Method for purifying high-temp. smoke from garbage incinerator

A waste incinerator and high-temperature flue gas technology, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as lime absorption, increased heat loss, and high-temperature corrosion of heating surfaces, so as to avoid Or reduce high temperature corrosion, improve reaction efficiency, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

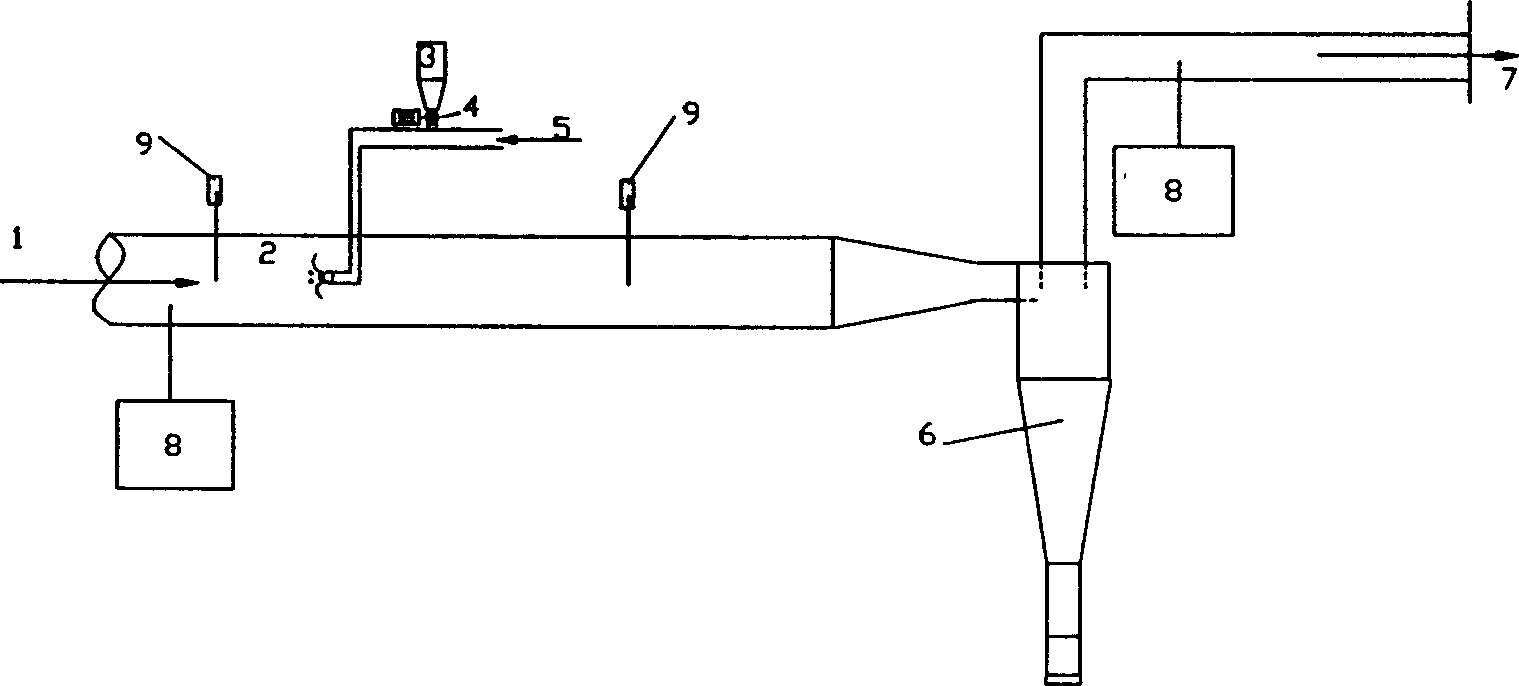

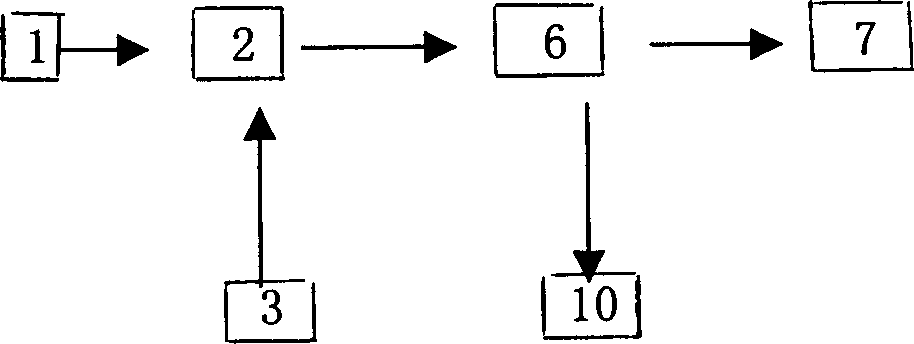

[0023] Such as figure 1 The schematic diagram of the example device is shown. The high-temperature flue gas 1 enters the thermal insulation flue reactor 2, and the carrying amount of fly ash in the high-temperature flue gas is 5-6g / Nm 3 , the concentration of HCl gas is measured by the sampling system 8 . A certain amount of modified lime is sprayed countercurrently from the transport medium air 5 into the reactor 2 and mixed with the flue gas. The flow velocity of the flue gas in the reactor 2 is 12-13m / s, and the flow rate of the flue gas is 380-450m 3 / h range. In order to transport modified lime, the flow rate of compressed air is 6.3~7.5m 3 / h, the flow velocity at the nozzle is 15-18m / s. After the reaction, it is sent to the cyclone dust collector 6 to separate the reaction products. An insulating layer is arranged outside the reaction flue 2 and the dust collector 6 . Several pairs of thermocouples 9 are arranged in the reactor 2 to measure the reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com