Wet material blender and use method thereof

A technology for mixers and wet materials, applied in mixer accessories, mixers with rotary mixing devices, chemical instruments and methods, etc., can solve the problems of uniform mixing of difficult materials, affecting the on-site environment, affecting product quality, etc. The effect of simplified structure and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below based on the drawings.

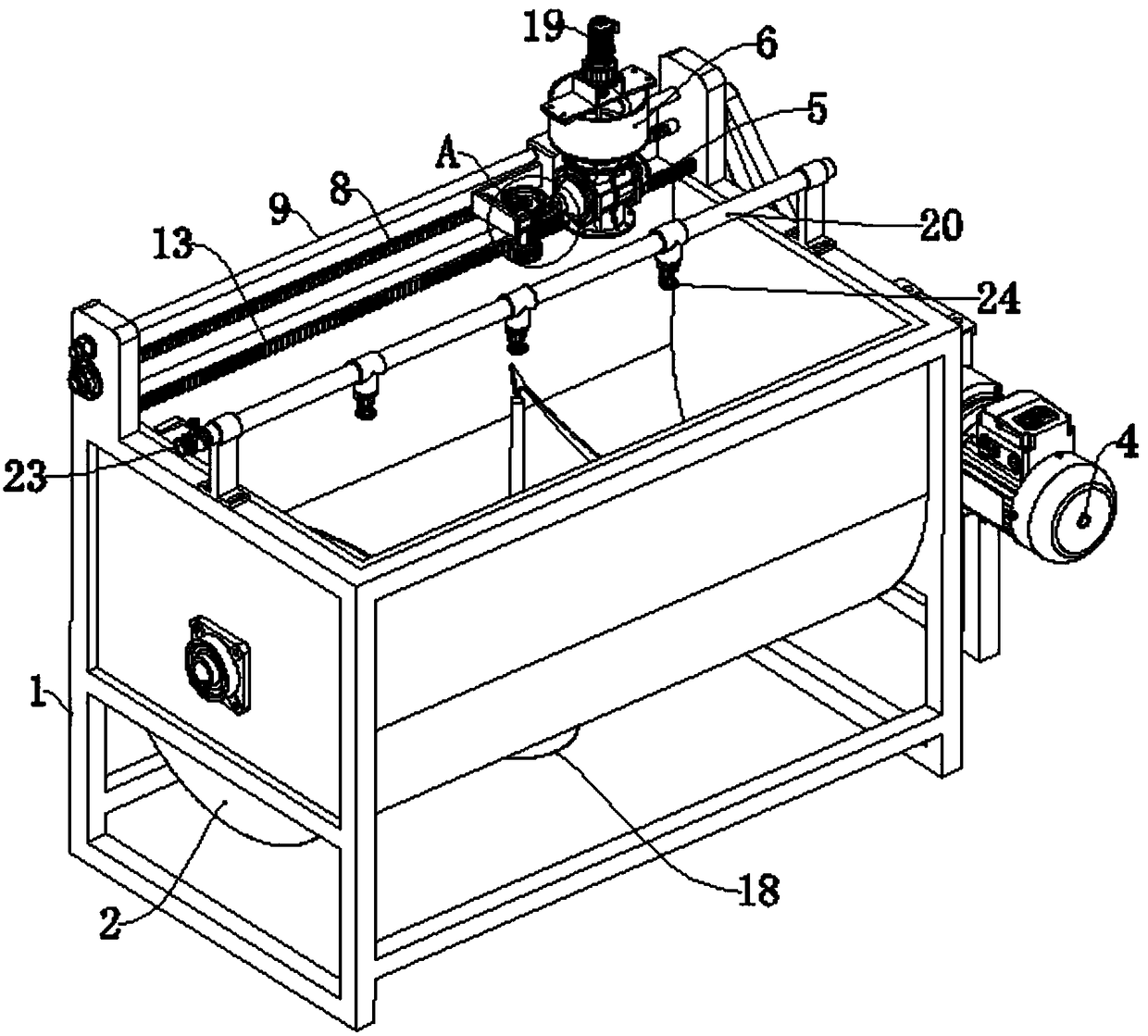

