Rotational fluidized bed powder mixing machine

A technology of mixer and fluidized bed, which is applied in the field of powder particle material mixing equipment, can solve the problem that the structural form is not as diverse as that of mechanical mixing equipment, and achieve the effect of simple equipment structure, low air consumption, and guaranteed mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The drawings and specific embodiments do not limit the scope of protection claimed by the present invention.

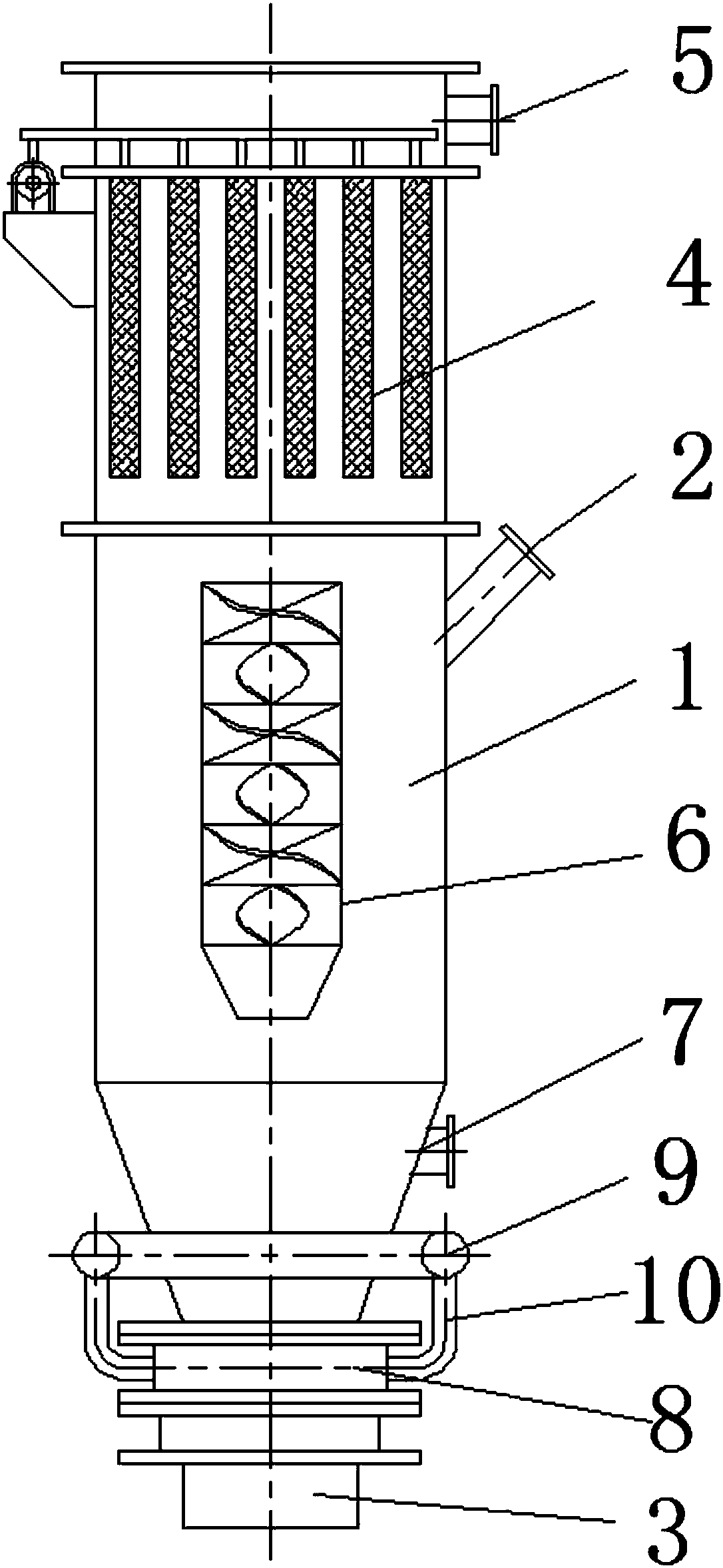

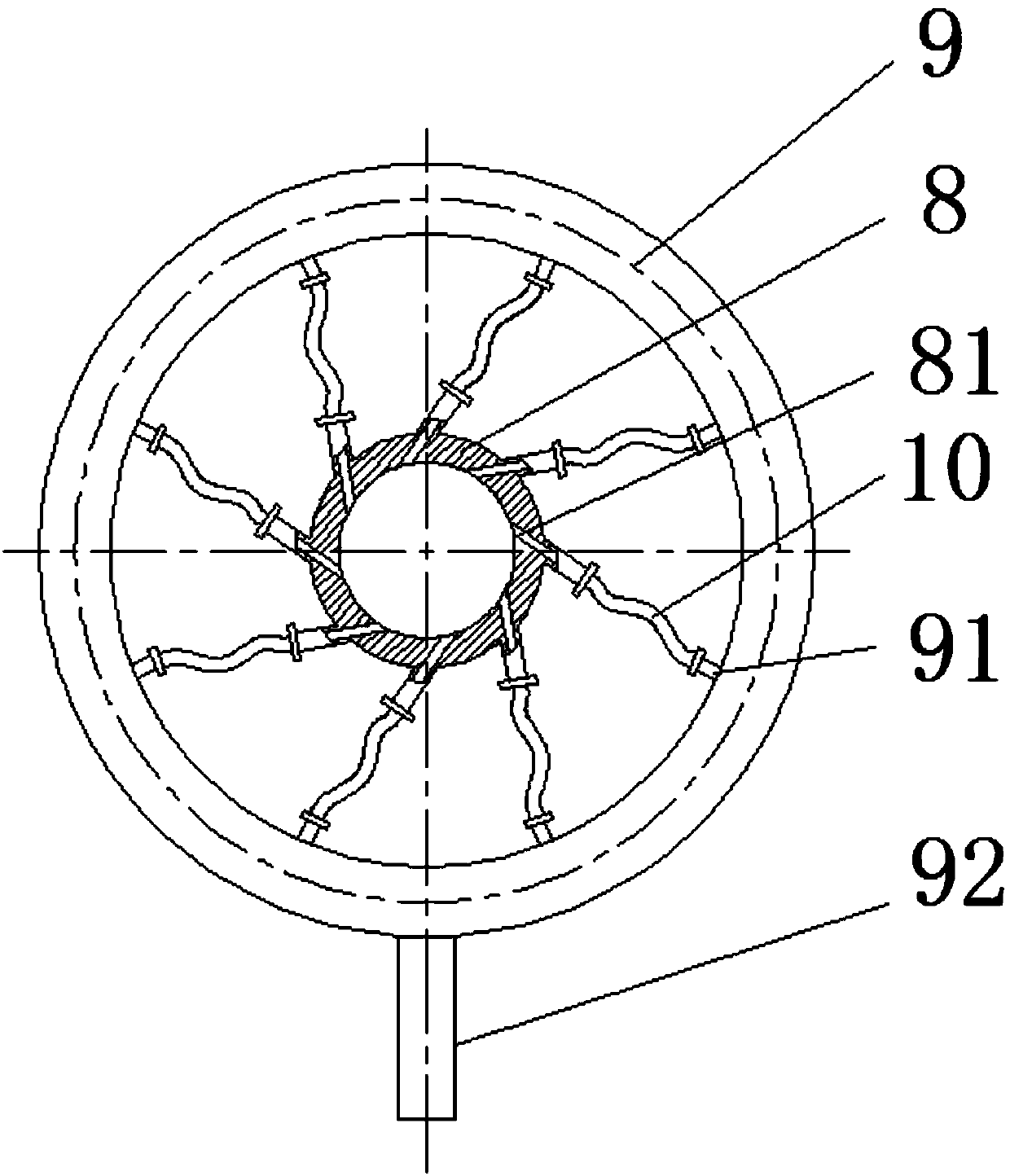

[0011] see figure 1 As shown in the rotary fluidized bed powder mixer of the present invention, its main body is the mixing silo cylinder 1, which is generally made of stainless steel and can be coated according to special needs. The side of the mixing silo body 1 is provided with a powder particle material feed port 2 and a sampling port 7, an exhaust port 5 is provided at the top, and a material outlet 3 is provided at the bottom. A static mixer 6 is arranged inside, and left-handed unit pieces and right-handed unit pieces are alternately arranged inside the static mixer 6, and the number of unit pieces can be set to 6-10. The upper part of the mixing silo body 1 is a pulse bag filter 4 for filtering exhaust gas. The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com