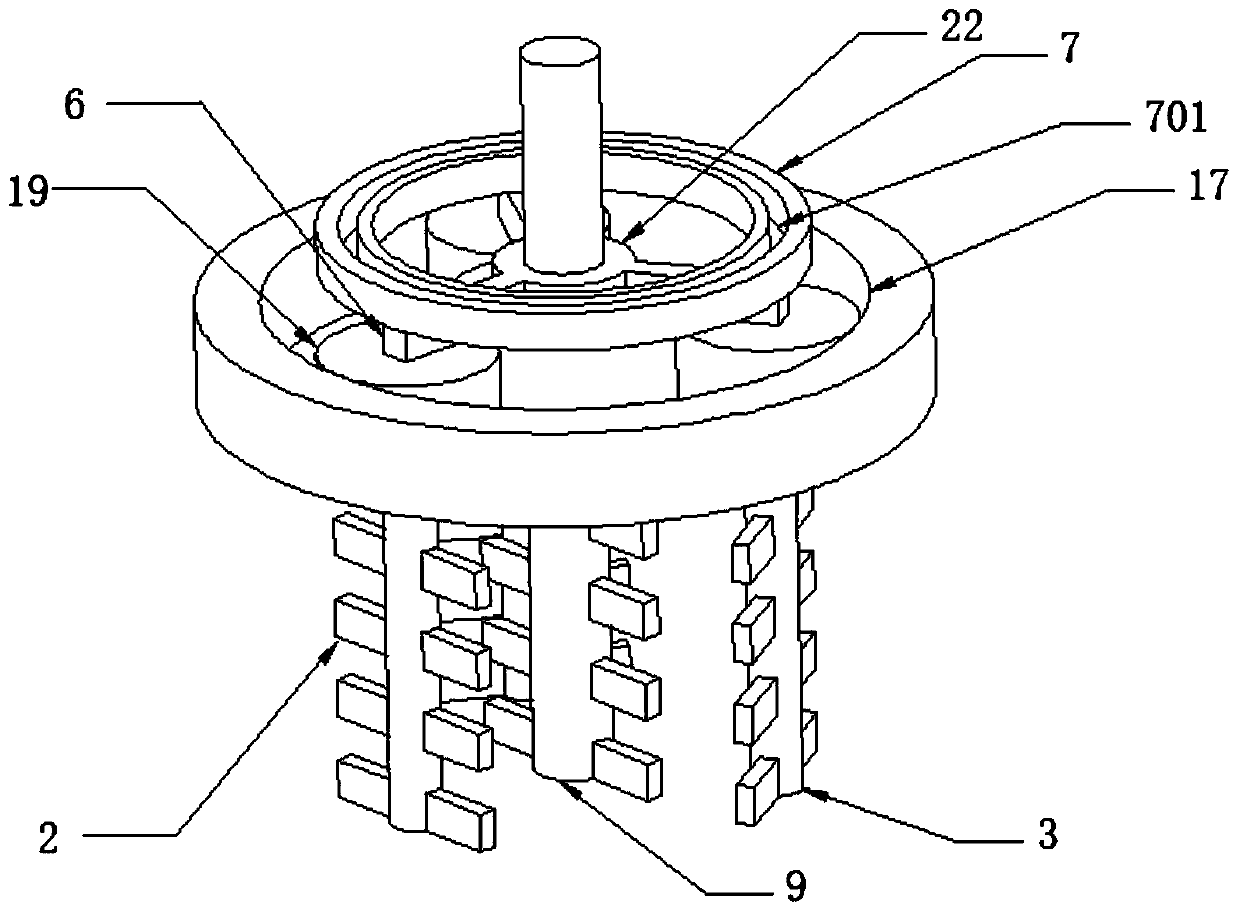

[0023] combine Figures 1 to 5 As shown, a stirring device for raw materials of paper products, the stirring device adopts a stirring tank 1, and the stirring device also includes a stirrer 20, a protection plate 5, and a stirring motor 8; a stirring motor 8 is arranged above the stirring tank 1; At the top position in the mixing tank 1, and the outer wall is close to the inner wall of the mixing tank 1; the agitator 20 includes a planetary gear transmission structure 27 and a stirring shaft 9; the planetary gear transmission structure 27 is located in the protection plate 5; the planetary gear transmission structure 27 includes Ring gear 17, sun gear 21, planetary gear 19; the ring gear 17 is coaxial with the mixing tank 1, and the outer wall of the ring gear 17 is close to the inner wall of the protection plate 5; the stirring shaft 9 is arranged at the inner center of the mixing tank 1; One end extends out of the mixing tank 1 and is fixedly connected with the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com