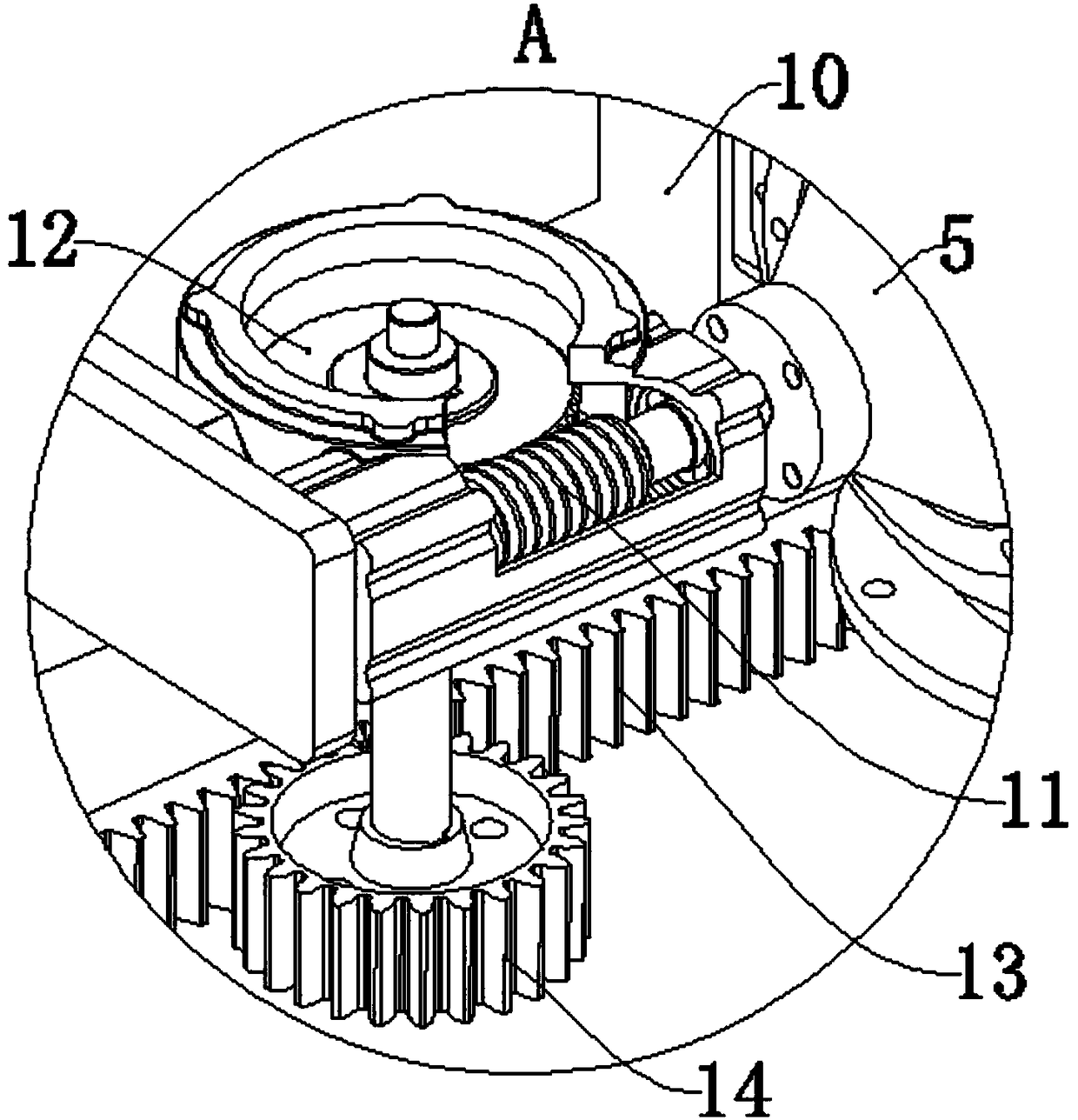

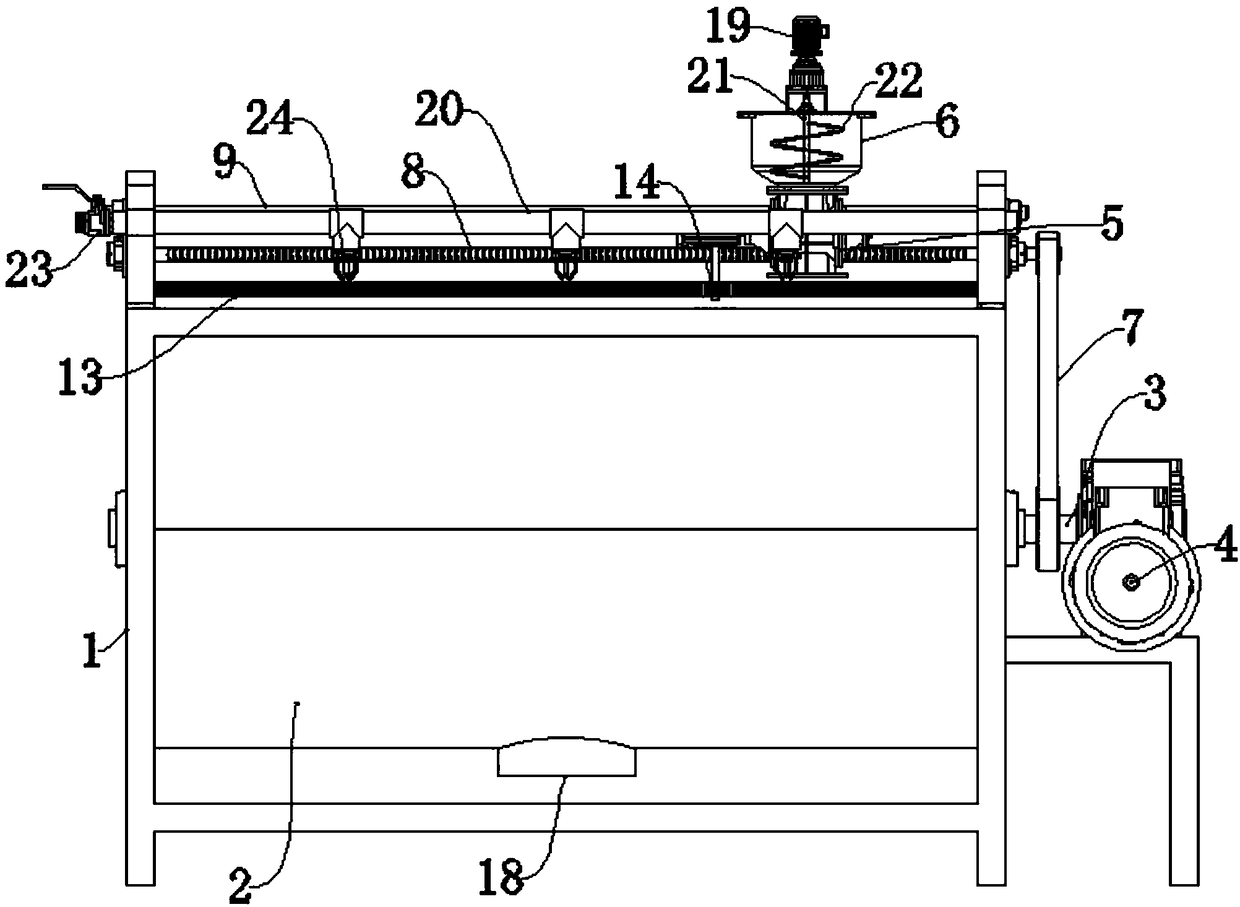

[0023] Such as Figure 1 ~ Figure 7 As shown, a wet material mixer includes a frame 1, a barrel body 2, a main shaft 3, a drive motor 4, a rotary feeder 5, an auxiliary hopper 6, an auxiliary material mixing motor 19, a spray pipe 20, and a belt transmission mechanism 7, Two-way screw 8, guide column 9, sliding block 10, worm 11, worm wheel 12, rack 13 and gear 14.

[0024] The barrel 2 is fixedly installed on the frame 1, the top of the barrel 2 is open, and the bottom of the barrel 2 is provided with a discharge port 18. The main shaft 3 is installed on the barrel 2 and its axis is in the left-right direction. The main shaft 3 is provided with main mixing blades. The main mixing blades include a left spiral blade 16 and a right spiral blade 17 (such as Figure 4 (Shown), the spiral direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com